Hi @dunginhawk

I'm configuring a CR-10 with Duet Wifi I'm learning but I think I can help you.

Your Z step is wrong, if is a stock CR-10 it should be Z.400, change it and see if is better.

What extruder are you using?

If is the stock extruder the starting steps should be E93.00, and then do a calibration.

I'm using the SEEMECNC EZR STRUDER and I have E119.88

The E420.00 is for a 3:1 gear reduction extruder like a Bondtech or a Titan

Here is my config.g

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.5 on Tue Oct 29 2019 22:40:39 GMT+0000 (Hora padrão da Europa Ocidental)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"CR10" ; set printer name

; Network

M551 P"XXXXXXX" ; set password

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E119.88 ; set steps per mm

M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z6000.00 E30000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z500.00 E500.00 ; set accelerations (mm/s^2)

M906 X750 Y750 Z750 E750 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y300 Z400 S0 ; set axis maxima

; Endstops

M574 X1 Y1 Z1 S1 ; set active high endstops

; Z-Probe

M558 P0 H2 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X0:0 Y0:0 S20 ; define mesh grid

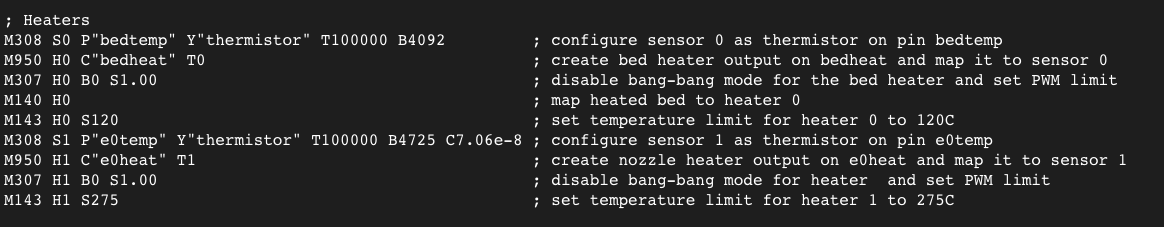

; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4092 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S285 ; set temperature limit for heater 1 to 285C

; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

Like I said I'm learning as well and maybe we can help each other

I leave here the settings I took from Marlin firmware from my CR-10

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min)

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {80.000,80.000,400.000,93.00} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {500,500,100,5000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 500 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 500 // X, Y, Z and E max acceleration in mm/s^2 for retracts

// Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing).

// The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder).

// For the other hotends it is their distance from the extruder 0 hotend.

// #define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis

// #define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 20.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)