Hi everyone.

After making suggested changes everything is working correctly now. Thanks a lot

Best posts made by luka1952

-

RE: Slicer shuts off hotend fan.posted in Using Duet Controllers

-

RE: Slicer shuts off hotend fan.posted in Using Duet Controllers

@generisi Sorry my mistake.

To be clear:

I have only one slider in duet web control and it is part cooling fan.

When I use it part cooling fan is working.

When I set temp. higher the 45 deg. on my hotend the hotend fan kicks in.

Latest posts made by luka1952

-

RE: Acceleration analysisposted in Tuning and tweaking

@dc42

Thanks, great.

Do you know more about when it’s going to be released? Is very soon days or more like weeks/months? -

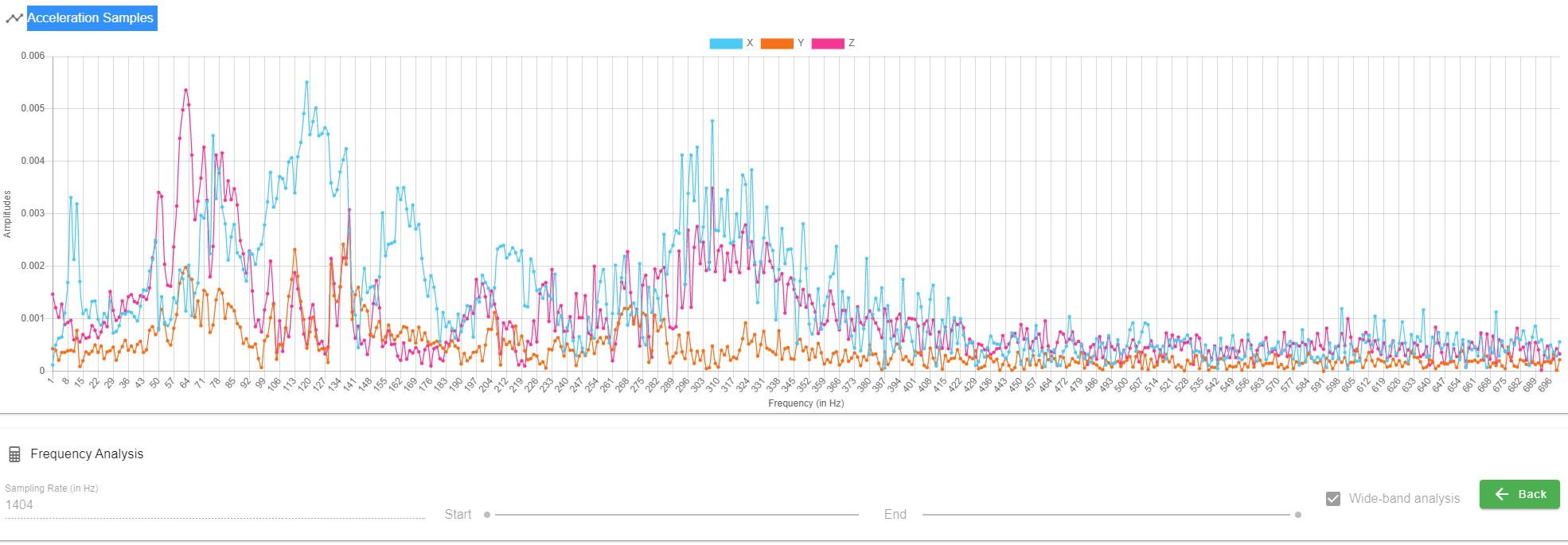

Acceleration analysisposted in Tuning and tweaking

Hi, I would like to use input shaping. Got this reading from my accelerometer after this command: G1 X-50 G4 S2 G1 X50 F20000 M400 M956 P0 S1000 A0.

But I've have no idea how to interpretate data. Which frequency should I cancel.

-

RE: Can't move the z axis in DWC more than 200posted in General Discussion

@engikeneer

Thanks, I've changed it and it works

Thank you very much.

There is one more problem I have but that's in the other topic. Could you have a look? I can't solve it... -

RE: Can't move the z axis in DWC more than 200posted in General Discussion

@engikeneer

I have dubbele z axis with two independent steppers/drivers.

This make possible to adjust the two z axis screws apart from each other. -

RE: Can't move the z axis in DWC more than 200posted in General Discussion

@phaedrux

Thanks for reply. This are my files you asked about.

When my print has finished I wanted to juggle the bed down to remove it easer. I hit +50 on z axis in DWC (the part I printed was 180mm high) so the bed supposed to move 50mm down. But it stops at 200 and refuse to lower further. I repeated the command seweral times. But didn't work. Then I moved up a bit and try to lower it again. But still the same. Stops at 200.M122:

18/02/2022, 07:20:51 M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.02 or later

Board ID: 0JD0M-9P6B2-NJ4S8-6JKDD-3SS6M-9B5GJ

Used output buffers: 3 of 24 (20 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 75636 of which 20 recycled

Never used RAM 14884, free system stack 184 words

Tasks: NETWORK(ready,13.7%,244) HEAT(delaying,0.1%,330) Move(notifyWait,0.1%,340) MAIN(running,85.7%,441) IDLE(ready,0.4%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:03:39 ago, cause: power up

Last software reset at 2022-02-17 16:55, reason: User, GCodes spinning, available RAM 15264, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 0

MCU temperature: min 25.1, current 31.4, max 31.6

Supply voltage: min 24.1, current 24.1, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 0, standstill, SG min/max not available

Driver 1: position 0, standstill, SG min/max not available

Driver 2: position 0, standstill, SG min/max not available

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2022-02-18 07:20:51

Cache data hit count 4294967295

Slowest loop: 4.58ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.5ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = 2 -1 -1 -1

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 21.00ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.26

WiFi MAC address e0:98:06:22:81:26

WiFi Vcc 3.31, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 21080

WiFi IP address 192.168.178.129

WiFi signal strength -73dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

Bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Dec 13 2021 17:52:06 GMT+0100 (czas środkowoeuropejski standardowy)

G28 ; home

M401 ; deploy Z probe (omit if using bltouch)

G30 P0 X0 Y185 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X330 Y185 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

M402 ; retract probe (omit if using bltouch)config.g

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Hypercube Evolution" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16:16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00:400.00 E693.00 ; set steps per mm

M566 X2000.00 Y2000.00 Z50.00:50.00 E3000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X20000.00 Y20000.00 Z2000.00:2000.00 E15000.00; set maximum speeds (mm/min)

M201 X10000.00 Y10000.00 Z50.00:50.00 E10000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800:800 E600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M671 X0:400 Y185:185 S1 ; leadscrews at left (connected to Z) and right (connected to E1) of X axisM572 D0 S0.01

; Axis Limits

M208 X0 Y0 Z0:0 S1 ; set axis minima

M208 X390 Y375 Z390:390 S0 ; set axis maxima; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z2 S2 ; configure Z-probe endstop for high end on Z

M915 X R0 F0; Z-Probe

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-28 Y-13 Z3.14 ; set Z probe trigger value, offset and trigger height

M557 X0:350 Y10:360 S60 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4085 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as PT100 on pin spi.cs1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S350 ; set temperature limit for heater 1 to 350C

M308 S2 P"e1temp" Y"thermistor" T100000 B4066 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create chamber heater output on e1heat and map it to sensor 2

M307 H2 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit

M141 H2 ; map chamber to heater 2

M143 H2 S80 ; set temperature limit for heater 2 to 80C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Filament Cooling Fan" S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"Hotend Fan" S1.0 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its freqeuncy

M106 P2 C"Filter Fan" S0 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 S"Sherpa/Dragon" D0 H1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0homeall.g

G91; relative positioning

G1 H2 Z10 F12000 ; lift Z relative to current position

G1 H1 Y-380 F3000 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y10 F6000 ; go back a few mm

G1 H1 Y-380 F360 ; move slowly to Y axis endstop once more (second pass)

M400

M913 X60 Y70; drop motor current to 60%

M201 X2000.00 Y2000.00

G1 H1 X-400 F5000 ; move quickly to X axis endstop and stop there (first pass)

G1 H2 X5 F12000 ; go back a few mm

G1 H1 X-400 F4000 ; move slowly to X axis endstop once more (second pass)

G1 X10

G92 X0

M201 X3000.00 Y3000.00

G90 ; absolute positioning

M400

M913 X100 Y100 ; return current to 100%

M400

G1 X200 Y200 F12000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed```homez.g

G91 ; relative positioning

G1 H2 Z5 F12000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X200 Y200 F12000 ; go to first probe point

G30 ; home Z by probing the bedM98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: Z axis maximum must be greater than minimum

Error: Z axis maximum must be greater than minimum

Warning: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 285C

Warning: Heater 2 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C - WiFi -

-

Can't move the z axis in DWC more than 200posted in General Discussion

Hi, Strangly i can't move z axis on my hypercube more than 200 in DWC. The z axis limit is 390. And before it was working ok.

What can cause this?

Is my board damaged? -

Problem with ledposted in General Discussion

Re: How do you connect a LED RGB strip

Hi I've connected my led like in the topic above. The white light is turning on when i turn on the printer. But I can't change its colours:

My settings in cofig.g:

; LED

M950 F3 C"exp.heater3" Q500 ; RGB Red

M106 P3 C"RGB Red" ; set RGB Red PWM

M950 F4 C"exp.heater4" Q500 ; RGB Green

M106 P4 C"RGB Green" ; set RGB Green PWM

M950 F5 C"exp.heater5" Q500 ; RGB Blue

M106 P5 C"RGB Blue" ; set RGB Blue PWMWhen I disconnect one of the pins then the colour changes. It looks like there is always power given to LED even when shows 0 (off) in DWC.

The power for (24+)led is connected directly to power supply.

Why can't I change colours with sliders in DWC? -

RE: Adding second (backup)thermistor to buildplateposted in General Discussion

@dc42

I’ve posted my config.g in the original post.

I’ve removed the M143 from it because it causes errors (Temperature reading error on sensor 3) and I need my printer to do some prints at the moment.But the missing command (last line) was looking like that:

M143 H0 T3 P1 S130 A2 -

RE: Adding second (backup)thermistor to buildplateposted in General Discussion

@mikeabuilder

This is really great idea. But it would required the switch to be somehow attached to build plate to sense the temperature, right?

Unfortunately I can’t placed it there because I’ve just insulated everything under the bed. And don’t really feel like undoing it. But maybe for next printer or if I’ll do any changes in this one I can still use it. Thanks

-

RE: Adding second (backup)thermistor to buildplateposted in General Discussion

@dc42

I have used M308 to configure the second thermistor(as you can see in my config.g)

But when I use M143 got errors after restart.

Do you have an example how does that command should look like?

Thanks