@fcwilt

Ok. Will change that.

Posts made by ecnsupplies

-

RE: Hotend alarm heating to slowposted in General Discussion

@ecnsupplies

Swapped the m307H0 R0.532 K0.167:0.000 D13.56 E1.35 S1.00 B0 added it to hotend and put back the bed defaults all working! thank you -

RE: Hotend alarm heating to slowposted in General Discussion

@fcwilt

Added M570 H1 P4 T15 in config file, shut down, waited 2 minutes then turned back on

It did not help! Same error at 183.6 deg. -

RE: Hotend alarm heating to slowposted in General Discussion

@droftarts

I have a backup. And the bed works fine. Just the hotend gives the error.

It's so close to getting to 205. Makes it to 185 in a min. Before it fails. -

RE: Hotend alarm heating to slowposted in General Discussion

@fcwilt

Manually in duet 3 web interface. Use drop down and put to 200 and activate .When using the auto tune it's m303 to m205 command and it runs all 4 tests. I gave you the last results that I put in the config.g and replaced it with the old one in there.

The test runs fine and goes up to 205 3 times with no issues.

Only fails when I do it manually or upload a gcode file to start a project.

Stupped why it works on auto test but not anyother way. It must be disabling something to run the test that's stoping it from normal use.

-

RE: Hotend alarm heating to slowposted in General Discussion

@fcwilt

Yes many times. Also wired thing is the auto tune takes the temp up to 205 3 times with no issues but when i manually try it. It fails. Or if i try and upload a gcode file.Last tune

Auto tuning heater 1 completed after 3 idle and 10 tuning cycles in 882 seconds. This heater needs the following M307 command:

M307 H1 R1.782 K0.652:0.006 D9.93 E1.35 S1.00 B0 V24.1

Edit the M307 H1 command in config.g to match this. Omit the V parameter if the heater is not powered from VIN. -

Hotend alarm heating to slowposted in General Discussion

Hotend alarm heating to slow

Ran the auto tuning and put the m307 in the config.g Still having issues. All started when i put in a new all metal hotend. It makes it to about 185 deg before i get this alarmHeater 1 fault: temperature rising too slowly: expected 1.25°C/sec measured 0.73°C/sec

Any help would be appreciated.

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) ; General preferences M929 S1 ; logs G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 5 Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 P192.168.1.87 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S1 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) X9000.00 Y9000.00 Z180.00 E6000.0 M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X5:225 Y0:225 Z300 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-40 Y-5 Z1.751 ; set Z probe trigger value, offset and trigger height original G31 P500 X0 Y0 Z3.75 M557 X15:200 Y40:200 S20 ; define mesh grid M557 X15:215 Y15:195 S20 G30 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H1 R1.857 K0.829:0.020 D9.60 E1.35 S1.00 B0 V24.1 ; enable bang-bang mode for the bed heater and set PWM limit H0 R0.532 K0.167:0.000 D13.56 E1.35 S1.00 B0 M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 S"Nozzle-0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; ensures a tool is selected upon start up (allowing extrusion/retraction) ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

RE: Wifi not working after a whileposted in General Discussion

@huge

Is your wifi 2.4 gigs. The diet 2 only supports 2.4 not 5.0. Or bonded wifi. It will drop the signal. I have many cameras and other devices that do this so I had to create a 2.4 network.

Might look into that -

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

@fcwilt

That was it. A little bowed in the middle but will get a glass plate or replace hotend bar.

Thank you again for all your help.

-

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

@fcwilt

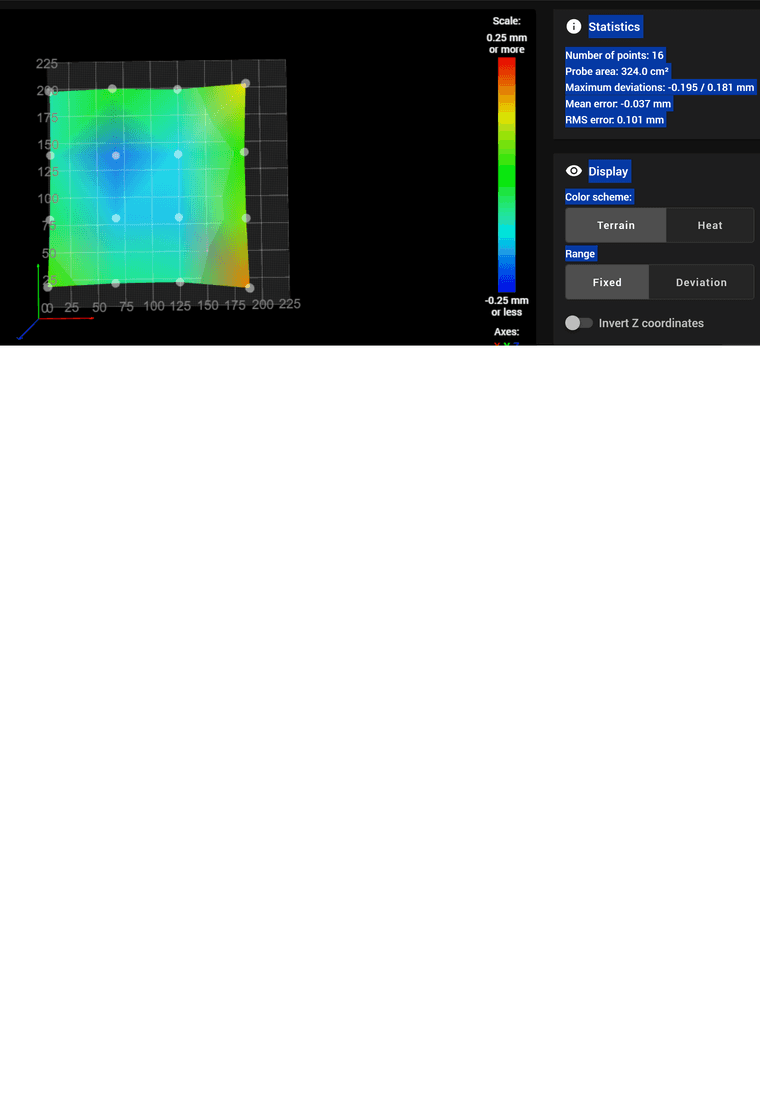

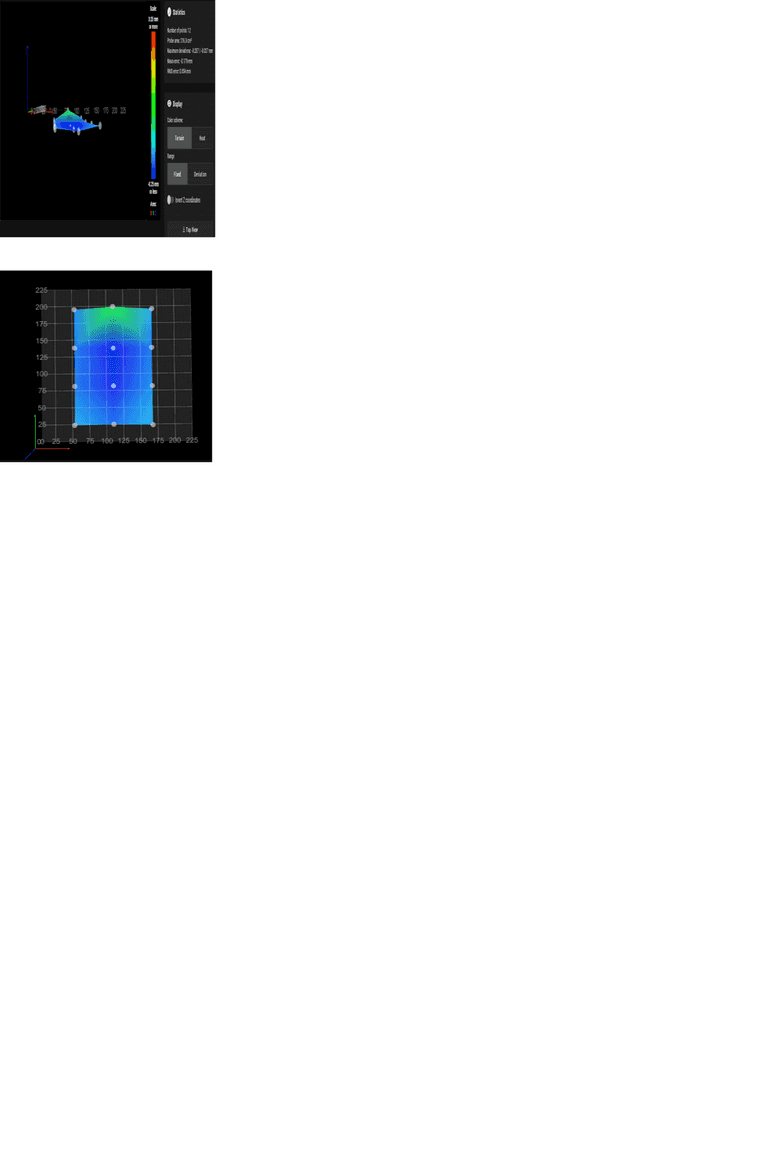

I think i have a brain Tumor. I clicked on invert z axis in the calibration page and it looks much better. Running the calibration again and hope this was all it was.

So sorry for not seeing that switch. -

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

@fcwilt said in Bed calibration error on g28 when using bl touch probe:

created a new height map

Please don't get flustered, i just don't know the terminology. Only way i know to create a new height map is to run the g29 in the compensation and calibration page on the duet dashboard.

First i run the g92 z0 to set the 0 head height then g30 s-1 to get the height that i put in the config.g G31 line.

I then open the compensation and calibration and run g29 to see that the bed plate design is below the 0 line. ALLMOST ALL BLUE.PS This all started when i changed the z motor steps from 400 to 800 because my height was off by 1/2

-

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

Did as you asked. Removed the g30 and measured the bl touch it was 40mm x and 5mm y Replaced the 10s to the new measurements in g31 line.

That only moved it over but not UP -

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

@fcwilt

I thought I had it figure out BUT NOT! I added the G30 as you requested as well to config.g and homeall.g? See below config.g and homeall.g files.

My problem is when I use the G29 command the bed on the chart shows below the 0 line, and gives this warning.Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh. 12 points probed, min error -0.257, max error -0.027, mean -0.179, deviation 0.054 Height map saved to file 0:/sys/heightmap.csvI ran the G92 ZO AND G30 S-1 to set and get the 0 height, It was 3.010 I added to the config.g under the

G31 ie: G31 X110 Y110 Z3.010

Every time I run the g29 to level the bed I get this warning and when I look at the chart its below the line and blue. I tried to manually change the bed height manually and also in the config.g it does not change it. Any ideas?RepRapFirmware height map file v2 generated at 2023-11-21 11:15, min error -0.257, max error -0.027, mean -0.179, deviation 0.054 axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1 X,Y,50.00,200.00,20.00,200.00,-1.00,60.00,60.00,3,4 -0.161, -0.201, -0.155 -0.194, -0.240, -0.181 -0.194, -0.257, -0.194 -0.185, -0.027, -0.160

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 5 Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 P192.168.1.87 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S1 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X225 Y225 Z300 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X10 Y10 Z1.944 ; set Z probe trigger value, offset and trigger height G31 P500 X0 Y0 Z3.75 M557 X50:220 Y20:220 S20 ; define mesh grid M557 X15:215 Y15:195 S20 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.532 K0.167:0.000 D13.56 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 S"Nozzle-0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; ensures a tool is selected upon start up (allowing extrusion/retraction) ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X225 Y225 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G1 H1 X225 Y225 F240 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X110 Y110 F6000 ; go to first bed probe point and home Z G1 X20 Y20 F6000 G30 X110 Y110 Z0 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning ; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X-5 Y15 F3000 ; go to first probe point G30 X110 Y110 Z0 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G3 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning ; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) M561 ; clear any bed transform G29 ; probe the bed and enable compensation -

RE: Bed calibration error on g28 when using bl touch probeposted in General Discussion

Never mind i found the issue. Sorry

-

Bed calibration error on g28 when using bl touch probeposted in General Discussion

When i run bed calibration with g29 command i get error

G29. Tried to lower and raise height on the g31 line in config. No noticeable change even if i go up 4.00 plus or minus! . I ran the height calibration many times using G92 Z0 and G30 S-1 to get height. bed stays blue to low.

Any help o this would be apricated.The Error

Warning: the height map has a substantial Z offset. Suggest use Z-probe to establish Z=0 datum, then re-probe the mesh.

12 points probed, min error -0.370, max error -0.140, mean -0.263, deviation 0.061

Height map saved to file 0:/sys/heightmap.csvRepRapFirmware height map file v2 generated at 2023-11-21 08:47, min error -0.370, max error -0.140, mean -0.263, deviation 0.061 axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1 X,Y,50.00,200.00,20.00,200.00,-1.00,60.00,60.00,3,4 -0.224, -0.264, -0.175 -0.264, -0.323, -0.250 -0.271, -0.370, -0.313 -0.252, -0.140, -0.309My config files, bed, home, probe ect.

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Ender 5 Pro" ; set printer name M918 P1 E4 F2000000 ; configure direct-connect display ; Network M552 P192.168.1.87 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S1 ; disable FTP M586 P2 S1 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z800.00 E93.00 ; set steps per mm M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z180.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X225 Y225 Z300 S0 ; set axis maxima ; Endstops M574 X2 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin io0.in M574 Y2 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin io1.in M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io7.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X10 Y10 Z1.944 ; set Z probe trigger value, offset and trigger height G31 P500 X0 Y0 Z3.75 M557 X50:220 Y20:220 S20 ; define mesh grid M557 X15:215 Y15:195 S20 ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.532 K0.167:0.000 D13.56 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S150 ; set temperature limit for heater 0 to 150C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S275 ; set temperature limit for heater 1 to 275C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"out9" Q500 ; create fan 2 on pin out9 and set its frequency M106 P2 S1 H1:0 T45 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 S"Nozzle-0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; ensures a tool is selected upon start up (allowing extrusion/retraction) ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X225 Y225 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X-5 Y-5 F6000 ; go back a few mm G1 H1 X225 Y225 F240 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X110 Y110 F6000 ; go to first bed probe point and home Z G1 X20 Y20 F6000 G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning ; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:41 GMT-0600 (Central Standard Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X-5 Y15 F3000 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G3 Z5 F200 ; lift Z relative to current position ;G90 ; absolute positioning ; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Thu Nov 16 2023 14:37:40 GMT-0600 (Central Standard Time) M561 ; clear any bed transform G29 ; probe the bed and enable compensation -

RE: Test cube is half the size it should be on test print.posted in General Discussion

@fcwilt

I downloaded a different slicer and will run it tonight just so I can say I did.

Let you know tomorrow -

RE: Test cube is half the size it should be on test print.posted in General Discussion

@fcwilt

Duet recommend cura so that's what I installed. -

RE: Test cube is half the size it should be on test print.posted in General Discussion

M579. Axis scale factors x1.000, y:1.000 z:1.000

-

RE: Test cube is half the size it should be on test print.posted in General Discussion

@fcwilt

One forum said it might be z accep and jerk are to high. Any clue were this would be? -

RE: Test cube is half the size it should be on test print.posted in General Discussion

@fcwilt

Made a test pattern to measure 25mm on each axis and jogged to each. They are exact.