In my experience a stepper motor that stalls easily and suddenly moves in a random direction is a good indication that one of the stepper coils is not connected or has a bad connection. How much of the wiring and connector are you not changing? If you plug everything including all wiring/connectors/motor that you plug in to E1 to the E0 port will it still have issues?

Posts made by Kezat

-

RE: E0 motor sometimes works sometimes doesnt E1 is perfectposted in Duet Hardware and wiring

-

RE: [Solved] Short-to-ground on driver 3posted in Duet Hardware and wiring

@pugzor Yay, glad it was a easy fix.

-

RE: My labor of Love/Hateposted in My Duet controlled machine

Cool! Looking forward to more details and specs:)

Are you using a 3 or 4 point leveling system? I ask because my custom printer has a similar 2020 (?) bed frame I experimented with a single beam in the center (T shape) to support the front center of the bed and also the way you have it with two beams on each side. (U shape)

It looked like to me that having a single beam in the center would allow less flex for the bed. (in the roll direction if you will) My thinking was if one side flexed up 1 mm and the other 1mm down it would be a 2mm difference, but with the T shape the flex in theory would only be that 1mm (for a example) but i guess you would have more weight on one beam. Perhaps I'm just overthinking it:) -

RE: [Solved] Short-to-ground on driver 3posted in Duet Hardware and wiring

@pugzor Yup! So the issue is not be the board, that's good news. I'm not sure if the Duet will show this type of error if you have the motor wired wrong ie if you have a coil connected across the two coil outputs but i would guess not, mostly likely your extuder motor cable actually does have the wires shorted out together or to a grounded metal frame.

-

RE: [Solved] Short-to-ground on driver 3posted in Duet Hardware and wiring

Just to be clear, you still get the short to ground error message on driver 3 when you try and command a move of driver 3 without anything connected to that board connector correct? I'm trying to determine if the board has a fault or the issue is the extruder motor/wiring (driver3?) that is at fault.

-

RE: [Solved] Short-to-ground on driver 3posted in Duet Hardware and wiring

Does unplugging the motor (power off board first) connector from the board clear the error? And make sure you don't have a bit of metal shorting out the underside of the board. If you cant clear the error by removing the connector a good visual inspection might be a good idea.

-

RE: Highly erratic temperature readings above certain temperatureposted in Tuning and tweaking

I was having vary similar issues as this with a E3D sensor, it was not always a spike but a 20-30c error at times then other times it would spike to the max. Replacing it solved all issues even though it was a new barely used sensor.

-

RE: LED flickering on PWM Heatbed?posted in Duet Hardware and wiring

Have you measured the actual current of the bed at full power? My KEENOVO 500w 120v AC heater pad draws around 4.8A at 120v AC so 580W or so. It may be that your closer then you think to the max of your 600W PSU or even over it you include hotend and motors.

-

RE: Dual PSUposted in Duet Hardware and wiring

You should be able to connect both negatives of the power supply's together directly on the negative of the board.

Then one or both of the positives on the heaters to the matching power supply, as with most controllers the Duet will switch the ground connection so it will still control correctly. -

RE: Y axis homes in correct direction, but moves in wrong directionposted in General Discussion

If i remember correctly my default Homeall.g came with positive homing moves that i had to change to negative, could it be that you have the axis inverted and also have the homing backwards?

-

RE: Large Format Printerposted in My Duet controlled machine

Wow! A beautiful printer. A video would be lovely when you have time. Here I was thinking my custom printer was a good size at ~300mm square.

Nice idea with the cheap stretched plastic enclosure, i might have to borrow that:) -

RE: A month of tweaking and still can not get a print….posted in Tuning and tweaking

@flippnswitchez said in A month of tweaking and still can not get a print….:

Tronxy x5s

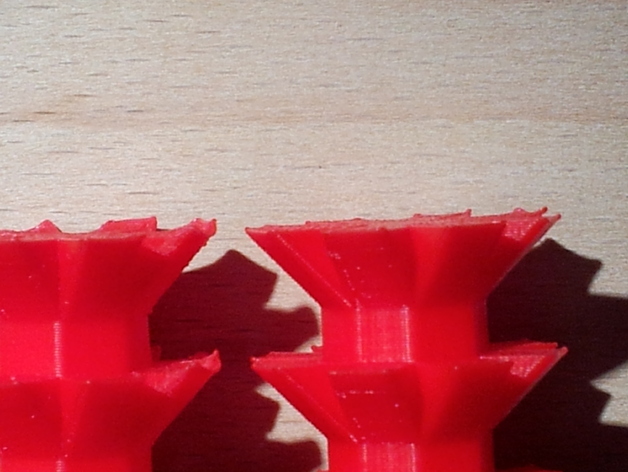

Perhaps the small part needs more cooling? Uploading photos of a

larger print like the 3D benchy might help with troubleshooting.

https://www.thingiverse.com/thing:763622 -

RE: Do home in Z max, help! Doubt in configposted in Tuning and tweaking

Do you have Z plus and Z minus mixed up by chance? Z zero (homed) is nozzle near the bed, a +100mm move will create a 100mm gap from nozzle to the bed. So if DWC shows 0 then it should not move in the Z- this is to prevent damage to the nozzle or bed.

If you really are using Zmax to home your Zhome (or homeall) code needs to set G92 to the max height of your Z and not Zero as is normally done.

So G92 Z300 for a 300 max z printer.

Or perhaps i'm missing your point?

-

RE: Do home in Z max, help! Doubt in configposted in Tuning and tweaking

When you home to max your setting G92 to max z height and not zero correct?

-

RE: Extruder issue?posted in General Discussion

Do you know what the model number of the motor is, I wonder if a really high inductance could cause this kind of issue.

I have also seen stepper motors behave strangely if you have the stepper motor free like that and with no load on the shaft at some speeds/current settings. Have you tried to install it on the printer yet, even holding the motor firmly to the table might cause it to change.It sounds like you may have tested it but like Phaedrux said make sure to check for a bad connection and you can try moving the wires around a little to see if you can make it run normally if the wires are put in to a specific bend.

-

RE: Extrusion calibration?posted in Tuning and tweaking

20mm is a bit on the small side to try and calibrate dimensional accuracy, i would say 100mm at the min but the more the better, you also need to be careful that you don't include any print defect/ringing, bed squash or over/under extrusion in your measurement.

For example if your part is 19.5mm but needs to be 20 and you adjust the M579 scale to make it 20mm you may end up with a 200mm part that is off by 5mm. It could be that if you had not changed any setting the part would still be off my only 0.5mm if it was 200mm long.

To put it another way it could be that your nozzle is moving the correct distance but its just the printed part that is not perfect due to other reasons not related to the XY scale or steps/mm.My current DIY CoreXY printer is using spectra line and 3d printed spools so it hard to calculate step/mm, the way i did so was to measure the actual carriage movement using calipers.

1. Power on motors and move carriage close to a edge.

2. Measure distance and zero out the calipers.

3. Command a 100mm move.

4. Measure new distance.

5. Take Commanded distance divided by measured distance then multiply that by my steps/mm. The output is the new steps/mm to be used.So if my commanded move is 100mm measured move is 103mm and my steps/mm started as 150.35 it would look like this:

100/103=0.9708 Then 0.9708*150.35=145.97. So the new corrected steps/mm is 145.97.

Again this is measuring the carriage movement and not the part, it can be done by measuring a printed part you just need to print it as big as you can and correct for any print defects. One way to correct for this is to print a small part say 10mm then most of the error you see should be the part itself and not the move. (unless its way off) Then subtract that error from the big part. -

RE: Speed Factor dont seem to increase speedposted in Tuning and tweaking

If you put the M92 command first and set the steps/mm as for x16 microstepping, then they will be adjusted automatically to account for any M350 command later in config.g.

Nice, that's handy. Does the Duet assume x16 or do we need to put the x1 value then have the M350 value adjust it to the microstepping?

Edit: Looks like it default x16 looking at the gcode command https://duet3d.dozuki.com/Wiki/Gcode#Section_M350_Set_microstepping_mode

"a) Set Steps/mm correctly for the default 1/16 microstepping, then set the microstepping to the desired amount using M350:"

-

RE: Some minor issues with The Duet WiFiposted in Tuning and tweaking

10000mm/m is 166mm/s witch is really really fast for printing speeds, is that correct? Most of my printers are in the 50-60mm/s prints speeds and 100-150mm/s for travel nonprint moves.

It also looks like you have a good deal of under extrusion going on, may want to tune that before moving to other issues, this could be caused by really fast print speeds if the extruder cant melt the plastic as fast as requested.

-

RE: Z axis movement + + -+ or -+–posted in Duet Hardware and wiring

In some situations you can get a stepper motor to turn in a random direction with only one coil connected, first thing i would double check is your wiring and look out for cheap breadboards, some times the the wires do not make the best contact. Hard to imagine this getting caused by the Duet as that kind of error can cause physical damage to a printer and we would hear about it.

-

RE: Suddenly skipping stepsposted in General Discussion

One thing to look out for are overhangs that curl up if the cooling is too low, you say the print it smooth but it can be hard to find the cause because the shifted print can hide the curling edges.

Here is the above model if you want to give it a try.

https://www.thingiverse.com/thing:1377893