@dc42 i have also problem with u axis

when i restard main board u axis or tool locking motor won't work,

If i after reset go to config.g and press save with out any change and when pop up question

Cancel Restart mainboard run Config file

If i choose run Config file, then u axis (tool locking motor works)

Posts made by matej1006

-

RE: Error 292 S3posted in Tuning and tweaking

-

RE: Error 292 S3posted in Tuning and tweaking

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0-beta.4 on Wed Jul 19 2023 13:39:45 GMT+0200 (Srednjeevropski poletni čas) M98 P"Turn_printer_on" ; General ############################################################################################################# M550 P"3D MONSTRUM" ; set hostname ; Network ############################################################################################################# M552 P192.168.0.39 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available ###################################################### G4 S2 ; Smart Drivers ####################################################################################################### M569 P0.0 S0 D2 ; driver 0.0 goes backwards (Z axis) M569 P0.1 S0 D2 ; driver 0.1 goes backwards (Z axis) M569 P0.2 S0 D2 ; driver 0.2 goes backwards (Z axis) M569 P0.3 S0 D2 ; driver 0.3 goes backwards (X axis) M569 P0.4 S0 D2 ; driver 0.4 goes backwards (Y axis) M569 P121.0 S0 D2 ; driver 121.0 goes forwards (extruder 0) M569 P122.0 S0 D2 ; driver 122.0 goes forwards (extruder 1) M569 P123.0 S0 D2 ; driver 123.0 goes forwards (extruder 2) M569 P124.0 S0 D2 ; driver 124.0 goes forwards (extruder 3) M569 P125.0 S0 D2 ; driver 125.0 goes forwards (tool locking motor) ; NOTE: This is later generated in the Axes and/or Extruders section ################################################## M906 X800 Y800 Z800 U1000 I30 ; set motor driver currents M906 E1200:1200:1500:1500 I10 ; set motor driver currents ; Motor Idle Current Reduction ######################################################################################## M84 S30 ; set motor current idle timeout ; External Drivers #################################################################################################### ; no external drivers mapped to axes or extruders ; Closed-Loop Drivers ################################################################################################# ; no drivers with encoders configured ; Kinematics ########################################################################################################## M669 K1 ; configure CoreXY kinematics ; Axes ################################################################################################################ M584 X0.3 Y0.4 Z0.0:0.1:0.2 ; set axis mapping M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 X80 Y80 Z1600 ; configure steps per mm M208 S1 X0 Y0 Z0 ; set axis minima M208 S0 X420 Y386 Z430 ; set axis maxima M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z300 ; set maximum speeds (mm/min) M201 X800 Y800 Z60 ; set accelerations (mm/s^2) ; Extruders ########################################################################################################### M584 E121.0:122.0:123.0:124.0 ; set extruder mapping M350 E16:16:16:16 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 E690:690:2812:2812 ; configure steps per mm M566 E300:300:2812:2812 ; set maximum instantaneous speed changes (mm/min) M203 E7200:7200:3600:3600 ; set maximum speeds (mm/min) M201 E3000:3000:1500:1500 ; set accelerations (mm/s^2) M572 D0 S0.02 ;pressure advance – to be calibrated M207 S1.5 F7200 Z0.2 ;firmware retraction ; Tool actuator ###################################################################################################### M584 U125.0 ; set extruder mapping M350 U4 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 U30.578 ; configure steps per mm M566 U50 ; set maximum instantaneous speed changes (mm/min) M203 U9000 ; set maximum speeds (mm/min) M201 U900 I60 ; set accelerations (mm/s^2) M208 U0:200 ; Probes ############################################################################################################# M558 P9 C"125.io0.in" H5 F120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X0 Y0 Z0.7 ; set Z probe trigger value, offset and trigger height M950 S5 C"125.io0.out" ; create servo #0 for BLtouch ; Endstops ########################################################################################################### M574 X1 P"125.pdec.a" S1 ; configure X axis endstop M574 Y1 P"0.io1.in" S1 ; configure Y axis endstop M574 Z1 S2 M574 U1 P"125.io1.in" S1 ; configure U axis endstop ; Mesh Bed Compensation ############################################################################################## M557 X0:380 Y114:364 S40 ; define grid for mesh bed compensation ; Sensors ############################################################################################################ M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B3950 ; configure sensor #0 M308 S1 P"121.temp0" Y"thermistor" A"Nozzle 1" T100000 B4725 C7.06e-8 ; configure sensor #1 M308 S2 P"122.temp0" Y"thermistor" A"Nozzle 2" T100000 B4725 C7.06e-8 ; configure sensor #2 M308 S3 P"123.temp0" Y"thermistor" A"Nozzle 3" T100000 B4725 C7.06e-8 ; configure sensor #3 M308 S4 P"124.temp0" Y"thermistor" A"Nozzle 4" T100000 B4725 C7.06e-8 ; configure sensor #4 M308 S5 P"125.temp0" Y"thermistor" A"WATER IN TO COOLER" T10000 B3435 ; configure sensor #5 M308 S6 P"125.temp1" Y"thermistor" A"WATER OUT OF COOLER" T10000 B3435 ; configure sensor #6 M308 S7 Y"drivers" P"1.dummy" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S8 Y"mcu-temp" P"1.dummy" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor M308 S9 P"121.temp1" Y"thermistor" A"WATER OUT T. HEAD 1" T10000 B3435 ; configure sensor #7 M308 S10 P"122.temp1" Y"thermistor" A"WATER OUT T. HEAD 2" T10000 B3435 ; configure sensor #8 M308 S11 P"123.temp1" Y"thermistor" A"WATER OUT T. HEAD 3" T10000 B3435 ; configure sensor #9 M308 S12 P"124.temp1" Y"thermistor" A"WATER OUT T. HEAD 4" T10000 B3435 ; configure sensor #10 ; Heaters ############################################################################################################ M950 H0 C"out0" T0 ; create heater #0 M143 H0 P0 T0 C0 S110 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0 M140 H0 R35 ; map heated bed to heater 0 M950 H1 C"121.out0" T1 ; create heater #1 M143 H1 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M950 H2 C"122.out0" T2 ; create heater #2 M143 H2 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #2 M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 M950 H3 C"123.out0" T3 ; create heater #3 M143 H3 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #3 M307 H3 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #3 M950 H4 C"124.out0" T4 ; create heater #4 M143 H4 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #4 M307 H4 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #4 ; Heated beds ####################################################################################################### M140 P0 H0 ; configure heated bed #0 ; Fans ############################################################################################################# M950 F0 C"!out6+out6.tach" Q450 ; create fan #0 M106 P0 C"MAIN BOARD NOCTUA" S1 L0.15 X1 B0.3 H7:8 T25:35 ; configure fan #0 M950 F1 C"out7" ; create fan #1 M106 P1 C"BERDAIR PUMP" S0 L0 X1 ; configure fan #1 M950 F2 C"!out5+out5.tach" Q25000 ; create fan #2 M106 P2 C"COLLER NOCTUA FANS" S1 L0.5 X1 B0.3 H5 T40:60 ; configure fan #2 M950 F3 C"!out4+out4.tach" ; create fan #3 M106 P3 C"WATER PUMP" S1 L0.35 X1 B0.3 H6 T20:60 ; configure fan #3 ; Tools ############################################################################################################# M563 P0 D0 H1 F1 S"TOOL 1" ; create tool #0 G10 P0 Z4.922 ; Set tool #0 offset from the bed M568 P0 R20 S30 ; set initial tool #0 active and standby temperatures to 0C M563 P1 D1 H2 F1 S"TOOL 2" ; create tool #1 G10 P1 Z4.947 ; Set tool #1 offset from the bed with tool-0 as a reference. M568 P1 R20 S30 ; set initial tool #1 active and standby temperatures to 0C M563 P2 D2 H3 F1 S"TOOL 3" ; create tool #2 G10 P2 Z-3.75 ; Set tool #2 offset from the bed M568 P2 R20 S30 ; set initial tool #2 active and standby temperatures to 0C M563 P3 D3 H4 F1 S"TOOL 4" ; create tool #3 G10 P3 Z-3.75 ; Set tool #3 offset from the bed M568 P3 R20 S30 ; set initial tool #3 active and standby temperatures to 0C ; Emergen1cy Stop ##################4################################################################################## M950 J1 C"!io0.in" ; Define Emergency endstop - emergency stop switch condition M581 P1 S0 T2 ; Define action to be taken with activation of emergency stop switch M582 T2 S0 ; set trigger #2 pending unconditionall M950 J2 C"^121.io0.in" ; define logical input for filament auto load TOOL1 M581 P2 T3 S0 R0 ; define trigger for filament auto load triggers trigger3.g M950 J3 C"^121.io2.in" ; define logical input for filament unload TOOL1 M581 P3 T4 S0 R0 ; define trigger for filament auto load triggers trigger4.g M950 J4 C"^122.io0.in" ; define logical input for filament auto load TOOL2 M581 P4 T5 S0 R0 ; define trigger for filament auto load triggers trigger3.g M950 J5 C"^122.io2.in" ; define logical input for filament unload TOOL2 M581 P5 T6 S0 R0 ; define trigger for filament auto load triggers trigger4.g; bed.g ; called to perform automatic bed compensation via G32 ; ; generated by RepRapFirmware Configuration Tool v2.0.4 on Sat Oct 12 2019 15:44:24 GMT+0200 (Srednjeevropski poletni čas) T-1 ; remove tool M561 ; Disable any Mesh Bed Compensation G30 P0 X0 Y76 Z-99999 ; Probe near Front left leadscrew G30 P1 X184 Y355 Z-99999 ; PROBE POINT 2 back middle G30 P2 X370 Y76 Z-99999 S3 ; PROBE POINT 3 Front right G29 S1 ; Enable Mesh Bed Compensation -

Error 292 S3posted in Tuning and tweaking

M292 S3

Error: This kinematics does not support auto-calibrationi have M669 set to K1 because i have Core XY.

Today at first start of Duet3 6HC board i did notification that kinematic does not support auto calibrationi have 3 z motor to control height of table/bed

in previous board did this work with out problem.

-

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@infiniteloop yes ok that i know. i just didn't know what cca temp i would like to have in system running.

-

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@infiniteloop so now i have temp. set to hold between 20 to 25 C.

what would you recommend to set between 50 to 60 C -

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@dc42 damm i missed this info sorry

-

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@infiniteloop ok yeah that far i wasn't thinking yeah

-

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@deckingman no i want to when it goes form 3.3 to 0. i did add a resistor 10kohm to gnd and io0.in. isn't helping and also i did try pull up in code nothing was working.

-

RE: Digital input problem's / pwm signal outputposted in Tuning and tweaking

@matej1006 here is also diagnose

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.4+1 (2022-11-15 17:36:33) running on Duet 3 MB6HC v1.02 or later (standalone mode) Board ID: 08DJM-9P63L-DJMSS-6JTD0-3S46L-9UFZ8 Used output buffers: 3 of 40 (18 max) === RTOS === Static ram: 152740 Dynamic ram: 100312 of which 172 recycled Never used RAM 97448, free system stack 200 words Tasks: NETWORK(ready,29.7%,218) ETHERNET(notifyWait,0.1%,445) HEAT(notifyWait,0.0%,344) Move(notifyWait,0.0%,351) CanReceiv(notifyWait,0.1%,799) CanSender(notifyWait,0.0%,336) CanClock(delaying,0.0%,339) TMC(notifyWait,7.0%,91) MAIN(running,62.9%,925) IDLE(ready,0.3%,30), total 100.0% Owned mutexes: === Platform === Last reset 00:00:46 ago, cause: power up Last software reset at 2023-07-25 18:49, reason: User, GCodes spinning, available RAM 97448, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Step timer max interval 127 MCU temperature: min 25.1, current 31.3, max 31.4 Supply voltage: min 24.0, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 11.8, current 12.2, max 12.5, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 8, reads 64014, writes 14 timeouts 0 Driver 1: standstill, SG min 0, mspos 8, reads 64015, writes 14 timeouts 0 Driver 2: standstill, SG min 0, mspos 8, reads 64015, writes 14 timeouts 0 Driver 3: standstill, SG min 0, mspos 8, reads 64016, writes 13 timeouts 0 Driver 4: standstill, SG min 0, mspos 8, reads 64016, writes 13 timeouts 0 Driver 5: standstill, SG min 0, mspos 8, reads 64018, writes 11 timeouts 0 Date/time: 2023-07-25 19:05:26 Slowest loop: 3.98ms; fastest: 0.06ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.3ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 463, received 3512, lost 0, boc 0 Longest wait 3ms for reply type 6053, peak Tx sync delay 621, free buffers 50 (min 49), ts 233/232/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 3.60ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = State: active Error counts: 0 0 0 1 0 0 Socket states: 2 5 2 2 2 0 0 0 = WiFi = Network state is disabled WiFi module is disabled Failed messages: pending 2779096485, notready 2779096485, noresp 2779096485 Socket states: 0 0 0 0 0 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 0 -

Digital input problem's / pwm signal outputposted in Tuning and tweaking

Hello i have problem that i can't read input or send out output signal

if i use optical end stop everything works fine i get detection.

Mean while i have tool locking mechanisem which have 2 end stop switches in serias with NC contact used. i have 3.3v from same connector and back to ( 1HCL board) and i can't read it.Same is for emergency stop on main board (6HC). i have 3.3V connected to COM on emergency contact and than signal back to io0.in.

here is config file:

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.0-beta.4 on Wed Jul 19 2023 13:39:45 GMT+0200 (Srednjeevropski poletni čas) M98 P"Turn_printer_on" ; General ############################################################################################################# M550 P"3D MONSTRUM" ; set hostname ; Network ############################################################################################################# M552 P192.168.0.39 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP ; Wait a moment for the CAN expansion boards to become available ###################################################### G4 S2 ; Smart Drivers ####################################################################################################### M569 P0.0 S0 D2 ; driver 0.0 goes backwards (Z axis) M569 P0.1 S0 D2 ; driver 0.1 goes backwards (Z axis) M569 P0.2 S0 D2 ; driver 0.2 goes backwards (Z axis) M569 P0.3 S0 D2 ; driver 0.3 goes backwards (X axis) M569 P0.4 S0 D2 ; driver 0.4 goes backwards (Y axis) M569 P121.0 S0 D2 ; driver 121.0 goes forwards (extruder 0) M569 P122.0 S0 D2 ; driver 122.0 goes forwards (extruder 1) M569 P123.0 S0 D2 ; driver 123.0 goes forwards (extruder 2) M569 P124.0 S0 D2 ; driver 124.0 goes forwards (extruder 3) M569 P125.0 S1 D2 ; driver 125.0 goes forwards (extruder 4) ; NOTE: This is later generated in the Axes and/or Extruders section ################################################## M906 X800 Y800 Z800 E1500:1500:1500:1500 U10 ; set motor driver currents ; Motor Idle Current Reduction ######################################################################################## M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; External Drivers #################################################################################################### ; no external drivers mapped to axes or extruders ; Closed-Loop Drivers ################################################################################################# ; no drivers with encoders configured ; Kinematics ########################################################################################################## M669 K1 ; configure CoreXY kinematics ; Axes ################################################################################################################ M584 X0.3 Y0.4 Z0.0:0.1:0.2 ; set axis mapping M350 X16 Y16 Z1600 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 X80 Y80 Z400 ; configure steps per mm M208 S1 X0 Y0 Z0 ; set axis minima M208 S0 X420 Y386 Z450 ; set axis maxima M566 X900 Y900 Z12 ; set maximum instantaneous speed changes (mm/min) M203 X6000 Y6000 Z300 ; set maximum speeds (mm/min) M201 X800 Y800 Z60 ; set accelerations (mm/s^2) ; Extruders ########################################################################################################### M584 E121.0:122.0:123.0:124.0 ; set extruder mapping M350 E16:16:16:16 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 E1756:2812:1756:1756 ; configure steps per mm M566 E1756:2812:1756:1756 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600:3600:3600 ; set maximum speeds (mm/min) M201 E1500:1500:1500:1500 ; set accelerations (mm/s^2) ; Tool actuator ###################################################################################################### M584 U125.0 ; set extruder mapping M350 U4 I1 ; configure microstepping with interpolation ; NOTE: See Smart Drivers section for motor currents M92 U30.578 ; configure steps per mm M566 U50 ; set maximum instantaneous speed changes (mm/min) M203 U7000 ; set maximum speeds (mm/min) M201 U800 ; set accelerations (mm/s^2) M208 U0:200 ; Probes ############################################################################################################# ; Endstops ########################################################################################################### M574 X1 P"125.pdec.a" S1 ; configure X axis endstop M574 Y1 P"0.io1.in" S1 ; configure Y axis endstop M574 Z1 S2 M574 U1 P"125.io1.in" S1 ; configure U axis endstop ; Mesh Bed Compensation ############################################################################################## M557 X0:380 Y114:364 S40 ; define grid for mesh bed compensation ; Sensors ############################################################################################################ M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B3950 ; configure sensor #0 M308 S1 P"121.temp0" Y"thermistor" A"Nozzle 1" T100000 B4725 C7.06e-8 ; configure sensor #1 M308 S2 P"122.temp0" Y"thermistor" A"Nozzle 2" T100000 B4725 C7.06e-8 ; configure sensor #2 M308 S3 P"123.temp0" Y"thermistor" A"Nozzle 3" T100000 B4725 C7.06e-8 ; configure sensor #3 M308 S4 P"124.temp0" Y"thermistor" A"Nozzle 4" T100000 B4725 C7.06e-8 ; configure sensor #4 M308 S5 P"125.temp0" Y"thermistor" A"WATER IN TO COOLER" T10000 B3435 ; configure sensor #5 M308 S6 P"125.temp1" Y"thermistor" A"WATER OUT OF COOLER" T10000 B3435 ; configure sensor #6 M308 S7 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S8 Y"mcu-temp" A"MCU" ; configure sensor 3 as on-chip MCU temperature sensor ; Heaters ############################################################################################################ M950 H0 C"out0" T0 ; create heater #0 M143 H0 P0 T0 C0 S110 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0 M140 H0 R35 ; map heated bed to heater 0 M950 H1 C"121.out0" T1 ; create heater #1 M143 H1 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M950 H2 C"122.out0" T2 ; create heater #2 M143 H2 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #2 M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 M950 H3 C"123.out0" T3 ; create heater #3 M143 H3 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #3 M307 H3 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #3 M950 H4 C"124.out0" T4 ; create heater #4 M143 H4 P0 T1 C0 S250 A0 ; configure heater monitor #0 for heater #4 M307 H4 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #4 ; Heated beds ####################################################################################################### M140 P0 H0 ; configure heated bed #0 ; Fans ############################################################################################################# M950 F0 C"!out6+out6.tach" Q450 ; create fan #0 M106 P0 C"MAIN BOARD NOCTUA" S1 L0.15 X1 B0.3 H7:8 T25:35 ; configure fan #0 M950 F1 C"out7" ; create fan #1 M106 P1 C"BERDAIR PUMP" S0 L0 X1 ; configure fan #1 M950 F2 C"!out5+out5.tach" Q25000 ; create fan #2 M106 P2 C"COLLER NOCTUA FANS" S1 L0.5 X1 B0.3 H5 T25:35 ; configure fan #2 M950 F3 C"!out4+out4.tach" ; create fan #3 M106 P3 C"WATER PUMP" S1 L0.35 X1 B0.3 H6 T20:70 ; configure fan #3 ; Tools ############################################################################################################# M563 P0 D0 H1 F1 S"TOOL 1" ; create tool #0 G10 P0 Z4.922 ; Set tool #0 offset from the bed M568 P0 R20 S30 ; set initial tool #0 active and standby temperatures to 0C M563 P1 D1 H2 F1 S"TOOL 2" ; create tool #1 G10 P1 Z4.947 ; Set tool #1 offset from the bed with tool-0 as a reference. M568 P1 R20 S30 ; set initial tool #1 active and standby temperatures to 0C M563 P2 D552 H3 F1 S"TOOL 3" ; create tool #2 G10 P2 Z-3.75 ; Set tool #2 offset from the bed M568 P2 R20 S30 ; set initial tool #2 active and standby temperatures to 0C M563 P3 D3 H4 F1 S"TOOL 4" ; create tool #3 G10 P3 Z-3.75 ; Set tool #3 offset from the bed M568 P3 R20 S30 ; set initial tool #3 active and standby temperatures to 0C ; Emergen1cy Stop ##################4################################################################################## M950 J1 C"io0.in" ; Define Emergency endstop - emergency stop switch condition M950 P4 C"io0.out" M581 P1 S0 T2 ; Define action to be taken with activation of emergency stop switch M582 T2 S0 ; set trigger #3 pending unconditionallyother problem or isn't it. i would like that if temp go up then i would like that to pwm signal goes in to slower mode not faster.

just because when i cooling water i want that to flow through cooler slower. that i will get more heat out of water. -

RE: EMERGENCY STOPposted in Tuning and tweaking

@Phaedrux yeah i know that i mean M112.

but why i don't get any input reading

also i have problem on 1HCL i can't read end stop for tool locking mech.

i have two micro switch in serias with NC. And when i press on end stop switch nothing happend od DWC.I have problem with input's and output's.

-

EMERGENCY STOPposted in Tuning and tweaking

Hello

i can't figurit out what is wrong

i would also like to when is pressed emergency that i get output activated.

this is my config.g code

; Emergen1cy Stop ##################4################################################################################## M950 J1 C"io0.in" ; Define Emergency endstop - emergency stop switch condition M950 P0 C"io0.out" M581 P1 S0 T1 ; Define action to be taken with activation of emergency stop switch M582 T1 S1 ; set trigger #3 pending unconditionallyand this trigger1.g

;trigger1.g M999 M42 P0 S1nothing happend when i press

i have 3.3V to com and NC back to input with 10Kohm ressistor to gnd

-

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

; Water colling PUMP M950 F2 C"!Fan0" Q25000 ; fan 2 is a 4-wire PWM fan so invert it, use high PWM frequency, tacho connected to PB6 on expansion connector M106 P2 H5 I1 T20:25 L255 ; set fan 2 value. Thermostatic control is turned onThis is my code from duet2 eth board

Now I have duet3 6hc

I try same code and it wasn't workIf I swap noctua fans with pump fans works on this output out6 pump on out5 is same nothing from her

That I didn't try I Will tommorow

-

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

@dc42 it is 12Vdc 17W pump which can be connected directly to pc Mother board

I did try to invert and pullup and nothing was different

-

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

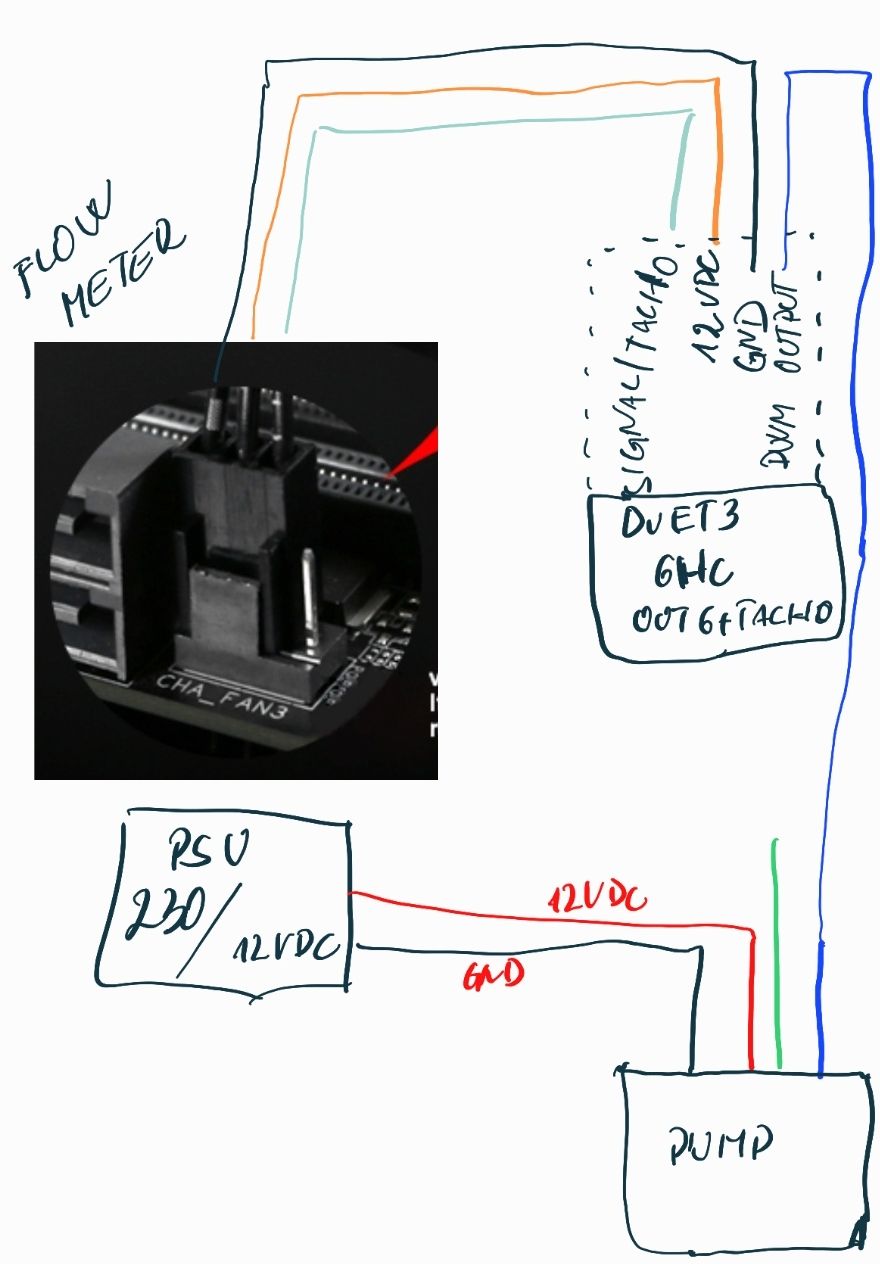

@dc42

this is how have now connected all . And pump won't start! GND is commom

this is how have now connected all . And pump won't start! GND is commom -

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

@dc42 if i connect 12v directly from power supply tacho won't work ?

-

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

@dc42 it is a 12V pc Water colling so i think it will be ok but i will check just to be sure about it

-

RE: Duet 3 Expansion 1HCL tacho readingposted in Tuning and tweaking

@dc42 can I use OUT 0 and OUT 1 on tisti same board for PWM controlling my noctua fans and water pump. Will be same as fan pwm output?

-

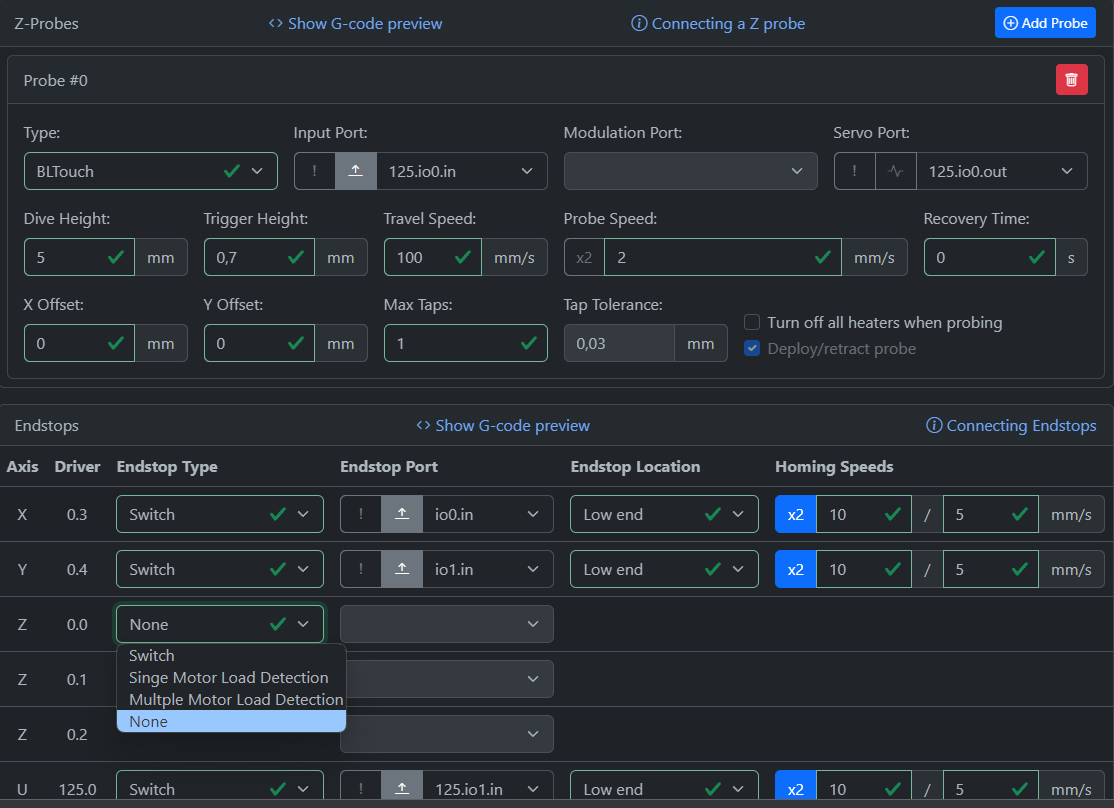

RE: New ConfigTool v3.5.0-beta.3 availableposted in Config Tool

BL TOUCH isn't possible if i select like that

-

RE: New ConfigTool v3.5.0-beta.3 availableposted in Config Tool

Duet 3 Expansion 1HCL allows to add just one temp0 and not temp1