@garyd9

That's the answer I was looking for!

I am looking at the 713maker mounts and they will fit my rig perfectly.

Now I'm off to get that Smart Effector!

Thx m8!

Latest posts made by nurbie

-

RE: Smart Effector usable w/o carriage set-up?posted in Smart effector for delta printers

-

Smart Effector usable w/o carriage set-up?posted in Smart effector for delta printers

Rebuilding a Rostock MaxV3 into a Duet2 WiFi machine with a DirectDrive extruder mounted at the hot end.

Need a calibration nozzle contact sensor/solution.

Recently discovered the Duet Smart Effector v1.3 (StrainEffector) pcb. Looks promising!Is the Smart Effector usable for Z touch-offs/calibration moves at the nozzle without the carriage inputs?

I see that the Duet Smart Effector involves the triangulation component with pcbs at the carriage glides but I don't think my carriages can accommodate those boards.

Not sure if the Duet Smart Effector is a waste of pcb if not employing the control arm/carriage loops?

Feedback?

-

RE: Duet 2 WiFi Dual Extruder testing w/o H1?posted in General Discussion

DOH!

I had just set that up for the clay machine!

AND,

the M302 works.

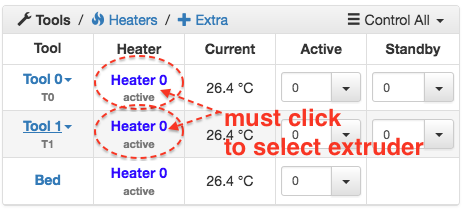

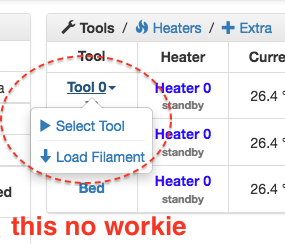

Well now, ain't life grand.One weirdness is that to select between the extruders I have to use the Heater section(?)

-

Duet 2 WiFi Dual Extruder testing w/o H1?posted in General Discussion

I want to balance my dual extruder setup(RostockV4/SMCNC) without engaging any heaters.

Duet GUI only allows extrude/retract when temps are at min 180c.

Is there something I can fudge in the config to allow me to test the steppers without having the HE come to temp? or to something less than 180c?Also, GUI only allows me to switch between the extruder steppers by clicking on the Heater ; when I go to Tool_0/1 and try to Select/Deselect the tool it has no effect. Is that normal?

My extruder config:

;extruder E0

M563 P0 D0 H1 ; Hotend (T0), drive (E0), heater (H1)

G10 P0 S0 R0 ; Hotend operating and standby temperatures;extruder E1

M563 P1 D1 H1 ; Hotend (T1), drive (E1), heater (H1)

G10 P1 S0 R0 ; Hotend (1) operating and standby temperatures -

RE: Stepper temp sensing for Duet2 WiFi PWM fan?posted in Duet Hardware and wiring

I must need sleep; no gcode needed when, CLEARLY, the fan comes on when the machine starts, and then has no reason to turn off because the thing is extruding until the model is printed.

At which time it will get shut off when I turn the machine off.Sensor version will be interesting.

I found some LM35 sensor boards online that are remarkably low-priced, so if I go the temp sensing way it's looking pretty simple, as I just discovered the E0 / E1 temp connections on the Duet! Awesome.

Plug-n-play??

We'll shall see about thatin later episodes

-

RE: Stepper temp sensing for Duet2 WiFi PWM fan?posted in Duet Hardware and wiring

Does anyone know how to set the config to turn on a fan when the E0 / E1 gets activated?

-

RE: Stepper temp sensing for Duet2 WiFi PWM fan?posted in Duet Hardware and wiring

It may not need it, but the guys that engineered the setup added it, SO,

I'm guessing it needs it.

Now, that said, I just swapped the stepper for one with about 1.5x the torque capability...might solve all(?).

Stepper is driving a (reverse archimedes-action )screw within the body and pushing clay out the nozzle, not melted plastic.

Probably the reason?Haven't had the chance to crank it all up yet!

-

Stepper temp sensing for Duet2 WiFi PWM fan?posted in Duet Hardware and wiring

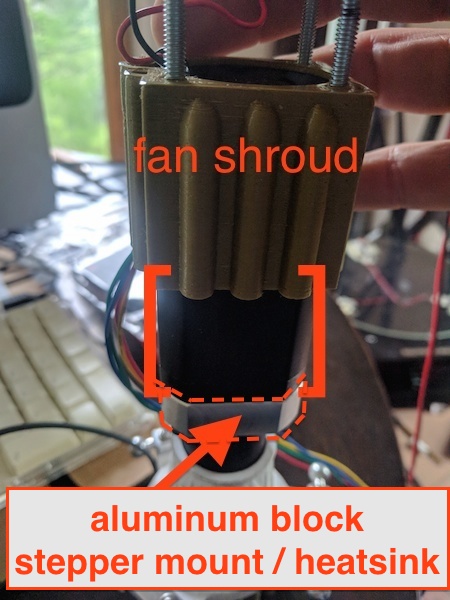

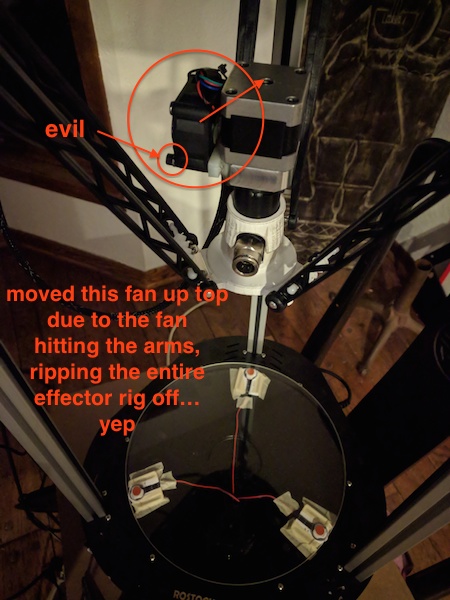

I've got a stepper riding on my Rostock Delta effector as an extruder. Homes and deck calibrates superbly.

Sporty fan + shroud mounts on top of the stepper and runs the wire bundle to the Duet above.

Currently running the fan from PWM2 on the Duet, with no variable control for when it runs(on all the time right now).

config slice:

M106 P0 H-1 ; PART-DRYING fan

M106 P1 T30 H100:101:102:103 S127 ; DUET CPU fan

M106 P2 S100 ; LDM fanM563 P0 D1 S"LDM_01" ; create a named tool using extruder drive 0

//This is the motor I'd like to trigger the fan coming on for//IDEAL choice would be to have the gcode drive the fan whenever the E0 or E1(whichever is driving the extruder stepper) is energized/running)

Thing starts to print, fans stays on, no sensor required.

Second choice is to mount a thermistor?/sensor (LM35?) in the mount/heatsink and wire it to the Duet.

Can I even do that without a board to manage the signal?What d'y'allses think, ehhh?

-

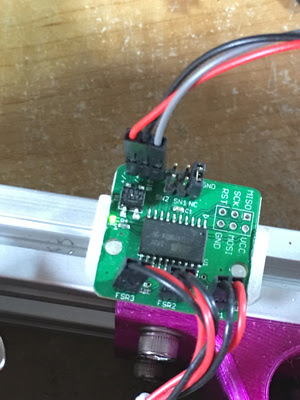

RE: DUET 2 WiFi FSR no workie - config?posted in General Discussion

Yes, the wiring diagrams I saw clearly are the first layout.

Then I found one that had some color-blindness going on,

but got me there:It states:

Grey is the Signal, red is 3v3 and black is ground

(this is not my board/trinket)

I was convinced 'gray'(my red) is 3.3v, because the board was getting power and working/sensing/lighting up the correct LEDs.

Right?

I just stared at my config and thought,"what could possibly go wrong? I might fry a $7 (USD) part, but ...

MAGIC COULD HAPPEN"

I mean,

SCIENCE COULD HAPPEN!

and there was much rejoicing