Hi,

I am getting reasonably good autocalibration deviations:

9:34:18 PMG32

Calibrated 8 factors using 16 points, deviation before 0.032 after 0.031

9:33:33 PMG32

Calibrated 8 factors using 16 points, deviation before 0.031 after 0.029

I improved this from 0.060-0.067 by tensioning the belts better. I don't use M500, I prefer to enter the autocalibration results into my config.g file.

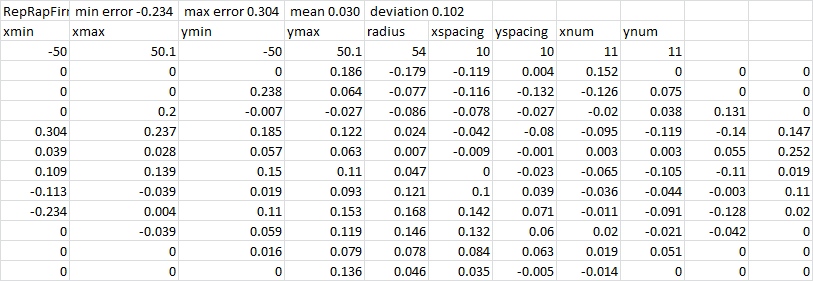

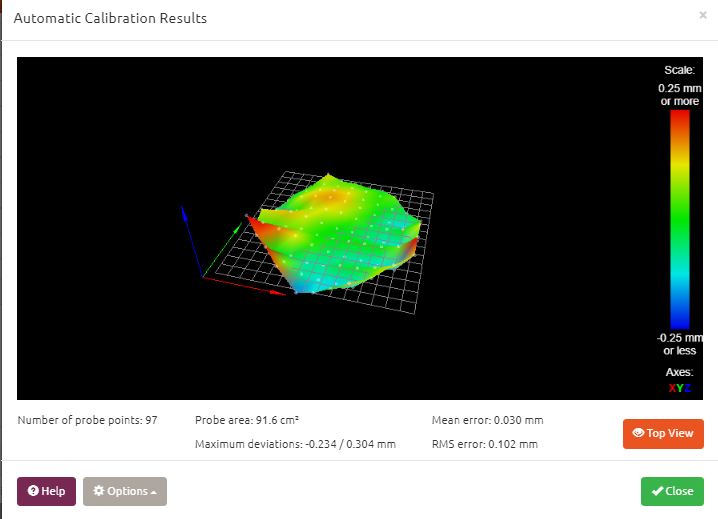

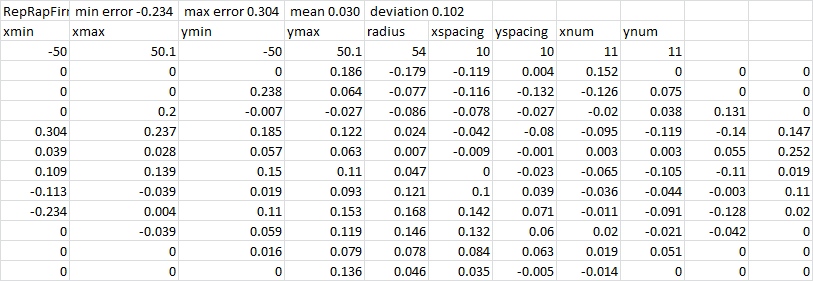

but my bed mesh is all over the place

RepRapFirmware height map file v2 generated at 2019-10-16 21:37 min error -0.234 max error 0.304 mean 0.030 deviation 0.102

RepRapFirmware height map file v2 generated at 2019-10-16 21:37 min error -0.234 max error 0.304 mean 0.030 deviation 0.102

xmin xmax ymin ymax radius xspacing yspacing xnum ynum

-50 50.1 -50 50.1 54 10 10 11 11

0 0 0 0.186 -0.179 -0.119 0.004 0.152 0 0 0

0 0 0.238 0.064 -0.077 -0.116 -0.132 -0.126 0.075 0 0

0 0.2 -0.007 -0.027 -0.086 -0.078 -0.027 -0.02 0.038 0.131 0

0.304 0.237 0.185 0.122 0.024 -0.042 -0.08 -0.095 -0.119 -0.14 0.147

0.039 0.028 0.057 0.063 0.007 -0.009 -0.001 0.003 0.003 0.055 0.252

0.109 0.139 0.15 0.11 0.047 0 -0.023 -0.065 -0.105 -0.11 0.019

-0.113 -0.039 0.019 0.093 0.121 0.1 0.039 -0.036 -0.044 -0.003 0.11

-0.234 0.004 0.11 0.153 0.168 0.142 0.071 -0.011 -0.091 -0.128 0.02

0 -0.039 0.059 0.119 0.146 0.132 0.06 0.02 -0.021 -0.042 0

0 0 0.016 0.079 0.078 0.084 0.063 0.019 0.051 0 0

0 0 0 0.136 0.046 0.035 -0.005 -0.014 0 0 0

Unfortunately when I downloaded this is didn't give me the heightmap image.

What can I do to improve this?

Small delta, config.g below ( this says firmware 2.03, but I am sure I am on 2.04, I think this file was originally generated before I installed 2.04)):

; Configuration file for Duet Maestro (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.4 on Tue Sep 17 2019 20:28:32 GMT+0100 (British Summer Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer naME

M665 L120.75:120.25:120.25 R61.788 H124.094 B55.0 X1.209 Y0.638 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed heigh

M666 X0.85 Y-1.18 Z0.33 A-1.93 B0.43 ; put end stop adjustments here, or let auto calibration find them

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 E256 I0 ; configure microstepping without interpolation

M350 X32 Y32 Z32 I1 ; configure microstepping with interpolat

M92 X204.520 Y204.520 Z204.520 E1675 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X600 Y600 Z600 E600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z-3 S1 ; set minimum Z

; Endstops

M574 X2 Y2 Z2 S0 ; set active low and disabled endstops

; Z-Probe

M558 P1 H10 I1 F1200 T12000 A5 ; set Z probe type to switch and the dive height + speeds

G31 P0001 X0 Y0 Z-0.2 ; set Z probe trigger value, offset and trigger height

M557 R54 S10 ; define mesh grid

; Heaters

M305 P1 T100000 B4138 R2200 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 A322.4 C143.5 D6.3 S1.00 V12.6 B0 ; SET pid FIGURES FROM AUTOTUNE

M305 P0 T100000

M143 H0 S120

; Fans

M106 P0 S0 I0 F500 H1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

;scaling

m570 x0.9481 y1.0115 ; scaling adjusted

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

Bed.g:

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool v2.0.4 on Tue Sep 17 2019 20:28:32 GMT+0100 (British Summer Time)

M561 ; clear any bed transform

G28 ; home all towers

; Probe the bed at 12 peripheral and 3 halfway points, and perform 3-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.40

M140 H0 S60

G30 P0 X0 Y48 H0.13 Z-99999

G30 P1 X24.95 Y43.21 H0.0772 Z-99999

G30 P2 X43.21 Y24.95 H-0.159 Z-99999

G30 P3 X48 Y0 H0.099 Z-99999

G30 P4 X43.21 Y-24.95 H0.1712 Z-99999

G30 P5 X24.95 Y-43.21 H-0.027 Z-99999

G30 P6 X0 Y-48 H-0.0902 Z-99999

G30 P7 X-24.95 Y-43.21 H0.133 Z-99999

G30 P8 X-43.21 Y-24.95 H0.192 Z-99999

G30 P9 X-48 Y0 H0-0.512 Z-99999

G30 P10 X-43.21 Y24.95 H-0.022 Z-99999

G30 P11 X-24.95 Y43.21 H0.1116 Z-99999

G30 P12 X0 Y24.9 H0.116 Z-99999

G30 P13 X21.56 Y-12.45 H0.008 Z-99999

G30 P14 X-21.56 Y-12.45 H0.146 Z-99999

G30 P15 X0 Y0 H0 Z-99999 S8

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)

The heightmap is high towards each tower, and is shows peaks and troughs. I think I may have a belt issue, I have GT2 16t drive gear and idlers with S2M belt. I am waiting for GT2 belt to arrive but it seems to be taking an age to come. Could this be causing the issue, or is there something else I can examine? Is it worth me redoing my trigger heights in case there has been any movement?

I can add some figures from a calibration object I printed later today if it would be of any use?

RepRapFirmware height map file v2 generated at 2019-10-16 21:37 min error -0.234 max error 0.304 mean 0.030 deviation 0.102

RepRapFirmware height map file v2 generated at 2019-10-16 21:37 min error -0.234 max error 0.304 mean 0.030 deviation 0.102