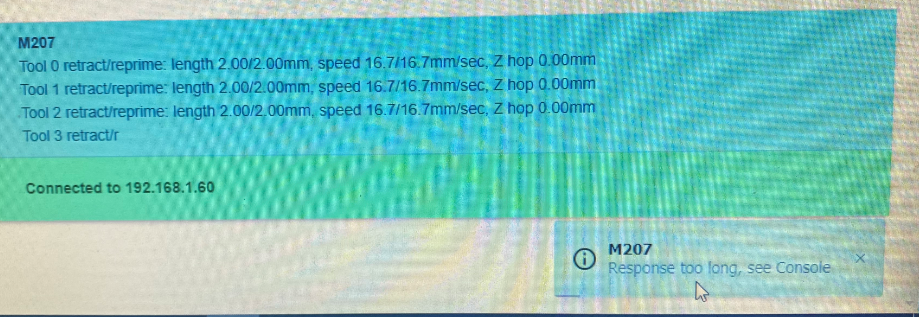

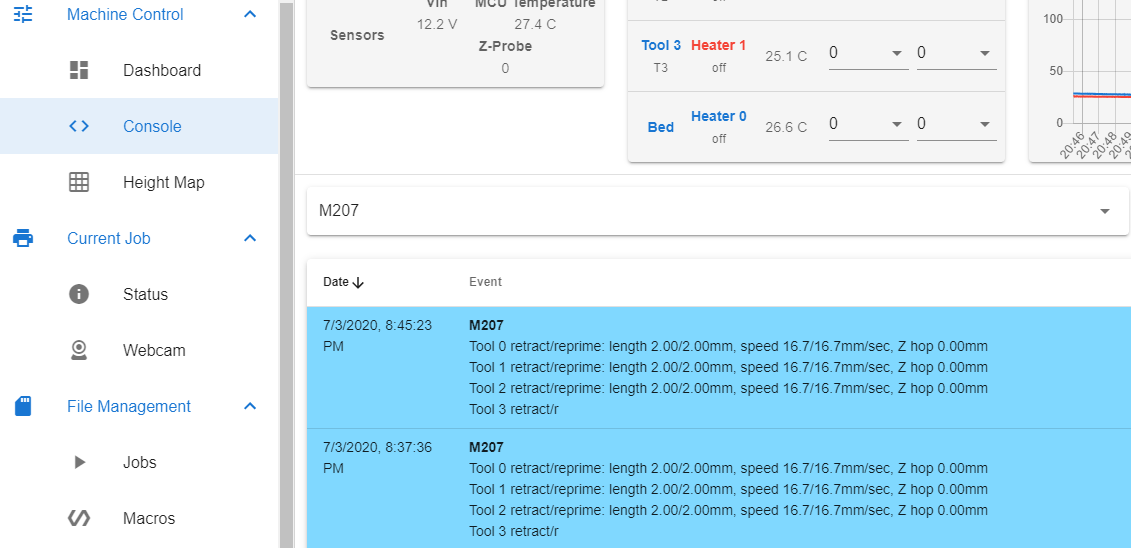

Quick follow up after some more play time, I have found the M207 retraction code line must come after tool definitions in config.g. Now I have accurate values in the console response to M207. However still truncated and I do still get the pop up message response too long.

;New mixing tools

M563 P0 D0:1:2 H1 F2 ; Define tool 0

G10 P0 X0 Y0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M568 P0 S1 ; Enable mixing for tool 0

M567 P0 E0.96:0.02:0.02 ; Set mixing ratios for tool 0 (90%,5%,5%)

M563 P1 D0:1:2 H1 F2 ; Define tool 1

G10 P1 X0 Y0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

M568 P1 S1 ; Enable mixing for tool 1

M567 P1 E0.02:0.96:0.02 ; Set mixing ratios for tool 1 (5%,90%,5%)

M563 P2 D0:1:2 H1 F2 ; Define tool 2

G10 P2 X0 Y0 ; Set tool 2 axis offsets

G10 P2 R0 S0 ; Set initial tool 2 active and standby temperatures to 0C

M568 P2 S1 ; Enable mixing for tool 2

M567 P2 E0.02:0.02:0.96 ; Set mixing ratios for tool 2 (5%,5%,90%)

M563 P3 D0:1:2 H1 F2 ; Define tool 3

G10 P3 X0 Y0 ; Set tool 3 axis offsets

G10 P3 R0 S0 ; Set initial tool 3 active and standby temperatures to 0C

M568 P3 S1 ; Enable mixing for tool 3

M567 P3 E0.34:0.33:0.33 ; Set mixing ratios for tool 3 (34%,33%,33%)

; Retraction

M207 S2.5 R0.0 Z0.2 F2400

That said I seem to have a printer that's now listening to my retraction settings.

But before moving the M207 line in config.g, the machine was retracting I guess by the values shown in my previous M207 response. Perhaps this is a default setting.

So when I was dynamically changing retraction during a print by sending console M207 bla bla bla, I may not have been changing anything hence no improvements to print quality.

More fun to be had