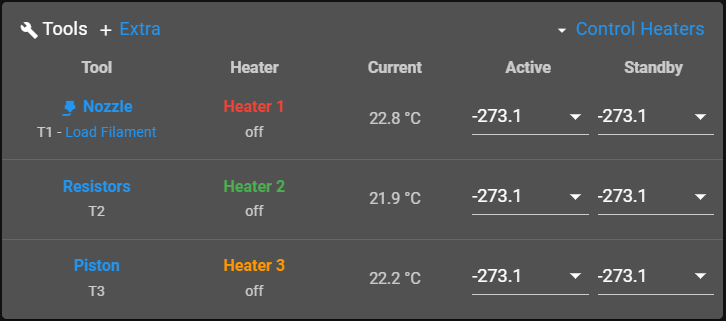

@droftarts Hi, and thank you for your response. Based on that I modified my config. code now to include also the minimum temperature which triggers the temperature fault. However, I removed the monitor disabled because I don't see any need for having that. Accordingly, I got same information related to how monitors are used for minimum and maximum of Heater 1 as you wrote above. Nevertheless, after I added the minimum temperature monitoring, I still have the erraneous temperatures for the Current and Standby temperatures (-273.1C), while Current temperature sensor reading is OK. When I have only the maximum monitoring defined, this error does not appear.

Please, find below my config.g file:

;PRINTER SETTINGS

;

; General preferences

M111 S0 ; Debugging off (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m111-set-debug-level)

G21 ; Work in millimetres (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g21-set-units-to-millimeters)

G90 ; Send absolute coordinates... (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g90-set-to-absolute-positioning)

M83 ; ...but relative extruder moves (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m83-set-extruder-to-relative-mode)

; Report local date and time (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m905-set-local-date-and-time)

M905

; Creating PanelDue2 (https://docs.duet3d.com/User_manual/Reference/Gcodes#m950-create-heater-fan-spindle-or-gpioservo-pin)

M950 J0 C"io0.in" ; Creating input for PanelDue

; Enabling PanelDue2 (https://docs.duet3d.com/User_manual/Reference/Gcodes#m575-set-serial-comms-parameters)

M575 P1 B57600 S1 ;

;Setting-up firmware compatibility (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m555-set-compatibility)

M555 P2 ; firmware compatibility to look like Marlin

; Setting-up device name (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m550-set-name)

M550 P"Device"; includes firmware version

; Enable network (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m552-set-ip-address-enabledisable-network-interface)

if {network.interfaces[0].type = "ethernet"}

M552 P192.168.1.14 S1

else

M552 S1

; Additional sensors visualized (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m308-set-or-report-sensor-parameters)

M308 S10 Y"mcu-temp" A"MCU"

; Setting-up Z probe (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m558-set-z-probe-type)

M558 P0 ; No z probe

;Setting-up Z probe trigger value, offset and trigger height (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g31-set-or-report-current-probe-status)

G31 X-30 Z1.1 P530 ; Not needed?

; Setting-up drives (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m569-set-motor-driver-direction-enable-polarity-mode-and-step-pulse-timing)

M569 P0 S0 ; Drive 0 (X motor) goes backwards

M569 P1 S0 ; Drive 1 (Y motor) goes forwards

M569 P2 S1 ; Drive 2 (Z motor) goes forwards

M569 P3 S0 ; Drive 3 (E motor) goes backwards

M569 P4 S0 ; Drive 4 (U motor) goes backwards

;Setting-up drive mapping (https://docs.duet3d.com/User_manual/Reference/Gcodes#m584-set-drive-mapping)

M584 X0 Y1 Z2 E3 U4;

; Setting-up axis movement restrictions (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m208-set-axis-max-travel)

M208 X0 Y0 Z0 S1 ;

M208 X150 Y130 Z100 S0 ;

; Setting-up endstop configuration (https://docs.duet3d.com/User_manual/Reference/Gcodes#m574-set-endstop-configuration)

M574 X1 S1 P"!io1.in" ; Active high endstop switch for low end on X

M574 Y1 S1 P"!io2.in" ; Active low endstop switch for low end on Y

M574 Z2 S1 P"!io3.in" ; Active high endstop switch for low end on Z

;Configuring microstepping with interpolation (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m350-set-microstepping-mode)

M350 X256 Y256 Z256 E16 U16 I1 ;

;Setting-up steps per mm (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m92-set-axis-steps-per-unit)

M92 X6400 Y6400 Z12800 E357 U1600;

;Setting-up maximum instantaneous speed changes (mm/min) (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m566-set-allowable-instantaneous-speed-change)

M566 X10 Y10 Z10 E1200 U7;

; Setting-up maximum speeds (mm/min) (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m203-set-maximum-feedrate)

M203 X600 Y600 Z240 E900 U600;

; Setting-up accelerations (mm/s^2) (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m201-set-max-acceleration)

M201 X60 Y60 Z60 E3000 U200

; Setting-up motor currents (mA) and motor idle factor in per cent (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m906-set-motor-currents)

M906 X759.8 Y759.8 Z759.8 E890.8 U1781.6 I20

; Allow movement before homing (https://docs.duet3d.com/User_manual/Reference/Gcodes#m564-limit-axes)

M564 H0 S1; Allow movement of axes that have not been homed and limited movement within axis boundaries

; Setting-up idle timeout (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m84-stop-idle-hold)

M84 S60 ; 60 seconds

; Setting-up Pt100 sensors (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m308-set-or-report-sensor-parameters)

M308 S1 P"spi.cs0" Y"rtd-max31865" A"Heater 1" U0.080, V-0.0040; required correcting factors for sensor reading

M308 S2 P"spi.cs2" Y"rtd-max31865" A"Heater 2" U0.18, V-0.0088 ; required correcting factors for sensor reading

M308 S3 P"spi.cs1" Y"rtd-max31865" A"Heater 3" ;

; Creating heaters (https://docs.duet3d.com/User_manual/Reference/Gcodes#m950-create-heater-fan-spindle-or-gpioservo-pin)

M950 H1 C"out1" Q10 T1 ; Heater 1

M950 H2 C"out2" Q10 T2; Heater 2

M950 H3 C"out3" Q10 T3 ; Heater 3

; Setting-up maximum temperatures for heaters (https://docs.duet3d.com/User_manual/Reference/Gcodes#m143-maximum-heater-temperature)

M143 H1 P0 T1 S250 A0 C0 ; Heater 1 maximum before heater fault

M143 H1 P1 T1 S0 A0 C1 ; Heater 1 minimum before heater fault

M143 H2 P0 T2 S250 A0 C0; Heater 2 maximum before heater fault

M143 H2 P1 T2 S20 A0 C1; Heater 2 minimum before heater fault

M143 H3 P0 T3 S250 A0 C0; Heater 3 maximum before heater fault

M143 H3 P1 T3 S20 A0 C1; Heater 3 minimum before heater fault

; Configuring heater fault detection https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m570-configure-heater-fault-detection

M570 H1 P2 T10 R2; Heater 1

M570 H2 P60 T10 R2; Heater 2

M570 H3 P40 T10 R2; Heater 3

;Setting-up PID parameters for heaters (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m307-set-or-report-heating-process-parameters)

M307 H1 R2.921 K0.455:0.000 D2.48 E1.35 S0.55 B0 ; Heater 1

M307 H2 R5.771 K0.276:0.000 D3.88 E1.35 S0.15 B0 ; Heater 2

M307 H3 A550 C303.1 S0.3 D15.0 B0 ; Heater 3

; Cold extrusion (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m302-allow-cold-extrudes)

M302 P1 S120 R110; Allowed from 120 and rectraction from 110

; Setting-up outputs (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m950-create-heater-fan-spindle-led-strip-or-gpioservo-pin)

M950 P4 C"out4" ;

M950 P5 C"out5" ;

M950 P7 C"out7" ;

M950 P0 C"out0" ;

M950 P6 C"out6" ;

M950 P11 C"out8" ;

M950 S10 C"out9" ;

; Setting-up inputs (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m950-create-heater-fan-spindle-led-strip-or-gpioservo-pin)

M950 J4 C"io4.in" ;

M950 J6 C"io6.in" ;

M950 J7 C"io7.in" ;

M950 J8 C"io8.in";

; Defining tools section (https://docs.duet3d.com/User_manual/Machine_configuration/Configuration_cartesian#tool-definition-section)

M563 P1 S"Tool 1" D0 H1 ; Tool 1 uses extruder drive 0 and Heater 1

M563 P2 S"Tool 2" H2 ; Tool 2 uses Heater 2, no fan or extruder drive defined

M563 P3 S"Tool 3" H3 ; Tool 3 uses Heater 3, no fan or extruder drive defined

; Setting-up Tool axis offsets (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g10-tool-temperature-setting)

G10 P1 X0 Y0 ; Tool 1

G10 P2 X0 Y0 ; Tool 2

G10 P3 X0 Y0 ; Tool 3

; Setting-up Tool active and standby temperatures (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m568-set-tool-settings)

M568 P1 R0 S0 A0; Set initial tool 1 active and standby temperatures to 0C

M568 P2 R0 S0 A0 ; Set initial tool 2 active and standby temperatures to 0C

M568 P3 R0 S0 A0 ; Set initial tool 3 active and standby temperatures to 0C

; Tool selecting (https://docs.duet3d.com/en/User_manual/Reference/Gcodes#t-select-tool)

T-1 ; deselected all

Here is the image of the erraneous Active and standby temperatures:

Here are the information of Duet firmware and board:

1/19/2025, 10:23:06 AM M115

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.5.3 ELECTRONICS: Duet 3 MB6HC v1.01 FIRMWARE_DATE: 2024-09-18 11:27:36

BR, Heidi