@droftarts Firmware version is 3.4.5

Here is the M122 response

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.5 (2022-11-30 19:36:12) running on Duet WiFi 1.02 or later

Board ID: 0JD2M-9F8TA-GJ4TD-6J9FG-3S86N-1RPG6

Used output buffers: 8 of 26 (26 max)

=== RTOS ===

Static ram: 23836

Dynamic ram: 76316 of which 388 recycled

Never used RAM 8180, free system stack 110 words

Tasks: NETWORK(notifyWait,35.8%,242) HEAT(notifyWait,3.2%,165) Move(notifyWait,0.6%,268) MAIN(running,59.2%,421) IDLE(ready,1.1%,30), total 100.0%

Owned mutexes: WiFi(NETWORK)

=== Platform ===

Last reset 70:58:01 ago, cause: software

Last software reset at 2025-04-25 12:15, reason: User, GCodes spinning, available RAM 9228, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00417000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x0c

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 28.3, current 30.4, max 35.9

Supply voltage: min 23.6, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/8, heap memory allocated/used/recyclable 2048/124/58, gc cycles 1

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0

Driver 1: standstill, SG min 0

Driver 2: standstill, SG min 0

Driver 3: standstill, SG min 0

Driver 4: standstill, SG min n/a

Driver 5:

Driver 6:

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2025-04-28 11:13:20

Cache data hit count 4294967295

Slowest loop: 205.61ms; fastest: 0.12ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.9ms, write time 19.6ms, max retries 0

=== Move ===

DMs created 83, segments created 21, maxWait 235090516ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 224, completed 224, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.0

Heater 1 is on, I-accum = 0.5

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== Network ===

Slowest loop: 51.88ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

= WiFi =

Network state is active

WiFi module is providing access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.27

WiFi MAC address 46:17:93:34:19:50

WiFi Vcc 3.35, reset reason Power up

WiFi flash size 2097152, free heap 23432

WiFi IP address 192.168.1.114

Connected clients 1

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

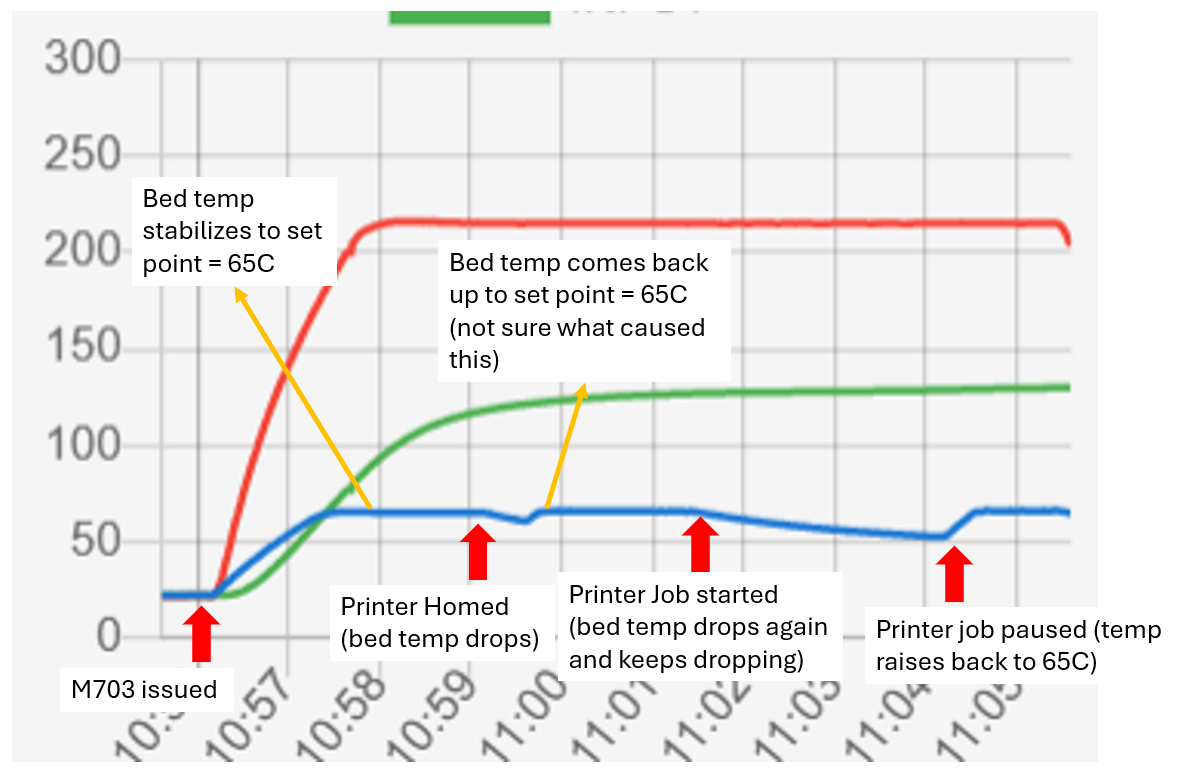

When I send M140 when job is running, I get

Bed heater 0 (slot 0) is currently at 62.4°C

At this point the temp has already dropped from 65C - which is the setpoint for the bed.

Below temperature graph shows the same - Blue line is the bed temperature

The pause.g is below

; pause.g

; called when a print from the SD card is paused

M83 ; Set extruder to relative mode

G1 E-5 F6000 ; Move

G91 ; Set to Relative Positioning

G1 Z1 F360 ; Move

G90 ; Set to Absolute Positioning

G1 F6000 X{move.axes[0].min} Y{move.axes[1].min} Z{move.axes[2].max} ; Move

M107 ; Fan Off

set global.dato0 = job.duration

echo >"0:/data/temp" ";Recorded Temperature" ; Echo command

echo >>"0:/data/temp" "G10 P0 S"^heat.heaters[1].active^":"^heat.heaters[2].active^" R"^heat.heaters[1].standby^":"^heat.heaters[2].standby ; Echo command

The 0:/data/temp contains

G10 P0 S0.0:0.0 R0.0:0.0

And eventually, after a while I get an error message