printer config 6HC + 1LC + inductive scan probe, SBC RPI5

I came to the printer this morning after a night of printing and it was in an interesting state. The print was finished but incomplete. The hotend was still at operating temperature, the tool fan was on, the heated bed was off, the printer was parked in the correct position at the end of the print. According to the print, there was an interruption somewhere around 70 percent of the Gcode.

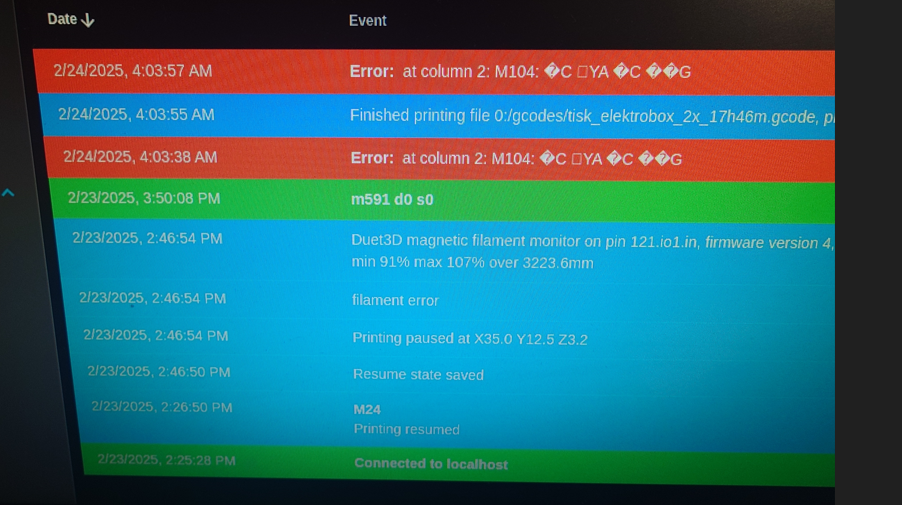

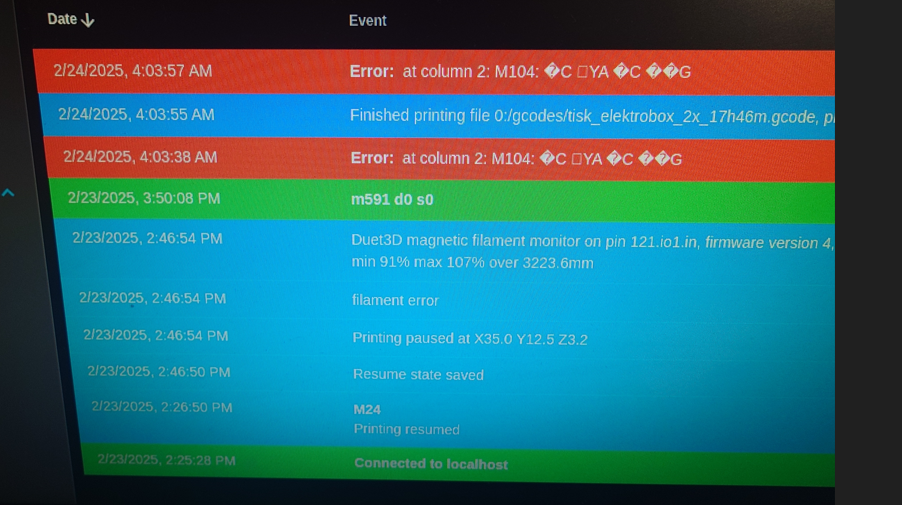

So I took a picture of what was on the monitor/console.

It looks like the tool board is frozen but the DIAG LEDs are flashing correctly. M122 listing:

24. 2. 2025 5:38:46 m122 b120

Diagnostics for board 120:

Duet SZP firmware version 3.6.0-beta.4 (2025-02-10 20:12:55)

Bootloader ID: SAMC21 bootloader version 2.10 (2023-11-16)

All averaging filters OK

Never used RAM 11612, free system stack 112 words

Tasks: ScanSens(6,nWait 4,12.8%,50) HEAT(2,nWait 6,0.2%,126) CanAsync(5,nWait 4,0.0%,46) CanRecv(3,nWait 1,0.0%,64) CanClock(5,nWait 1,0.0%,52) ACCEL(3,nWait 6,0.0%,72) MAIN(1,running,63.9%,422) IDLE(0,ready,0.0%,26) AIN(2,nWait 2,23.1%,112), total 100.0%

Owned mutexes:

Last reset 20:54:25 ago, cause: power up

Last software reset data not available

Peak sync jitter 1/20, peak Rx sync delay 309, resyncs 0/2, no timer interrupt scheduled

VIN voltage: min 4.9, current 5.0, max 5.0

MCU temperature: min 23.9C, current 28.5C, max 41.9C

Last sensors broadcast 0x00008000 found 1 78 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 605387, send timeouts 0, received 959470, lost 0, ignored 0, errs 6940, boc 0, free buffers 18, min 17, error reg ff0000

Accelerometer: LIS2DW, status: 00

Inductive sensor: raw value 43344638, frequency 4.04MHz, current setting 22, ok

I2C bus errors 0, naks 3, contentions 0, other errors 0

24. 2. 2025 5:38:37 m122 b121

CAN response timeout: board 121, req type 6024, RID 1127

24. 2. 2025 5:38:29 m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.4 (2025-02-11 09:51:22) running on Duet 3 MB6HC v1.01 (SBC mode)

Board ID: 08DJM-956BA-NA3TN-6J1D2-3S86T-9VBAS

Used output buffers: 1 of 40 (17 max)

=== RTOS ===

Static ram: 137396

Dynamic ram: 98828 of which 208 recycled

Never used RAM 105728, free system stack 126 words

Tasks: LASER(5,nWait 7,0.6%,167) SBC(2,nWait 7,1.0%,785) HEAT(3,nWait 6,0.0%,323) Move(4,nWait 6,0.4%,213) TMC(4,nWait 6,3.1%,341) CanReceiv(6,nWait 1,0.1%,770) CanSender(5,nWait 7,0.0%,325) CanClock(7,delaying,0.0%,341) MAIN(1,running,94.7%,500) IDLE(0,ready,0.1%,29) USBD(3,blocked,0.0%,149), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 20:54:13 ago, cause: software

Last software reset at 2025-02-23 08:44, reason: User, Gcodes spinning, available RAM 108328, slot 1

Software reset code 0x2003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Segments created 79, maxWait 4890069ms, bed comp in use: mesh, height map offset 0.000, hiccups added 0/0 (0.00/6841.03ms), max steps late 1, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 25000.00/25000/0.00 42000.00/42000/0.00 83926.00/83926/-0.00

Next step interrupt due in 265 ticks, disabled

Driver 0: standstill, SG min 0, mspos 200, reads 23380, writes 968 timeouts 93

Driver 1: standstill, SG min 0, mspos 664, reads 23382, writes 966 timeouts 93

Driver 2: standstill, SG min 0, mspos 696, reads 23404, writes 944 timeouts 93

Driver 3: standstill, SG min 0, mspos 824, reads 23404, writes 944 timeouts 93

Driver 4: standstill, SG min 0, mspos 8, reads 23435, writes 913 timeouts 93

Driver 5: standstill, SG min 0, mspos 8, reads 23435, writes 913 timeouts 93

Phase step loop runtime (us): min=0, max=554, frequency (Hz): min=528, max=57692

=== DDARing 0 ===

Scheduled moves 1721902, completed 1721902, LaErrors 0, Underruns [1, 0, 0]

Segments left 0, axes/extruders owned 0x80000007, drives owned 0x80000007

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1 -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.3

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File* is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue* is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause* is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== Filament sensors ===

Driver 31: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

=== CAN ===

Messages queued 2239549, received 2369863, lost 0, ignored 0, errs 300132, boc 8

Longest wait 3ms for reply type 6061, peak Tx sync delay 65241, free buffers 50 (min 47), ts 356651/356593/0

Tx timeouts 0,0,53,0,0,4 last cancelled message type 30 dest 127

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 22161/22161

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a80

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.6.0-beta.4 (2025-02-11 12:05:38, 64-bit)

HTTP+Executed:

> Executing M122

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 39.49, max time between full transfers: 926.7ms, max pin wait times: 70.9ms/7.6ms

Codes per second: 7.78

Maximum length of RX/TX data transfers: 4436/1656

after emergenci stop reset:

24. 2. 2025 5:40:46 m122 b120

Diagnostics for board 120:

Duet SZP firmware version 3.6.0-beta.4 (2025-02-10 20:12:55)

Bootloader ID: SAMC21 bootloader version 2.10 (2023-11-16)

All averaging filters OK

Never used RAM 11636, free system stack 112 words

Tasks: ScanSens(6,nWait 6,11.9%,50) HEAT(2,nWait 6,0.2%,126) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,64) CanClock(5,nWait 1,0.0%,52) ACCEL(3,nWait 6,0.0%,72) MAIN(1,running,64.0%,422) IDLE(0,ready,0.0%,26) AIN(2,nWait 2,23.8%,112), total 100.0%

Owned mutexes:

Last reset 00:00:32 ago, cause: power up

Last software reset data not available

Peak sync jitter 2/6, peak Rx sync delay 261, resyncs 0/0, no timer interrupt scheduled

VIN voltage: min 5.0, current 5.0, max 5.0

MCU temperature: min 28.4C, current 28.7C, max 28.7C

Last sensors broadcast 0x00008000 found 1 213 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 276, send timeouts 0, received 415, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0

Accelerometer: LIS2DW, status: 00

Inductive sensor: raw value 43345756, frequency 4.04MHz, current setting 22, ok

I2C bus errors 0, naks 3, contentions 0, other errors 0

24. 2. 2025 5:40:40 m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.4 (2025-02-11 09:51:22) running on Duet 3 MB6HC v1.01 (SBC mode)

Board ID: 08DJM-956BA-NA3TN-6J1D2-3S86T-9VBAS

Used output buffers: 1 of 40 (17 max)

=== RTOS ===

Static ram: 137396

Dynamic ram: 98332 of which 0 recycled

Never used RAM 108328, free system stack 202 words

Tasks: LASER(5,nWait 7,0.0%,269) SBC(2,nWait 7,0.7%,811) HEAT(3,nWait 6,0.0%,369) Move(4,nWait 6,0.0%,333) TMC(4,nWait 6,2.3%,377) CanReceiv(6,nWait 1,0.0%,794) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,341) MAIN(1,running,95.6%,500) IDLE(0,ready,1.4%,29) USBD(3,blocked,0.0%,149), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:00:34 ago, cause: software

Last software reset at 2025-02-24 05:40, reason: User, Gcodes spinning, available RAM 105728, slot 2

Software reset code 0x2003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00

Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00

Next step interrupt due in 282 ticks, disabled

Driver 0: standstill, SG min 0, mspos 8, reads 54797, writes 30 timeouts 0

Driver 1: standstill, SG min 0, mspos 8, reads 54797, writes 30 timeouts 0

Driver 2: standstill, SG min 0, mspos 8, reads 54799, writes 28 timeouts 0

Driver 3: standstill, SG min 0, mspos 8, reads 54799, writes 28 timeouts 0

Driver 4: standstill, SG min 0, mspos 8, reads 54805, writes 22 timeouts 0

Driver 5: standstill, SG min 0, mspos 8, reads 54805, writes 22 timeouts 0

Phase step loop runtime (us): min=0, max=2, frequency (Hz): min=1913, max=2089

=== DDARing 0 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x80000003, drives owned 0x80000003

Code queue is empty

=== DDARing 1 ===

Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0]

Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000

Code queue is empty

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1 -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

=== Filament sensors ===

Driver 31: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

=== CAN ===

Messages queued 301, received 811, lost 0, ignored 0, errs 30898, boc 0

Longest wait 5ms for reply type 6024, peak Tx sync delay 44474, free buffers 50 (min 49), ts 162/131/0

Tx timeouts 0,0,30,0,0,0 last cancelled message type 30 dest 127

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 1138/1138

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x27a80

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.6.0-beta.4 (2025-02-11 12:05:38, 64-bit)

HTTP+Executed:

> Executing M122

Failed to deserialize the following properties:

- Board -> BoardState from "timedOut"

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 39.73, max time between full transfers: 44.3ms, max pin wait times: 43.4ms/1.2ms

Codes per second: 2.86

Maximum length of RX/TX data transfers: 4390/756

24. 2. 2025 5:40:32 m122 b121

Diagnostics for board 121:

Duet TOOL1LC rev 1.1 or later firmware version 3.6.0-beta.4 (2025-02-10 20:13:03)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

All averaging filters OK

Never used RAM 6820, free system stack 124 words

Tasks: Move(3,nWait 7,0.0%,140) TMC(2,nWait 6,3.6%,60) HEAT(2,nWait 6,0.2%,120) CanAsync(5,nWait 4,0.0%,58) CanRecv(3,nWait 1,0.0%,72) CanClock(5,nWait 1,0.0%,60) ACCEL(3,nWait 6,0.0%,72) MAIN(1,running,91.3%,318) IDLE(0,ready,0.0%,26) AIN(2,delaying,4.7%,120), total 100.0%

Owned mutexes:

Last reset 00:00:18 ago, cause: power up

Last software reset data not available

Moves scheduled 0, hiccups 0 (0.00/0.00ms), segs 0, step errors 0 (types 0x0), maxLate 0 maxPrep 0, ebfmin 0.00 max 0.00

Peak sync jitter 1/4, peak Rx sync delay 199, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4280810105 ticks, disabled

VIN voltage: min 26.2, current 26.2, max 26.3

MCU temperature: min 45.8C, current 45.8C, max 46.2C

Driver 0: pos 0, 420.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 12, reads 9419, writes 12, timeouts 0, DMA errors 0, CC errors 0

Last sensors broadcast 0x00001802 found 3 132 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 408, send timeouts 0, received 257, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

Accelerometer: LIS3DH, status: 00

I2C bus errors 0, naks 3, contentions 0, other errors 0

=== Filament sensors ===

Interrupt 4 to 9us, poll 8 to 645us

Driver 0: pos 2160.0, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0

24. 2. 2025 5:40:13 Connection established