Found the problem, the Modix crash detector is a magnetic sensor and when

triggered it sends the same Emergency Stop that we were getting mid print. Even the one 20 min into the print. My guess is a faulty crash sensor, running

like normal now that it is temp. bypassed.

Best posts made by Sculpt Fabricator

-

RE: Automatic Emergency Stopposted in Duet Hardware and wiring

-

Connecting PT100 to Bed Tempposted in Duet Hardware and wiring

We currently have a self contained high voltage bed heater that uses a TCN4 that controls and displays bed temperature and does not connect to our duet wifi board. We had originally drilled a thermistor into the side of the bed and hooked to the Bed Temp input on the duet wifi board to be able to get some visual on the computer that the bed was on and working, but the temperature is not close to being correct.

The TCN4 uses a PT100 to read the bed temperature. We hoped we could connect to this at the TCN4 input and hook to the Bed Temp input of the duet wifi board and get an accurate reading, but we are getting around 540C reading when off and the ambient is around 23C

After some research I see that the PT100 needs an adapter board like we have on our two extruder PT100's but not sure how one would plug into the Bed Temp location, if this is even the issue, or maybe just a setting, any help would be much appreciated.We are running Duet WiFi 1.02 or later + DueX5 version 2.05 (2019-12-13b1)

M305 P0 T100000 ; Set thermistor + ADC parameters for bed heat

Sorry, I tried to upload some pictures of what we had but keep getting an error !

-

RE: Connection lost, attempting to reconnectposted in Duet Hardware and wiring

@phaedrux we actually followed the

Fallback procedure #1 and got it back up and running again, thank you for your help -

RE: Automatic Emergency Stopposted in Duet Hardware and wiring

@droftarts

The SD card was really full we deleted everything out of it. I will look into

that more

Latest posts made by Sculpt Fabricator

-

RE: Print auto-paused due to low voltageposted in Duet Hardware and wiring

@dc42 I found the problem.

We moved the power plug to the front of the machine so we could get to it.

there is a plug at the switch at burnt up.Thank you very much for your help

-

RE: Print auto-paused due to low voltageposted in Duet Hardware and wiring

just happened again

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.5.3 (2024-09-18 11:25:32) running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DLM-996RU-N85T0-6J1D4-3SJ6K-TAVZR Used output buffers: 3 of 26 (22 max) === RTOS === Static ram: 23376 Dynamic ram: 73956 of which 12 recycled Never used RAM 12728, free system stack 104 words Tasks: NETWORK(1,ready,19.5%,217) HEAT(3,nWait 5,0.1%,307) Move(4,nWait 5,1.9%,298) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,78.5%,744) IDLE(0,ready,0.1%,29), total 100.0% Owned mutexes: === Platform === Last reset 02:40:47 ago, cause: software Last software reset at 2025-04-28 15:08, reason: User, Gcodes spinning, available RAM 13312, slot 1 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 MCU temperature: min 29.0, current 31.4, max 33.6 Supply voltage: min 21.1, current 22.9, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/14, heap memory allocated/used/recyclable 2048/256/24, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min n/a Driver 3: standstill, SG min 0 Driver 4: standstill, SG min n/a Driver 5: standstill, SG min 0 Driver 6: standstill, SG min 0 Driver 7: standstill, SG min 0 Driver 8: standstill, SG min 0 Driver 9: standstill, SG min 0 Driver 10: Driver 11: Date/time: 2025-04-28 17:49:42 Cache data hit count 4294967295 Slowest loop: 261.02ms; fastest: 0.14ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 9 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 13.7ms, write time 123.9ms, max retries 0 === Move === DMs created 83, segments created 23, maxWait 1361375ms, bed compensation in use: mesh, height map offset 0.130, max steps late 0, min interval 0, bad calcs 0, ebfmin -0.00, ebfmax 1.00 no step interrupt scheduled Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0 === DDARing 0 === Scheduled moves 70570, completed 70570, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1 === Heat === Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.3 === GCodes === Movement locks held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is doing "G1 X253.730 Y259.100 E0.89922" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Q0 segments left 0 Code queue 0 is empty === Filament sensors === check 17248501 clear 13476390 Extruder 0 sensor: ok === DueX === Read count 0, 0.00 reads/min === Network === Slowest loop: 139.89ms; fastest: 0.07ms Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.1.0 MAC address ec:fa:bc:5b:41:b9 Module reset reason: Turned on by main processor, Vcc 3.38, flash size 4194304, free heap 42392 WiFi IP address 192.168.5.247 Signal strength -64dBm, channel 11, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

RE: Print auto-paused due to low voltageposted in Duet Hardware and wiring

@dc42 I did check that last time I ended up replacing the power supply.

I will check it again though. We are using Ferrules -

RE: Print auto-paused due to low voltageposted in Duet Hardware and wiring

I am having the same problem, out of the blue every other print "Print Auto-Paused due to Low Voltage" I thought I had it fixed after swapping power supply and finding a burned connector on one

of z motors. I have a UPS battery backup on this machine for several years, also replaced the battery in it a month ago.Duet2 wifi and Duex5 firmware 3.5.3

Config G-

; General preferences_________________________________________________________ G21 ; dimentions in mm G90 ; for X,Y,Z use absolute coordinate values M83 ; for E0,E1,etc use relative coordinate values M111 S0 ; Debug off M555 P2 ; Set output to look like Marlin M575 P0 B57600 S2 ; communication parameters for USB serial M575 P1 B57600 S1 ; Set auxiliary serial port baud rate and require checksum (for PanelDue) ; Network_____________________________________________________________________ M550 P"Big 60" ; set printer name M552 S1 ; enable (S1) networking (WiFi) M586 S1 P1 ;T0 ; enable (S1) FTP (P1) Disable TLS (T0) M586 S1 P2 ;T0 ; enable (S1) Telnet (P2) Disable TLS (T0) ; mode control variables _____________________________________________________ ;global g_probe_z_trigger = 1.745 ; default - set as appropriate for the Z probe global g_z_home = 5 ; can be used to always move Z to known height global g_z_datum_set = false ; can be used to prevent unneeded setting of Z=0 datum global g_map_mode = "300 point" ; determines which kind of height map is created/loaded global g_probe_mode = "two consecutive" ; determines if z proving used consecutive or averaging global g_level_mode = "4 point" ; determines if 3 or 4 points are used for leveling global g_print_beg_prime = 10 ; default - set desired in filament config.g global g_print_beg_retract = 0 ; default - set desired in filament config.g global g_print_end_retract = 0 ; default - set desired in filament config.g global g_print_end_mode = "heat off" ; determines if heaters are turned off when print is done ; Drives_________________________________________________________________________ ;Main board______________________________________________________________________ M569 P0 S0 ; Physical drive 0 . X1 labled "X motor" M569 P1 S1 ; Physical drive 1 . X2 labled "Y motor" M569 P2 S0 ; Physical drive 2 . Disabled stacked on end of board labled "Z motors" M569 P3 S0 ; Physical drive 3 . Main Extruder labled "E0 motor" M569 P4 S0 ; Physical drive 4 . Disabled next to E0 E1 Heaters labled "E1 motor" ;Duex5 board_____________________________________________________________________ M569 P5 S0 ; Physical drive 5 . Y M569 P6 S0 ; Physical drive 6 . Z1 RF (678.59, -75.73) M569 P7 S0 ; Physical drive 7 . Z2 LF (-169, -75.73) M569 P8 S0 ; Physical drive 8 . Z3 LR (-169, 652.6) M569 P9 S0 ; Physical drive 9 . Z4 RR (678.59, 652.6) ;Motor to stepper motor driver mapping__________________________ M584 X0:1 Y5 Z6:7:8:9 E3 P3 ; Driver mapping M671 X678.59:-169:-169:678.59 Y-75.73:-75.73:652.6:652.6 S10.5 ; position of leadscrew/bed pivot point at RF, LF, LR, RR ;Motor settings and acceleration limits_____________________________________________ M350 X16 Y16 E16 I1 ; Configure microstepping with interpolation M350 Z16 I0 ; Configure microstepping without interpolation M92 X100.00 Y100.00 Z2000.00 E431.07 ; Set steps per mm M566 X360 Y360 Z30.00 E300.00 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z400.00 E7200.00 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z200.00 E5000.00 ; Set accelerations (mm/s^2) M204 P500 T1000 ; Set print and travel accelerations (mm/s^2) M906 X1800 Y1800.00 E800 I40 ; Set motor currents (mA) and motor idle factor in per cent M906 Z2300.00 I50 ; Set motor currents (mA) and motor idle factor in per cent M84 S100 ; Set idle timeout - 100 seconds ; Axis Limits M208 X0:600 Y0:575 Z-.5:630 ; set axis minima and maxima ; Endstops M574 X1 S1 P"xstop + e0stop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ; Z-Probe M98 P"config_probe.g" M556 S50 X0 Y0 Z0 ; set orthogonal axis compensation parameters M376 H20 ; stop z-leveling after 20 layers ; Bed Heaters___________________________________________________________ ;;M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp ;;M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 ;;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit ;;M140 H0 ; map heated bed to heater 0 ;;M143 H0 S120 ; set temperature limit for heater 0 to 120C M140 H-1 ; disable heated bed (overrides default heater mapping) ;E0_________________________________________________________________ M308 S1 P"spi.cs1" Y"rtd-max31865" A"Lower Main Extruder" ; This is the sensor closest to the nozzle. It controls the heaters. PRIME HOT END Red heat shrink M308 S2 P"spi.cs2" Y"rtd-max31865" A"1st backup Extruder" ; This is a backup sensor. PRIME HOT END Brwn heat shrink M308 S4 P"spi.cs4" Y"rtd-max31865" A"2nd backup Extruder" ; This is a backup sensor. PRIME HOT END Yel/Grn heat shrink M950 H0 C"e0heat+e1heat" T1 ; Creates a heater by combining the 2 heater inputs as 1 logical heater that is controlled by 1 sensor M307 H0 B0 S1.0 ; Disable bang-bang mode for heater and set PWM limit M307 H0 R1.682 K0.131:0.000 D11.65 E1.35 S1.00 B0 V22.7 ; PID tuning at 300C (You will want to run this on your own) M570 H0 P180 ; Hotend may be a little slow to heat up so allow it 180 seconds M143 H0 S450 ; Set temperature limit for heater 0 to 450C (Change this to your maximum value) M143 H0 P1 S460 T2 A0 ; Set temperature monitor limit to 450C for sensor 2 M143 H0 P2 S460 T4 A0 ; Set temperature monitor limit to 450C for sensor 4 ; Fans & LED___________________________________________________________ M950 F0 C"fan0" Q2000 ; create fan 0 on pin fan0 and set its frequency M42 P1 S0.2 ; set 20% PWM on GPIO port 1 M106 P0 C"CPAP Fan" S0 B0.1 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency ;M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create air filter fan on fan 2 on pin fan2 and set its frequency M106 P2 C"Filter Fan" S0 H-1 ; set fan 2 value. Thermostatic control is turned on M950 F7 C"!duex.fan7" Q500 ; create LED on pin fan7 and set its frequency M106 P7 S0 H-1 ; Disable fan channel for LED M106 P7 S255 ; remove ";" to set the LED to full brightness by default M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin fan3 and set its frequency M106 P3 S1 H-1 ; set fan 3 value. Thermostatic control is turned on Bed relay to on ; Tools______________________________________________________________ ;T0_________________________________________________________________ M563 P0 S"E0 Main" D0 H0 F0 ; define tool, tool 0 usees extruder 0, Heater 0, fan 0 PRIME HOT END G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets PRIME HOT END G10 P0 R0 S265 ; set initial tool 0 active and standby temperatures to 0C PRIME HOT END ;T1_________________________________________________________________ ;T2____________________________________________________________________ ;T3___________________________________________________________________ ; Custom settings__________________________________________________ ;M950 J0 C"exp.e2stop" ;M581 T1 P0 S0 R1 M591 D0 P7 C"e1stop" S1 L3.2 E10 R10:1000 ; Clog Detector E0 [Add-On] M42 P2 S255 ; Start up air filter ; Automatic power saving____________________________________________ M911 S21.1 R29.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss. Power Failure Pause``` M122M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.5.3 (2024-09-18 11:25:32) running on Duet WiFi 1.02 or later + DueX5

Board ID: 08DLM-996RU-N85T0-6J1D4-3SJ6K-TAVZR

Used output buffers: 10 of 26 (22 max)

=== RTOS ===

Static ram: 23376

Dynamic ram: 73900 of which 12 recycled

Never used RAM 13336, free system stack 186 words

Tasks: NETWORK(1,ready,13.6%,217) HEAT(3,nWait 5,0.1%,328) Move(4,nWait 5,0.0%,357) DUEX(5,nWait 5,0.0%,23) MAIN(1,running,83.0%,744) IDLE(0,ready,3.3%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:00:22 ago, cause: software

Last software reset at 2025-04-28 15:08, reason: User, Gcodes spinning, available RAM 13312, slot 1

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 28.8, current 29.3, max 29.6

Supply voltage: min 24.0, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/13, heap memory allocated/used/recyclable 2048/220/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a

Driver 1: standstill, SG min n/a

Driver 2: standstill, SG min n/a

Driver 3: standstill, SG min n/a

Driver 4: standstill, SG min n/a

Driver 5: standstill, SG min n/a

Driver 6: standstill, SG min n/a

Driver 7: standstill, SG min n/a

Driver 8: standstill, SG min n/a

Driver 9: standstill, SG min n/a

Driver 10:

Driver 11:

Date/time: 2025-04-28 15:09:17

Cache data hit count 832331944

Slowest loop: 7.00ms; fastest: 0.19ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.5ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Q0 segments left 0

Code queue 0 is empty

=== Filament sensors ===

check 0 clear 85620

Extruder 0 sensor: no data received

=== DueX ===

Read count 1, 2.67 reads/min

=== Network ===

Slowest loop: 36.87ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 2 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.1.0

MAC address ec:fa:bc:5b:41:b9

Module reset reason: Turned on by main processor, Vcc 3.38, flash size 4194304, free heap 42568

WiFi IP address 192.168.5.247

Signal strength -72dBm, channel 11, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0 -

RE: Duet temperature chart reading not smooth, spikyposted in General Discussion

its fine now 35 layers into the print

Is there a style of connector that people like for these sensors, I am using JST SM connectors.

-

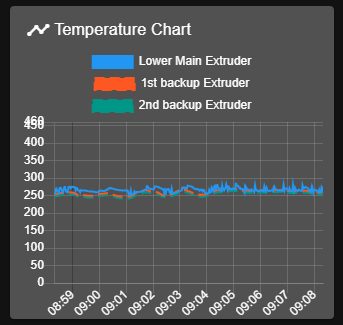

RE: Duet temperature chart reading not smooth, spikyposted in General Discussion

@droftarts and @jay_s_uk

Thanks for the info, I just broke down the hot end and check the wires at the top of the sensors.

If it was interference wouldn't all three sensors be doing the same thing. They are all running the same

route to the daughter boards.they are all two wire sensors, non shielded wiring.

after braking it down they are all smoothed out. we will see if it comes back when we start printing.

-

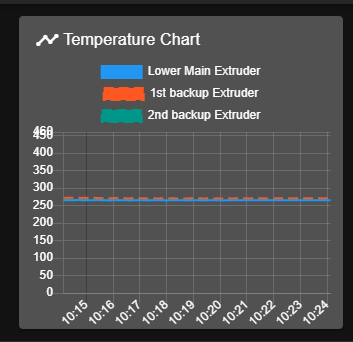

Duet temperature chart reading not smooth, spikyposted in General Discussion

I have a new hot end that has 3 Pt100 sensors and the main sensor started getting

a really spiky, fluctuating, reading.

Would this be a sensor problem. or connection problem ?

-

RE: Daughter Board Sensor Positionposted in Duet Hardware and wiring

@droftarts Exactly what I was looking for, makes sense now, Thank you

-

RE: 3 Temp sensors on one toolposted in General Discussion

@jay_s_uk M593 configure input shaping ?