I run flexion extruders on 3 of my older printers, but flexion are no longer around. The newest printer is using the lgx mosquito. Has the shortest filament path is what you want for the soft filaments

Posts made by SJI

-

RE: Extruder for flexible filamentsposted in 3D Printing General Chat

-

RE: [3.4.6+SBC] DWC - "Object Height" issue/bug?posted in Duet Web Control

@oozeBot I've noticed the same with simplify 3d v5 lately on rrf 3.5rc2. Not all gcode files but a few. I thought initially it was S3D causing it

-

RE: Can I edit Gcode in DWCposted in General Discussion

What is the size limit for g code files in dwc

-

RE: Strange Extruder Behavior 1LCposted in General Discussion

I've just completed a 23hr print with a 1lc, but I'm having to print at slower speeds as I'm using soft tpu.

My chamber and 1lc temps are low.

IMHO, With the current issues around the 1lc I wonder if it's a print speed related. I'm no software guru, it's just a hunch -

RE: spamposted in General Discussion

I thought the bots took care of the spam filtering. 33 posts from him. Everyone is entitled to a sick day.

-

RE: Did I just fried the 1LC Toolboardposted in General Discussion

@dc42 said in Did I just fried the 1LC Toolboard:

@SJI it sounds to me that the 3.3V regulator on the tool board has failed. That regulator powers OUT1, the accelerometer and the analog reference for the ADC. It's possible to replace it using hot air rework equipment. The component reference is U5 and depending on your tool board version the part number is either AP2127K-3.3 or AP7366-W5-7.

Another possibility is that the accelerometer chip has failed and it is shorting out the 3.3V rail.

Cheers. Not having the required tools for smd work, think I'll buy another and have a go later at replacing said 3.3V regulator

-

Did I just fried the 1LC Toolboardposted in General Discussion

I was installing the laser filament monitor as I had it sitting around for a long time.

Wired it up to the Toolboard io1 correctly. Must of had a bad crimp on the GND wire for IO1 hence the pauses. Didn't notice the GND wire for IO1 was floating in mid air, my fat fingers must of shorted it to OUT1.

I now have no accelerometer, Toolboard temp reading is at 2000, T0 temp is at 2000, Laser Filament Monitor isn't flashing any Leds.Think I've done a number on the lot

29/07/2023, 12:15:41 pm M98 P"0:/macros/Setup/Diagnostics Output" === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.6 (2023-07-21 14:11:38) running on Duet 3 MB6HC v1.01 (standalone mode) Board ID: 08DJM-956BA-NA3TN-6J1D6-3SJ6K-TV8AU Used output buffers: 1 of 40 (25 max) === RTOS === Static ram: 153252 Dynamic ram: 97808 of which 60 recycled Never used RAM 99552, free system stack 194 words Tasks: NETWORK(ready,34.5%,172) ETHERNET(notifyWait,0.1%,320) HEAT(notifyWait,0.0%,321) Move(notifyWait,0.0%,352) CanReceiv(notifyWait,0.0%,798) CanSender(notifyWait,0.0%,335) CanClock(delaying,0.0%,349) TMC(notifyWait,7.7%,90) MAIN(running,57.6%,925) IDLE(ready,0.1%,30), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:03:09 ago, cause: power up Last software reset at 2023-07-29 11:10, reason: User, GCodes spinning, available RAM 99260, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 258 MCU temperature: min 10.6, current 14.5, max 19.0 Supply voltage: min 23.9, current 24.0, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 8, reads 9654, writes 14 timeouts 0 Driver 1: standstill, SG min 0, mspos 8, reads 9654, writes 14 timeouts 0 Driver 2: standstill, SG min 0, mspos 8, reads 9657, writes 11 timeouts 0 Driver 3: standstill, SG min 0, mspos 8, reads 9654, writes 14 timeouts 0 Driver 4: standstill, SG min 0, mspos 8, reads 9654, writes 14 timeouts 0 Driver 5: standstill, SG min 0, mspos 8, reads 9655, writes 14 timeouts 0 Date/time: 2023-07-29 12:15:41 Slowest loop: 25.49ms; fastest: 0.05ms === Storage === Free file entries: 9 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 3.3ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters 2 8 -1 -1, ordering errs 0 === GCodes === Segments left: 0 Movement lock held by null HTTP is ready with "M122" in state(s) 0 0, running macro Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 1778, received 1373, lost 0, boc 0 Longest wait 28ms for reply type 6018, peak Tx sync delay 60538, free buffers 50 (min 49), ts 949/948/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 12.02ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 = Ethernet = State: active Error counts: 0 0 0 0 0 0 Socket states: 5 2 2 2 2 0 0 0 === Multicast handler === Responder is inactive, messages received 0, responses 029/07/2023, 12:14:01 pm M98 P"0:/macros/1LC Toolboard/Toolboard Diagnostics" Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.6 (2023-07-21 14:17:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3828, free system stack 88 words Tasks: Move(notifyWait,0.0%,155) HEAT(notifyWait,0.1%,115) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) TMC(notifyWait,3.0%,67) MAIN(running,92.0%,429) IDLE(ready,0.0%,26) AIN(delaying,4.9%,142), total 100.0% Last reset 00:00:52 ago, cause: power up Last software reset data not available Driver 0: pos 0, 80.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 26322, writes 9, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/3, peak Rx sync delay 513, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.2, current 24.2, max 24.4 MCU temperature: min 53.7C, current 53.7C, max 57.1C Last sensors broadcast 0x00000000 found 0 194 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 441, send timeouts 0, received 483, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: none I2C bus errors 0, naks 12, other errors 0 29/07/2023, 12:12:38 pm Connection established 29/07/2023, 12:12:26 pm Connection interrupted, attempting to reconnect... HTTP request timed out29/07/2023, 12:11:09 pm M98 P"0:/macros/1LC Toolboard/Toolboard Diagnostics" Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.6 (2023-07-21 14:17:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3828, free system stack 88 words Tasks: Move(notifyWait,0.0%,155) HEAT(notifyWait,0.1%,115) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) TMC(delaying,3.0%,67) MAIN(running,92.0%,441) IDLE(ready,0.0%,26) AIN(delaying,4.9%,148), total 100.0% Last reset 00:00:37 ago, cause: power up Last software reset data not available Driver 0: pos 0, 80.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 18723, writes 9, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/3, peak Rx sync delay 504, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.2, current 24.2, max 24.3 MCU temperature: min 52.3C, current 52.3C, max 55.4C Last sensors broadcast 0x00000000 found 0 245 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 319, send timeouts 0, received 346, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: none I2C bus errors 0, naks 12, other errors 0 29/07/2023, 12:10:28 pm Error: Response timeout: CAN addr 20, req type 6024, RID=2929/07/2023, 12:10:27 pm M98 P"0:/macros/1LC Toolboard/Toolboard Diagnostics" Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.6 (2023-07-21 14:17:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 3828, free system stack 88 words Tasks: Move(notifyWait,0.0%,155) HEAT(notifyWait,0.0%,141) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.1%,76) CanClock(notifyWait,0.0%,65) TMC(notifyWait,2.7%,67) MAIN(running,92.7%,441) IDLE(ready,0.5%,26) AIN(delaying,4.8%,148), total 100.7% Last reset 00:00:00 ago, cause: power up Last software reset data not available Driver 0: pos 0, 80.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 91, writes 9, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/0, peak Rx sync delay 186, resyncs 0/0, no step interrupt scheduled VIN voltage: min 24.3, current 24.3, max 24.3 MCU temperature: min 999.0C, current 0.0C, max -273.2CHMMMM 999 deg C

29/07/2023, 12:09:14 pm Connection established 29/07/2023, 11:56:33 am Connection interrupted, attempting to reconnect... HTTP request timed out 29/07/2023, 11:56:08 am Resume state saved 29/07/2023, 11:55:04 am Printing paused at X-8.9 Y-8.9 Z4.4 29/07/2023, 11:55:03 am Resume state saved 29/07/2023, 11:54:31 am Printing paused at X1.7 Y-6.5 Z4.2 29/07/2023, 11:54:30 am Resume state saved 29/07/2023, 11:52:15 am Printing paused at X-12.3 Y-20.3 Z3.8 29/07/2023, 11:52:14 am Resume state saved 29/07/2023, 11:51:47 am M591 D0 Duet3D laser filament monitor v2 on pin 20.io1.in, enabled, allow 40% to 120%, check printing moves every 3.0mm, calibration factor 1.000, version 2, quality 224, brightness 162, shutter 136, measured min 106% avg 108% max 112% over 33.7mm -

RE: Can I use a negative pressure advance value?posted in 3D Printing General Chat

@Arminas

I predominantly print tpu.

I have my config with no PA, direct drive, 90A tpu. 45mm/s print speed, with retractionsWhat is the shore A?

Do you have bulging corners?

What's the print speed?

What's the extruder? -

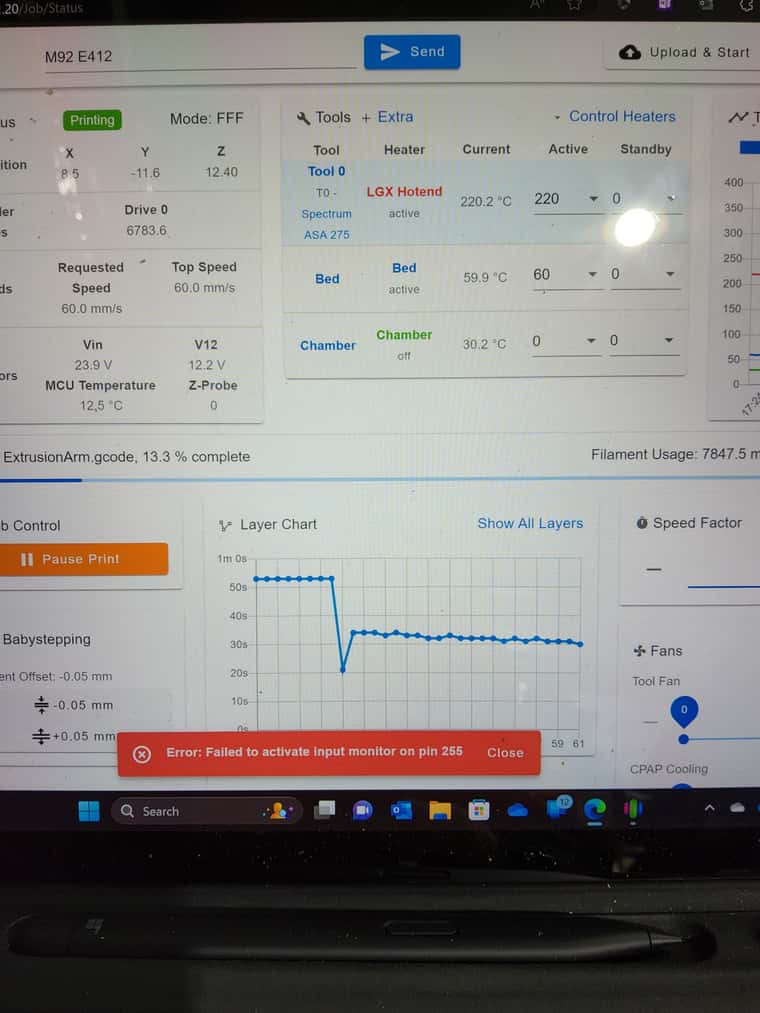

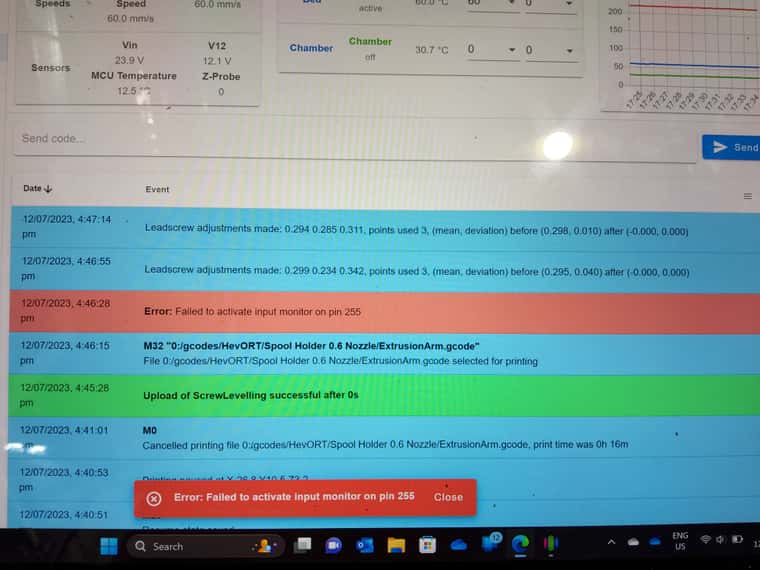

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@droftarts

You are a champion. I didn't even see that error in the probesettings.g -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@dc42

Yes end stops working correctly.

They are optical endstops

X endstop is Min

Y endstop is Min -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@jay_s_uk

Nothing like a good challenge

-

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

; tpre0.g ; called before tool 0 is selected ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Wed Jan 27 2021 10:10:40 GMT+1100 (Australian Eastern Daylight Time); tpost0.g ; called after tool 0 has been selected ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Wed Jan 27 2021 10:10:41 GMT+1100 (Australian Eastern Daylight Time) ; Wait for set temperatures to be reached M116 P0 -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@jay_s_uk

Just did a diagnostic on the toolboard whilst it's still runningM122 B20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.4 (2022-10-14 11:46:33) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK Never used RAM 2648, free system stack 45 words Tasks: Move(notifyWait,0.5%,91) HEAT(notifyWait,0.9%,75) CanAsync(notifyWait,0.0%,61) CanRecv(notifyWait,0.1%,74) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,6.1%,57) MAIN(running,82.3%,351) IDLE(ready,0.0%,26) AIN(delaying,10.0%,142), total 100.0% Last reset 03:09:29 ago, cause: power up Last software reset data not available Driver 0: pos 12140682, 412.0 steps/mm,ok, SG min 0, read errors 0, write errors 0, ifcnt 13, reads 32782, writes 13, timeouts 0, DMA errors 0, CC errors 0, steps req 12686994 done 12686873 Moves scheduled 66473, completed 66472, in progress 1, hiccups 0, step errors 0, maxPrep 656, maxOverdue 1, maxInc 1, mcErrs 0, gcmErrs 0 Peak sync jitter -2/4, peak Rx sync delay 231, resyncs 0/0, next step interrupt due in 218 ticks, enabled VIN voltage: min 23.9, current 24.1, max 24.2 MCU temperature: min 38.6C, current 54.8C, max 56.2C Last sensors broadcast 0x00000002 found 1 109 ticks ago, 0 ordering errs, loop time 1 CAN messages queued 227681, send timeouts 0, received 169009, lost 0, free buffers 37, min 35, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 658, adv 32902/74661 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0I'll look into the panel due issue

My actual chamber temp is 31 degrees and I can't see anything out of the ordinary on the 1LC -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

; thumbnail begin 160x160 7692 ;Removed for posting ; thumbnail end ; G-Code generated by Simplify3D(R) Version 5.1.1 ; Jul 12, 2023 at 4:08:35 PM ; Settings Summary ; processName,Process 1 ; targetModels,ExtrusionArm ; profileName,HevORT ; profileVersion,2023-07-12 16:07:33 ; app,S3D-Software 5.1.1 ; technology,fff ; baseProfile, ; extruder,Extruder 1 ; toolheadNumber,0 ; nozzleDiameter,0.60000 ; extrusionMultiplier,1.00000 ; extrusionWidthMode,automatic ; extrusionWidth,0.30000 ; useRetraction,0 ; retractDistance,1.00000 ; extraRestartDistance,0.00000 ; retractVerticalLift,0.00000 ; retractSpeed,1800.00000 ; useCoasting,0 ; coastingDistance,0.20000 ; useWiping,0 ; wipingDistance,5.00000 ; speedMaxFlowRate,1000.00000 ; toolheadOffsetX,0.00000 ; toolheadOffsetY,0.00000 ; filamentDiameter,1.75000 ; filamentPricePerKilogram,52.00000 ; filamentDensity,1.22000 ; primaryExtruder,Extruder 1 ; layerHeight,0.20000 ; topSolidLayers,5 ; bottomSolidLayers,5 ; outlinePerimeters,1 ; useVaseMode,0 ; useAdaptiveLayerHeights,0 ; minAdaptiveLayerHeight,0.10000 ; maxAdaptiveLayerHeight,0.30000 ; adaptiveSmoothingLevel,5 ; horizontalOuterCompensation,0.00000 ; horizontalInnerCompensation,0.00000 ; firstLayerUnits,percentage ; firstLayerHeightPercentage,100 ; firstLayerWidthPercentage,100 ; firstLayerSpeedPercentage,100 ; firstLayerHeightAbsolute,0.30000 ; firstLayerWidthAbsolute,0.40000 ; firstLayerSpeedAbsolute,900.00000 ; startPointStrategy,closest ; alignStartPointsX,0.00000 ; alignStartPointsY,0.00000 ; restrictStartPoints,0 ; perimeterPrintingOrder,inside_out ; islandPrintingOrder,closest ; printInfillBeforePerimeters,0 ; useSkirt,1 ; skirtExtruder,Extruder 1 ; skirtLayers,1 ; skirtOffset,1.00000 ; skirtOutlines,5 ; useRaft,0 ; raftExtruder,Extruder 1 ; raftBaseLayers,2 ; raftTopLayers,3 ; raftOffset,3.00000 ; raftSeparationDistance,0.14000 ; raftSpeedUnits,percentage ; raftSpeedPercentage,30 ; raftSpeedAbsolute,600.00000 ; usePrimePillar,0 ; primePillarExtruder,Extruder 1 ; primePillarWidth,12.00000 ; primePillarLocation,north_west ; primePillarSpeedPercentage,100 ; primePillarInfillPercentage,100 ; autoStopPrimePillar,1 ; primePillarLayersAfterAutoStop,0 ; useOozeShield,0 ; oozeShieldExtruder,Extruder 1 ; oozeShieldOffset,2.00000 ; oozeShieldOutlines,1 ; oozeShieldSidewallShape,waterfall ; oozeShieldSidewallAngle,30 ; oozeShieldSpeedPercentage,100 ; autoStopOozeShield,1 ; oozeShieldLayersAfterAutoStop,0 ; sparseInfillExtruder,Extruder 1 ; sparseInfillPattern,rectilinear ; sparseInfillRotation,0 ; sparseInfillPercentage,100 ; sparseInfillExtrusionWidthPercentage,100 ; sparseInfillCombinedLayers,1 ; denseInfillLayers,0 ; denseInfillPercentage,100 ; infillOutlineOverlapPercentage,25 ; minInfillLength,0.00000 ; externalInfillPattern,rectilinear ; externalInfillRotation,0 ; solidInfillThresholdArea,0.00000 ; solidInfillExtraExpansion,0.00000 ; useMonotonic,1 ; useDiaphragm,1 ; diaphragmSolidLayers,3 ; diaphragmSpacingLayers,20 ; topLayerExtraExpansion,1.00000 ; topLayerExtrusionModifier,100 ; overrideFanSpeedForTopLayer,0 ; topLayerFanSpeedPercentage,100 ; useIroning,0 ; ironingOutlineOffsetPercentage,50 ; ironingExtrusionWidthPercentage,25 ; ironingExtrusionModifier,15 ; ironingSpeedModifier,30 ; sparseSupportExtruder,Extruder 1 ; sparseSupportInfillPattern,aligned ; sparseSupportInfillRotation,0 ; sparseSupportInfillPercentage,30 ; sparseSupportOutlines,0 ; sparseSupportCombinedLayers,1 ; upperDenseSupportLayers,0 ; lowerDenseSupportLayers,0 ; denseSupportExtruder,Extruder 1 ; denseSupportInfillPercentage,70 ; denseSupportExtraExpansion,0.00000 ; baseSupportLayers,0 ; supportInflationDistance,0.00000 ; supportHorizontalPartOffset,0.30000 ; supportUpperSeparationLayers,1 ; supportLowerSeparationLayers,1 ; defaultPrintSpeed,3600.00000 ; outerPerimeterSpeedPercentage,100 ; innerPerimeterSpeedPercentage,100 ; topLayerSpeedPercentage,100 ; solidInfillSpeedPercentage,100 ; sparseSupportSpeedPercentage,90 ; denseSupportSpeedPercentage,70 ; travelSpeedXY,9000.00000 ; travelSpeedZ,3600.00000 ; reduceSpeedForQuickLayers,1 ; speedMaxQuickLayerTime,10.00000 ; minQuickLayerSpeedPercentage,30 ; reduceSpeedForShortPerimeters,1 ; speedMaxShortPerimeterLength,40.00000 ; minShortPerimeterSpeedPercentage,50 ; reduceSpeedForMaxFlowRate,0 ; accelXY,10000.00000 ; accelZ,500.00000 ; accelE,10000.00000 ; jerkXY,600.00000 ; jerkZ,24.00000 ; jerkE,300.00000 ; exportFileFormat,gcode ; useStickyCommands,1 ; use5D,1 ; relativeExtrusionDistances,0 ; allowExtruderAxisZeroing,1 ; independentExtruderAxes,0 ; includeM10123,1 ; includeThumbnailImages,1 ; thumbnailImageEncoding,standard ; thumbnailImageSizes,160|160,400|400 ; x3gMachineProfile,r2 ; overrideStepsPerMillimeter,0 ; stepsPerMillimeterX,88.57319 ; stepsPerMillimeterY,88.57319 ; stepsPerMillimeterZ,400.00000 ; stepsPerMillimeterA,96.27520 ; stepsPerMillimeterB,96.27520 ; xyzFileFormatVersion,1 ; makerBotMachineProfile,replicator_5 ; makerBotModelExtruder,mk13 ; makerBotSupportExtruder,mk14_s ; makerBotModelMaterial,pla ; makerBotSupportMaterial,pva ; globalOffsetX,0.00000 ; globalOffsetY,0.00000 ; globalOffsetZ,0.00000 ; applyToolheadOffsets,0 ; buildVolumeShape,rectangular ; buildVolumeX,260.00000 ; buildVolumeY,290.00000 ; buildVolumeZ,325.00000 ; buildVolumeDiameter,200.00000 ; originOffsetX,130.00000 ; originOffsetY,145.00000 ; originOffsetZ,0.00000 ; homingDirectionX,max ; homingDirectionY,min ; homingDirectionZ,min ; mirrorVisualX,0 ; mirrorVisualY,1 ; mirrorVisualZ,0 ; machineBackgroundModel, ; startingScript,"G90|M82|M98 P""0:/macros/Setup/Safety_Contactor_ON""|M98 P""0:/macros/Setup/StartScript""||;Select Bed Mesh||;M117 ""Bed Mesh Full X260 Y290""|;M98 P""0:/macros/Bed/BedMeshFullX260Y290""||;M117 ""Bed Mesh Half X130 Y145""|;M98 P""0:/macros/Bed/BedMeshHalfX130Y145""||M117 ""Bed Mesh Small X65 Y72.5""|M98 P""0:/macros/Bed/BedMeshSmallX65Y72.5""||;M117 ""Bed Mesh Ulti X150 Y130""|;M98 P""0:/macros/Bed/BedMeshUltiX150Y130""||T0" ; preLayerChangeScript, ; postLayerChangeScript, ; preRetractionScript, ; postRetractionScript, ; preToolChangeScript, ; postToolChangeScript, ; processChangeScript, ; endingScript,"M98 P""0:/macros/Setup/Safety_Contactor_OFF""|M98 P""0:/macros/Setup/EndScript""|" ; postProcessingScript,"{REPLACE ""M101"" ""G11""},|{REPLACE ""M103"" ""G10""},|{STRIP ""M102""},|{REPLACE ""Material Length"" ""Filament length""}" ; useBridging,1 ; bridgingThresholdArea,50.00000 ; bridgingInfillExtraExpansion,1.00000 ; bridgingExtrusionModifier,100 ; bridgingSpeedModifier,100 ; overrideFanSpeedForBridging,0 ; bridgingFanSpeedPercentage,100 ; useFixedBridgingAngle,0 ; fixedBridgingAngle,0 ; applyBridgingToPerimeters,0 ; bridgingPerimeterExtraOverlap,0.00000 ; minBridgingPerimeterLength,10.00000 ; useToolChangeRetraction,0 ; toolChangeRetractDistance,12.00000 ; toolChangeExtraRestartDistance,-0.50000 ; toolChangeRetractSpeed,600.00000 ; toolChangePrimeOnFirstUse,0 ; toolChangeRetractAtEnd,0 ; externalThinWallType,single_extrusions ; internalThinWallType,gap_fill ; thinWallAllowedOverlapPercentage,10 ; singleExtrusionMinLength,0.20000 ; singleExtrusionMinWidthPercentage,50 ; singleExtrusionMaxWidthPercentage,200 ; singleExtrusionEndpointExtensionDistance,0.20000 ; onlyRetractWhenCrossingOutlines,1 ; retractBetweenLayers,1 ; retractOnTopLayers,1 ; useRetractionMinTravel,0 ; retractionMinTravel,5.00000 ; useRetractionMinExtrusion,0 ; retractionMinExtrusion,3.00000 ; onlyVerticalLiftOnTopLayers,1 ; retractWhileWiping,0 ; wipingMode,outer_perimeter ; avoidCrossingOutlines,1 ; maxMovementDetourFactor,3.00000 ; openLoopSlicingBehavior,thicken ; openLoopThickenWidth,0.10000 ; slicingRegionRepairMode,positive G90 M82 G90 M82 M98 P"0:/macros/Setup/Safety_Contactor_ON" M98 P"0:/macros/Setup/StartScript" ;Select Bed Mesh ;M117 "Bed Mesh Full X260 Y290" ;M98 P"0:/macros/Bed/BedMeshFullX260Y290" ;M117 "Bed Mesh Half X130 Y145" ;M98 P"0:/macros/Bed/BedMeshHalfX130Y145" M117 "Bed Mesh Small X65 Y72.5" M98 P"0:/macros/Bed/BedMeshSmallX65Y72.5" ;M117 "Bed Mesh Ulti X150 Y130" ;M98 P"0:/macros/Bed/BedMeshUltiX150Y130" T0 ; process Process 1 ; layer 1, Z = 0.2000 T0 ; feature skirt ; tool H0.2000 W0.720 G1 X41.756 Y16.740 F9000 G1 Z0.2000 F3600 G11 G92 E0.00000 G1 X-41.756 Y16.740 E4.99975 F3600 G1 X-44.240 Y14.256 E5.21004 G1 X-44.240 Y-14.256 E6.91703 G1 X-41.756 Y-16.740 E7.12732 G1 X41.756 Y-16.740 E12.12707 G1 X44.240 Y-14.256 E12.33736 G1 X44.240 Y14.256 E14.04435 G1 X41.756 Y16.740 E14.25464 G10 G1 X41.458 Y16.020 F9000 G11 G92 E0.00000 G1 X-41.458 Y16.020 E4.96404 F3600 G1 X-43.520 Y13.958 E5.13862 G1 X-43.520 Y-13.958 E6.80990 G1 X-41.458 Y-16.020 E6.98448 G1 X41.458 Y-16.020 E11.94852 G1 X43.520 Y-13.958 E12.12310 G1 X43.520 Y13.958 E13.79439 G1 X41.458 Y16.020 E13.96897 G10 G1 X41.160 Y15.300 F9000 G11 G92 E0.00000I've also noticed I'm not getting the full information when selecting the file on the 7" PanelDue. Layer Height, Sliced By, etc

heres the end code

G10 ; layer end M98 P"0:/macros/Setup/Safety_Contactor_OFF" M98 P"0:/macros/Setup/EndScript" ; Build Summary ; Build Time: 4 hours 45 minutes ; Filament length: 58879.2 mm (58.88 m) ; Material Volume: 141621.0 mm^3 (141.62 cc) ; Material Weight: 172.78 g (0.38 lb) ; Material Cost: 8.98 -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@jay_s_uk i'm not using daemon.g or start.g

It's got me stumped.

Oh I'm on build 3.4.5

Board: Duet 3 MB6HC (MB6HC)

Firmware: RepRapFirmware for Duet 3 MB6HC 3.4.5

Duet Web Control 3.4.5

1LC was updated too 3.4.5 -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

;Simplify 3d – Scripts – Starting G90 M82 M98 P"0:/macros/Setup/Safety_Contactor_ON" M98 P"0:/macros/Setup/StartScript" ;Select Bed Mesh ;M117 "Bed Mesh Full X260 Y290" ;M98 P"0:/macros/Bed/BedMeshFullX260Y290" ;M117 "Bed Mesh Half X130 Y145" ;M98 P"0:/macros/Bed/BedMeshHalfX130Y145" M117 "Bed Mesh Small X65 Y72.5" M98 P"0:/macros/Bed/BedMeshSmallX65Y72.5" ;M117 "Bed Mesh Ulti X150 Y130" ;M98 P"0:/macros/Bed/BedMeshUltiX150Y130" T0;P"0:/macros/Setup/Safety_Contactor_ON" ;Safety Contactor ON M42 P2 S1;P"0:/macros/Setup/StartScript" ;Here is the start of the macros for bed leveling, etc M98 P"0:/macros/Setup/Filament_Loaded_message" M98 P"0:/macros/BLTouch/Probesettings.g" ;BLTouch Parameters M117 "Screw Levelling" M98 P"0:/macros/Bed/ScrewLevelling" ;Levels Bed Screws;P"0:/macros/Setup/Filament_Loaded_message" M291 P"FILAMENT LOADED?" S3 G4 S1 M117 "LET'S PRINT" G4 S1;P"0:/macros/BLTouch/Probesettings.g" M574 Z0 P"20.nil" M950 S0 C"20.io0.out" M558 P9 C"^20.io0.in" H20 F500 T12000 G31 P500 X0 Y-30.0 Z1.4 ; set Z probe trigger value, offset and trigger height;P"0:/macros/Bed/ScrewLevelling" ;3 x LeadScrews Levelling ;BLTouch OffSets ;X axis = 0 no offset ;Y axis = -30 in front of the nozzle M561 ; clear bed transform G29 S2 ; clear height map G28 ; home all axis G90 ; use absolute co-ordinates M671 X-142:0:142 Y-88:152:-88 S50 M558 H20 F480 T12000 ;Set Z probe dive height (H) + speeds (F Probe 1st probe 8mm/s:2nd probe) (T Travel 200mm/s) ; Probe the bed at 3 points adjacent to motors G30 P0 X-142 Y-88 H0 Z-99999 ;X-142 Y88 Driver 3 G30 P1 X0.0 Y122 H0 Z-99999 ;X0 Y304 Driver 4 G30 P2 X142 Y-88 H0 Z-99999 S3 ;X142 Y88 Driver 5 G28 Z ;Home Z Axis Again M558 H5 F120 ;Set Z Axis Dive Height + F = 2mm/s G30 P0 X-142 Y-88 H0 Z-99999 ;X142 Y88 Driver 3 G30 P1 X0.0 Y122 H0 Z-99999 ;X0 Y304 Driver 4 G30 P2 X142 Y-88 H0 Z-99999 S3 ;X142 Y88 Driver 5 G28 ; Home all axes for establishing datums -

RE: Error:Failed to activate input monitor on pin 255posted in General Discussion

@jay_s_uk

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Tue Jul 11 2023 13:25:33 GMT+1000 (Australian Eastern Standard Time); General preferences

; Wait a moment for the CAN expansion boards to start

; Toolboard 1LC CAN Address B20

G4 S2 ; Wait for Toolboard 1LC to Start

;--------------------------------------------------------------------------------------------------------------------------------------------------------------G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"HevORT - Midnight" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 P192.168.1.20 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards X

M569 P0.1 S0 ; physical drive 0.1 goes backwards Y

M569 P20.0 S0 ; Toolboard 1LC physical drive 0.2 goes backwards E

M569 P0.3 S1 ; physical drive 0.3 goes backwards Z1

M569 P0.4 S0 ; physical drive 0.4 goes forwards Z2

M569 P0.5 S0 ; physical drive 0.5 goes backwards Z3

M584 X0.0 Y0.1 Z0.3:0.4:0.5 E20.0 ; set drive mapping MB6 and Toolboard 1LC B20 Address

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E412 ; set steps per mm

M566 X1200.00 Y1200.00 Z155.00 E5000.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z1200.00 E10000.00 ; set maximum speeds (mm/min)

M201 X10000.00 Y10000.00 Z500.00 E30000.00 ; set accelerations (mm/s^2)

M906 X1200 Y1200 Z1000:1000:1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Axis Limits - Define X,Y Origin

;X0.0 Y0.0 = Bed Center

M208 X-142 Y-152 Z0 S1 ; set axis minima

M208 X142 Y152 Z320 S0 ; set axis maxima;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Endstops

M574 X1 S1 P"20.io2.in" ; Tool board 1LC configure active-low X axis endstop

M574 Y1 S1 P"io2.in" ; configure active-high endstop for low end on Y via pin io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"Bed" ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120CM308 S1 P"20.temp1" Y"thermistor" T500000 B4723 C1.196220e-7 A"LGX Hotend" ; configure sensor 1 as thermistor on pin temp1 - Slice Engineering HTT 13/5/21

M950 H1 C"20.out0" T1 ; create nozzle heater output on out0 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M307 H1 R3.048 K0.408:0.041 D3.32 E1.35 S1.00 B0 ; LGX Tuned for 220 deg 12/07/2023

M143 H1 S400 ; set temperature limit for heater 1 to 400CM308 S2 P"temp2" Y"thermistor" T100000 B4138 A"Chamber" ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"out2" T2 ; create chamber heater output on out2 and map it to sensor 2

M307 H2 B1 S1.00 ; enable bang-bang mode for the chamber heater and set PWM limit

M141 H2 ; map chamber to heater 2

M143 H2 S280 ; set temperature limit for heater 2 to 280C;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Fans

M950 F0 C"0.out9" Q2000 ; create fan 0 on pin out7 and set its frequency

M106 P0 C"CPAP Cooling" S0 H-1 B0.1 L0.15 ; set fan 0 name and value. Thermostatic control is turned offM950 F1 C"20.out2" Q100 ; Toolboard 1LC create fan 2 on pin OUT2 and set its frequency

M106 P1 C"LGX Cooling" H1 T45:150 ; Toolboard 1LC set fan 1 name and value. Thermostatic control is turned on;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Z-Probe

; Pushed to macro's

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"^20.io0.in" H20 F500 T12000 ; set Z probe type to bltouch and the dive height + speeds;--------------------------------------------------------------------------------------------------------------------------------------------------------------

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossM950 P2 C"out3" ; Set out3 to Heatbed Safety Contactor

M42 P2 S0 ; Set Heatbed Safety Contactor OffM912 P0 S-8.3 ; Set Electronics Temperature Monitor Adjustment

T0 ; select first tool;Toolboard 1LC

M955 P20.0 I20 ; Configure accelerometer on toolboard with CAN address 20 and specify orientation

; Accelerometer Orientation - Accelerometer X+ = Axis X+, Accelerometer Y+ = Axis Y+

M593 P"zvddd" F40.5 ; use ZVDDD input shaping to cancel ringing at 40.5Hz

;------------------------------------------------------------------------------------------------------------------------------------------------------------- -

Error:Failed to activate input monitor on pin 255posted in General Discussion

Hi all.

I have a genuine duet 3 and 1LC. I have just installed and commissioned the 1LC. When I go to print a gcode file I get this error first Error:Failed to activate input monitor on pin 255. It must be the 1LC toolboard as I've never seen this message before

What is this related too? Accelerometer on the toolboard

-

RE: Teaser for today - can you guess the answer?posted in General Discussion

@deckingman would that then constitute as a bug