After the 6HC + 6HC combination did not work woth the boards I had, I tried a 6HC v1.01a (mainboard) + 3HC (expansion1) + Mini 5+ (expansion2).

The toolchanger nog gives good quality prints with all 4 tools.

Posts made by Maurits

-

RE: Duet 3 6HC + 6HC as expansion: print quality issues?posted in Duet Hardware and wiring

-

RE: Duet 3 6HC + 6HC as expansion: print quality issues?posted in Duet Hardware and wiring

@dc42 I did some further testing today and it seems I spoke too soon in saying the issue with print quality was solved.

When the 6HC 1.0 acts as expansion, it controls extruders, fans, temp & heat for thee of the four tools. I follow your logic in thinking temperature input problems on the board causing the described quality issues.

With the 6HC 1.0 as mainboard its main task is to drive the motion system. Now I have issues where extruders are skippings steps intermittently and prints getting knocked off the bed halfway through a print.Do you think it is possible that the 6HC 1.0 is faulty in more ways, causing these issues?

-

RE: Duet 3 6HC + 6HC as expansion: print quality issues?posted in Duet Hardware and wiring

@jay_s_uk thank you for the suggestion. I am already running 3.6b2 on all the Duet boards.

-

RE: Duet 3 6HC + 6HC as expansion: print quality issues?posted in Duet Hardware and wiring

Update:

I tried one last board setup that I hadn't tried yet, using the 6HC v1.0 as mainboard and the 6HC v1.01 as expansion board (revering the role of the two 6HC boards).

This yielded surprising results with good print quality. All tools are printing just fine!So the issue is solved, but I'm still curious as to why there were print quality issues when I used the v1.0 6HC as expansion board. Any clue?

-

Duet 3 6HC + 6HC as expansion: print quality issues?posted in Duet Hardware and wiring

Hi,

I'm trying to get a combination of a 6HC v1.01 mainboard + 6HC v1.0 as expansion to run 4 extruders for my Jubilee toolchanger. I came from a setup with 6HC v1.01 + 3HC v1.02a with three tools running on the 3HC board.

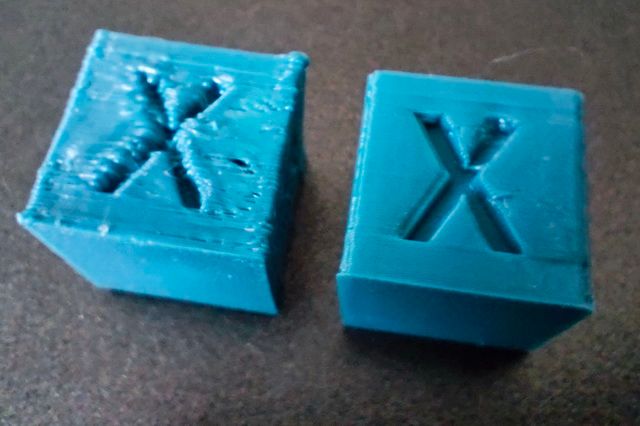

After some problems getting all stepper motors running all the hardware seems to be functioning. (Thanks again droftarts & dc24)Now I'm having print quality issues that I didn't have before. Every print I do shows a number of issues, including underextrusion toward corners, overextrusion on corners, messy top- layer, etc. This happens with all tools on the printer. The pictures show the difference in print quality.

I tried a few things in a effort to find the cause.

Change the expansion board back to the 3HC in order to rule out any mechanical/wiring fault: This resulted in good print quality on all tools like before.

Next I tried a combination of the 6HC v1.0 board + 3HC in order to see if thee 6HCv1.0 board had a fault: Again good print quality like before on all tools.

I'm running RRF 6.3.0 beta 2 on all boards, and have used the same wiring, filaments & print setting to exclude any issues there.Any idea what could be causing the drastic difference in print quality?

Config.g for the 6HC v1.01 + 6HC v1.0 setup

Config.g for the 6HC (v1.01 or v1.0) + 3HC setup

M122 for the 6HC v1.0 + 3HC setup -

RE: Duet 3 6HC + 6HC as expansion: Extruder motors not workingposted in Duet Hardware and wiring

@dc42 Thanks for the tip! I'll definitly include the S4 command.

-

RE: Duet 3 6HC + 6HC as expansion: Extruder motors not workingposted in Duet Hardware and wiring

@droftarts Thank you for pointing in the right direction. Just updated firmware on both boards to 3.6.0beta2 and all extruders divers are working fine again.

Again thank you for your help!

-

Duet 3 6HC + 6HC as expansion: Extruder motors not workingposted in Duet Hardware and wiring

Hi,

I'm trying to run a 6HC v1.01 mainboard + 6HC v1.0 as expansion to accomodate 4 extruders on my Jubilee toolchanger, but I'm having trouble getting the extruder motors to work.

Until yesterday I had a working system with the 6HC v1.01 + 3HC v1.02a, with three tools all running on the 3HC board.

I changed the 3HC for a 6HC v1.0. All changes were made to enable the 6HC to run as an expansion board: congif.g for the expansion board with only the M954 command, both boards running RFF 3.5.4, and congif.g for the 6HC v1.01 mainboard was changed to accomodate for the changed adresses for the fans. M122 report look fine:6HC v1.01 mainboard:

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.4 (2024-11-24 10:47:10) running on Duet 3 MB6HC v1.01 (standalone mode) Board ID: 08DJM-9P63L-DJ3T0-6J1DL-3SN6N-KS3BA Used output buffers: 3 of 40 (18 max) === RTOS === Static ram: 155464 Dynamic ram: 122892 of which 596 recycled Never used RAM 67040, free system stack 202 words Tasks: NETWORK(1,ready,41.7%,182) ETHERNET(5,nWait 7,0.2%,278) HEAT(3,nWait 6,0.0%,327) Move(4,nWait 6,0.0%,335) CanReceiv(6,nWait 1,0.0%,796) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,348) TMC(4,nWait 6,9.2%,53) MAIN(1,running,48.0%,103) IDLE(0,ready,0.9%,29), total 100.0% Owned mutexes: === Platform === Last reset 00:02:05 ago, cause: power up Last software reset at 2024-12-22 19:40, reason: User, Gcodes spinning, available RAM 66728, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 19.8, current 32.2, max 32.3 Supply voltage: min 24.2, current 24.2, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min n/a, mspos 8, reads 39203, writes 17 timeouts 0 Driver 1: standstill, SG min n/a, mspos 8, reads 39203, writes 17 timeouts 0 Driver 2: standstill, SG min n/a, mspos 32, reads 39203, writes 17 timeouts 0 Driver 3: standstill, SG min n/a, mspos 8, reads 39203, writes 17 timeouts 0 Driver 4: standstill, SG min n/a, mspos 8, reads 39204, writes 17 timeouts 0 Driver 5: standstill, SG min n/a, mspos 8, reads 39204, writes 17 timeouts 0 Date/time: 2024-12-22 19:52:19 Slowest loop: 10.87ms; fastest: 0.07ms === Storage === Free file entries: 19 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.4ms, write time 15.7ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === CAN === Messages queued 1166, received 2537, lost 0, errs 6, boc 0 Longest wait 1ms for reply type 6018, peak Tx sync delay 935, free buffers 50 (min 49), ts 630/629/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 40.10ms; fastest: 0.03ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = Interface state: active Error counts: 0 0 0 1 0 0 Socket states: 5 5 2 2 2 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 06HC v1.0 expansion board:

m122 b1 Diagnostics for board 1: RepRapFirmware for Duet 3 MB6HC version 3.5.4 (2024-11-24 10:47:10) running on Duet 3 MB6HC v1.0 or earlier Last reset 00:06:09 ago, cause: power up Driver 0: 416.0 steps/mm,, SG min n/a, mspos 8, reads 6812, writes 18 timeouts 0 Driver 1: 414.4 steps/mm,, SG min n/a, mspos 8, reads 6818, writes 18 timeouts 0 Driver 2: 390.1 steps/mm,, SG min n/a, mspos 8, reads 6825, writes 18 timeouts 0 Driver 3: 80.0 steps/mm,, SG min n/a, mspos 8, reads 6837, writes 11 timeouts 0 Driver 4: 80.0 steps/mm,, SG min n/a, mspos 8, reads 6843, writes 11 timeouts 0 Driver 5: 80.0 steps/mm,, SG min n/a, mspos 8, reads 6850, writes 11 timeouts 0 VIN: 24.1V, V12: 12.0V, MCU temperature: min 11.2C, current 25.5C, max 25.6C Peak sync jitter -6/-3, peak Rx sync delay 183, resyncs 0/0, no step interrupt scheduledIssue:

None of the extruder motors respond to any extrusion command when the appropriate tool is selected & hot.Checked fans, themistors & heaters: working properly.

Checked extruder motors and drivers on the 6HC v1.0 board: working properly when configured as a axis instead of an extruder.

Then I started to check in the config.g file to see if I missed anyhting in configuring the tools....And that's where I'm stuck.

Can someone please take a look at my config.g to see if I'm doing anything wrong?

I'd really appreciate the help!; Configuration file for Jubilee CoreXY ToolChanging Printer ; for Duet 3 Mainboard 6HC & Expansion 6HC ; General setup ;------------------------------ M111 S0 ; Debug off M929 P"eventlog.txt" S1 ; Start logging to file eventlog.txt M555 P2 ; Set Marlin-style output G21 ; Set dimensions to millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M575 P1 S1 B57600 ; Enable PanelDue Display ; Network ;------------------------------ M550 P"Seybi" ; Name used in ui and for mDNS http://Seybi.local M552 S1 ; Enable networking ; Drive definitions of the frame ;------------------------------ ; Connected to the Mainboard 6HC as the table below ; _________________________________ ; | X(Right) | Y(Left) | U(lock) | ; | Z(Back) | Z(Right) | Z(Left) | M584 X0 Y1 ; Set drive mapping X to driver0 and Y to driver1 for CoreXY M584 U2 ; Set drive mapping U to driver2 for toolchanger lock M584 Z3:4:5 ; Set drive mapping Z to driver3, 4 and 5 for kinematic bed suspension M569 P0 S0 D3 ; Drive 0 | X stepper goes backward in Stealthchopper mode M569 P1 S0 D3 ; Drive 1 | Y Stepper goes backward in Stealthchopper mode M906 X1800 ; Set max current to 1800mA, 90% of maximum ; Can be set to {0.9*sqrt(2)*2000} alternatively M906 Y1800 ; Set max curtrent to 1800mA, 90%^of maximum ; Can be set to {0.9*sqrt(2)*2000} alternatively M569 P2 S0 D3 ; Drive 2 | U Tool Changer Lock goes backward in Stealthchopper mode M906 U700 I60 ; Set max current to 700mA, 70% of maximum, idle at 60% shared for all drives ; Can be set to {0.7*sqrt(2)*1000} alternatively M569 P3 S0 D3 ; Drive 3 | Front Left Z goes backward in Stealthchopper mode M569 P4 S0 D3 ; Drive 4 | Front Right Z goes backward in Stealthchopper mode M569 P5 S0 D3 ; Drive 5 | Back Z goes backward in Stealthchopper mode M906 Z1800 ; Set max current to 1400mA, 70% of maximum ; Can be set to {0.7*sqrt(2)*2000} alternatively ; Expansion board 6HC ;------------------------------ ; Tool steppers on expansion board M584 E1.0:1.1:1.2 ; Extruders for three tools on expansion board 1 M569 P1.0 S1 D3 ; Drive 6 | Extruder T0 goes forward in Stealthchopper mode M569 P1.1 S1 D3 ; Drive 7 | Extruder T1 goes forward in Stealthchopper mode M569 P1.2 S1 D3 ; Drive 8 | Extruder T2 goes forward in Stealthchopper mode M906 E900 ; Set maximum current to 900mA, 90% of maximum ; can be set to {0.7*sqrt(2)*1400} alternatively. ; Expressions might not be supported for extruders ; Kinematics ;------------------------------ M669 K1 ; Set kinematics mode to CoreXY ; Kinematic bed ball locations ; Locations are extracted from CAD model assuming lower left build plate corner ; is (0, 0) on a 305x305mm plate. M671 X297.5:2.5:150 Y313.5:313.5:-16.5 S10 ; Front Left: (297.5, 313.5) ; Front Right: (2.5, 313.5) ; Back: (150, -16.5) ; Up to 10mm correction ; Axis and motor configuration ;------------------------------ M350 X1 Y1 Z1 U1 E1:1:1 ; Disable microstepping to simplify calculations M92 X{1/(0.9*16/180)} ; step angle * tooth count / 180 M92 Y{1/(0.9*16/180)} ; The 2mm tooth spacing cancel out with diam to radius M92 Z{360/0.9/2} ; 0.9 deg stepper / lead (2mm) of screw M92 U{13.76/1.8} ; gear ration / step angle for tool lock geared motor. M92 E26.000:25.900:24.379 ; Extruder 0 and 1 - BMG 1.8 deg/step, Extruder 2 - Hemera 1.8 deg/step ; Enable microstepping all step per unit will be multiplied by the new step def M350 X16 Y16 I1 ; 16x microstepping for CoreXY axes. Use interpolation. M350 U4 I1 ; 4x for toolchanger lock. Use interpolation. M350 Z16 I1 ; 16x microstepping for Z axes. Use interpolation. M350 E16:16:16 I1 ; 16x microstepping for Extruders T0,T1 and T2. Use interpolation. ; Speed and acceleration ;------------------------------ M201 X1100 Y1100 ; Maximum X and Y Accelerations (mm/s^2) M201 Z100 ; Maximum Z Acceleration (mm/s^2) M201 U800 ; Maximum U Acceleration (mm/s^2) M201 E1300 ; Maximum Extruder Acceleration (mm/s^2) M203 X18000 Y18000 Z800 E8000 U9000 ; Maximum axis speeds (mm/min) M566 X500 Y500 Z500 E3000 U50 ; Maximum jerk speeds (mm/min) ; Endstops and probes ;------------------------------ ; Connected to the Mainboard 6HC as the table below. ; | | Z | ; | X | U | ; | Y | M574 U1 S1 P"^io4.in" ; homing position U1 = low-end, type S1 = switch M574 X1 S1 P"^io1.in" ; homing position X1 = low-end, type S1 = switch M574 Y1 S1 P"^io2.in" ; homing position Y1 = low-end, type S1 = switch M574 Z0 ; we will use the switch as a Z probe not endstop M558 P8 C"io3.in" H10 F360 T6000 ; H = dive height (was 3) F probe speed T travel speed G31 K0 X0 Y0 Z-2 ; Set the limit switch position as the "Control Point." ; Note: the switch free (unclicked) position is 7.2mm, ; but the operating position (clicked) is 6.4 +/- 0.2mm. ; A 1mm offset (i.e: 7.2-6.2 = 1mm) would be the ; Z to worst-case free position, but we add an extra 1mm ; such that XY travel moves across the bed when z=0 ; do *not* scrape or shear the limit switch. ; Set axis software limits and min/max switch-triggering positions. ; Adjusted such that (0,0) lies at the lower left corner of a 300x300mm square ; in the 305mmx305mm build plate. M208 X-13.75:313.75 Y-44:341 Z0:295 M208 U0:200 ; Set Elastic Lock (U axis) max rotation angle ; Heaters and temperature sensors ;------------------------------ ; Bed M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; Keenovo thermistor M950 H0 C"out0" T0 ; H = Heater 0 ; C is output for heater itself ; T = Temperature sensor M143 H0 S130 ; Set maximum temperature for bed to 130C M307 H0 R1.008 K0.196:0.000 D1.88 E1.35 S1.00 B0 ; Set PWM/PID paramaters for bed heater ; for 600w 230v heater w/built in thermistor ; mandala rose bed M140 H0 ; Assign H0 to the bed ; Tool0 Afterburner M308 S1 P"1.temp0" Y"thermistor" A"Heater0" B4725 C7.06e-8 ; Create tempsensor1 on expansion board temp0 M950 H1 C"1.out1" T1 ; Create Heater1 for Extruder0 on exp.board out1 with tempsensor1 M307 H1 R1.810 K0.302:0.347 D6.60 E1.35 S1.00 B0 V24.4 ; Set PWM/PID values for heater1 M143 H1 S285 ; Set maximum temperature for heater1 to 285C ; Tool1 Afterburner M308 S2 P"1.temp1" Y"thermistor" A"Heater1" B4725 C7.06e-8 ; Create tempsensor2 on expansion board temp1 M950 H2 C"1.out2" T2 ; Create Heater2 for Extruder1 on ep.board out2 with tempsensor2 M307 H2 R1.692 K0.444:0.458 D6.18 E1.35 S1.00 B0 V24.4 ; Set PWM/PID values for heater2 M143 H2 S285 ; Set maximum temperature for heater2 to 285C ; Tool2 Hemera M308 S3 P"1.temp2" Y"thermistor" A"Heater2" B4725 C7.06e-8 ; Create tempsensor3 on expansion board temp2 M950 H3 C"1.out3" T3 ; Create Heater3 for Extruder2 on ep.board out3 with tempsensor3 M307 H3 R1.778 K0.296:0.233 D5.38 E1.35 S1.00 B0 V24.4 ; Set PWM/PID values for heater3 M143 H3 S285 ; Set maximum temperature fot heater3 to 285C ; Fans ;------------------------------ M950 F1 C"!1.out4+out4.tach" ; Create fan1 on exp.board out4 M106 P1 S255 H1 T45 C"HeatBreakCool0" ; S = Speed of fan P1 ; H1 = heater for thermo mode ; T = temps for thermo mode ; C = to name the fan M950 F2 C"1.out7" ; Create fan2 on exp.board out7 M106 P2 C"PrintCool0" ; Set name of fan P2 as PrintCool0 M950 F3 C"!1.out5+out5.tach" ; Create fan3 on exp.board out5 M106 P3 S255 H2 T45 C"HeatBreakCool1" ; S = Speed of fan P3 ; H2 = heater for thermo mode ; T = temps for thermo mode ; C = to name the fan M950 F4 C"1.out8" ; Create fan4 on exp.board out8 M106 P4 C"PrintCool1" ; Set name of fan P2 as PrintCool1 M950 F5 C"!1.out6+out6.tach" ; Create fan5 on exp.board out6 M106 P5 S255 H3 T45 C"HeatBreakCool2" ; S = Speed of fan P5 ; H2 = heater for thermo mode ; T = temps for thermo mode ; C = to name the fan M950 F6 C"1.out9" ; Create fan6 on exp.board out9 M106 P6 C"PrintCool2" ; Set name of fan P6 as PrintCool2 ; Tool definitions ;------------------------------ M563 P0 S"Tool0" D0 H1 F2 ; P0 = Tool number ; D0 = Drive Number ; H1 = Heater Number ; F2 = Fan number print cooling fan G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures M572 D0 S0.085 ; Set pressure advance M563 P1 S"Tool1" D1 H2 F4 ; P1 = Tool number ; D1 = Drive Number ; H2 = Heater Number ; F4 = Fan number print cooling fan G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures M572 D1 S0.085 ; Set pressure advance M563 P2 S"Tool2" D2 H3 F6 ; P2 = Tool number ; D2 = Drive Number ; H3 = Heater Number ; F6 = Fan number print cooling fan G10 P2 S0 R0 ; Set tool 2 operating and standby temperatures M572 D2 S0.085 ; Set pressure advance ; All tools M98 P"/sys/Toffsets.g" ; Set tool offsets from the bed for all tools ; LED strips ;------------------------------ ;M950 E0 C"led" T2 U20 Q3000000 ; Create neopixel lights named "led" with 20 LED's ; Other sensors M308 S10 Y"mcu-temp" A"MCU" ; defines sensor10 as mainboard cpu temperature sensor ;M308 S11 Y"drivers" A"Stepper drivers" ; defines sensor11 as stepper driver temperature sensor ;End section ;------------------------------ ;M501 ; Load saved parameters from non-volatile memory -

RE: Random Hard Fault resets on Duet 3 Mini WiFiposted in General Discussion

@dc42 I'm located in the Netherlands and of course I'll provide the board including SD card. Please contac met via email or other non-public way to make futher arrangements.

-

RE: Random Hard Fault resets on Duet 3 Mini WiFiposted in General Discussion

@dc42 In one of the earlier threads I reported having this issue on RRF 3.5.3.

I now temporarily swapped my Mini5+ WiFi for a 6HC since I have a project due.

I'd be happy to lend out my Mini WiFi if that would help you to eg. reproduce the issue and find a solution? -

RE: Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

@dc42 I upgraded to RRF 3.5.3 today. During the 2nd print I experienced a hard reset. Please see the M122 report underneath:

=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.3 (2024-09-18 11:25:48) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: 7MPG2-K396U-D65J0-40KMQ-JQ03Z-Z0D1Q Used output buffers: 3 of 40 (18 max) === RTOS === Static ram: 103368 Dynamic ram: 121604 of which 0 recycled Never used RAM 16776, free system stack 198 words Tasks: NETWORK(2,nWait 7,13.5%,217) HEAT(3,nWait 6,0.0%,350) Move(4,nWait 6,0.0%,355) CanReceiv(6,nWait 1,0.0%,939) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,334) TMC(4,nWait 6,0.8%,110) MAIN(1,running,84.6%,665) IDLE(0,ready,0.2%,29) AIN(4,delaying,0.8%,268), total 100.0% Owned mutexes: === Platform === Last reset 00:05:29 ago, cause: reset button Last software reset time unknown, reason: HardFault invState, Gcodes spinning, available RAM 27292, slot 2 Software reset code 0x4863 HFSR 0x40000000 CFSR 0x00020000 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x20012580 Task TMC Freestk 125 ok Stack: 2001948c 20012334 200014e8 e000e000 00000060 00091d55 00000000 6100f000 00000000 00000000 00000000 cf410005 0041ff05 d7000000 0002ff05 3a130000 00000000 00000000 00000000 00000000 00000053 2003b5d0 20012c24 00000dae 20019494 20012e5c 2001261c Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 247196, completed 247196, timed out 0, errs 0 MCU temperature: min 31.8, current 31.8, max 34.9 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 2, read errors 0, write errors 1, ifcnt 27, reads 17320, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 27, reads 17320, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 4, read errors 0, write errors 1, ifcnt 23, reads 17319, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 21, reads 17319, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 27, reads 17320, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-09-21 16:43:50 Cache data hit count 603090100 Slowest loop: 25.74ms; fastest: 0.16ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 1.3ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 1548989 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 2965, received 0, lost 0, errs 1595525, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 26 (min 26), ts 1648/0/0 Tx timeouts 0,0,1647,0,0,1316 last cancelled message type 4514 dest 127 === Network === Slowest loop: 28.03ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address d8:bf:c0:15:0a:5c Module reset reason: Power up, Vcc 3.38, flash size 2097152, free heap 42652 WiFi IP address 172.16.0.142 Signal strength -47dBm, channel 5, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0 -

RE: Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

@droftarts I reverted to RRF 3.4.5, DWC 3.4.5 and WiFi 1.27 as you suggested and the results are not improving.

I dug a little deeper into the forum and found this article about similar symptoms. Although the root cause is very different (and not possible since I don't use an SSR), the direction in which @T3P3Tony was searching might suggest a hardware fault.

Could this be worth having a look at or does that seem too unlikely?Maurits

-

RE: Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

@droftarts I downgraded succesfully to RRF 3.4.6.

The first print I ran stopped at layer 4 and the mini5+ reset itself. After trying to run about 20 more prints I notices a few things:- during most prints the duet still resets mid-print.

- the point at which the reset occurs (print file progress) it different each time.

- only prints with a single object alway succeeed.

- prints with mutiple objects are sliced to print 'all at once'

Unfortunately it doesn't make things any clearer to me. Any suggestions?

-

RE: Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

@droftarts Hi Ian. Thanks so much for your quick reply.

I usually keep a log of all the firmware files I've installed over time so I'm quite sure I have this issue with RRF 3.4.6 as well.

To doublecheck I'll downgrade to 3.4.6 and post the result tomorrow. -

RE: Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

I forgot to mention that the issue started while I was running firmware v3.4.6. Unfortunately upgrading to v3.5.2 did not fix it.

-

Duet 3 mini5+ randomly resets during printingposted in Duet Hardware and wiring

Since a few weeks my Duet 3 mini5+ randomly resets during a print. This happens mostly during the first layer, sometimes during the second. I've been running a series of prints using the same set of gcode files and seemingly out of the blue this problem is happening almost every print I try.

My printer is a modified Ender 5 with a Duet 3 mini5+, BLtouch clone and an E3D Hemera direct drive printhead.

I currently use a standard E3D .4mm nozzle with a generic brand PLA and I've never had any problems with it before.Since I know the gcode files are OK I started looking for a hardware fault.

Most logical cause I thought to be the power supply, so I replaced it. The new one is much more quiet so I'll be keeping that one anyway.

Checked all the wiring & connections for faults, but couldn't find any.I'd really appreciate any help in finding the problem here. I've got a project tot finish before christmas for the 100+ members of my sports club so I'd like to get this fixed really soon.

I've included the config.g file and the M122 diagnostics file after a reset occurs.config.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Jan 06 2022 19:32:52 GMT+0100 (Midden-Europese standaardtijd) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Pluisje" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 D3 ; physical drive 0.0 goes forwards in driver mode stealthchop M569 P0.1 S1 D3 ; physical drive 0.1 goes forwards in driver mode stealthchop M569 P0.2 S0 D3 ; physical drive 0.2 goes backwards in driver mode stealthchop M569 P0.4 S1 D3 ; physical drive 0.4 goes forwards in driver mode stealthchop M584 X0.0 Y0.1 Z0.2 E0.4 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E394.57 ; set steps per mm old value was E394.67 M566 X1200.00 Y1200.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1800.00 E1500.00 ; set maximum speeds (mm/min) M201 X800.00 Y800.00 Z100.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S300 ; Set idle timeout ;Pressure Advance M572 D0 S0.075 ; enable Pressure advance ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X220 Y200 Z300 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io5.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io5.in M574 Y1 S1 P"io6.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io6.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X45 Y-4 Z3.460 ; set Z probe trigger value, offset and trigger height M557 X45:215 Y5:195 S27 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.343 K0.363:0.000 D3.36 E1.35 S1.00 B0 ;disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R2.032 K0.592:0.000 D4.83 E1.35 S1.00 B0 V23.7 ; disable ban-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 285C ; Fans M950 F0 C"out5" Q500 ; create fan 0 on out5 with and set its frequency ;M106 P0 C"FAN0" S0.6 H1 T45 ; set fan 0 name and value. Thermostatic control is turned on M950 F1 C"!out4+out4.tach" Q500 ; create fan 1 on out4 with tacho and set its frequency M106 P1 C"FAN1" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Filament Monitor ;M591 D0 P3 C"io1.in" S0 ; Duet3D magnetic filament monitor connected to io1.inM122

M122 === Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.5.2 (2024-06-11 17:14:16) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: 7MPG2-K396U-D65J0-40KMQ-JQ03Z-Z0D1Q Used output buffers: 14 of 40 (28 max) === RTOS === Static ram: 103368 Dynamic ram: 121568 of which 0 recycled Never used RAM 16480, free system stack 198 words Tasks: NETWORK(2,nWait 7,10.5%,217) HEAT(3,nWait 1,0.0%,355) Move(4,nWait 6,0.0%,355) CanReceiv(6,nWait 1,0.0%,939) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,334) TMC(4,nWait 6,0.8%,110) MAIN(1,running,86.8%,665) IDLE(0,ready,1.0%,29) AIN(4,delaying,0.9%,265), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:00:24 ago, cause: reset button Last software reset time unknown, reason: HardFault invState, Gcodes spinning, available RAM 27292, slot 2 Software reset code 0x4863 HFSR 0x40000000 CFSR 0x00020000 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x20012580 Task TMC Freestk 125 ok Stack: 2001948c 20012334 200014e8 e000e000 00000060 00091d55 00000000 6100f000 00000000 00000000 00000000 cf410005 0041ff05 d7000000 0002ff05 3a130000 00000000 00000000 00000000 00000000 00000053 2003b5d0 20012c24 00000dae 20019494 20012e5c 2001261c Error status: 0x00 Aux0 errors 0,0,0 MCU revision 3, ADC conversions started 24848, completed 24847, timed out 0, errs 0 MCU temperature: min 31.6, current 31.8, max 32.2 Supply voltage: min 23.9, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 2, read errors 0, write errors 1, ifcnt 43, reads 1284, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 1: standstill, SG min 16, read errors 0, write errors 1, ifcnt 43, reads 1284, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 2: standstill, SG min 4, read errors 0, write errors 1, ifcnt 40, reads 1284, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 32, reads 1283, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 43, reads 1284, writes 10, timeouts 0, DMA errors 0, CC errors 0 Driver 5: not present Driver 6: not present Date/time: 2024-09-17 16:15:14 Cache data hit count 47397715 Slowest loop: 14.86ms; fastest: 0.16ms === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 1.7ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x0000000 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 119043 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 223, received 0, lost 0, errs 118088, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 26 (min 26), ts 125/0/0 Tx timeouts 0,0,124,0,0,97 last cancelled message type 30 dest 127 === Network === Slowest loop: 26.64ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 2 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address d8:bf:c0:15:0a:5c Module reset reason: Power up, Vcc 3.38, flash size 2097152, free heap 42956 WiFi IP address 172.16.0.142 Signal strength -40dBm, channel 5, mode 802.11n, reconnections 0 Clock register 00002001 Socket states: 0 0 0 0 0 0 0 0