@deckingman

Thank you very much for your help. Actually, I learned a lot of good

Thanks alot

Posts made by mahmoudz

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Thanks alot.

I understand it. Basically, the actual speed is set by the slicer and we include a limit for that speed so that the speed does not exceed that value. it's true?

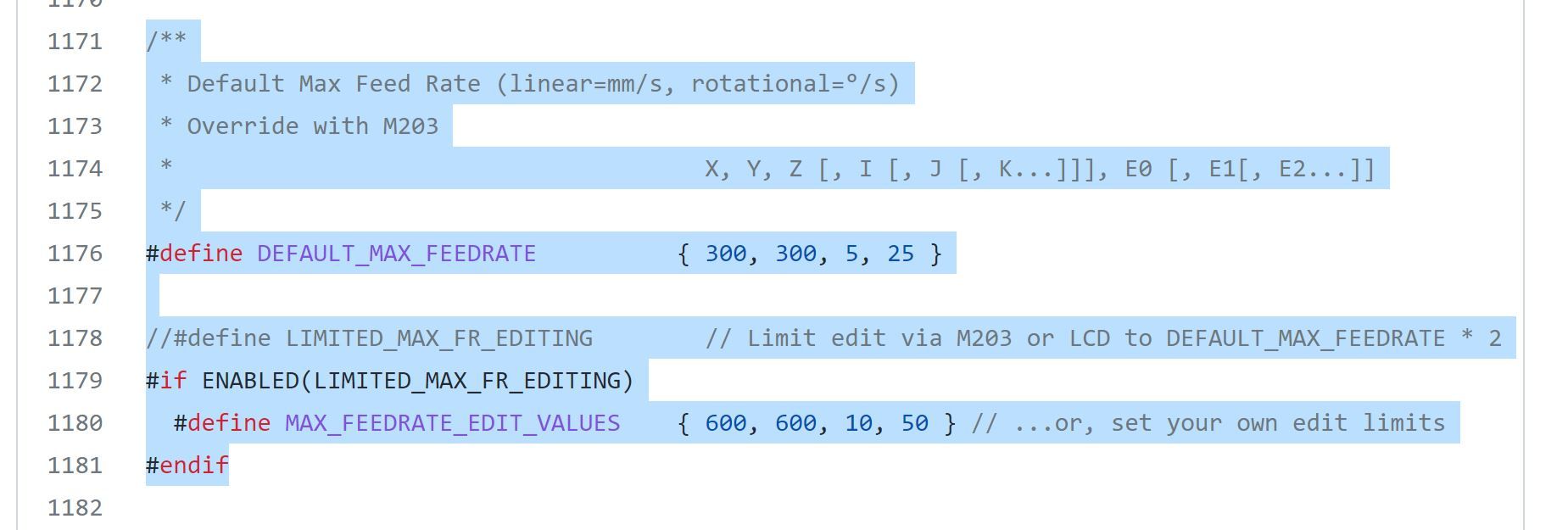

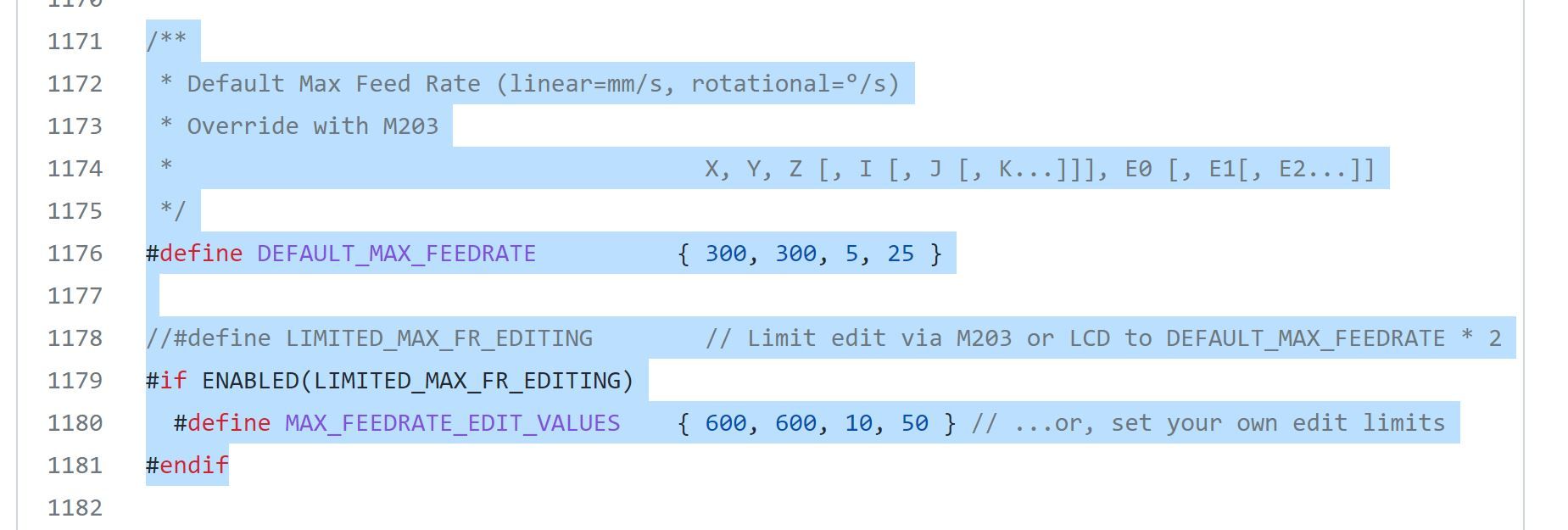

And the following 4 numbers (300,300,5,25) mean for X, Y, Z and extruder?

And in addition to the extruder, this maximum speed should be defined for other triple axes (X,Y,Z) as well (Basically, here it is meant to limit the speed of the motors for the other three axes)?

Thank you very much for your help. That’s very kind.

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@mahmoudz

Hello Sir. How are you?

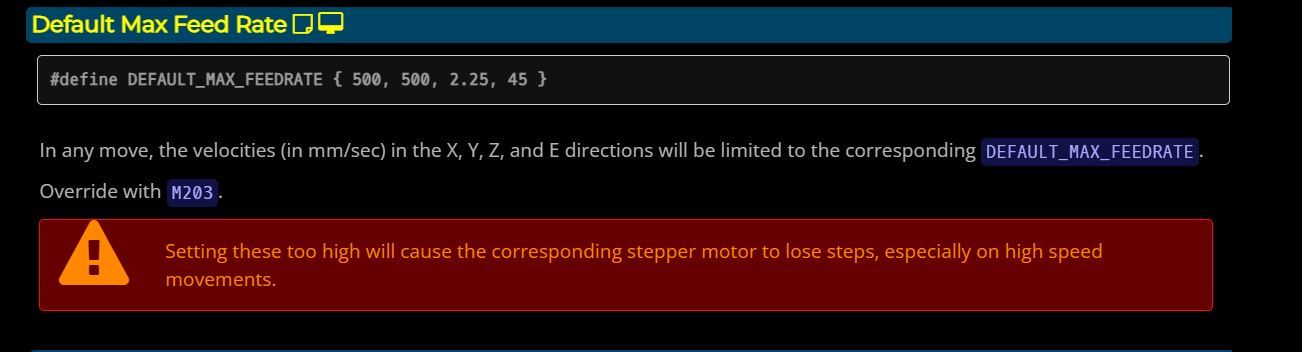

Sir do you know what is "max feedrate" in marlin? how these “max federate” numbers are calculated?I checked the Marlin examples folder and checked different models of printers and each of them included unique settings for “.And because of the uniqueness of these numbers in different printers, I guessed that this section must be very important because different printers use unique numbers.

I did a lot of searching on a topic in Hypercube printers and I couldn't find the answer for how to calculate max feedrate. I even asked this question in Facebook groups and I still haven't found the answer. also, On Marlin's website, there is not much information about this issue.

And forgive me for asking you so many questions during this time. I really search for topics first, and if the topic is unclear, I come and ask questions in forums and groups. thanks a lot for your help.

Unfortunately, malin website does not explain how the numbers should be calculated.

(And even the numbers in the Marlin firmware are not the same as the numbers in the Marlin manual.).

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Thank you very much. That’s very kind.

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Hi sir. I saw on the internet that some people use a system called V-slot wheels instead of using rails and wagons in 3D printers.

Is it worth using this system in the axes of the 3D printer, or will the wheels break down and wear out very quickly? Can you please guide me regarding the friction and life of these wheels and if these wheels are good, which model should I get? (because I realized that these wheels have different materials)

Thanks alot

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Thanks alot sir.

You have taught me many things during this time.

Thank you very much.. -

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

hello. sir i have a few more questions.

if we use BLTouch and connect it to Zmin, There is no need to use mechanical endstops for the zmin axix?

And usually 3 end-stops ( 2 mechanical for x and y and one bltouch for z min) are enough for xycore pritners?I saw a video on YouTube saying that "Power less Recovery feature" in Marlin program may not work well for xycore printers. Thanks to your advice, I realized that if I use a 2 mm lead screw, the bed will not fall. The point is that if the bed does not fall, it is easy to use the power less recovery function in the Marlin program without any problem?

thanks.

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Hi sir. thank you.

I think I have to read all the messages again. Since English is not my native language, I am translating my questions and answers with the help of Google. And because in some places Google does not do this translation well, I may not understand some sentences well. -

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@percar

Hello. Thank you very much for the tips -

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@mrehorstdmd

Hello. Thank you very much for the tips and links you sent me. Yes, you are right that it is better to start with smaller sizes and after I have mastered it, proceed to make bigger printers. -

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@deckingman

Hi sir. thank you. Yes, I downloaded it. Thank you very much again for your advice. -

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@mrehorstdmd

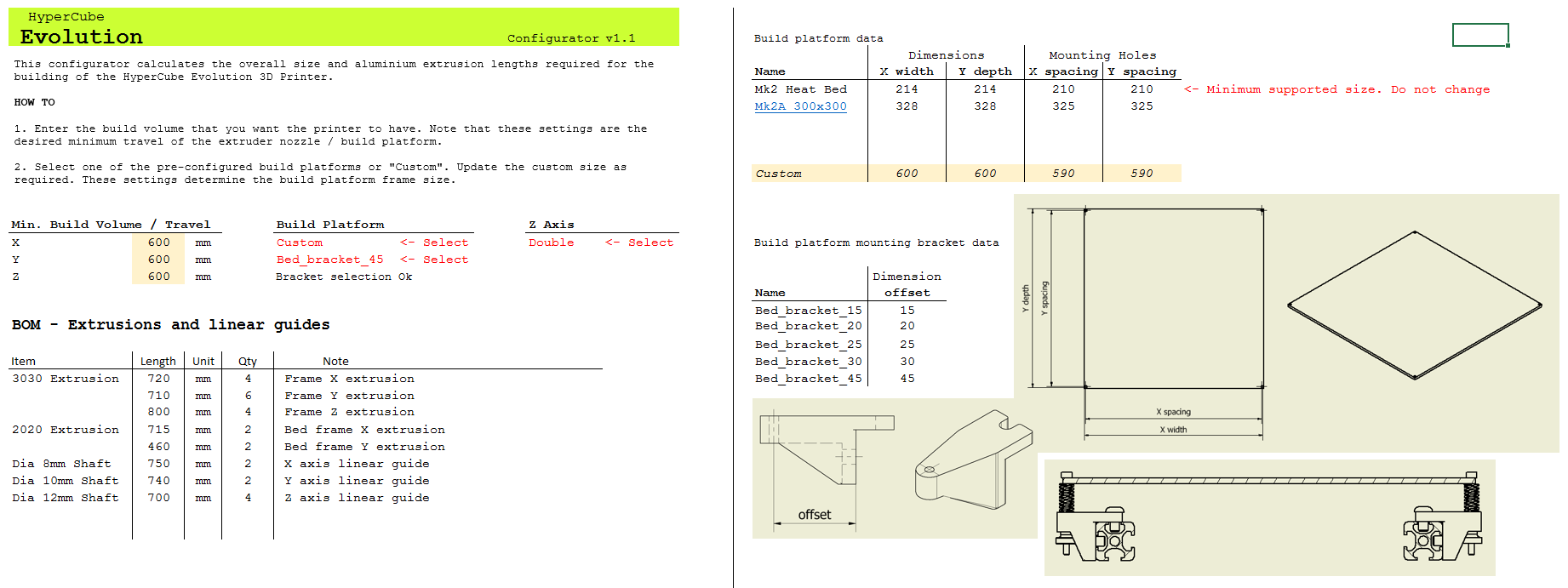

Despite these many problems, I was convinced to change the architecture of the device to the Hypercube model.

The point is, if I use anti backlash for Z lead screws , will we be sure that the device will not fall after the power cut? This issue of continuing to print after a power cut is very important to me.

i see some 3030cm hypercube on "thingiverse" that the manufacturer had used 2 nema 17 to move bed in the Z direction. if i change the bed to 5050cm still can use 2 nema 17 to lift the z axis?This is the 30*30cm printer that caught my attention. Do you think I can convert this device to 50x50cm without changing Nima 17 motors, power, board, etc.

https://www.thingiverse.com/thing:2254103And this is the first time I see the printer datasheet.

In the table on the right side of the picture below, where it says 60x60, does it mean that it is easy to make this device with these specifications up to 60x60 dimensions without changing the parts?

Or for 60x60, electronic or mechanical parts must be changedand this is the datasheet of it:

And another question that I did not find the answer to is this. How should we know which engine to choose for the bad size we want?

Sometimes it is light and sometimes it is heavy.

Do you know the mathematical calculation of this case, how to find out which engine is suitable for our designed printer?Thanks alot

-

RE: Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

@mrehorstdmd

thanks.

yes, this is my first project. but i need to print large models.

According to my research, I found out that printers that Bed move vertically may have problems like power loss or fall after a power cut.and i found if the bed moving along z axis, and if its weight is high, if power will be cut off and the lead screw is not suitable, there is a possibility of it falling and you cannot continue printing after the power is connected Or it will be very difficult to continue printing.

if we add more GT2 pulley with 6mm belt for Y axis, still we have wobble effects when the bed moving?

Do you think it is possible to use a lighter alloy for aluminum that will be a light Bed in the end?

Or should we use a stronger motor for the Y axis?And can you please tell me what footprint is? I did not understand this word in your previous message.

And can you give me a solution to move the bad in the Y direction and the problems will not arise in the previous message and the speed will not be too slow.

-

Are these parts suitable for this 3D printer design?posted in Duet Hardware and wiring

Hello my friends. I don't have much experience for building my 3d printer.

I have a few questions. I know that if the BED of the 3d printer moves in the vertical direction and its weight is high, if power will be cut off and the lead screw is not suitable, there is a possibility of it falling and you cannot continue printing after the power is connected Or it will be very difficult to continue printing.

I have designed a printer that I will tell you about and I would appreciate it if you could help me with the questions I have.

Bed size: aluminum 50x50x0.6cm with a glass on top. This bed only move in Y axis.

1- Can 1 nema 17 (4.4kg/cm) with GT2 pulley with 6mm belt move this Bed in Y axis without any problem? You probably tell me that it depends on the bed weight. And my question is, what should be the weight of this bed? so that 1 nema 17 (4.4kg/cm) can move it horizontally?2- The accuracy in the Z direction is very important for us. and for this reason, I chose this lead screw: (( D= 8mm/ lead= 1mm/ Pitch = 1mm/ 1 start )) and the driver is DRV8825 which has a 1/32 microstep. My extruder is indirect and only E3d-v6 attach to x axix and I attach MK8 filament driver to Structure and moving filament with PTFE pipe 4-2mm.

With these conditions, if the power is cut off, the X-axis will not fall in the vertical direction if I use this lead screw? I used two lead screws with these specifications in the vertical direction.

And this is my hand sketch

Please guide me so that I don't go the wrong way and buy the wrong parts.

-

RE: what kind of step motor do i need for this situation?posted in Duet Hardware and wiring

@deckingman

Thank you very much for your help.

-

RE: what kind of step motor do i need for this situation?posted in Duet Hardware and wiring

@deckingman

Thanks. Sorry for asking so many questions. Because I do not have much experience in this field

could you please tell me more about this:1- 2 stepper motor 17 nema, cant lift the 7kg bed? What is the maximum weight these 2 stepper motor 17 nema can lift?

2- I watched your video about lead screw carefully on YouTube. In some parts of the video, you said that one of the things to fix backlash in 3D printers is to increase the weight of the machine to use the law of gravity to remove the backlash. You also said in the 16th minute for backlash" that the guide should be nice and free" what is the guide? You mean a rod that is not threaded and is placed next to the lead screw?

3- And experimentally, how much should the weight of the printer with 50x50 bed?

4- and if we use Nema 23, It is still possible to use this board or this board must be changed completely (mega2560 with ramps1.4)?

and power of the printer also have to chage?I am doing a lot of research, I met you in this forum. Can I have your email so that I can ask you if I have any questions?

Thanks again