Great news everyone! With the upcoming RRF 3.6.0-rc.1, dc42 just announced experimental support for nozzle touch probing!

Posts made by jbjhjm

-

RE: Duet SZP nozzle probing like beacon contact?posted in Duet Hardware and wiring

-

Duet SZP nozzle probing like beacon contact?posted in Duet Hardware and wiring

Hi!

In spring, a beacon firmware update introduced a new "Contact" feature, shorty described as "Low Force Nozzle Touch Probing for Beacon".

See blog post for some details: https://beacon3d.com/press-release/It appears they've managed to find a reliable way to detect when the nozzle impacts the bed with minimal force.

With this feature, finally full and detailed, automated Z homing and calibration becomes possible.My question is, will this feature be implemented for Duet SZP and alikes as well? Is it maybe already being worked on?

Couldn't find any info or thread on this, so I thought its the right time to open one

Thank you,

Jannik -

RE: Thoughts on an auto-z offsett macroposted in Gcode meta commands

Great work! I'm thinking of adding such a setup to my V-Core in the future. Thanks for sharing, this will be helpful! It was a bit difficult to see in the vid... what sensor is being used to measure the nozzle Z position? The demo that I recently saw had an aditional fixed Z probe mounted in a corned of the bed, but watching the video it looks like you use a different approach.

-

RE: [3.4-b5] bug - initial config not running correctlyposted in Beta Firmware

ah yes this makes sense thanks @gloomyandy !

-

RE: [3.4-b5] bug - initial config not running correctlyposted in Beta Firmware

@t3p3tony weird, I just powered up to check on any errors as you suggested, but this time everything was initialized correctly.

I'll let you know here in case it happens again. -

[3.4-b5] bug - initial config not running correctlyposted in Beta Firmware

I saw some movement issues on my printer the last few days. Turns out that some/all settings that should be loaded in config.g via macro call M98 P"config_defaults.g" are not being applied.

For that reason the printer tried to use way off acceleration and velocity values.

I guess it likely is the call of the macro that doesn't work like before.Using 3.4 b5 in SBC mode.

config.g

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ; M550 P"V-Core 3" ; set printer name -- only for standalone use with network M669 K1 ; CoreXY G29 S1 ; Set Units to Millimeters ; mainboard ; OUT4-6 @ 12V ; OUT 7-9 @ 24V ; 0.DRIVER_0 => Z ; 0.DRIVER_1 => Z ; 0.DRIVER_2 => Z ; 0.DRIVER_3 => Y ; 0.DRIVER_4 => X ; 0.DRIVER_5 => Extruder ; 0.IO_0 => X Endstop ; 0.IO_1 => Y Endstop ; 0.IO_5 => Z Probe BLtouch ; 0.TEMP_0 => Bed Temp ; 0.OUT_1 => Bed Heater ; 0.OUT_2 => Hotend Heater ; 0.OUT_4 => Duet/Raspi Fan (Fan10) ; 0.OUT_7 => Hotend Fan (Fan0) (2pin) ; 0.OUT_8 => Layer Fan (Fan1) (2pin) ; 0.TEMP_1 => Hotend Temp ; OUT9 5V/PWM is used for powering relay ; toolboard uses default CAN address #121 ; 121.IO_0 => Z Probe BLtouch ; 121.IO_1 => (Filament Monitor) ; 121.IO_2 => X Endstop ; 121.TEMP_0 => Hotend Temp ; 121.OUT_0 => Heater ; 121.OUT_1 => Hotend Fan 4-pin ; 121.OUT_2 => Layer Fan 3-pin ; 121.DRIVER_0 => Extruder G4 S1 ; wait for expansion boards to start ; Define Motors ===================================================================== M569 P0.0 S0 D3 ; Z motors run backwards M569 P0.1 S0 D3 ; Z motors run backwards M569 P0.2 S0 D3 ; Z motors run backwards M569 P0.3 S1 D3 ; Y goes forwards M569 P0.4 S1 D3 ; X goes forwards M569 P121.0 S1 D3 ; Ext goes forwards M584 X0.4 Y0.3 Z0.0:0.1:0.2 E121.0 ; assign drives to axes M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation ;Step sizes M92 X80.00 Y80.00 Z800.00 ; set steps per mm M906 X1000 Y1000 Z800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Define Axes and endstops ===================================================================== ; define axis limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X310 Y287 Z300 S0 ; set axis maxima ; define endstops ;M574 X1 S1 P"io0.in" ; configure active high endstops M574 X1 S1 P"121.IO_2.in" ; configure active high endstops M574 Y2 S1 P"0.IO_1.in" ; configure active high endstops M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Define Bed ===================================================================== ; Lead screw positions ; this defines the position of the SCREWS! ; to configurate measurement points, check bed.g ; Y axis is reduced to 287 [13-300], adapted Y position of Z screws accordingly! M671 X-3:150:306.5 Y-16:292:-16 S2 ; define positions of Z leadscrews or bed levelling screws | ideal: X-4.5:150:304.5 Y-4.52:305:-4.52 S5 M557 X10:275 Y10:262 P5 ; define 5x5 mesh grid -- Y is limited to 287, update Y range accordingly! ; configurate heat bed M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out5 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C ; Set the Bed PID values - gathered from PID tune M307 H0 B0 R0.435 C373.3 D1.30 S1.00 V23.9 ; Define BLTouch Sensor ===================================================================== M950 S0 C"121.IO_0.out" ; Create servo pin 0 on io5 M558 P9 C"121.IO_0.in" H8 F320 T18000 A5 ; set Z probe type to unmodulated - dive height increased from 5mm, Feed rate increased from 240. P9 = type bltouch ; Z offset calibrated using guide https://betrue3d.dk/bltouch-on-duet-wifi-configuratio-and-usage/#testandcalibrate ; Z3 means: Set Z=3mm when probe is triggered. So a smaller value will set the minimum Z further away from the head. ; Calibrate Z so that a piece of paper does only move with friction between nozzle and bed. Babystepping adds a senseful offset for printing. G31 P25 X-28.00 Y-23.00 Z4.21 ; set Z probe trigger value, offset and trigger height, more Z means closer to the bed ; Define Tool 0 ===================================================================== M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; hotend heater and temperature sensor M308 S1 P"121.TEMP_0" Y"pt1000" A"Hotend" ; register hotend temperature sensor M950 H1 C"121.OUT_0" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S290 ; set the maximum temperature in C for heater ; Set the Hotend PID values - gathered from PID tune ;M307 H1 B0 R1.989 C208.6 D6.92 S1.00 V23.9 M307 H1 B0 R1.926 C77.3 D5.96 S1.00 V24.2 ; define extruder / hotend M92 E830 ; set extruder steps per mm, 0.9 angle/step (LDO Pancake) M906 E800 ; set extruder motor current (mA) and idle factor in per cent M302 S150 R110 ; Allow extrusion starting at 150°C and retractions starting at 110°C M207 S4.0 F1600 Z0.1 ; configurate G10/G11 extruder retraction, move 4mm, also move bed 0.1mm ; Define Fans ===================================================================== ; Hotend Fan - sunon fan needs high PWM, foun in an amazon review M950 F0 C"121.OUT_1" Q31400 ; create fan on pin out7 and set frequency to 31 kHz M106 P0 C"Hotend Fan" S0 H1 L0 X0.5 T60:250 ; configurate fan. H1 = Thermostatic control ON , -1 = OFF | L/X = min/max Speed | T = temperature range ; Layer Fan M950 F1 C"121.OUT_2" Q500 ; create fan on pin out8 and set its frequency M106 P1 C"Layer Fan" S0 H-1 L0.5 ; configurate fan. Thermostatic control is turned off ; back CPU/PSU fans M308 S10 Y"mcu-temp" A"MCU" ; configure sensor 10 to represent MCU temp M308 S11 Y"drivers" A"Drivers" ; configure sensor 11 to represent Drivers temp M950 F10 C"!out4+^out4.tach" Q100 ; create fan 10 on out4 (1st PWM slot) M106 P10 C"Duet/RasPi Fan" H10:11 L0.3 X1 B0.3 T35:70 ; assign fan 10 to sensors 10 and 11 | B = run x seconds on full power | L + X = min/max bounds ; setup Accelerometer ===================================================================== ; First digit: orientation of accelerometer Z axis ; second digit: orientation of acc. X axis ; 0 = +X, 1 = +Y, 2 = +Z, 4 = -X, 5 = -Y, 6 = -Z. M955 P121.0 I24 ; use accelerometer @ 121.0, axis config 2,4 ; set defaults ===================================================================== ; contains default movement and acceleration speeds ; as well as things like speed / eextrusion factor, microstepping etc ; nozzle / filament diameter M98 P"config_defaults.g" ; for unknown reasons this does not work in config.g but in homeall.g. ; toggle the ATX relay once to let duet know we use one. THis will show the ATX power widget in DWC ;M80 ;G4 P1000 ; need a short pause ;M81 S0config_defaults.g

; (re)set defaults M566 X400.00 Y400.00 Z6.00 E120.00 P1 ; set maximum instantaneous speed changes (mm/min) // same as M205 but with mm/min M201 X6000 Y6000 Z50 E3600 ; set accelerations (mm/s^2) M203 X10800.00 Y10800.00 Z600.00 E3600.00 ; set maximum speeds (mm/min) M204 P6000 T6000 ; Set printing and travel accelerations M205 X8 Y8 Z8 ; custom jerk - A M593 P"zvd" F44.3 ; Input shaping T0 ; Select tool 0 M220 S100 ; Set speed factor to 100% M221 S100 ; Set extrusion factor to 100% M290 R0 Z0.25 ; babystepping 0 , R0 = absolute mode R1 = relative, add to configurated babystepping offset ;G10 P0 R0 S80 ; Set extruder to 80 and release M404 N1.75 D0.4 ; Filament width and nozzle diameter -

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

@t3p3tony I will let you know if anything new occurs. Maybe b5 and the tweaked raspi settings helped to make it go away. As the error did not occur often in the past, I'll continue and observe for some days.

-

RE: Heater Fault handling improvementsposted in General Discussion

@owend I agree to your thoughts, however I think my idea is a bit different to what you described. Maybe my initial post was too imprecise.

I am not talking about a macro REPLACING the automated fault reaction.

I am talking about a macro called AFTER reacting to a fault.As far as I can see this does not violate any safety behavior or risk the safety routines to be broken.

However it allows for additional, individual measurements. Let yourself be notified by a beeper that there's some trouble for example. That would even increase safety because one will take notice sooner and can react faster.In other cases, like those that have just happened to me, there was no real fault, just the layer fan at 100% cooling the hotend so much that a fault was detected.

In this case, if the printer stops immediately (Toolboard CAN fix) and notifies me immediately (beep, show a big message), I am able to react fast enough to check what has happened and allow the print to continue. (Of course only if I'm 100% sure no real fault has happened. And yes, I already did this successfully, but only could do so cause I knew a certain print will very likely fail due to "cooldown fault" and was sitting next to the printer with a finger on the pause key.) -

RE: Get current job file offsetposted in Gcode meta commands

@chrishamm works perfectly fine thank you for helping me out!

-

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

@t3p3tony chrome shutdown/crash is fixed by the solution proposed in other topic!

About the number of processes, that's my fault. I just noticed that htop was showing not only processes but every thread too. I do still see a dozen processes but that is not unusual for chrome.

-

RE: [3.4.B5] bug - chromium crashes on startup [sbc]posted in Beta Firmware

@chrishamm that fixes it thank you!

-

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

The duplicate chromium seems to be related to beta5.

Just did a full restart and the screen showed a crashed chromium window right away.

This has never happened before so I'm quite sure it has to do with beta5.

Opened a but report to discuss this separately.

https://forum.duet3d.com/topic/25542/3-4-b5-bug-chromium-crashes-on-startup-sbc -

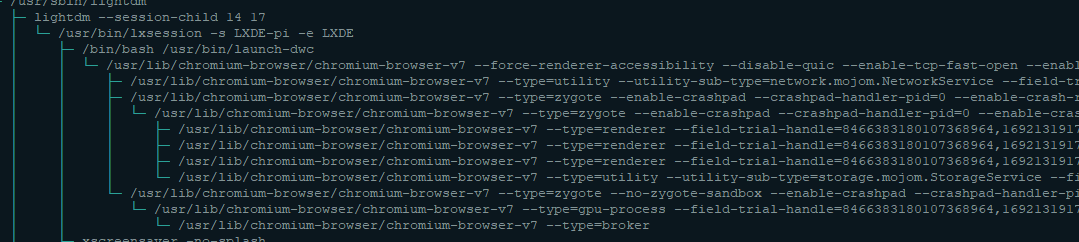

[3.4.B5] bug - chromium crashes on startup [sbc]posted in Beta Firmware

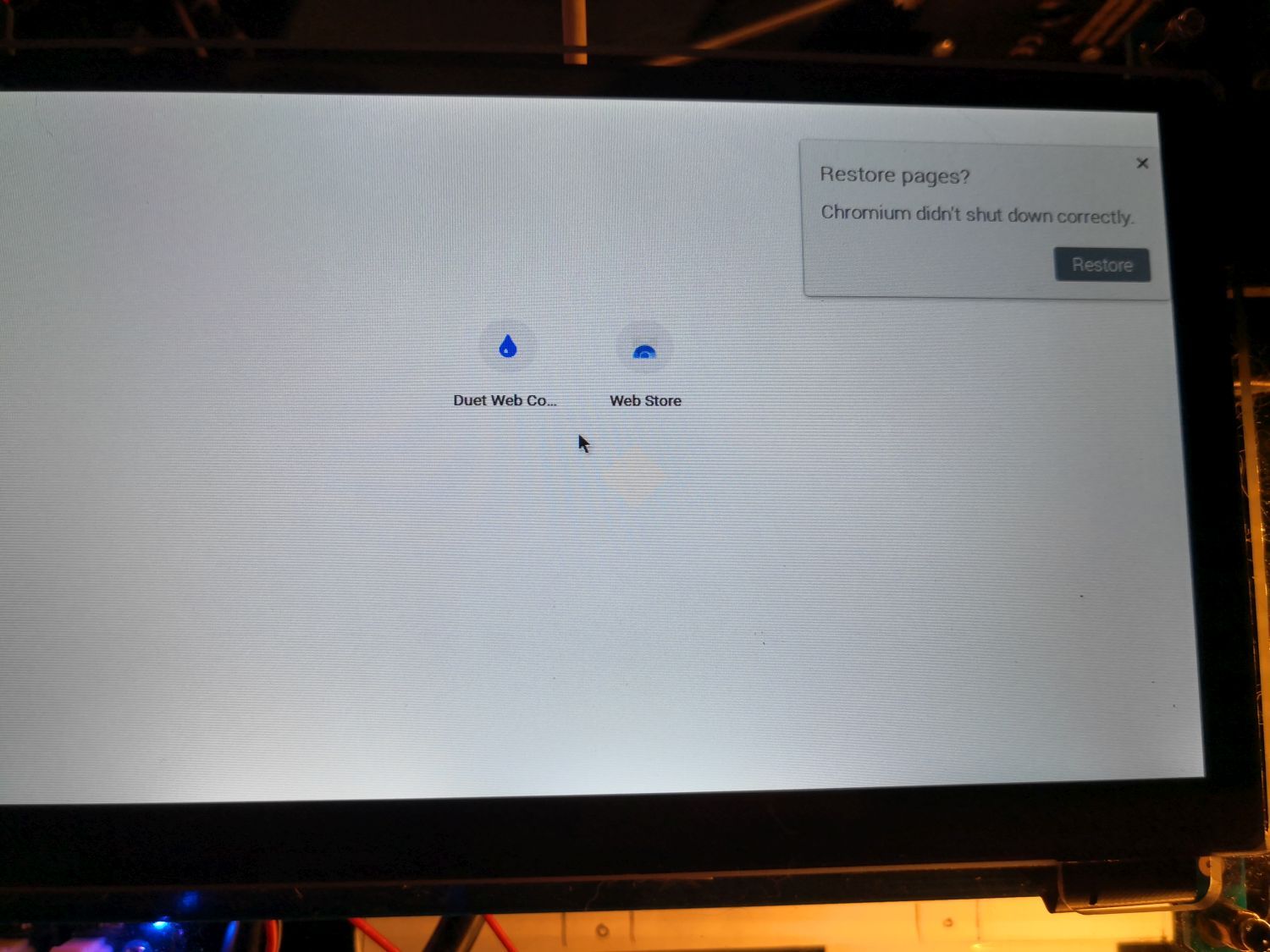

Since updating to 3.4-b5 this morning, the touch panel connected to my raspi shows a crashed chromium window right after startup.

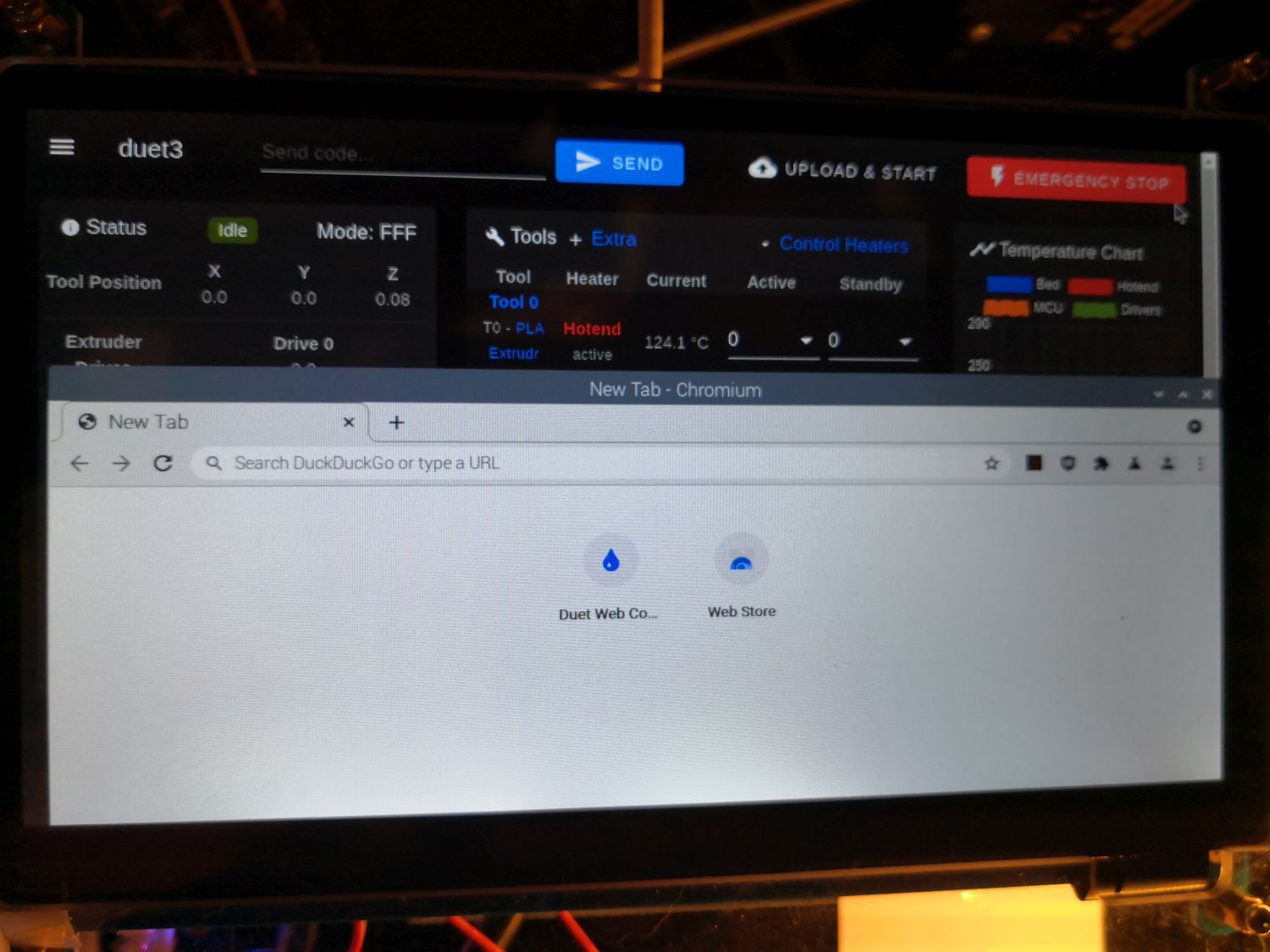

When exiting fullscreen and moving it away one can see there's a second chromium window with a working DWC tab.

As described here:

https://forum.duet3d.com/topic/25254/crashes-during-printing-spi-connection-has-been-reset/14?_=1634233362101

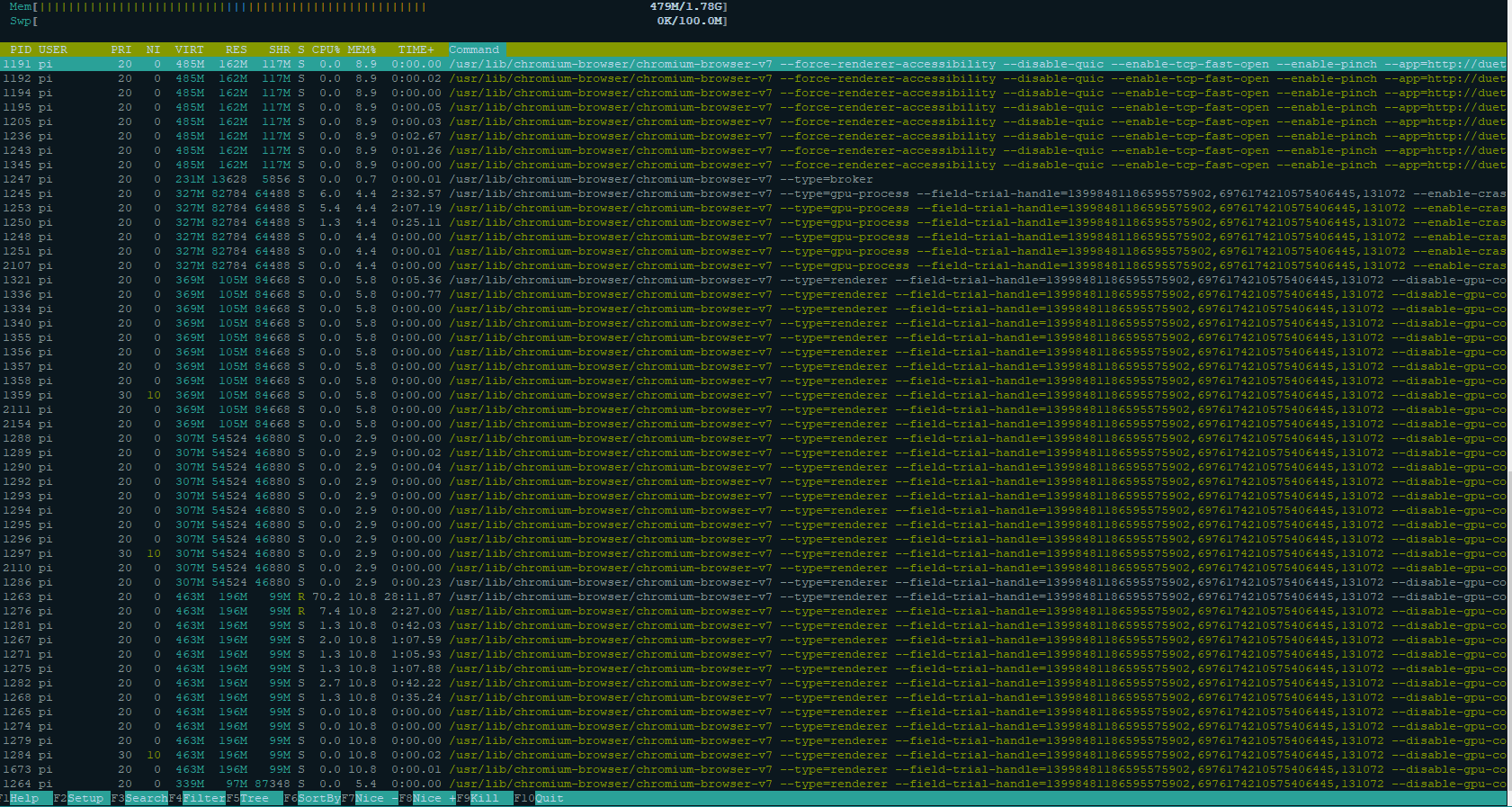

There's also a high amount of chromium processes running. I have not checked running processes before b5, but it feels unusual. -

RE: 2 issues from Pausing print - sets new base speed bugposted in Beta Firmware

Pausing works fine again and the speed multiplier seems to be fixed too!

-

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

@t3p3tony when my next print is completed I'll do a full restart and check chrome status right after, if two instances are running and such.

If someone can point me into the right direction for finding the duetPi startup script, I'll check if there's anything unusual going on.Attached bootlog.txt by the way.

Don't know enough about raspi + linux to spot anything useful unfortunately. -

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

ok it seems that the pi's network connection has again crashed just a few minutes ago; it's still listed in the routers active devices list, responds to pings, but DWC does not load anymore. The print is still being executed though.

So I checked what happened on the touch panel: Chrome displayed a white page + a note that it has crashed and if it should reload.

Now this is weird: I dismissed that message, exited fullscreen and then saw another instance of Chrome running below the crashed instance!

I have no clue why it is there. I did not tweak the startup routine provided by duetPi.

After closing the crashed chrome window, it seems that the network connection was recreated too...

Nothing really useful in journal (re-enabled logging hoping to hunt down networking issues). Just way too many network connection losses and reconnects. This is related to the bad wifi that I still have to improve. Disallowed auto-switching frequency bands and 2.4/5Ghz, hopefully that will make the connection a bit more robust. -

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

@t3p3tony ah now I get you. It's both, the pi has a permanently attached screen, and I often access DWC through network too for more complex tasks and if I'm not in the same room.

-

RE: Heater Fault handling improvementsposted in General Discussion

thanks for explaining @t3p3tony ! Looking forward to seeing that limitation being blown away!

Til then, best bet for everyone may be to try out the deamon.g checker.

https://forum.duet3d.com/topic/20722/heater-fault-checking-routine-to-be-run-in-daemon-g -

RE: Crashes during printing - "SPI connection has been reset".posted in General Discussion

@t3p3tony no voltage issues reported so far by vcgencmd.

I'm not sure I understand what you meant with your last comment.DWC is running on the Pi (at least as far as I understand Duet's SPC mode, all that is handled by the Pi while the mainboard only handles printing and reports back values?).

DWC also is the only opened chromium tab.

Nontheless chromium runs a bunch of different processes.

In Time/CPU columns you can see though that there is just one chromium process that uses lots of CPU time.

-

RE: Heater Fault handling improvementsposted in General Discussion

@t3p3tony yes, using a Toolboard v1.1!