Hi,

I'm struggeling with my issue since weeks. I posted it here erlier, send my configs and till today nobody could found any reason for it.

I entered a Facebook group (Duet3d Unofficial) and found out, that there are many more people with the same problem: mesh compensation didn't do it's job.

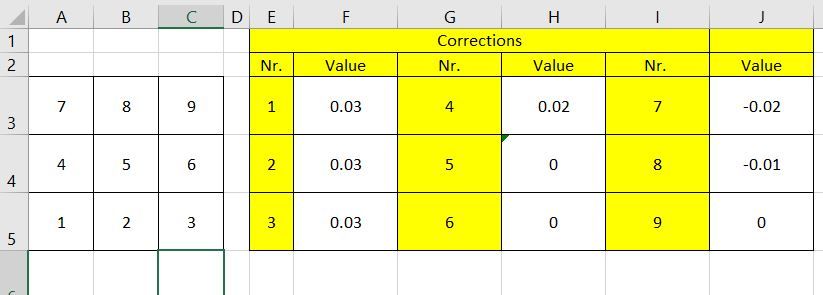

After many discussions here and there I made some sequences to check if results are repeatable - and yes - it is. So my conclusion is, that there are somewhere deep in the RAM are old values stored which leads to wrong bed calculations.

As I had independent z configured as first (with RRF2.0x) then went over to non-independent, went back to independent, go on to RRF3.0.xRCx. Having made a full earase and reinstalled the FW again - the issue is still there.

So I asked again @dc42: do you have any idea, what could be the reason for, that the calculated bed didn't match manually measurements at all?

I measured manually the same points which G29 did - and allways G29 delivers other results.

The next: I power up, run

M561

G29 S2

G32

and got a correction of -0.065/0.059, then I run G32 again and got (as expected) -0.004/-0.002 (where it should be 0.0/0.0 - but errors in that range are ok).

After this:

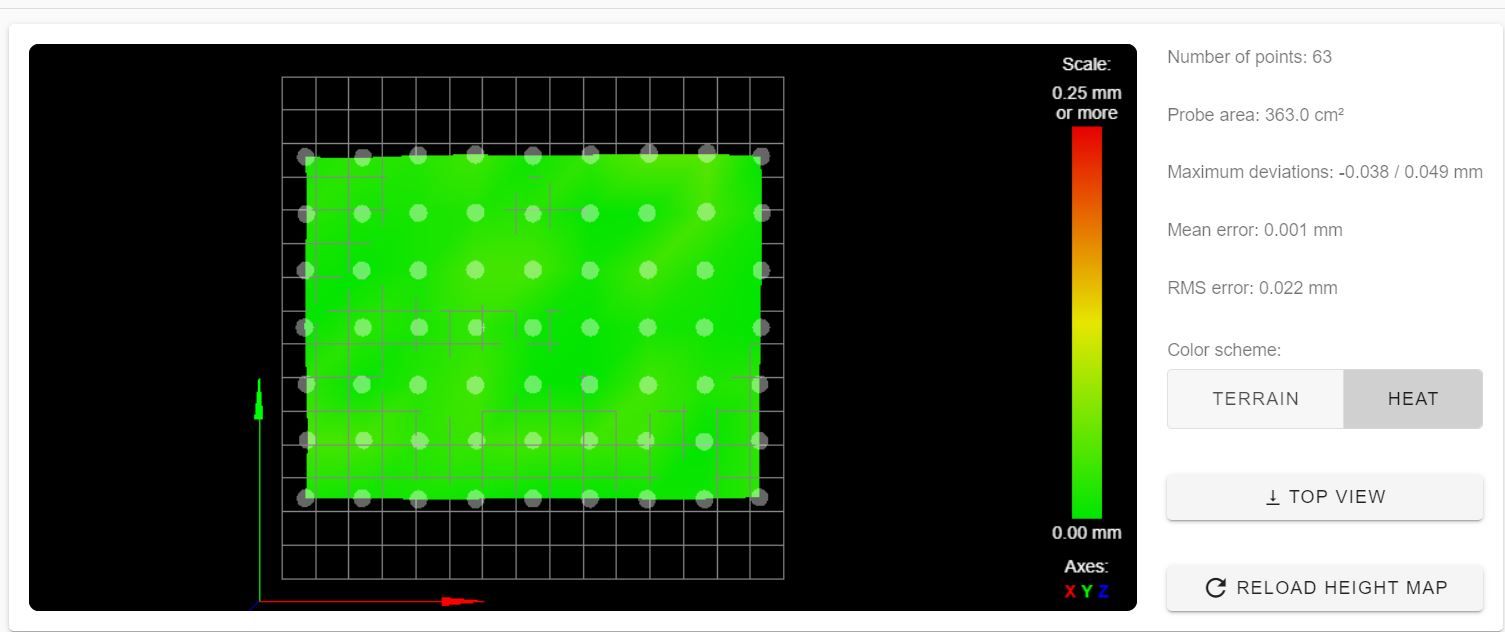

G29

49 points probed, min error -0.090, max error 0.046, mean -0.019, deviation 0.035

which should be ok.

Then after this I run G32 again (and it doesn't matter if I run again M561, G29 before ore not): -0.043/-0.026

and this is repeatable as often as I like.

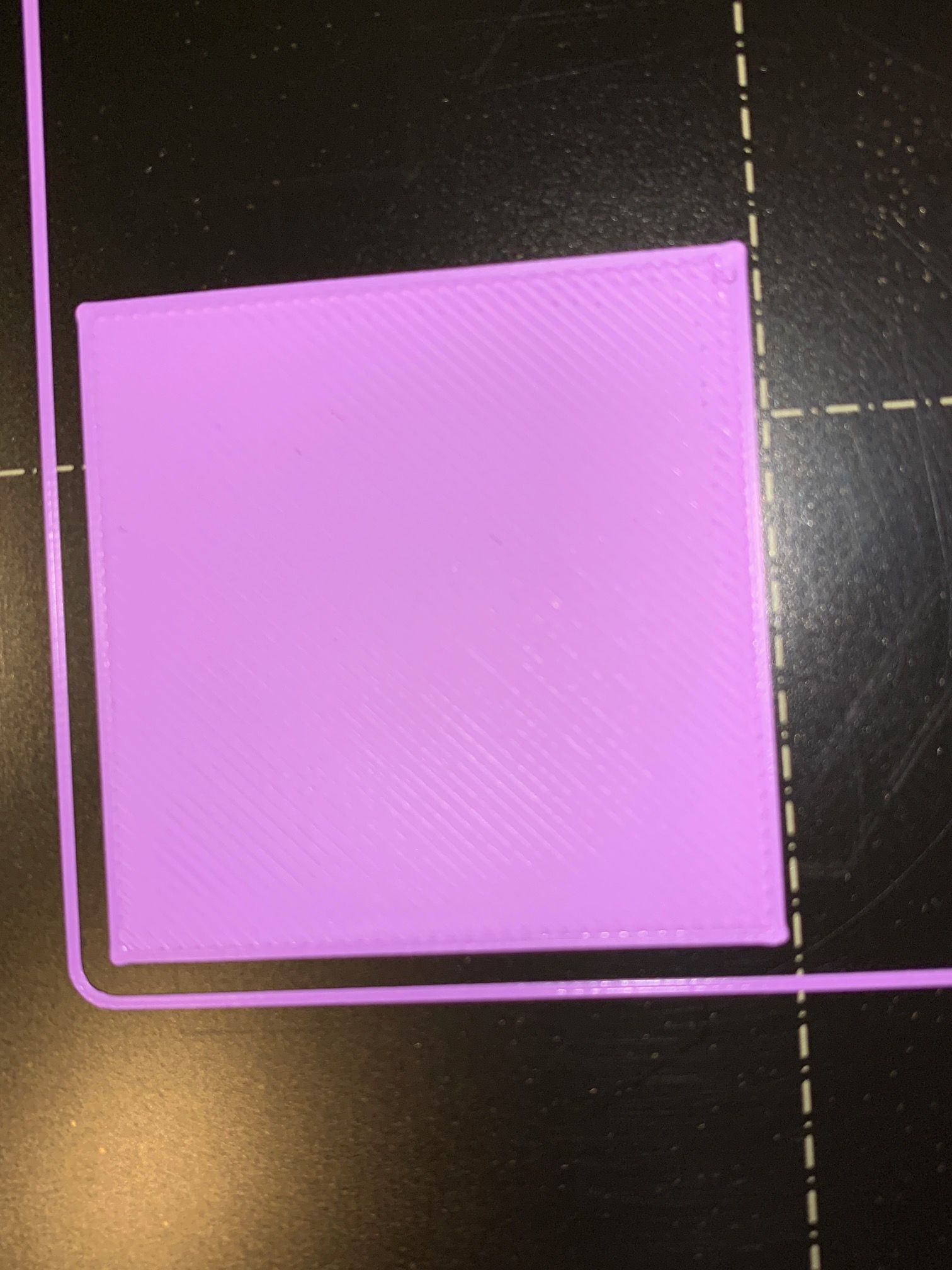

When printing a test pattern allways on the left side the nozzle is to far from the bed, in the middle is ok and on the right side it is too close to the bed, and again - it does not depend from z-motor configuration if it is independent or not. Also I changed all steppers to exclude something here and the BLTouch. Only the Wifi-Board I didn't change till now.

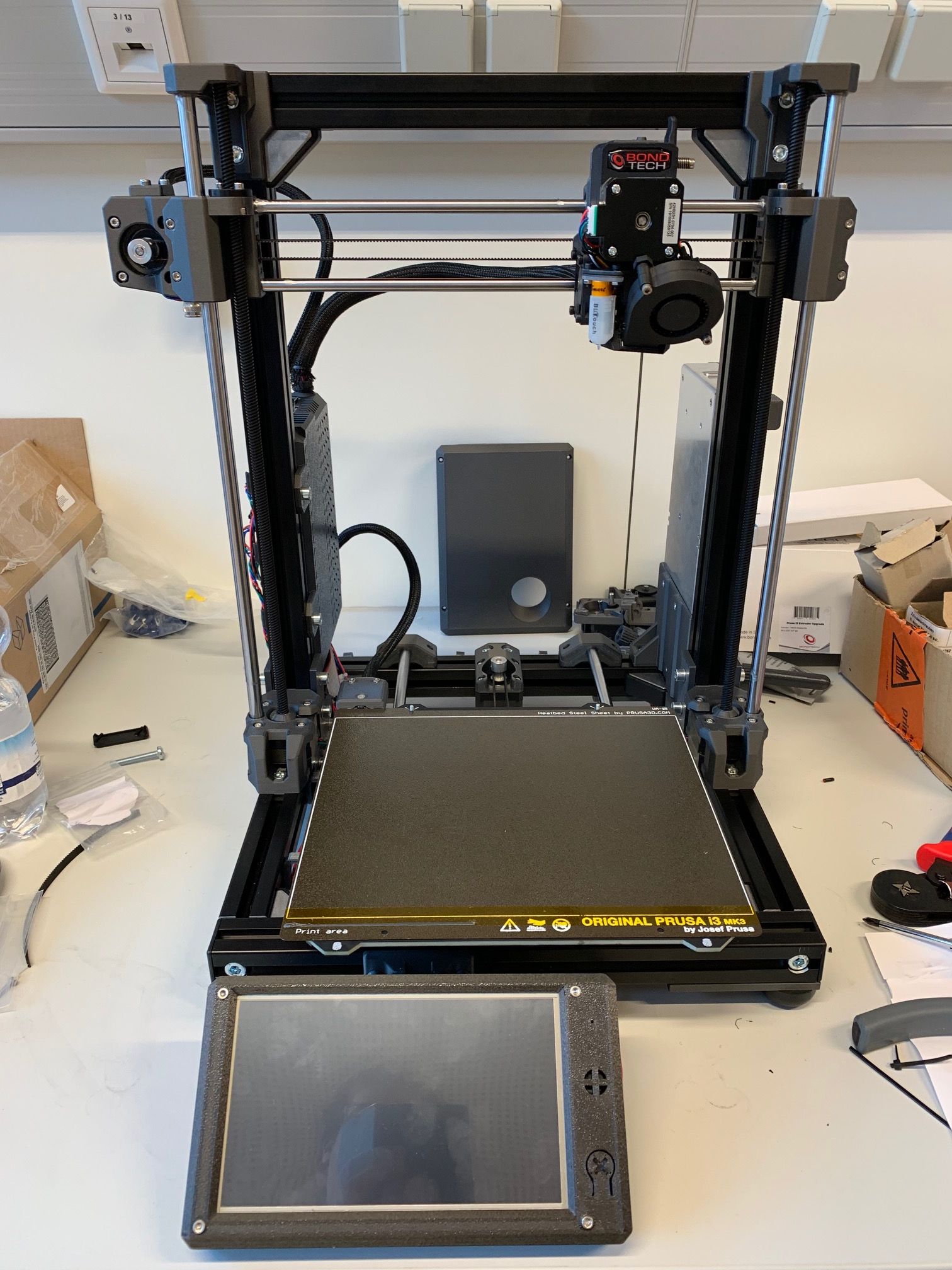

As readers shoudln't search for long, here are all machine details (but again - in the FB group are many user with different setups and the SAME problem!). I also add some pictures for the problems below.

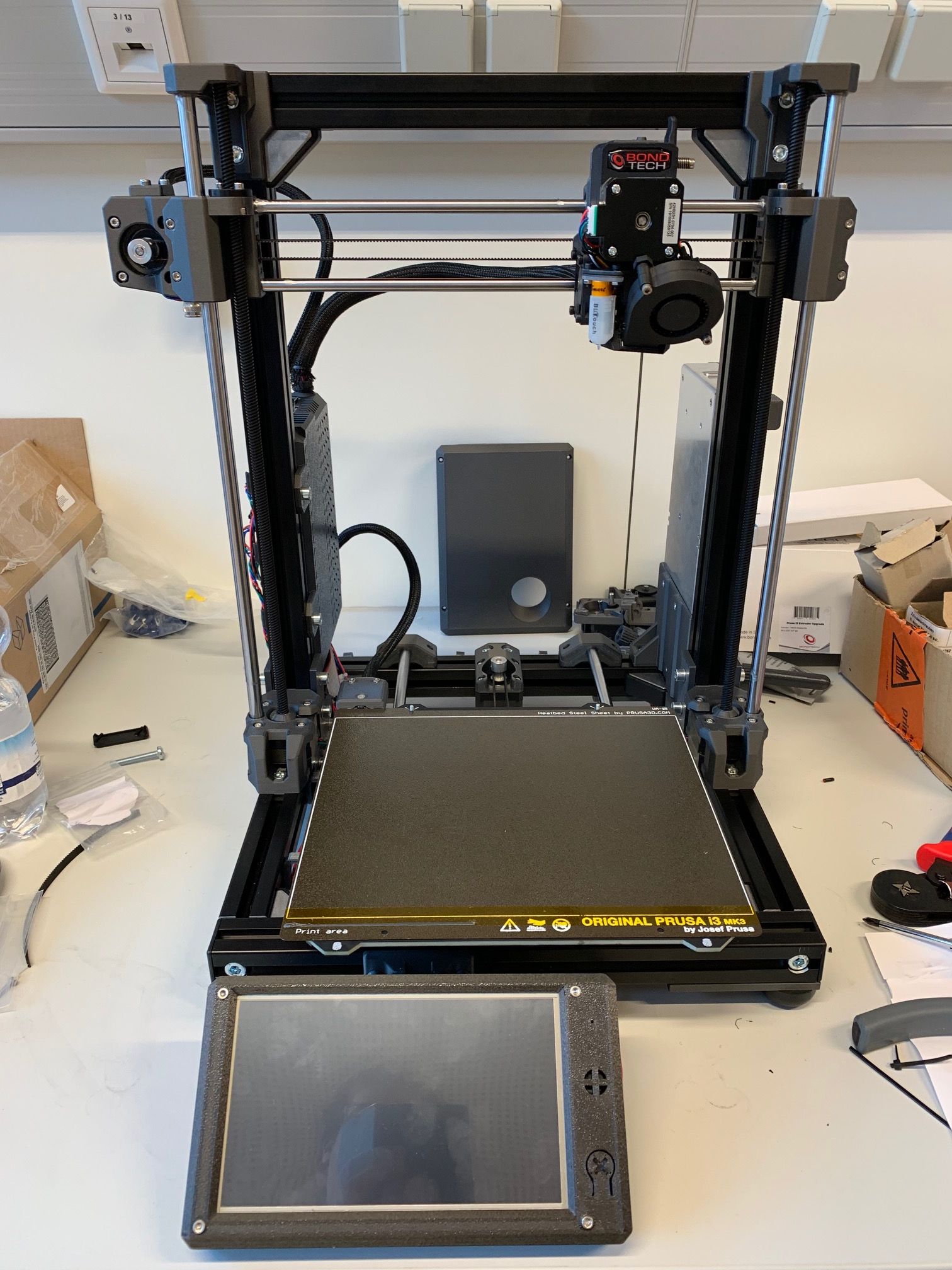

Printer is a Prusa-Like setup, Duet2 1.04 Wifi-Board, actual RRF3.01RC3

x,y steppers: Nema17/48mm 1,8° / 200 steps / 2A,

z-steppers Nema17 35mm 1,8° /200 steps / 1A with TR8x8 leadscrew

Mosquito/BMG Hotend with stepper: 1.8°/200 steps / geared 1:3

Magnetic MK52 Board@24 V, Meanwell 320W PSU, original BLTouch v3.1

if I forgot details, please ask for.

config.g

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Mjolnir" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards - x-axis

M569 P1 S0 ; physical drive 1 goes backwards - y-axis

M569 P2 S0 ; physical drive 2 goes backwards - z - left

M569 P3 S1 ; physical drive 3 goes forwards - Extruder

M569 P4 S0 ; physical drive 4 goes backwards - r - right

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M671 X-36.5:293.5 Y0:0 S1.0 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis

M350 X16 Y16 E16 Z16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E415.00 ; set steps per mm

M566 X620.00 Y620.00 Z20.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z360.00 E1800.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z200.00 E2000.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z850 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-1 Y-5 Z0 S1 ; set axis minima

M208 X254 Y210 Z310 S0 ; set axis maxima

; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y2 S3 ; configure sensorless endstop for high end on Y

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M591 P2 C"e1_stop" S1 ; configure extruder endtstop (filament sensor)

; Stallgaurd Sensitivy

M915 X S2 F0 H200 R0 ; Set X axis Sensitivity

M915 Y S1 F0 H200 R0 ; Set y axis Sensitivity

; Z-Probe

M950 S3 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 R0.25 S0.003 F120 T3000 A10 B1 ; set Z probe type to bltouch and the dive height + speeds

G31 P125 X-22.6 Y-34.7 Z2.40 ; set Z probe trigger value, offset and trigger height

M557 X5:230 Y10:175 P7:7 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 A"Bed" ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S110 ; set temperature limit for heater 0 to 110C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T500000 B4681 C1.143895e-7 A"Nozzle" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S4 P"mcu-temp" Y"mcu-temp" A"MCU" ; set virtual heater for MCU

M308 S5 P"drivers" Y"drivers" A"Driver" ; set virtual heater for stepper drivers

; Fans

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan0 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan1 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M302 S190 R190

; Custom settings are not defined

M501 ; use config-override (for Thermistor Parameters)

homex.g

G91 ; relative positioning

G1 H1 Z5 F180

G1 H1 X5 F1000 ; move slowly away

M913 X20 ; lower motor current to 20% for senserless homing

G1 H1 X-260 F2000 ; move quickly to X axis endstop and stop there (first pass)

G1 X10 F1000 ; go slowly back a few mm

G1 H1 X-260 F2000 ; move to X axis endstop once more (second pass)

M913 X100 ; Rise motor current to 100% again after sensorless homing

G90 ; absolute positioning

G1 X15 F1000 ; go to X=15

homey.g

G91 ; relative positioning

G1 H1 Y-5 F1000 ; move slowly away

M913 Y30 ; lower motor current to 30% for senserless homing

G1 H1 Y230 F2000 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y-10 F1000 ; go back a few mm

G1 H1 Y230 F2000 ; move slowly to Y axis endstop once more (second pass)

M913 Y100 ; Rise motor current to 100% again after sensorless homing

G1 Y-10 F1000 ; go back a few mm

G90 ; absolute positioning

homez.g

G91 ; relative positioning

G90 ; absolute positioning

G1 X147.6 Y139.7 F3600 ; Move probe to middle of bed - first probing point, regarding Z-probe offsets

G30 ; home Z by probing the bed

G91 ; relative positioning

G90 ; absolute positioning

homeall.g

M98 P"homex.g" ; Call "homex.g"

M98 P"homey.g" ; Call "homey.g"

M98 P"homez.g" ; Call "homez.g"

bed.g

M561 ; Clear any bed transform

G29 S2 ; Clear bed height map

G30 P0 X10 Y105 Z-99999 ; probe near left leadscrew, half way along Y axis

G30 P1 X230 Y105 Z-99999 S2 ; probe near right leadscrew and calibrate 2 motors

G90 ; Absolute Positioning

G1 X125 Y105 Z25 F5000.0 ; go to the middle of the bed

My normal start sequence:

M561

G29 S2

G28

G32

G32

G29 (only at the moment - my aim is to get a reliable config, that I just to have load a mesh...)

start print

As described here are the pictures:

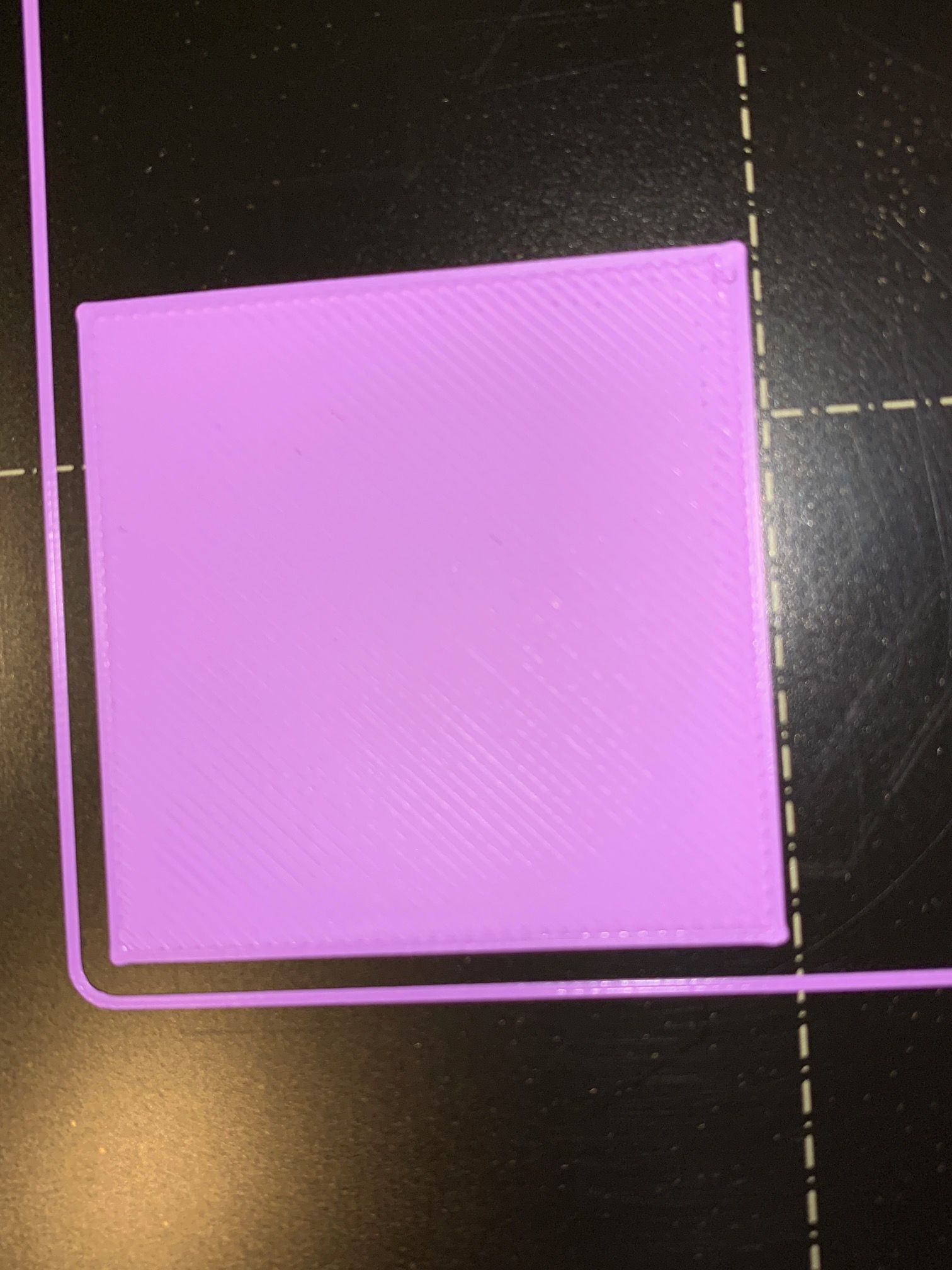

left

right where you can clearly see, that the nozzle is way too deep:

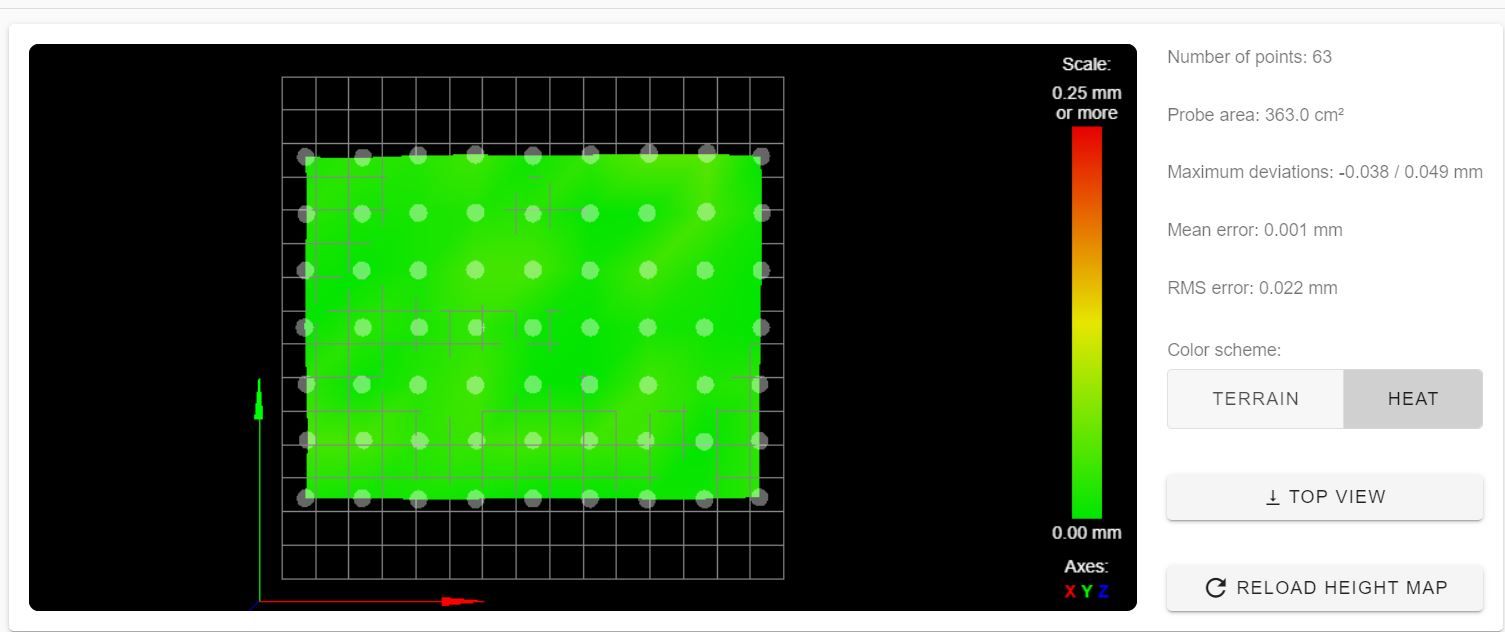

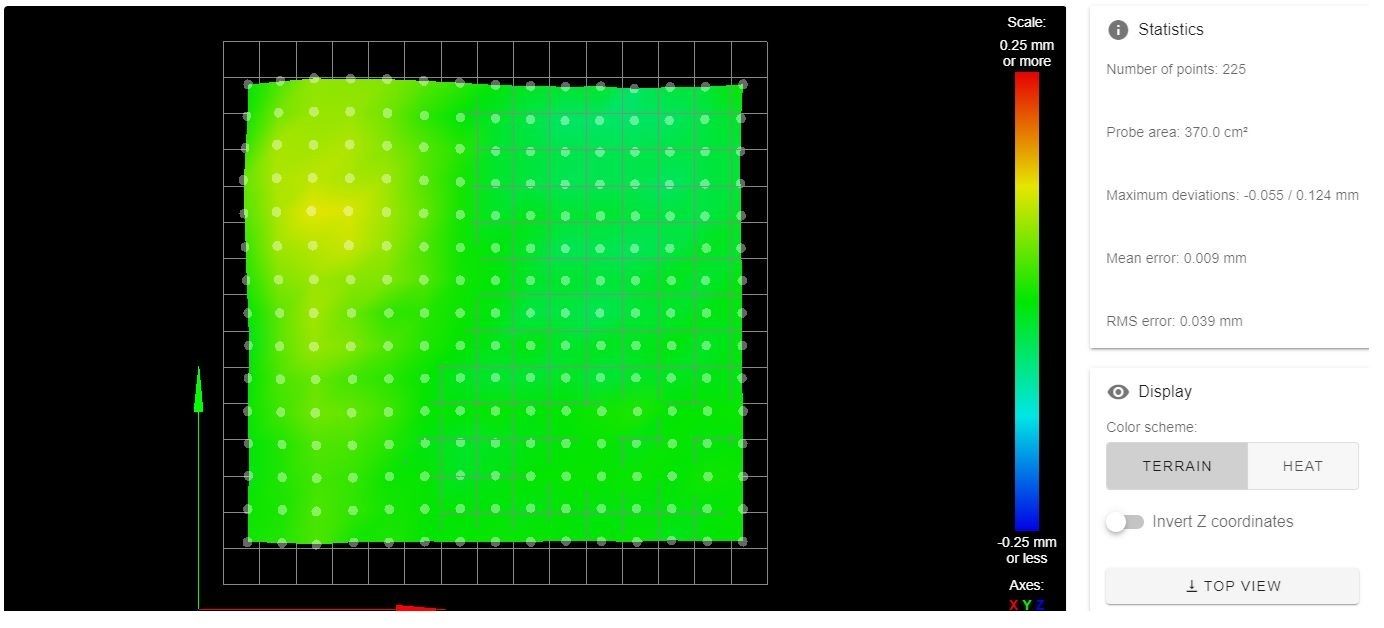

mesh (which was measured for the prints in the pictures):

printer:

I've no further ideas anymore, what the problem could cause....

I've no further ideas anymore, what the problem could cause....