Thank you, @T3P3Tony

I was glad to help where I could, after all the help I had had!

Thank you, @T3P3Tony

I was glad to help where I could, after all the help I had had!

Hmm, interesting thought. No, it wasn't something you said

I'm out of here, guys.

I decided to sell my Duet3-controlled CNC and bid it a final farewell today - to a very excited new CNCer.

I pointed him in the direction of this forum, so hopefully he will join your ranks very soon - if he hasn't already.

Before I go, I would like to thank all of you who helped me - directly or otherwise - and to wish you all the best for the future.

By the way, if anyone wants a spare Duet2 with an ethernet module, I happen to have one here in the UK, (courtesy of @jay_s_uk). Make me a reasonable offer, via PM, to include postage and I'll send it out once I've been paid and have the delivery address (UK preferred).

Good luck, guys and gals.

@achrn Whoops! Thanks for that

It's time for me to move on from my RatRig 1075 KillerBee CNC machine, which has served me well with my hobby over the last 12 months - and yes, it's only a year old! It is fully configured and ready to run - you only need to provide a PC.

I’m selling my RatRig KillerBee 1075 CNC milling machine, which is fully configured and ready to run. This would suit anyone with an interest in CNC woodworking hard or soft woods, and those who wish to produce machined woodworking for a new or existing business. The machine is a solid, properly fettled woodworking machine, also capable of machining non-ferrous metals, acrylic and other materials.

The CNC machine is controlled by a fully configured 32-bit, Duet3 control board via a 24v power supply, both of which sit inside a fan-ventilated enclosure. The enclosure can be mounted on the wall or beneath the worktop.

The CNC machine is constructed from 2040 C-beam aluminium extrusions and 8mm thick steel plates for exceptional rigidity, and the MGN15 leadscrews on all four axes, which are all fitted with needle roller thrust bearings, are driven by high torque NEMA23 1.8degree/step, 345oz/in stepper motors. Proximity sensors are installed on all axes, providing auto-alignment of the Y axes, and flexible drag chains provide cable support and management. The work envelope of the machine is 550 x 788 x 100mm.

The CNC machine was bought from new in March 2022 and comes configured and ready to run, but you will need to provide the laptop or PC to access the interface of the Duet3 control board via a web browser, via a network cable.

The milling motor is a Sorotec SFM 1000 PV-ER, which has soft start, infinitely variable speeds between 4,000 and 25,000rpm, idle speed reduction, constant speed under load and integrated overload protection. It has a ER16 collet with high-precision concentricity of <0.05mm at 25mm (in the cone < 0.01 mm) due to the balanced armature and. An enclosed double ball bearing is used for better absorption of axial forces. It comes complete with a 1/8" and a 1/4" collet and a 43mm mount and dust shoe.

Also included will be the spoilboard, which is practically unmarked. It is manufactured from 25mm thick, moisture resistant (green) MDF with 4, 19mm t-tracks and an array of threaded inserts to hold the workpiece. The spoilboard is removable to allow for milling the ends of boards for cutting dovetails, although a cut-out will be required through the table/surface it will be mounted on.

If you have any questions, please feel free to make contact, but it’s highly recommended you come to see the machine in action, to explain its operation in more detail and demonstrate it working.

It’s located in north Wiltshire, on the border with Gloucestershire, in the United Kingdom.

Payment by bank transfer only, please, and you can take it away once payment has cleared. Not before, sorry. It's too big/heavy to ship, so it's collection only.

Priced at £1250 including the Sorotec milling motor and mount or £975 without.

The Killerbee can be used with a Makita RT0700CX4 Compact Router or similar, and I can provide the 65mm mount, if required.

I think, but I'm not completely sure, if it's not the same thing. You just need to make sure the design file shows the correct starting point, i.e. the surface of the material or the baseboard, and the correct corner or centre of the stock.

I think...

I'm not going to be able to help you with this issue I'm afraid, as I had the same occur to me with my Shapeoko machine a couple of years ago, and Carbide3D were unable to resolve it as it was always my fault, apparently - and part of the reason I sent it back to the retailer.

Carbide Create, when used in conjunction with a BitSetter and a BitZero is flakey at best, dangerous at worst - even on Carbide3D's own machines - so I would be reluctant to run it on (what appears to be) a different manufacturer's machine. Are you using their control board (Carbide Motion) to run the machine or, as you're posting the question here, a Duet board?

What would help any potential support response is to provide the Carbide Create software version, exactly what control board (and firmware version), maybe a copy of the config.g file, and what machine you're using.

Also, have you checked the gcode file in a viewer, eg NC Viewer?

I'm not sure if I'm being a bit too simplistic here, but this is what I do, after producing the GCode toolpath for surfacing, usually with a 0.15mm depth of cut, or sometimes more...

Run the toolpath. Once complete, if there are still low spots, lower the spindle/motor to Z0, then lower it again to the toolpath's cut depth (0.15mm), reset Z0 and rerun the toolpath.

Continue as necessary, but as you get closer to 'flat', you could reduce the 0.15mm accordingly.

@wilriker

Sorry to have to keep asking silly questions, but i've tried to run RFM from the folder it's installed in, from the command line in Windows, and I get the error:

-domain is mandatory

I've used both the IP address and domain name of the control board, i.e.:

rfm backup -device Weeble //Libraries/CNC File O:/

and

rfm backup -device 192.168.1.121 //Libraries/CNC File O:/

With the same result.

Have I missed something (else!) please?

Thank you

Thanks, @dc42

I’ll see how I get on tomorrow.

TBH I’m reluctant to test a beta version as my current configuration is really stable, but I could try with a different microSD card, so I’ve got a fallback.

Thanks, @T3P3Tony

With the current configuration files it only saves about 6 lines but, to be completely honest, I haven't spent a lot of time trying to sort this out as there have been other issues that have taken priority.

I've got a project to run tomorrow (Friday) so I'll finish that off and then concentrate on this, including a simulated power failure.

Just out of curiosity, am I correct in thinking the pause.g file is relevant to this process, and that the resume.g file can be used after powering down and restarting the machine, or have I got my wires crissed?

Thanks

Sorry to resurrect this post, but I started to look at the Pi Pico to provide "support services" for my CNC machine, with a view to taking some of the overheads away from the Duet3 MB6HC board.

Currently, my ideas are an IR digital tachometer, thermal sensor to control the enclosure fans for the Duet, and an XY laser zeroing system.

All I've got to do, is learn microPython - or any one of the other supported programming options.

So, I've been out to the workshed (too small to be a workshop, too big to be a toolshed) and, with the (cheapest) PWM-Voltage converter managed to achieve the following:

Programmed - Actual Speeds

M10000 gives 10,150rpm

M14000 gives 14,010rpm

M18000 gives 18,000rpm

As this is the speed range within which I primarily use the spindle, I think that'll do!

Thanks to you all for your help!

@dc42 I don't think I'm running anything external from the 5V power rail and I am using a 24V 350W PSU, but there doesn't seem to be enough time for the resurrect.g file to be written.

Here's the appropriate line from the config.g file:

M911 S23 R23.5 P"M98 P""SaveSpindleSpeed.g""M913 X0 Y0" ; set voltage thresholds and actions to run on power loss

...and here's the savespindlespeed.g file:

var fName = "RestoreSpindleSpeed.g"

echo >{var.fName} "if {!exists(global.abort_process)}"

echo >>{var.fName} " global abort_process = true"

echo >>{var.fName} "else"

echo >>{var.fName} " set global.abort_process = true"

echo >>{var.fName} "M291 S3 R""Resurrect:"" P""Continue with <"^{job.file.fileName}^">?"""

echo >>{var.fName} "set global.abort_process = false"

echo >>{var.fName} "M3 S"^{spindles[0].active}

All this was brought about by my desire to ensure the CNC machine saved all the necessary information, in the event of a power failure, to be able to resume the cut when mains power returns. For whatever reason, the power drain is too quick for the files to be written, hence my thoughts of connecting a 5V backup battery to the microUSB port.

We discussed this, at length, here, here and this thread, but not yet found a solution.

Awesome, thank you @wilriker

You are completely forgiven.

The backup folder will actually be on a NAS (hopefully), but you've given me plenty to get on with.

Thanks again

Thank you, @T3P3Tony

No, I just want to power the board from the 5V long enough to ensure the Resume.g file can be written (although the PowerBank kept my Duet2 Network board powered for almost 2 hours!)

I don't have a SBC connected, no. I run the machine from a web browser on my Surface Pro.

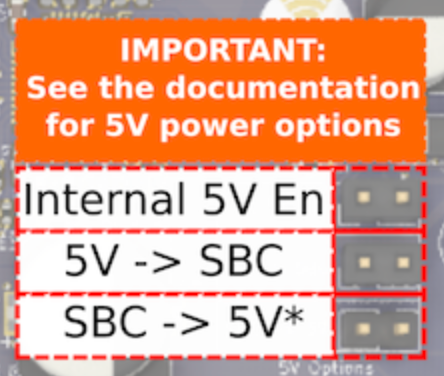

So, only a single jumper across the Internal 5V En pins, and not the other two.

Brilliant, thanks again

Yup, they're gone!

Further to this, though... The one that does come close still only provides 9.6VDC, and that's with the brass screw all the way in, but I had to use 24V directly from the PSU, not 12V/GND supply adjacent to the VFD/Laser/Servo Driver header.

I really don't understand why the converter won't give the 10V the spindle needs.

Perhaps it's time to persuade Duet to design it into the control board

Could someone help with this, please?

I'm kinda stuck until I can make some progress.

Thanks

I have a CNC machine controlled by a Duet3 MB6HC v1.01 board, running RRF 3.4.5

I've asked before about the machine powering down so quickly it doesn't have time to fully prepare a resurrect.g file which includes the spindle speed of the milling motor, but have not yet achieved this.

Recently, I came across the Raspberry Pi Pico and thought I could use this, with a pair of relays, to provide a 5V supply from a PowerBank to give the Duet3 a bit more time to save the resurrect.g file, but the issue comes when getting the Pico to 'sense' the loss of the 24V supply from the PSU, as it doesn't support such a high voltage.

It was recently pointed out that I could use the 24V supply from the PSU and a 5V supply from the PowerBank (in turn connected to a USB supply) so that when the 24V failed, the 5V would be around long enough for the file to be saved.

Is this true and, if it is, how should I set the 5V jumpers shown here:

The documentation isn't particularly clear (to me) about this, so I just need some clarification.

Thank you