That has quickly devolved into some weird drama, but for what it's worth... This level of entitlement and lack of gratitude is simply astounding. Duet forums are amazing as far as support goes. I haven't seen any big open source projects where the lead dev is so quick to respond and help users with very mundane problems. Not to mention that the whole project is very much alive, with constant firmware and hardware updates. And both are kept as open source as they can be. Simply amazing, hope you guys can keep it up.

Best posts made by Mike

-

RE: Dave's so proudposted in General Discussion

-

Water cooling on the Smart Effector.posted in Smart effector for delta printers

I've finally completed transitioning my second printer to a water cooled hotend setup. I admit that's a bit of an overkill, but I really appreciated the performance of this beauty (https://youprintin3d.de/hotendszubehoer/e3d/wasserkuehlung/792/water-cooled-heatsink.html) on my other machine. Luckily for me, the guy behind it has published .step files, so it wasn't hard to modify it for the Smart Effector even with my level of Fusion 360 skills.

Here's what I got (the water cooled one already has the RC cooling jacket on, didn't thing about taking a picture before I put that on):

I got the thread size a bit wrong (I think the original heatsink has moved to 1mm pitch instead of 1.5mm in beta), but other than that it's a drop-in replacement. So there was no need to change my print cooling setup or the config. Oh and the CNC company couldn't do the lip E3D now does for the push-fit connector, so I had to push in an E3D brass fitting instead.

So far I'm pretty happy with the results - the hotend fan was by far the loudest thing on my delta, my retractions are down and I can reliably use soluble filaments in my switching extruder setup. On the minus side water cooling is definitely another hassle, but I haven't had any leaks with my other machine with a similar arrangement for more than a year.

I'll gladly share the source files if anyone's interested. I did use openly shared models to create this anyway.

-

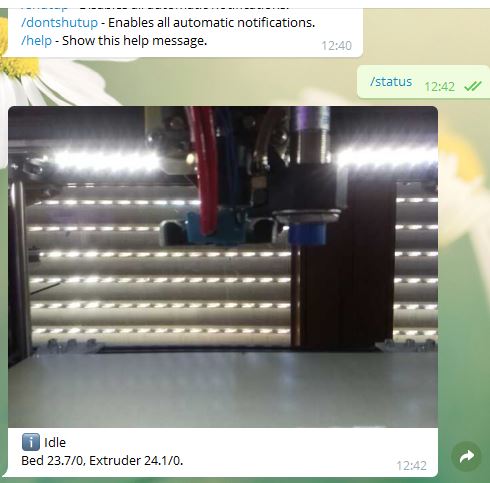

Duet Telegram botposted in General Discussion

I've read about one being in development for a while, but have only recently came across a more or less finished bot here https://www.npmjs.com/package/duet-telegram.

Works really well, I run it on my Pi Zero W along with Motioneye. Very convenient for those of us with really wonky ISPs, in my case that means I don't have to bother with weird IPv6 tunneling issues if I want to keep an eye on my printer during the day.

-

RE: HOT BED 220V DUETWIFI RESETposted in Duet Hardware and wiring

@ivang Don't use that! It's a mechanical relay that's only rated for 12V. Running 220V at the output is dangerous and has probably just fried the contacts. I'd advise you to get a DC/AC Solid State Relay. I don't know where you are, but you can easily get those off Amazon and e-bay. Just make sure it's the DC/AC type.

-

RE: Silicone Heated Bedposted in General Discussion

If you order from Keenovo, I'd recommend asking them to include a bimetallic switch in your heater. Costs something like 2 dollars, makes the whole thing a lot safer. I've ordered mine with a 155 °C cutoff temperature.

-

RE: HOT BED 220V DUETWIFI RESETposted in Duet Hardware and wiring

I was referring to the contacts inside the relay - it's a mechanical one, there's a lot more stress on them if they're switching a higher voltage. Wow, I haven't noticed that they actually advertised it as 220V compatible. That's extremely irresponsible and downright dangerous. And I would really advise you to follow the suggestion above, mains voltage is a lot less forgiving.

-

Duet hardware actually makes it into Thomas Salanderer's videosposted in General Discussion

https://youtu.be/snBZX9P4RBw?t=10m39s. Maybe he'll even test one some day.

-

RE: HOT BED 220V DUETWIFI RESETposted in Duet Hardware and wiring

@ivang This one won't do. Look closer - it's a DC/DC relay. You need an DC/AC one, like https://www.amazon.es/heschen-Single-SSR-40DA-estado-sólido/dp/B071HP9NJD/ref=sr_1_5?ie=UTF8

-

RE: Looking for a ready to use printbedposted in General Discussion

I've converted to PEI-coated aluminum. I get mine from clever3d.de, but I'm fairly sure you can find someone who does those wherever you're at.

They cut you a flat tooling plate to size and dip it (I think) into some PEI. The resulting coating in very robust (although you can damage it if you try) and extremely convenient. I now use glue-based adhesive aides only for some exotics. It's also a bit less sticky than your usual PEI sheet, so I don't bother with release agents for TPU or PETG.

-

RE: Better safe than sorry: mains voltage AC controlled bedposted in Duet Hardware and wiring

@bartolomeus Not to the bed, to the silicone heater - I've bought a tube of high-temp RTV silicone and literally moulded the fuse in. The RTV silicone is very chemically similar to the heater, which makes for a very reliable contact.

-

RE: Any good guides for setting up dual extrusion?posted in General Discussion

It'd really depend on what exactly do you want to set up. Separate extruders/heater blocks (like E3D Chimera), mixing extruders (Diamond, E3D Cyclops), IDEX carriages, toolchanger, a switching hotend (Prometheus System, Prusa MMU 1)... There are a lot of possibilities, and all of those would require very different approaches.

-

RE: Issue with dual extruderposted in Duet Hardware and wiring

I'd remove the point from the M92 command, although not sure if that actually matters. I know it's very basic advice, but have you tried looking at the hardware? Your config settings are exactly identical for both extruders, so it would make sense to assume it's harware based. Maybe you accidentally mixed the stepper motors and one of them is 0.9 degrees and the other is 1.8.

I'd try switching the stepper connectors on the board. If that changes which drive is overextruding - it's a hardware problem. If it doesn't - either a config bug or something's wrong with the board.