Hello all,

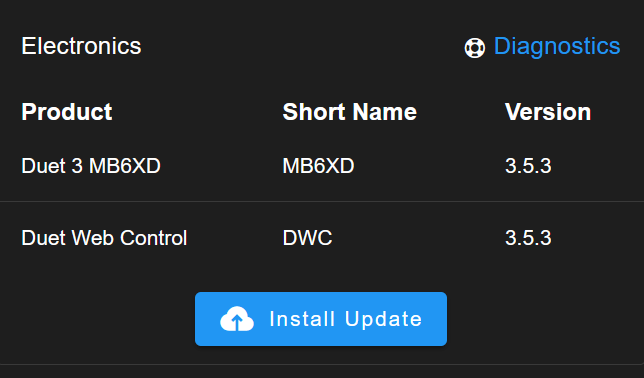

I updated from 3.4.5 to 3.5.3 and instantly had HTTP dropouts every 20-40 sec.

Running a 6XD on ethernet, so not used to having dropout issues.

I downloaded the firmware from github and updated via the web interface, had issues, then downloaded the DuetWebControl-SD and also updated, still the same issues.

Also cleared browser cache in desperation.

shows as updated

Not sure what to do next.

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6XD version 3.5.3 (2024-09-18 11:27:56) running on Duet 3 MB6XD v1.0 (standalone mode)

Board ID: 08DLM-956DA-M2NS4-6J1FD-3S06Q-9A26S

Used output buffers: 1 of 40 (36 max)

=== RTOS ===

Static ram: 153760

Dynamic ram: 135120 of which 0 recycled

Never used RAM 54256, free system stack 198 words

Tasks: NETWORK(1,ready,35.0%,172) ETHERNET(5,nWait 7,0.2%,316) HEAT(3,nWait 6,0.0%,355) Move(4,nWait 6,0.0%,335) CanReceiv(6,nWait 1,0.0%,939) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,339) MAIN(1,running,64.5%,128) IDLE(0,ready,0.2%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:22:18 ago, cause: power up

Last software reset at 2024-10-26 10:29, reason: User, Gcodes spinning, available RAM 57424, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

MCU temperature: min 25.0, current 32.8, max 33.4

Supply voltage: min 24.0, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 11.9, current 12.1, max 14.8, under voltage events: 0

Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/352/352, gc cycles 0

Events: 4 queued, 4 completed

Driver 0: ok

Driver 1: ok

Driver 2: ok

Driver 3: ok

Driver 4: ok

Driver 5: ok

Date/time: 2024-10-26 11:18:25

Slowest loop: 850.08ms; fastest: 0.07ms

=== Storage ===

Free file entries: 20

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 150.0ms, write time 136.4ms, max retries 0

=== Move ===

DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x0000000

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 6692, received 0, lost 0, errs 6318399, boc 0

Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 50 (min 50), ts 6692/0/0

Tx timeouts 0,0,6691,0,0,0 last cancelled message type 30 dest 127

=== Network ===

Slowest loop: 137.33ms; fastest: 0.03ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8

= Ethernet =

Interface state: active

Error counts: 0 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0

=== Multicast handler ===

Responder is inactive, messages received 0, responses 0

Anyone having this issue? It is quite debilitating.