I started by trying to go through the upgrade steps for firmware as recommended.

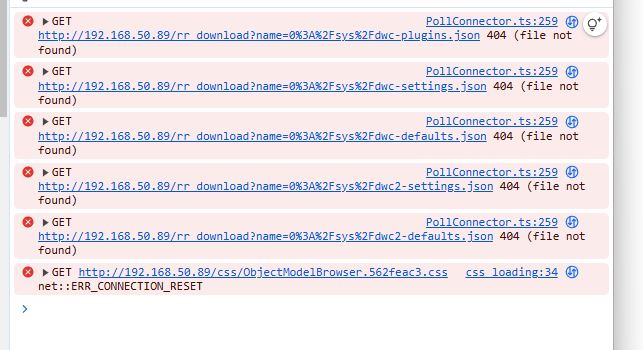

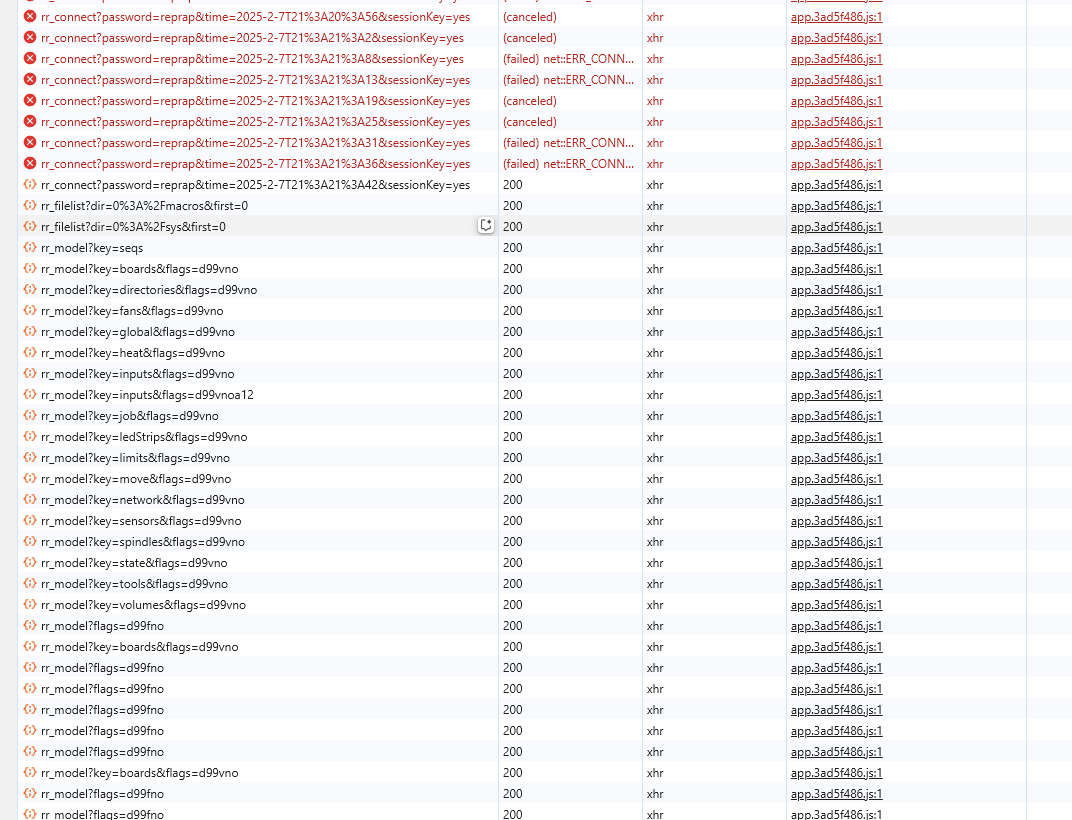

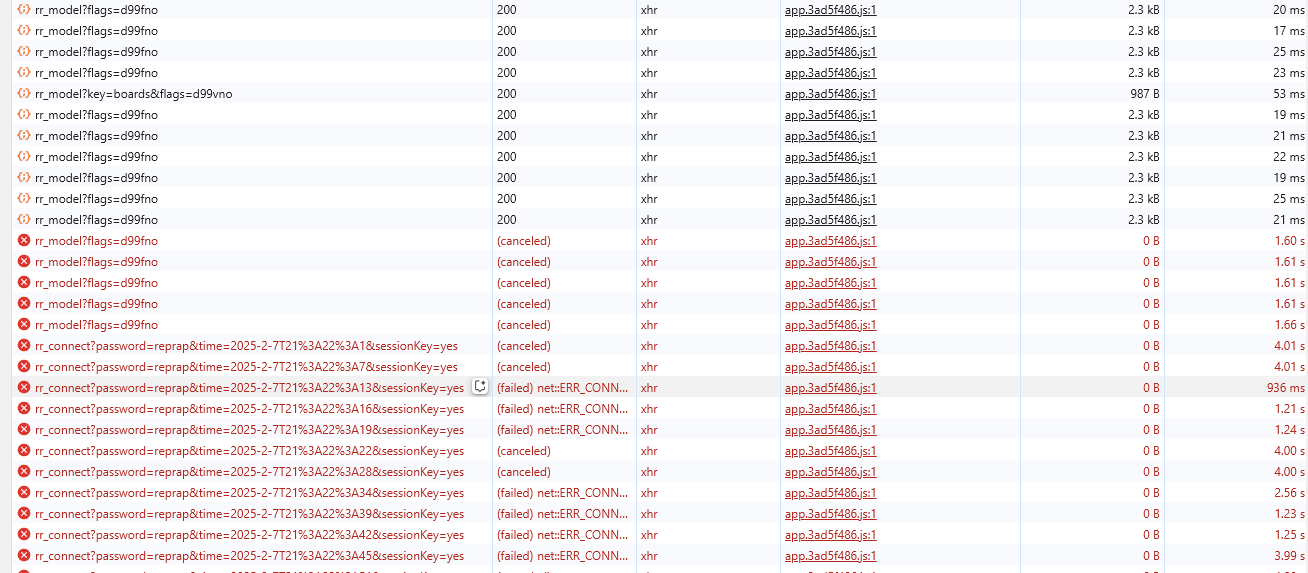

I continued to have an issue where I couldn't stay connected to DWC.

I eventually found myself down to fallback #2.

I was able to flash 3.5.4 successfully via that method.

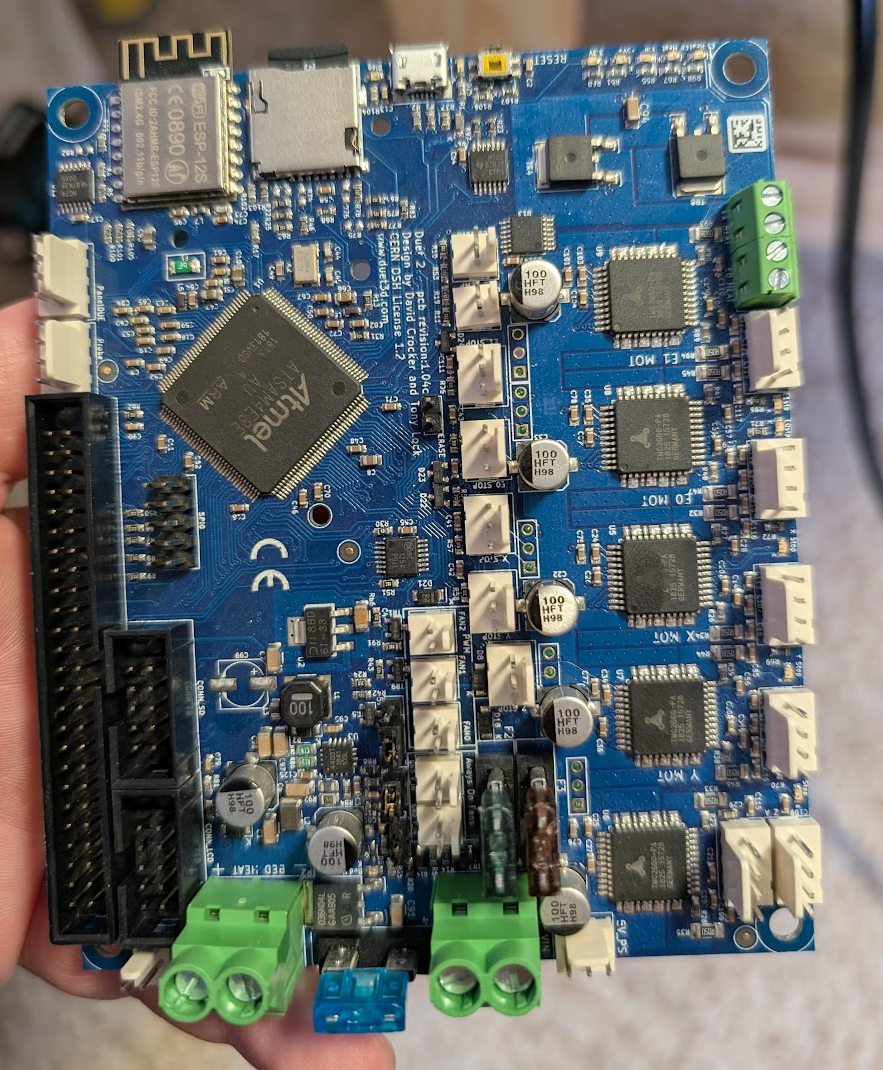

M115 spits out

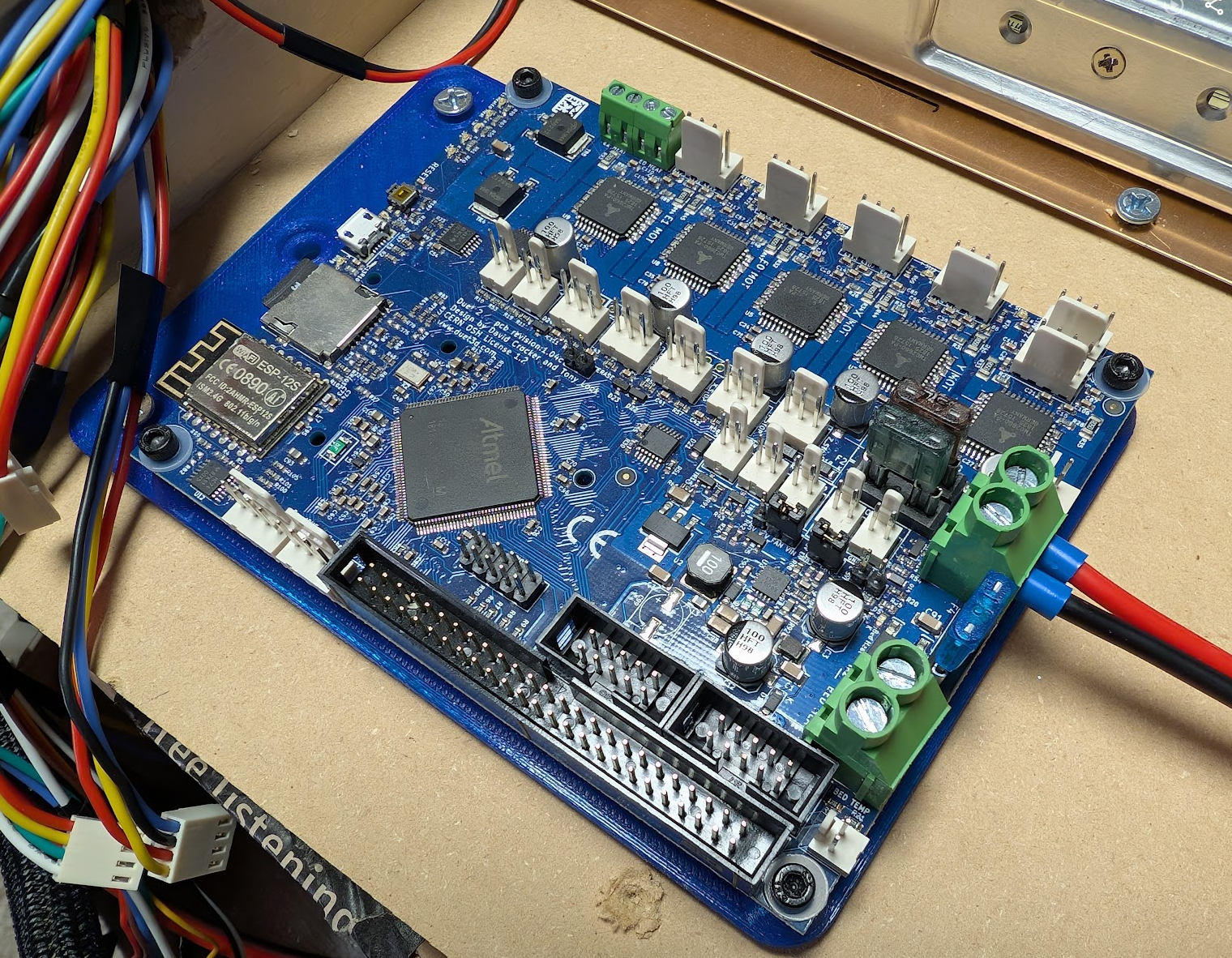

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.5.4 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2024-11-24 10:43:42

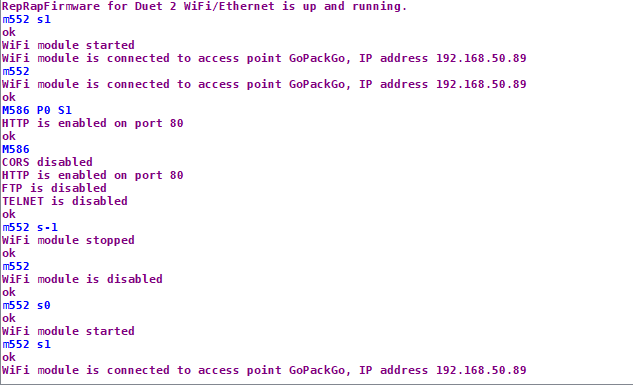

I ran M122 and saw the wifi module is disabled. Fine.

M552 S0.

ok

WiFi module is started

I noticed my blue light never came on and it never connects to anything.

I ran a M587 and can see my networks.

Remembered networks:

TNCAP2FCC19 IP=192.168.1.14 GW=0.0.0.0 NM=0.0.0.0

GoPackGo IP=0.0.0.0 GW=0.0.0.0 NM=0.0.0.0

GoPackGoGuest IP=0.0.0.0 GW=0.0.0.0 NM=0.0.0.0

Ok...

So I thought maybe I should look at fallback #1.

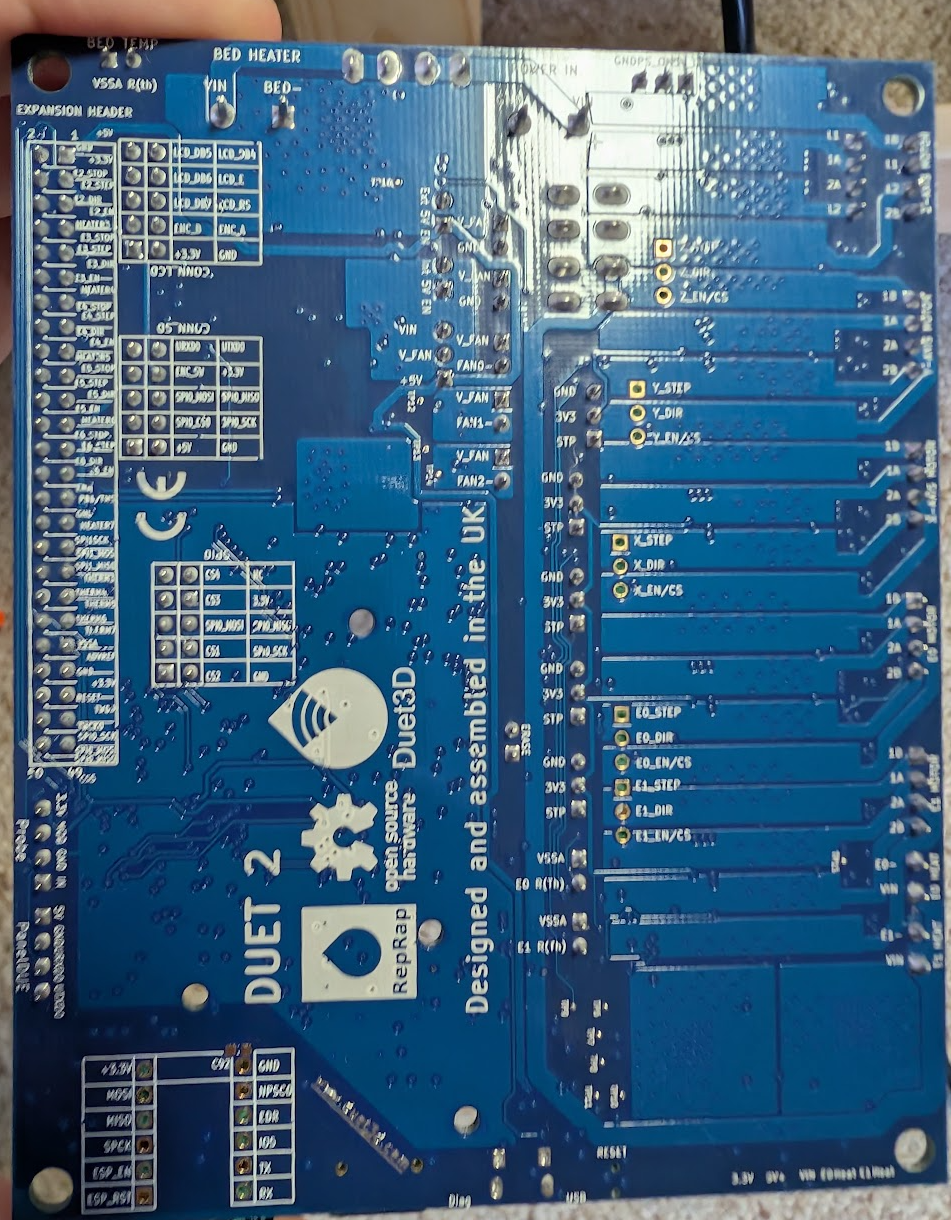

I've got the SD card set up with a firmware folder containing only Duet2CombinedFirmware.bin and DuetWiFiServer.bin. Then in the sys folder I only have Duet2_SDiap32_WiFiEth.bin. The other folders exist and I put the contents of DWC.zip into the www folder. Looks similar to my backup card, but with less stuff in sys.

I ran m997 s1

Trying to connect at 230400 baud: success, found ESP8266

Erasing 8192 bytes...

Erasing 690688 bytes...

Uploading file...

5% complete

10% complete

15% complete

20% complete

25% complete

30% complete

35% complete

40% complete

45% complete

50% complete

55% complete

60% complete

65% complete

70% complete

75% complete

80% complete

85% complete

90% complete

95% complete

Upload successful

ok

The blue light had a faint flicker so I figured ok that must have worked.

M552 S0 and no light, just ok wifi module started.

So I found a command to enable debugging. M111 S1 P14.

I did an M552 S-1

WiFi module stopped

ok

Followed by another M552 S0.

m552 s0

WiFi:

WiFi: ets Jan 8 2013,rst cause:2, boot mode:(3,6)

WiFi:

WiFi: load 0x40100000, len 5548, room 16

WiFi: tail 12

WiFi: chksum 0xf7

WiFi: ho 0 tail 12 room 4

WiFi: load 0x3ffe8008, len 24, room 12

WiFi: tail 12

WiFi: chksum 0x1e

ok

WiFi: ho 0 tail 12 room 4

WiFi: load 0x3ffe8020, len 2412, room 12

WiFi: tail 0

WiFi: chksum 0x2a

WiFi: csum 0x2a

WiFi: phy_version: 1163.0, 665d56c, Jun 24 2020, 10:00:08, RTOS new

WiFi module started

ESP reported status change

ESP reported status change

Wondering where I've gone wrong. I noticed that in the SD Card docs (can't post link due to rep) it says the Duet2_SDiap32_WiFiEth.bin should be in the firmware folder and says nothing about the DuetWiFiServer.bin file.

Hoping I'm closer after that infuriating DWC disconnect mess. I understand that the issue may be related to my network. GoPackGo is 5Ghz/2.4Ghz with a different router than I had previously. I was hoping I could maybe try to connect to GoPackGoGuest which is strictly 2.4Ghz and used for other IoT devices in my house.