@jltx In the standalone there is no configuration file. I put the the program files in the home directory, within an FTP share, so that I can access the videos over FTP. You can also access them from a web browser. The configuration is done upon launch with command switches. This is what I use, it is for 2 cameras:

sudo python3 /home/pi/ftp/files/DuetLapse/DuetLapse3.py -duet 192.168.1.8 -minvideo 3 -maxvideo 12 -seconds 3 -detect none -dontwait -restart -camera1 stream -weburl1 http://cam.local:8081/101/stream -camera2 stream -weburl2 http://cam.local:8081/102/stream -basedir /home/pi/ftp/files/DuetLapse -standby -deletepics -verbose -keeplogs -port 8094 -extratime 2 -fps 30

This produces a maximum of 12 seconds of video (less if the print time is very short). If the print time is longer, the frame rate goes up instead of the duration of the video. At the end, there will be 2 seconds of a still image of the finished print. This is for a corexy printer, if you have a bedslinger you will need to have commands to center the bed for each snapshot, and you would probably want to do it between layers.

In order to run duetlapse at startup, I put the preceeding command in my "/etc/rc.local" file.

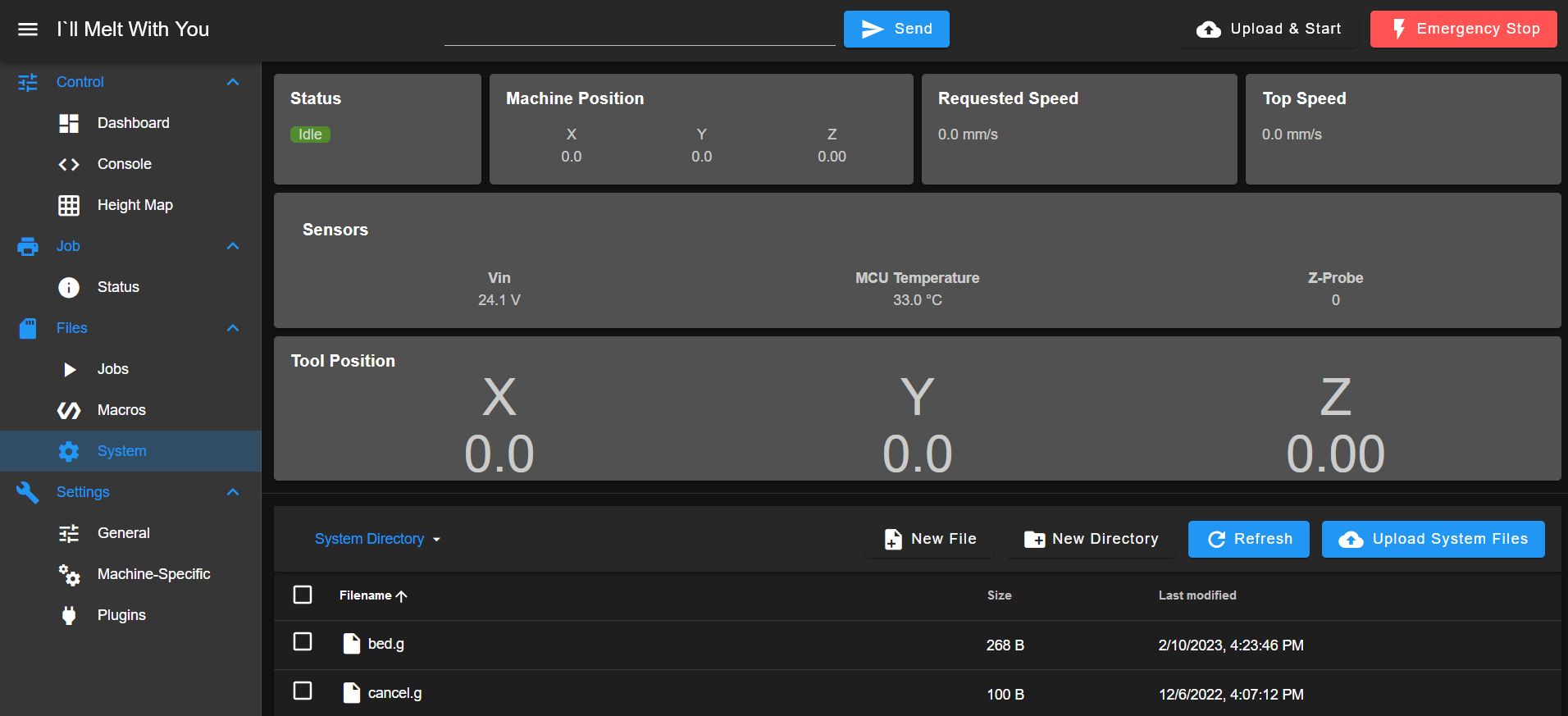

In order to automatically trigger duetlapse, you need to create 4 (ideally) .g files in your printers' system folder. I have it set up like this:

DuetLapse3Start.g

M291 P"DuetLapse3.start" S1 T5 ;Start DuetLapse3

DuetLapse3Pause.g

M291 P"DuetLapse3.pause" S1 T5 ;pause DuetLapse3

DuetLapse3Continue.g

M291 P"DuetLapse3.continue" S1 T5 ;resume DuetLapse3

DuetLapse3Stop.g

M291 P"DuetLapse3.completed" S1 T5 ;Stop DuetLapse3

G4 S10 ;pause for 10 seconds

in my pause.g file, I add this line:

M98 P"DuetLapse3pause.g" ;Pause DuetLapse 3

This pauses the timelapse when you pause the print.

In my resume.g file I add this line:

M98 P"DuetLapse3continue.g" ;resume timelapse

This resumes the timelapse when I resume a print.

In order to trigger the timelapse upon the start of a print, I need to add commands to my slicer's start and end gcode.

To the start gcode:

M98 P"DuetLapse3Start.g" ;start timelapse

Place this after your command to turn on LED Lighting, if you have it.

To the end gcode:

M98 P"DuetLapse3Stop.g" ;Stop Timelapse

M400 ;Wait for timelapse to stop

Place this line before your command to turn off your LED lighting, if you have it.

That should about do it