Thank you. After update firmware to 3.01-RC11 extruder fan turn on and works after starting print.

Posts made by radekzl

-

RE: 3.01-RC10 - Extruder cooling fan not turn onposted in Beta Firmware

-

RE: 3.01-RC10 - Extruder cooling fan not turn onposted in Beta Firmware

I check settings of tools in my config.g and I think that maybe I have mistake in parameter M563 and mapping fans for tools.

Current:

M563 P0 D0 H1 X3 F3 ; Define tool 0M563 P1 D1 H2 F4 ; Define tool 1

New settings:

M563 P0 D0 H1 X3 F0:3 ; Define tool 0M563 P1 D1 H2 F1:4 ; Define tool 1

What do you think? Now I am at work. After I will come home I check it.

-

RE: 3.01-RC10 - Extruder cooling fan not turn onposted in Beta Firmware

Here is my complete config.g file:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Fri Feb 01 2019 23:24:57 GMT+0100 (Středoevropský standardní čas); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare; Network

M550 PZBox Mk. I ; Set machine name

M552 S1 ; Enable network

M587 S"kluci" P"723753155" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disable TelnetM584 X0 Y1:6 Z2 U5 E3:4 ; Create U axis for second X carriage before we try to configure it

; Drives

M569 P0 S1 D2 ; Drive 0 goes forwards

M569 P1 S0 D2 ; Drive 1 goes forwards

M569 P2 S0 D2 ; Drive 2 goes forwards

M569 P3 S1 D2 ; Drive 3 goes forwards

M569 P4 S0 D2 ; Drive 4 goes forwards

M569 P5 S0 D2 ; Drive 5 goes forwards

M569 P6 S1 D2 ; Drive 5 goes forwardsM350 X256 Y256:256 U256 Z256 E256:256 I0 ; Configure microstepping without interpolation

M201 X700 Y700:700 U700 Z15 E800 ; Accelerations (mm/s^2)

M203 X5000 Y5000 U5000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X450 Y450 U450 Z30 E20 ; Maximum jerk speeds mm/minuteM208 X0:276 Y-75:200 U-59:208 Z-10:200 ; Set axis minima:maxima (adjust to suit your machine) x-60:216 u0:250

M92 X2582.48954 Y2593.77082 U2579.6913 Z6546.644 ; Set axis steps/mm

M92 E6592.55:6592.55 ; Set extruder steps per mm

M906 X800 Y900:900 U800 Z500 E1000:1000 I70 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop" ; Set active high endstops

M574 U1 S1 P"e0stop" ; Set active high endstops

M574 Z0 P"nil" ; Z has no endstop; Disable heaters H3-H7 to free up pins

M950 H3 C"nil"

M950 H4 C"nil"

M950 H5 C"nil"

M950 H6 C"nil"

M950 H7 C"nil"; Z-Probe

M558 P9 C"^zprobe.in" H5 F800 T3000 R0.5 ; Set Z probe type to bltouch and the dive height + speeds

M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch

G31 P25 X1.0 Y-31.25 Z1 ; Set Z probe trigger value, offset and trigger height Z+ pousouva osu Z smerem dolu k podlozce (stará tisková hlava X7.9 Y58.8)

M557 X15:195 Y5:175 S20 ; Define mesh grid; Laser sensor

M591 D0 P5 C"zstop" R5:130 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D0 ; display filament sensor parameters for extruder drive 0

M591 D1 P5 C"e1stop" R15:250 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D1 ; display filament sensor parameters for extruder drive 0; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M140 H0 ; Set temperature limit for heater 0 to 120C

M143 H0 S120; Hot end - levý

M308 S1 P"spi.cs1" Y"rtd-max31865" A"EXTRUDER LEVY" ; Configure thermocouple for heater 1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 A361.3, C127.9, D11.9 S1

M143 H1 S400 ; Set temperature limit for heater 1 to 280C; Hot end - pravý

M308 S2 P"spi.cs2" Y"rtd-max31865" A"EXTRUDER PRAVY" ; Configure thermocouple for heater 2

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 A364.1 C146.0 D4.5 S1.00 V23.8 B0

M143 H2 S300 ; Set temperature limit for heater 2 to 280CM308 S3 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper; Fans

M950 F1 C"fan1"

M106 P1 H1 T45 S255 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F0 C"fan0"

M106 P0 H2 T45 S255 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F3 C"duex.fan3"

M106 P3 H-1 C"Chlazeni levy"

M950 F4 C"duex.fan4"

M106 P4 H-1 C"Chlazeni pravy"

M950 F5 C"duex.fan5"

M106 P5 T32:40 H100:101:102 C"Duet Fan" ;cooling fan that starts to turn on when the MCU temperature (virtual heater 100) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 101 and 102) report that they are over-temperature; Tools

M563 P0 D0 H1 X3 F3 ; Define tool 0

G10 P0 X0 Y0 U0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0.05 U9.6 Z0.4 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C;Pressure advance

;M572 D0:1 S0.05:0.05;Configure motor stall detection

M915 P0:1:5:6 S10 F1 R3; Automatic saving after power loss is not enabled

M911 S22 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000"; Custom settings are not configured

At afternoon I catch video on camera of this problem with extruder cooling fan.At afternoon I catch video on camera of this problem with extruder cooling fan.

-

RE: 3.01-RC10 - Extruder cooling fan not turn onposted in Beta Firmware

Before I had this settings of fans in config.g file:

; Fans

M950 F1 C"fan1"

M106 P1 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F0 C"fan0"

M106 P0 H2 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F3 C"duex.fan3"

M106 P3 H-1 C"Chlazeni levy"

M950 F4 C"duex.fan4"

M106 P4 H-1 C"Chlazeni pravy"

M950 F5 C"duex.fan5"

M106 P5 T32:40 H100:101:102 C"Duet Fan" ;cooling fan that starts to turn on when the MCU temperature (virtual heater 100) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 101 and 102) report that they are over-temperatureFor your advice I edited config.g file. Now I have this settings of fans:

; Fans

M950 F1 C"fan1"

M106 P1 H1 T45 S1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F0 C"fan0"

M106 P0 H2 T45 S1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F3 C"duex.fan3"

M106 P3 H-1 C"Chlazeni levy"

M950 F4 C"duex.fan4"

M106 P4 H-1 C"Chlazeni pravy"

M950 F5 C"duex.fan5"

M106 P5 T32:40 H100:101:102 C"Duet Fan" ;cooling fan that starts to turn on when the MCU temperature (virtual heater 100) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 101 and 102) report that they are over-temperatureUnfortunately the behavior is the same. Cooling fan of extruder still not turn on after starting print.

I tried another settings M106 P1 H1 T45 S255 and M106 P0 H2 T45 S255, but without any changes cooling fan of extruder still not turn on after starting print.

-

3.01-RC10 - Extruder cooling fan not turn onposted in Beta Firmware

Hello,

I have IDEX printer and I use slicer Simplify3D and after upgrade firmware from 3.01-RC8 to 3.01-RC10 I have the problem with cooling fan of extruder. When I start printing extruder cooling fan do not turn on. When I cancel print extruder coling fan turn on. Manually I can turn on extruder cooling fan, when I manualy adjust extruder temperature then cooling fan works.This is really strange behavior and I do not know why. Do you have any ideas?

Here is part of starting g-code from Simplify3D:

G90

M82

M106 S0

M140 S110

M190 S110

M104 S0 T0

M104 S230 T1

M109 S230 T1

G28 X0 Y0 U0

G0 X100 Y100

G28 Z0 ; home all axes

M557 X15:195 Y5:195 S20

G29 S1

; process Process1

; layer 1, Z = 0.200

T1

G92 E0.0000

G1 E-0.8000 F2100

; feature skirt

; tool H0.200 W0.400

G1 Z0.200 F1002

G1 X73.147 Y59.322 F7200

G1 E0.0000 F2100

G92 E0.0000

G1 X73.509 Y58.780 E0.0217 F2520Thank you.

-

RE: Need Help with BL Touch Set upposted in Third-party add-ons

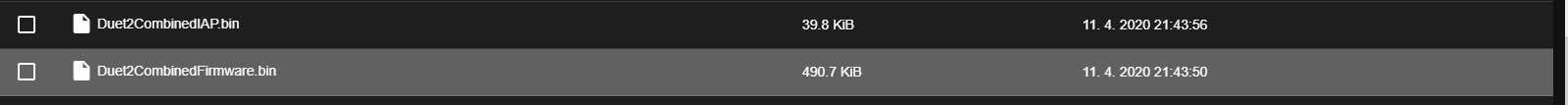

I'm so sorry, but I have only this two files for firmware 3.01 RC6 and everything works fine.

and all standard files .g

-

RE: Need Help with BL Touch Set upposted in Third-party add-ons

Hello,

I have same problem two days ago:https://forum.duet3d.com/topic/15549/bl-touch-setting-on-reprap-firmware-3-0

In this topic is part of my config.g which is OK.

And check sd card if you do not have on sd card file iap4e.bin and delete it.

-

RE: BL-touch setting on Reprap Firmware 3.0posted in Firmware installation

Awesome. Thank you very much for your advice. Now it is ok.

Here is my functional part of config.g:

; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop" ; Set active high endstops

M574 U1 S1 P"e0stop" ; Set active high endstops

M574 Z0 P"nil" ; Z has no endstop; Disable heaters H3-H7 to free up pins

M950 H3 C"nil"

M950 H4 C"nil"

M950 H5 C"nil"

M950 H6 C"nil"

M950 H7 C"nil"; Z-Probe

M558 P9 C"^zprobe.in" H5 F800 T3000 ; Set Z probe type to bltouch and the dive height + speeds

M950 S0 C"duex.pwm5" ; create servo pin 0 for BLTouch

G31 P25 X1.0 Y-31.25 Z1 ; Set Z probe trigger value, offset and trigger height Z+ pousouva osu Z smerem dolu k podlozce (stará tisková hlava X7.9 Y58.8)

M557 X15:195 Y5:175 S20 ; Define mesh grid -

BL-touch setting on Reprap Firmware 3.0posted in Firmware installation

Hello,

today I tried upgrade firmware on my Duet Wifi from 2.05.1 to 3.01RC6. Upgrade was successfull but unfortunately my BL Touch not work after upgrade.I connected BL TOUCH according to this manual:

https://betrue3d.dk/bltouch-on-duet-wifi-configuratio-and-usage/With FW version 2.05.1 BL TOUCH worked OK. I understand that I must edit config.g, deployprobe.g, retractprobe.g and home files. I did it, but BL TOUCH not work. After power on BL TOUCH did self test, but thats all. Commands M401, M402 or M280 from console not work and homez and home all not work too.

Here is my config.g:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Fri Feb 01 2019 23:24:57 GMT+0100 (Středoevropský standardní čas); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare; Network

M550 PZBox Mk. I ; Set machine name

M552 S1 ; Enable network

M587 S"kluci" P"" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disable TelnetM584 X0 Y1:6 Z2 U5 E3:4 ; Create U axis for second X carriage before we try to configure it

; Drives

M569 P0 S1 D2 ; Drive 0 goes forwards

M569 P1 S0 D2 ; Drive 1 goes forwards

M569 P2 S0 D2 ; Drive 2 goes forwards

M569 P3 S1 D2 ; Drive 3 goes forwards

M569 P4 S0 D2 ; Drive 4 goes forwards

M569 P5 S0 D2 ; Drive 5 goes forwards

M569 P6 S1 D2 ; Drive 5 goes forwards; Laser sensor

M591 D0 P5 C"zstop" R5:130 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D0 ; display filament sensor parameters for extruder drive 0

M591 D1 P5 C"e1stop" R15:250 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D1 ; display filament sensor parameters for extruder drive 0M350 X256 Y256:256 U256 Z256 E256:256 I0 ; Configure microstepping without interpolation

M201 X700 Y700:700 U700 Z15 E800 ; Accelerations (mm/s^2)

M203 X5000 Y5000 U5000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X450 Y450 U450 Z30 E20 ; Maximum jerk speeds mm/minuteM208 X0:276 Y-75:200 U-59:208 Z-10:200 ; Set axis minima:maxima (adjust to suit your machine) x-60:216 u0:250

M92 X2582.48954 Y2593.77082 U2579.6913 Z6546.644 ; Set axis steps/mm

M92 E6592.55:6592.55 ; Set extruder steps per mm

M906 X600 Y700:700 U600 Z500 E1000:1000 I20 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop" ; Set active high endstops

M574 U1 S1 P"e0stop" ; Set active high endstops

M574 Z1 S2 ; Z has no endstop; Disable heaters H3-H7 to free up pins

M950 H3 C"nil"

M950 H4 C"nil"

M950 H5 C"nil"

M950 H6 C"nil"

M950 H7 C"nil"; Z-Probe

;M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F800 T3000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X1.0 Y-31.25 Z1 ; Set Z probe trigger value, offset and trigger height Z+ pousouva osu Z smerem dolu k podlozce (stará tisková hlava X7.9 Y58.8)

M557 X15:195 Y5:175 S20 ; Define mesh grid; Heaters

;M307 H7 A-1 C-1 D-1 ; Disable bang-bang mode for the bed heater and set PWM limit

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C; Hot end - levý

;M305 P1 X200

M308 S1 P"spi.cs1" Y"rtd-max31865" A"EXTRUDER LEVY" ; Configure thermocouple for heater 1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 A361.3, C127.9, D11.9 S1

M143 H1 S400 ; Set temperature limit for heater 1 to 280C; Hot end - pravý

;M305 P2 X201

M308 S2 P"spi.cs2" Y"rtd-max31865" A"EXTRUDER PRAVY" ; Configure thermocouple for heater 2

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 A364.1 C146.0 D4.5 S1.00 V23.8 B0

M143 H2 S300 ; Set temperature limit for heater 2 to 280CM308 S3 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper;M305 P101 X1001 S"Drivers Duet" ; Temperature of drivers Duet

;M305 P102 x1002 S"Drivers Duex5" ; Temperature of drivers Duex5; Fans

M950 F1 C"fan1"

M106 P1 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F0 C"fan0"

M106 P0 H2 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F3 C"duex.fan3"

M106 P3 H-1 C"Chlazeni levy"

M950 F4 C"duex.fan4"

M106 P4 H-1 C"Chlazeni pravy"

M950 F5 C"duex.fan5"

M106 P5 T32:40 H100:101:102 C"Duet Fan" ;cooling fan that starts to turn on when the MCU temperature (virtual heater 100) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 101 and 102) report that they are over-temperature; Tools

M563 P0 D0 H1 X3 F3 ; Define tool 0

G10 P0 X0 Y0 U0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0.05 U9.6 Z0.4 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C;Pressure advance

;M572 D0:1 S0.05:0.05; Automatic saving after power loss is not enabled

; Custom settings are not configured

Here is my homeall.g:

; homeall.g

; called to home all axesG91 ; relative positioning

G1 Z5 F6000 H2 ; lift Z relative to current position

G1 H1 X515 Y515 U-515 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 X-5 Y-5 U5 F6000 ; go back a few mm

G1 H1 X215 Y215 U-215 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X100 Y100 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bedHere is my homez.g:

; homez.g

; called to home the Z axisG91 ; relative positioning

G1 Z5 F6000 H2 ; lift Z relative to current position

G90 ; absolute positioning

T1

G1 X100 Y100 F6000 ; go to first probe point

G30 ; home Z by probing the bedHere is my deployprobe.g:

; deployprobe.g

; called to deploy a physical Z probe

M280 P0 S10Here is my retractprobe.g:

; retractprobe.g

; called to retract a physical Z probe

;

M280 P0 S90I do not know, what is wrong. Can you help me please?

Thank you very much.

-

RE: BLtouch with Reprap Firmware 3.0posted in Tuning and tweaking

Hello,

today I tried upgrade firmware on my Duet Wifi from 2.05.1 to 3.01RC6. Upgrade was successfull but unfortunately my BL Touch not work after upgrade.I connected BL TOUCH according to this manual:

https://betrue3d.dk/bltouch-on-duet-wifi-configuratio-and-usage/With FW version 2.05.1 BL TOUCH worked OK. I understand that I must edit config.g, deployprobe.g, retractprobe.g and home files. I did it, but BL TOUCH not work. After power on BL TOUCH did self test, but thats all. Commands M401, M402 or M280 from console not work and homez and home all not work too.

Here is my config.g:

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Fri Feb 01 2019 23:24:57 GMT+0100 (Středoevropský standardní čas); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P1 ; Set firmware compatibility to look like RepRapFirmare; Network

M550 PZBox Mk. I ; Set machine name

M552 S1 ; Enable network

M587 S"kluci" P"" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disable TelnetM584 X0 Y1:6 Z2 U5 E3:4 ; Create U axis for second X carriage before we try to configure it

; Drives

M569 P0 S1 D2 ; Drive 0 goes forwards

M569 P1 S0 D2 ; Drive 1 goes forwards

M569 P2 S0 D2 ; Drive 2 goes forwards

M569 P3 S1 D2 ; Drive 3 goes forwards

M569 P4 S0 D2 ; Drive 4 goes forwards

M569 P5 S0 D2 ; Drive 5 goes forwards

M569 P6 S1 D2 ; Drive 5 goes forwards; Laser sensor

M591 D0 P5 C"zstop" R5:130 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D0 ; display filament sensor parameters for extruder drive 0

M591 D1 P5 C"e1stop" R15:250 E6.0 S1 ; Duet3D laser sensor for extruder drive 0 is connected to endstop input 3 (E0), tolerance 40 to 120%, 3mm comparison length

M591 D1 ; display filament sensor parameters for extruder drive 0M350 X256 Y256:256 U256 Z256 E256:256 I0 ; Configure microstepping without interpolation

M201 X700 Y700:700 U700 Z15 E800 ; Accelerations (mm/s^2)

M203 X5000 Y5000 U5000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X450 Y450 U450 Z30 E20 ; Maximum jerk speeds mm/minuteM208 X0:276 Y-75:200 U-59:208 Z-10:200 ; Set axis minima:maxima (adjust to suit your machine) x-60:216 u0:250

M92 X2582.48954 Y2593.77082 U2579.6913 Z6546.644 ; Set axis steps/mm

M92 E6592.55:6592.55 ; Set extruder steps per mm

M906 X600 Y700:700 U600 Z500 E1000:1000 I20 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop" ; Set active high endstops

M574 U1 S1 P"e0stop" ; Set active high endstops

M574 Z1 S2 ; Z has no endstop; Disable heaters H3-H7 to free up pins

M950 H3 C"nil"

M950 H4 C"nil"

M950 H5 C"nil"

M950 H6 C"nil"

M950 H7 C"nil"; Z-Probe

;M307 H7 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F800 T3000 ; Set Z probe type to bltouch and the dive height + speeds

G31 P25 X1.0 Y-31.25 Z1 ; Set Z probe trigger value, offset and trigger height Z+ pousouva osu Z smerem dolu k podlozce (stará tisková hlava X7.9 Y58.8)

M557 X15:195 Y5:175 S20 ; Define mesh grid; Heaters

;M307 H7 A-1 C-1 D-1 ; Disable bang-bang mode for the bed heater and set PWM limit

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C; Hot end - levý

;M305 P1 X200

M308 S1 P"spi.cs1" Y"rtd-max31865" A"EXTRUDER LEVY" ; Configure thermocouple for heater 1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 A361.3, C127.9, D11.9 S1

M143 H1 S400 ; Set temperature limit for heater 1 to 280C; Hot end - pravý

;M305 P2 X201

M308 S2 P"spi.cs2" Y"rtd-max31865" A"EXTRUDER PRAVY" ; Configure thermocouple for heater 2

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 A364.1 C146.0 D4.5 S1.00 V23.8 B0

M143 H2 S300 ; Set temperature limit for heater 2 to 280CM308 S3 Y"drivers" A"DRIVERS" ; configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet

M308 S4 Y"mcu-temp" A"MCU" ; configure sensor 3 as thermistor on pin e1temp for left stepper;M305 P101 X1001 S"Drivers Duet" ; Temperature of drivers Duet

;M305 P102 x1002 S"Drivers Duex5" ; Temperature of drivers Duex5; Fans

M950 F1 C"fan1"

M106 P1 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F0 C"fan0"

M106 P0 H2 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on

M950 F3 C"duex.fan3"

M106 P3 H-1 C"Chlazeni levy"

M950 F4 C"duex.fan4"

M106 P4 H-1 C"Chlazeni pravy"

M950 F5 C"duex.fan5"

M106 P5 T32:40 H100:101:102 C"Duet Fan" ;cooling fan that starts to turn on when the MCU temperature (virtual heater 100) reaches 45C and reaches full speed when the MCU temperature reaches 65C or if any TMC2660 drivers (virtual heaters 101 and 102) report that they are over-temperature; Tools

M563 P0 D0 H1 X3 F3 ; Define tool 0

G10 P0 X0 Y0 U0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0.05 U9.6 Z0.4 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C;Pressure advance

;M572 D0:1 S0.05:0.05; Automatic saving after power loss is not enabled

; Custom settings are not configured

Here is my homeall.g:

; homeall.g

; called to home all axesG91 ; relative positioning

G1 Z5 F6000 H2 ; lift Z relative to current position

G1 H1 X515 Y515 U-515 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 X-5 Y-5 U5 F6000 ; go back a few mm

G1 H1 X215 Y215 U-215 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X100 Y100 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bedHere is my homez.g:

; homez.g

; called to home the Z axisG91 ; relative positioning

G1 Z5 F6000 H2 ; lift Z relative to current position

G90 ; absolute positioning

T1

G1 X100 Y100 F6000 ; go to first probe point

G30 ; home Z by probing the bedHere is my deployprobe.g:

; deployprobe.g

; called to deploy a physical Z probe

M280 P0 S10Here is my retractprobe.g:

; retractprobe.g

; called to retract a physical Z probe

;

M280 P0 S90I do not know, what is wrong. Can you help me please?

Thank you very much.

-

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

Thank you very much for your idea. I do little improvement on bearings I put there black heat shrink tube. Between bearings and heat shrink tube I put chemoprene glue and everythink works fine. Surface is black and scanning is stable:

Duet3D laser filament monitor v1 on input 4, enabled, allow 15% to 250%, check every 6.0mm, version 1, measured min 154% avg 166% max 174% over 6397.2mm

This values are stable for all materials which I tested yet.

-

RE: DWC 2.02 - Estimated End Time missingposted in Duet Web Control

I have version DWC 2.07 and Estimated End Time still missing. Is it possible, bring this back, please? Thank you.

-

Duet 2 Wifi - connection and settings aqua cooling kitposted in Duet Hardware and wiring

Hello,

I have question about wiring and settings in firmware for Aqua cooling kit from alliexpress:Is it possible connect into the Duet 2 Wifi? I am not sure, because this kit has 4 pins:

Thank you for your answer.

Best regards Radek