@phaedrux

Hi, thank you for the fast responce  .

.

Here is my config.g

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Network

M111 S0 ; Debug off

M550 Deluxe600 ; Machine name (can be anything you like)

M551 inman. ; Machine password (used when you connect Duet Web Control or via FTP)

M540 PBE:EF:DE:AD:FE:ED ; MAC Address (only needed if you have more than one Duet 0.6 or 0.8.5 on the same network)

M552 S1 P192.168.210.202 ; IP address (0 = use DHCP)

M554 P192.168.104.217 ; Gateway (not used yet)

M553 P255.255.255.0 ; Netmask

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S1 ; Set auxiliary serial port baud rate and require checksum (for PanelDue)

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 Z8 X16 Y16 I1 ; Configure microstepping with interpolation

M350 E32 I0 ; Configure microstepping without interpolation

M92 X50 Y50 Z400 E280 ; Set steps per mm

M566 X480 Y480 Z5 E270 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z720 E7200 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z125 E5000 ; Set accelerations (mm/s^2)

M906 X1400 Y1400 Z2200 E700 I1 ; Set motor currents (mA) and motor idle factor in per cent

M84 S5 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S0 ; Set axis minima

M208 X545 Y545 Z675 S0 ; Set axis maxima

; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

;M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" A5 H4 F100 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 X0 Y0 Z0.9 ; set Z probe trigger value, offset and trigger height

M557 X0:500 Y40:500 S100:100 ; define mesh grid

;Filament Runout Sensor

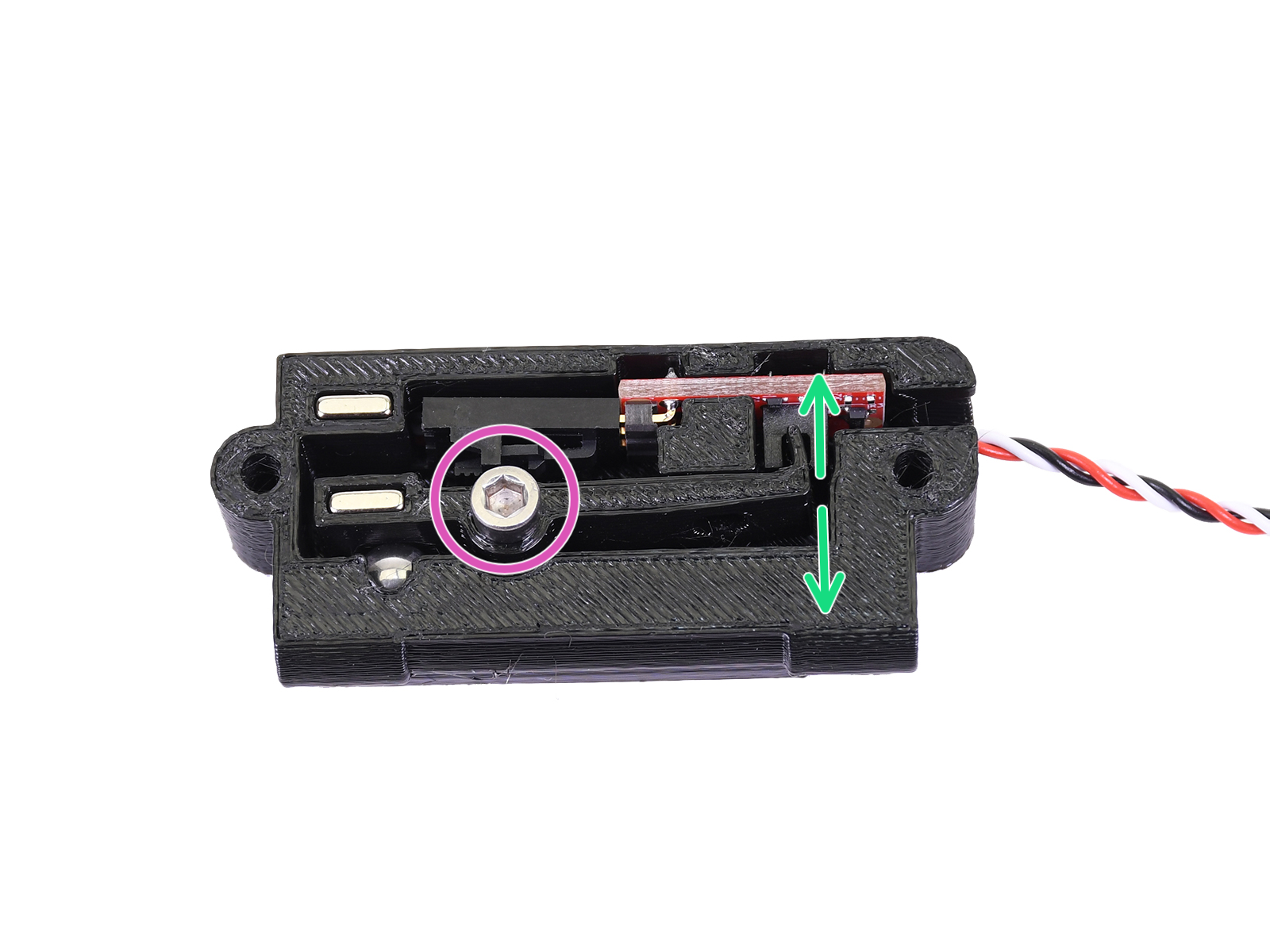

M591 P1 C"e0stop" S1 D0 ; filament monitor connected to E0 endstop

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S0.5 H1 T60 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 (bed) on pin fan2 and set its frequency

M106 P2 S1 H0 T50

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R20 S0 ; Set initial tool 0 active and standby temperatures to 0C

;LED control

M950 P5 C"e1heat" ;set e1heat as a GPIO output pin

M501

M107

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet Ethernet 1.02 or later

Board ID: 08DDM-9FAMU-JW4S4-6JKD8-3SJ6M-T3Y7V

Used output buffers: 3 of 24 (15 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 70804 of which 0 recycled

Never used RAM 19736, free system stack 126 words

Tasks: NETWORK(ready,24.5%,244) HEAT(delaying,0.0%,330) Move(notifyWait,0.1%,313) MAIN(running,75.2%,445) IDLE(ready,0.3%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:05:30 ago, cause: power up

Last software reset at 2021-07-28 10:51, reason: User, GCodes spinning, available RAM 16640, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 29.0, current 39.8, max 40.2

Supply voltage: min 24.1, current 24.3, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 750, standstill, SG min/max not available

Driver 1: position 0, standstill, SG min/max 0/226

Driver 2: position 1964, standstill, SG min/max 0/376

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2021-07-31 20:31:26

Cache data hit count 4294967295

Slowest loop: 6.18ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 1.4ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 136889ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 14, completed moves 14, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Filament sensors ===

Extruder 0 sensor: ok

=== Network ===

Slowest loop: 15.52ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

Interface state active, link 100Mbps full duplex

M98 P"config.g"

RepRap name: My Duet

Error: Bad command: man.

Error: Z axis maximum must be greater than minimum

7/31/2021, 8:31:27 PM M122

filament-change.g

M83 ; relative extruder moves

G1 E-5 F2000 ; retract 5mm of filament

G91 ; relative positioning

G1 Z10 F360 ; lift Z by 10mm

G90 ; absolute positioning

G1 X5 Y272.5 F6000 ; go to X=0 Y=0

M98 P"Unload"

M25

. Anyway thank you for your help in understanding the problem. It works much better now . Have a great day

. Anyway thank you for your help in understanding the problem. It works much better now . Have a great day

image url)

image url)