@MichaelKallner my config.g

#4;Magnum+ Config

M111 S0 ;Debug Modus S0=aus

M550 PTractus3D #4 -T2300 ;Maschinenname (DNS Name)

M98 P"_UserSettings.g" ;Macro laden

M552 S1 ;Netzwerk starten

M555 P1 ;Emulationstyp 1= Reprap

G21 ;Einheiten auf mm

G90 ;Koordinaten auf absolut relativ gesetzt

M83 ;Extruder auf auf relativ gesetzt

M400 ;Alles beenden, Puffer löschen

M569 P0 S0 ;E0 ; Laufrichtung Stepper (0=rückwärts 1=vorwärts)

M569 P1 S1 ;E1 ; Laufrichtung Stepper (0=rückwärts 1=vorwärts)

M569 P4 S0 ;Y ; Laufrichtung Stepper (0=rückwärts 1=vorwärts)

M569 P2 S0 ;X ; Laufrichtung Stepper (0=rückwärts 1=vorwärts)

M569 P3 S0 ;Z ; Laufrichtung Stepper (0=rückwärts 1=vorwärts)

M575 P1 B115200 S0 ; Paneldue P=Seriennummer, B=Baudrate, S0= ohne Prüfsumme

M584 X2 Y4 Z3 E0 ; Laufwerksnummer Stepper

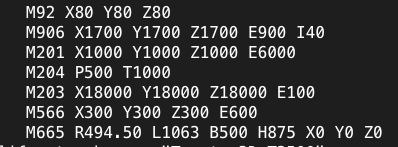

M92 X80 Y80 Z80 ; E-Steps XYZ

M906 X1700 Y1700 Z1700 E700 I40 ; Motorstrom in mA (I=Leerlaufstrom)

M201 X1000 Y1000 Z1000 E6000 ; Maximalbeschleunigung mm/sec

M204 P400 T1000 ; Druckbeschleunigung (P=Druck + T=Travel)

M203 X18000 Y18000 Z18000 E18000 ; Maximaler Vorschub mm/min

M566 X300 Y300 Z300 E600 P1 ; Max Geschwindigkeitsänderung (Ruckgeschwindigkeit)

M665 R494.50 L1063 B500 H879 X0 Y0 Z0 ; Delta Konfig: R=Radius:2 // L=Armlänge // B=Druckradius:2 // H= Düsenhöhe über Bett im Homeing

M666 X0 Y0 Z0 A0 B0 ; Achsen Endstop Korrektur (Position Endstop)

M574 X2 S1 P"xstop" ; Endstopkonfig: X2=Highend S1=aktiver High-End-Stop-Eingang P=Pin

M574 Y2 S1 P"ystop" ; Endstopkonfig: X2=Highend S1=aktiver High-End-Stop-Eingang P=Pin

M574 Z2 S1 P"zstop" ; Endstopkonfig: X2=Highend S1=aktiver High-End-Stop-Eingang P=Pin

M308 S0 A"Bed" Y"thermistor" P"bedtemp" T100000 B4400 R4700 ; Thermistor Druckbett

M308 S1 A"Magnum +" P"e0temp" Y"thermistor" T100000 B4680 C6.455513e-8 ; Thermistor Hotend

M950 H0 C"bedheat" T0 ; Heizung Pinvergabe

if sensors.analog[1].lastReading<0

M575 P1 B57600 S1 ; Paneldue P=Seriennummer, B=Baudrate, S1= mit Prüfsumme

G4 P200 ; Maschinenstillstand für P200 Millisekunden

M291 P{"Please check your print head / connection! Try again?"} R"No print head detected!" S3 ; Nachricht anzeigen

M999 ; Neustart

M92 E408 ; E-Steps Extruder

M308 S6 A"MCU" Y"mcu-temp" ; Sensor 6 MCU Temp

M575 P1 B115200 S0 ; Paneldue P=Seriennummer, B=Baudrate, S0= ohne Prüfsumme

M950 P0 C"exp.heater3" ; Heizung Pinvergabe

M950 H1 C"e1_heat" T1 ; Heizung Pinvergabe

M950 F1 C"fan0" ; Lüfter Pinvergabe

M950 F0 C"fan1" ; Lüfter Pinvergabe

M950 F2 C"fan2" ; Lüfter Pinvergabe

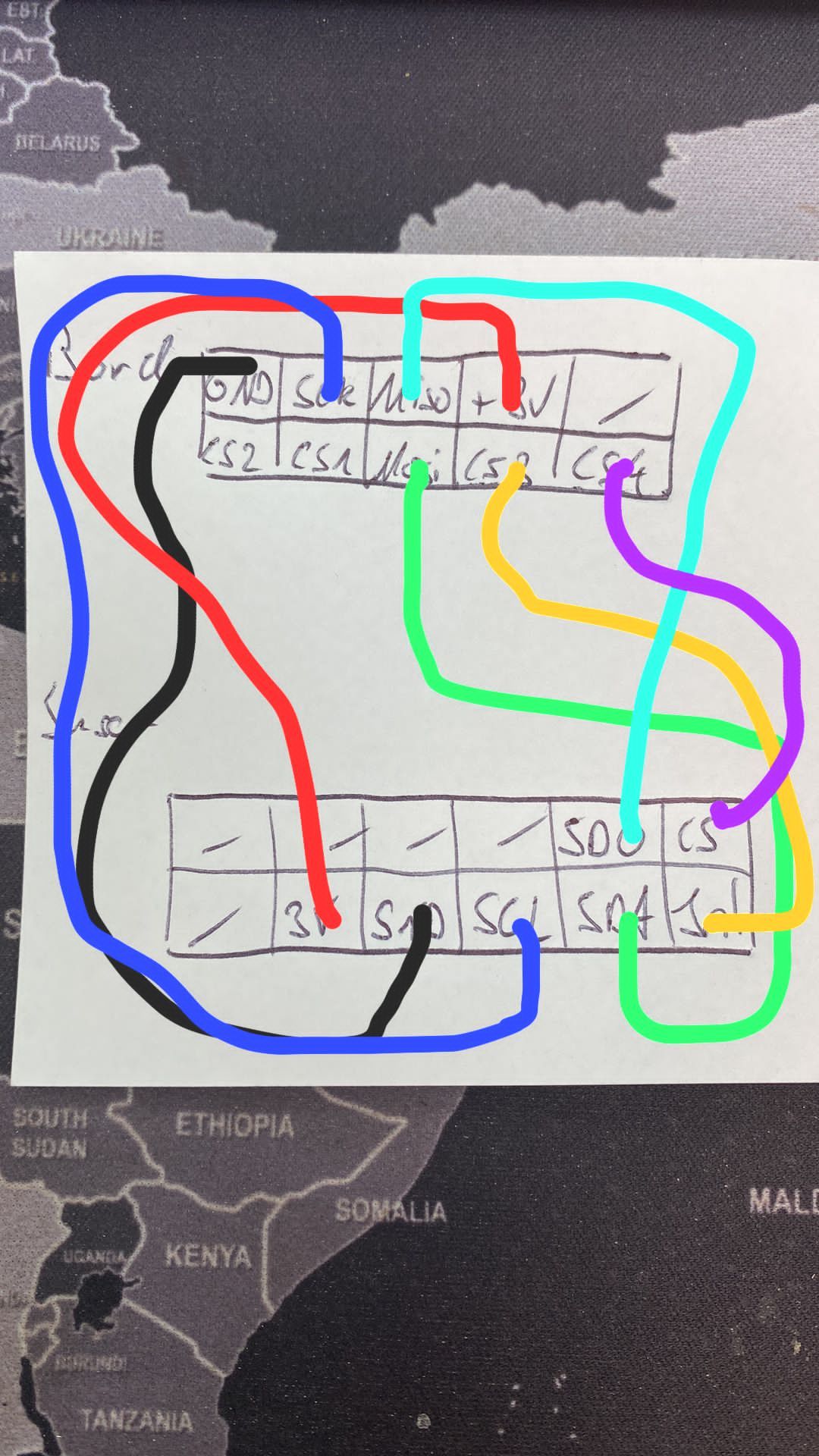

M950 J1 C"!e1stop" ; Einganspin Pinvergabe estop1

M950 J2 C"exp.e2stop" ; Einganspin Pinvergabe estop2

M106 P1 S0 H-1 C"Part cooling" ; P=Lüfter T=Temperatur H=Aktivieren Thermostat S=255 Drehzahl

;M106 P1 T50 H1 S255 ; P=Lüfter T=Temperatur H=Aktivieren Thermostat S=255 Drehzahl

;M106 P2 T40:60 H6 L0.50 X1.0 ; P=Lüfter T=Temperatur H=Aktivieren Thermostat S=255 Drehzahl

M570 H0 P2000 T20 ; Heizung Fehlererkennung H=Heizung P=Zeit in Sekunden des Fehlers T=Erlaubte Abweichung in Grad

M570 H1 P15 T20 ; Heizung Fehlererkennung H=Heizung P=Zeit in Sekunden des Fehlers T=Erlaubte Abweichung C

M563 P0 D0 H1 F0 S"Hotend 1" ; Definition Werkzeug /Druckopf

G10 P0 S0 R0 ; Setze Werte Druckkopf S=Aktive R=Standby

M140 H0 ; Bettemperatur einstellen

M307 H0 R0.500 K0.170:0.000 D13.78 E1.35 S1.00 B1

; M307 H0 R0.500 K0.566:0.000 D20.56 E1.35 S1.00 B1 ;PID Einstellungen Druckbett

M307 H1 R2.003 K0.197:0.000 D8.22 E1.35 S1.00 B0 V24.0 ;PID Einstellungen Druckkopf

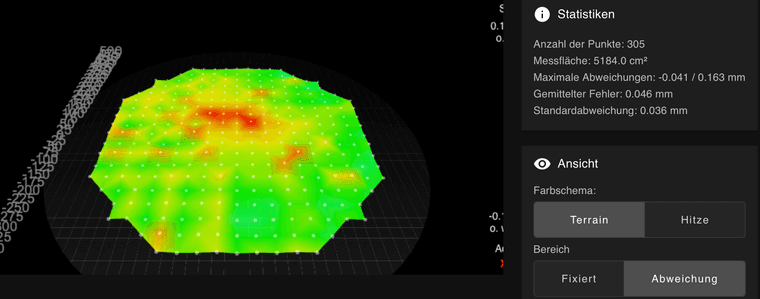

M558 P5 C"e0stop" X0 Y0 Z0 F100 T10000 ; Z-Sonde P=Typ C=Contakt XYZ=Auslösehöhe F=Vorschub Z mm/min T=Travel zwischen den Punkten

G31 X0 Y0 Z18.48 P500 ; XY= Sondenoffset // Z=Z-Triggerhöhe. // P=Triggerwert

M557 R400 S40 ; Sondierungsraster R=Radius/2 // S=Abstand

M208 S1 Z-2.5 ; Achsbegrenzung

M911 S20.5 R22.0 P"G91 M83 G1 Z3 E-3 F3000 M929 S0" ; Druckabbruch bei Unterspannung

M579 X0.9952 Y0.9983 ; Skalierung der Achsen (Bei Abweichungen der Form)

M912 P6 S1 ; Überwachung der Elektronik Temperatur (MCU)

M143 H0 P0 S110 A2 ; Maximaltemperatur mit Abschaltschwelle

M143 H0 P1 S130 A0 ; Maximaltemperatur mit Abschaltschwelle

M143 H1 P0 S300 A2 ; Maximaltemperatur mit Abschaltschwelle

M143 H1 P1 S320 A0 ; Maximaltemperatur mit Abschaltschwelle

M42 P0 S255 ; IO Pin P=Pin nummer S=Wert

M42 P1 S255 ; IO Pin P=Pin nummer S=Wert

M581 P1 T2 S0 R1 ; Externen Pin Schalten

M23 "0:/sys/config-override.g" ; Macro "...laden"

if result == 0 ; wenn erfolgreich dann...

M501 ; lade

else ; sonst...

M575 P1 B57600 S0 ;

M400 ;

M98 P"stpwzd.g" ;

M29 ;

M23 "0:/sys/firstuse.g" ; Macro "...laden"

if result == 0 ; wenn erfolgreich dann...

M23 "0:/sys/bed.g" ; lade

M575 P1 B57600 S0 ;

M400 ;

M98 P"stpwzd.g" ;

M400 ;

M575 P1 B57600 S1 ; Paneldue P=Seriennummer, B=Baudrate, S1= mit Prüfsumme

M929 P"0:/sys/printerlog2.txt" S1 ; Printerlog S1= ein // S0= aus

G28 ; Homeing

M309 P0 S0.00 ; Feedvorward Heizung

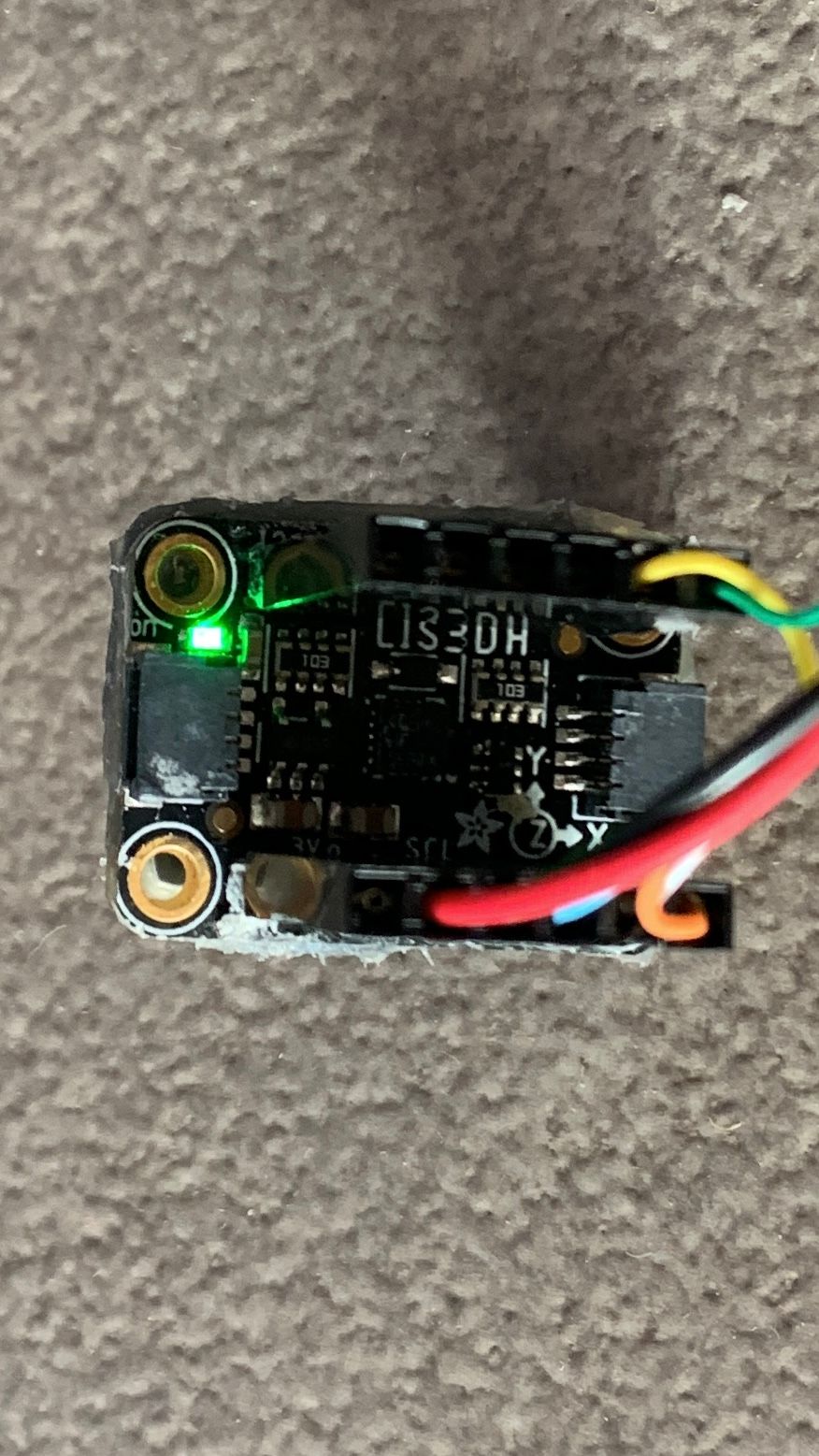

;M955 P0 C"spi.cs4+spi.cs3" ; Accelerometer

;M593 P"mzv" F20.5