This worked, Thank you!

Posts made by gw3d3

-

RE: Duplicate heaters after print complete or cancelled.posted in Duet Web Control

-

RE: Duplicate heaters after print complete or cancelled.posted in Duet Web Control

@droftarts Thank you! I will try this with a short print and post results!

-

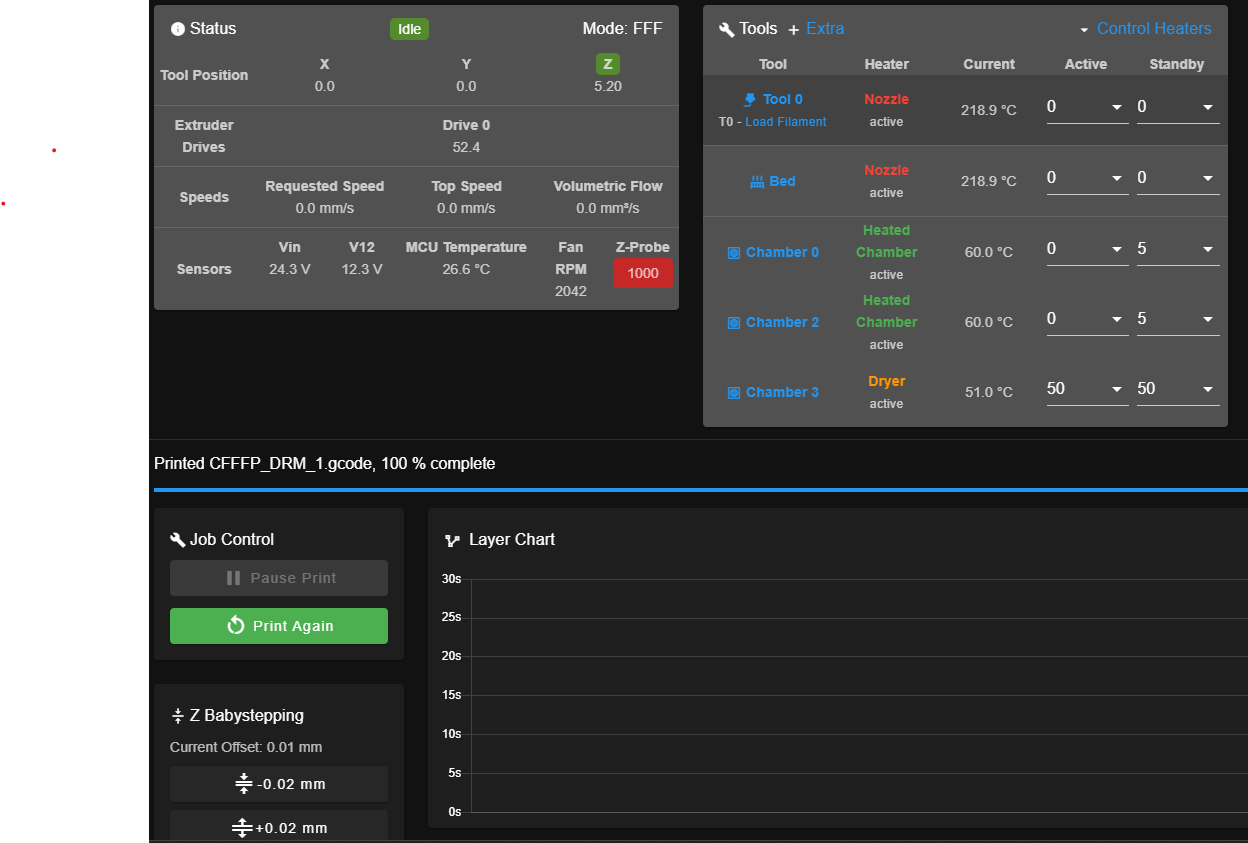

Duplicate heaters after print complete or cancelled.posted in Duet Web Control

Hey all, I've been trying to set my machine up so that the dryer will stay on at the requested temperature after a print. I believe in attempting to do so I caused this issue, but I'm unsure of the best way forward here.

All the functionality is still there and it goes away with a power cycle.I use Cura as a slicer. Here is the end G code:

;Retract the filament and move tool head away.

G92 E1

G1 E-0.5 F300 ; Retract filament 0.5mm

G28 XY ; Move tool head to home position

M84 ; Disable stepper motors

M0 ; Triggers stop.g in Duet system files

Stop.g:

;stop.g

M104 T0 S0 ;Turn off hotend

M140 H1 S0 ;Turn off heated bed

M141 H2 S0 ;Turn off printer chamber heaterThank you all in advance for any insight!

-

RE: Keeping the Filament dryer always on?posted in General Discussion

@chrishamm Thank you I will try this out.

;stop.g keeping dryer active

M104 H0 S0 ;Turn off hot end

M140 H1 S0 ;Turn off heated bed

M141 H2 S0 ;Turn off printer chamber heater

End G code in Cura

;Retract the filament and move tool head away.

G92 E1

G1 E-0.5 F300

G28 XY

M84

M0

-

Keeping the Filament dryer always on?posted in General Discussion

I have a custom build that has a built in filament dryer. After a print is completed all of the heaters shut down as usual.

Is there a way that I can keep the dryer heater active after the print is done? The chamber blower is hardwired (always on) so it is just the matter of keeping the heater running at the requested temperature afterwards. I'm using Cura as the slicing software.

Here is a copy of the config.g for heaters and sensors. It is not the most up-to-date, but it's what I had available to copy at the moment.

; Sensors

M308 S0 P"temp2" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0

M308 S1 P"nil" Y"thermocouplemax31856" A"Nozzle" K"J" F60 ; configure sensor #1

M308 S2 P"temp0" Y"thermistor" A"Heated Chamber" T100000 B4725 C7.06e-8 ; configure sensor #2

M308 S3 P"temp1" Y"thermistor" A"Dryer" T100000 B4725 C7.06e-8 ; configure sensor #3; Heaters

M950 H0 C"out3" T1 ; create heater #0

M143 H0 P0 T0 C0 S450 A0 ; configure heater monitor #0 for heater #0

M307 H0 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #0

M950 H1 C"out0" T0 ; create heater #1

M143 H1 P0 T1 C0 S190 A0 ; configure heater monitor #0 for heater #1

M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1

M950 H2 C"out1" T2 ; create heater #2

M143 H2 P0 T1 C0 S100 A0 ; configure heater monitor #0 for heater #2

M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2

M950 H3 C"out2" T3 ; create heater #3

M143 H3 P0 T1 C0 S90 A0 ; configure heater monitor #0 for heater #3

M307 H3 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #3; Heated beds

M140 P1 H1 ; configure heated bed #1; Heated chambers

M141 P2 H2 ; configure heated chamber #2

M141 P3 H3 ; configure heated chamber #3Thanks!

-

RE: Question about controlling a PWM fan.posted in General Discussion

@jay_s_uk Thank you, I set the Q value to 25kHz as per Noctua's specs and it is working well now!

-

RE: Question about controlling a PWM fan.posted in General Discussion

@jay_s_uk So, that did invert the behavior but now anything under 100 is just off.

-

RE: Question about controlling a PWM fan.posted in General Discussion

@jay_s_uk Oh ok, it is a 4-wire fan. Is the the PWM pin inverted by the "!" sign?

-

Question about controlling a PWM fan.posted in General Discussion

I use this fan to move air over my chamber heating element.

The RPM range is listed as 750-3000RPM and when I start the printer it is on, at full speed. When I look at DWC the fan says that it is at "0" on the slider. When I move the slider to anything other than zero the fan turns off and won't turn back on until I put the slider back to "0". I will post my fans from config.g below.

Is this a wiring issue or did I miss something in my firmware configuration?

Thanks!

; Fans

M950 F0 C"out7" ; create fan #0

M106 P0 C"Part Cooling Fan" S0 L0 X1 B0.1 ; configure fan #0

M950 F1 C"out8" ; create fan #1

M106 P1 C"Hot End Fan" S0 B0.1 H1 T35 ; configure fan #1

M950 F2 C"out4+out4.tach" ; create fan #2

M106 P2 C"Chamber Fan" S0 L0.2 X1 B1 ; configure fan #2 -

RE: Homing sequence different in latest RRF Version?posted in General Discussion

@droftarts Thank you all for the replies.

This corrected the issue!

-

RE: Homing sequence different in latest RRF Version?posted in General Discussion

@jay_s_uk Thanks for the reply.

So I made the change:

; home X

var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm

G1 H1 X{var.maxTravel} F600 ; coarse home in the +X direction

G1 H2 X-5 F6000 ; move back 5mm

G1 X{var.maxTravel} F300 ; fine home in the +X directionI'm still getting the same behavior.

-

Homing sequence different in latest RRF Version?posted in General Discussion

This is my first machine built with the latest firmware version and when I home the axes, instead of backing off 5mm as written in the homex.g and homey.g it moves all the way back to the zero position.

Since my homing switches are at the maxima of each axis this makes the homing sequence take quite a while. I tried using the home code from a previous build and nothing changed. What am I missing? I'll post the homex.g and homey.g below.

Thanks!

; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.5.1 on Sat Jun 22 2024 12:58:51 GMT-0400 (Eastern Daylight Time); increase Z

G91 ; relative positioning

G1 Z5 ; move Z relative to current position to avoid dragging nozzle over the bed

G90 ; absolute positioning; home X

var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm

G1 H1 X{var.maxTravel} F600 ; coarse home in the +X direction

G1 X-5 F6000 ; move back 5mm

G1 H1 X{var.maxTravel} F300 ; fine home in the +X direction; decrease Z again

G91 ; relative positioning

G1 Z-5 F6000 ; move Z relative to current position

G90 ; absolute positioning

; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.5.1 on Sat Jun 22 2024 12:58:51 GMT-0400 (Eastern Daylight Time); increase Z

G91 ; relative positioning

G1 Z5 ; move Z relative to current position to avoid dragging nozzle over the bed

G90 ; absolute positioning; home Y

var maxTravel = move.axes[1].max - move.axes[1].min + 5 ; calculate how far Y can travel plus 5mm

G1 H1 Y{var.maxTravel} F600 ; coarse home in the +Y direction

G1 Y-5 F6000 ; move back 5mm

G1 H1 Y{var.maxTravel} F300 ; fine home in the +Y direction; decrease Z again

G91 ; relative positioning

G1 Z-5 F6000 ; move Z relative to current position

G90 ; absolute positioning -

RE: V1.1 Thermocouple Daughterboard with MAX31855 Chipposted in Duet Hardware and wiring

@droftarts So, I'm issuing a correction to my original post.

After using the macro lens on my camera to take a picture of the IC I realized it was the correct part number! I switched from a "J" type to a "T" type in my config.g and it seems to be working now.

I was having an issue with an intermittent over/under voltage error but I crimped up another heater assembly and it seems to be stable. Whether or not it was a bad crimp or the actual T.C. I don't know.

I'm using Igus Chainflex shielded cable which is drained to an earth ground. There is about 5" of exposed, but twisted pair lead from where the shielding terminates to the daughterboard. Is this too much?

-

V1.1 Thermocouple Daughterboard with MAX31855 Chipposted in Duet Hardware and wiring

I'm working towards the delivery of my first unit to a customer and the deadline is tight. This is my first time using thermocouples on the build. I bought a thermocouple daughterboard V1.1 that was supposed to have the MAX31856 controller, but it does not. It has the MAX31855. This was purchased from PrintedSolid who is an authorized reseller here in the U.S.

I'm using a type "J" Thermocouple that is permanently installed into the heater block so switching to a "K" Type is not an option. Almost no resellers in the U.S./Canada have them in stock and the ones that do are suspect. I ordered one from Ooznest and I'm hoping for the best from DHL Express shipping.

In the mean time I can have one of these by tomorrow.

Would it be possible to fit this to a MB6HC even though the pinout is not the same?