Well one thing I hate about forums is when you see these big problems discussed, and advice and solutions offered, but then there's an abrupt stop in the conversation, and you never know what happened.

Several weeks ago, as you may have read here, I was really struggling with my supplied build plate, as it's 500x500 and only 4mm thick. Also, I struggled to find anybody in Western Australia, that could supply an aluminium plate that was guaranteed to be "flat", and when I enquired in Sydney, there were limited options for tool plate.

Long story short, thanks to the collective experience of everybody in this forum, I learned how I should go out and source a new plate, or at least, work with the constrains arising due to my location, and get a plate produced.

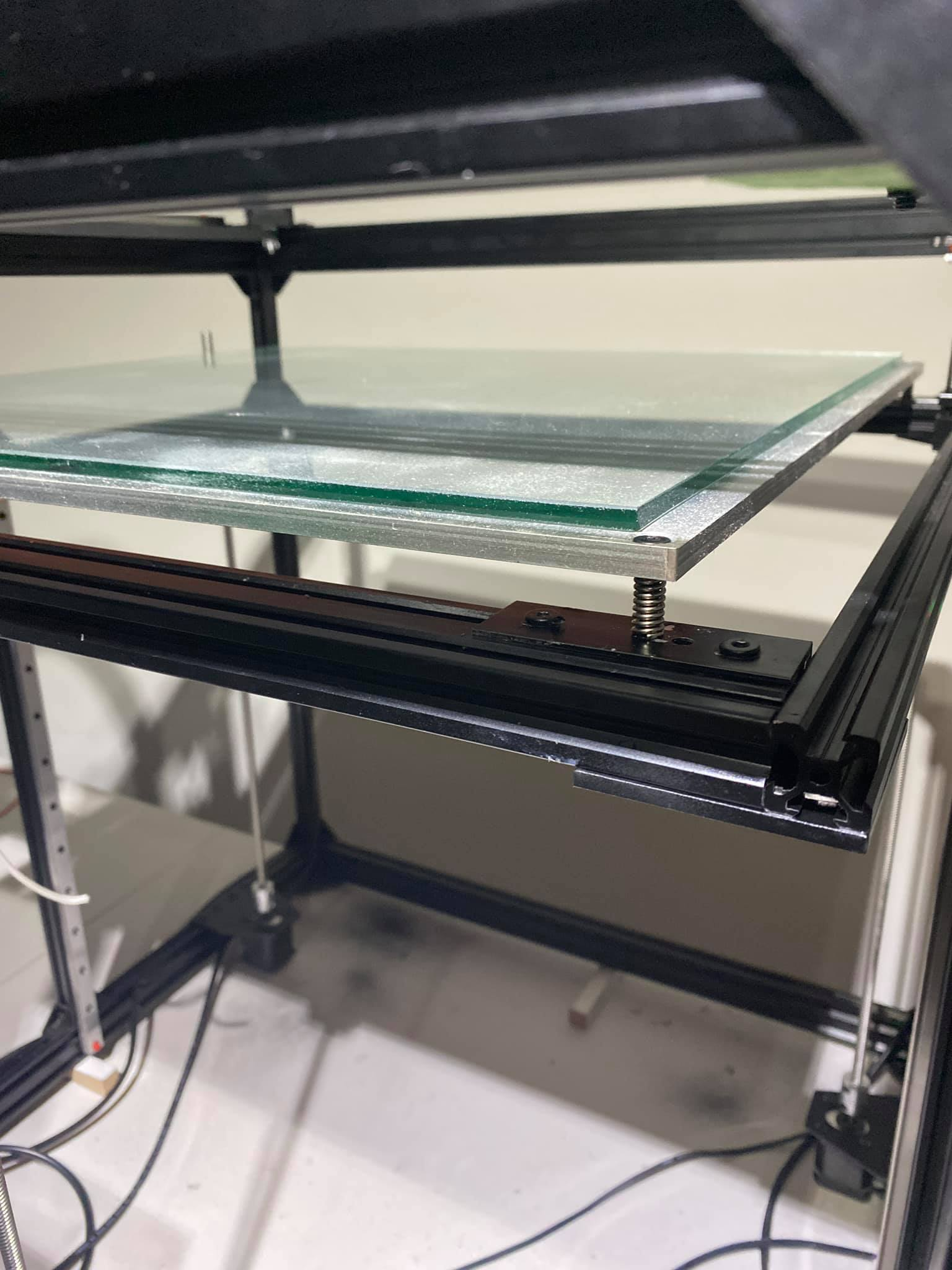

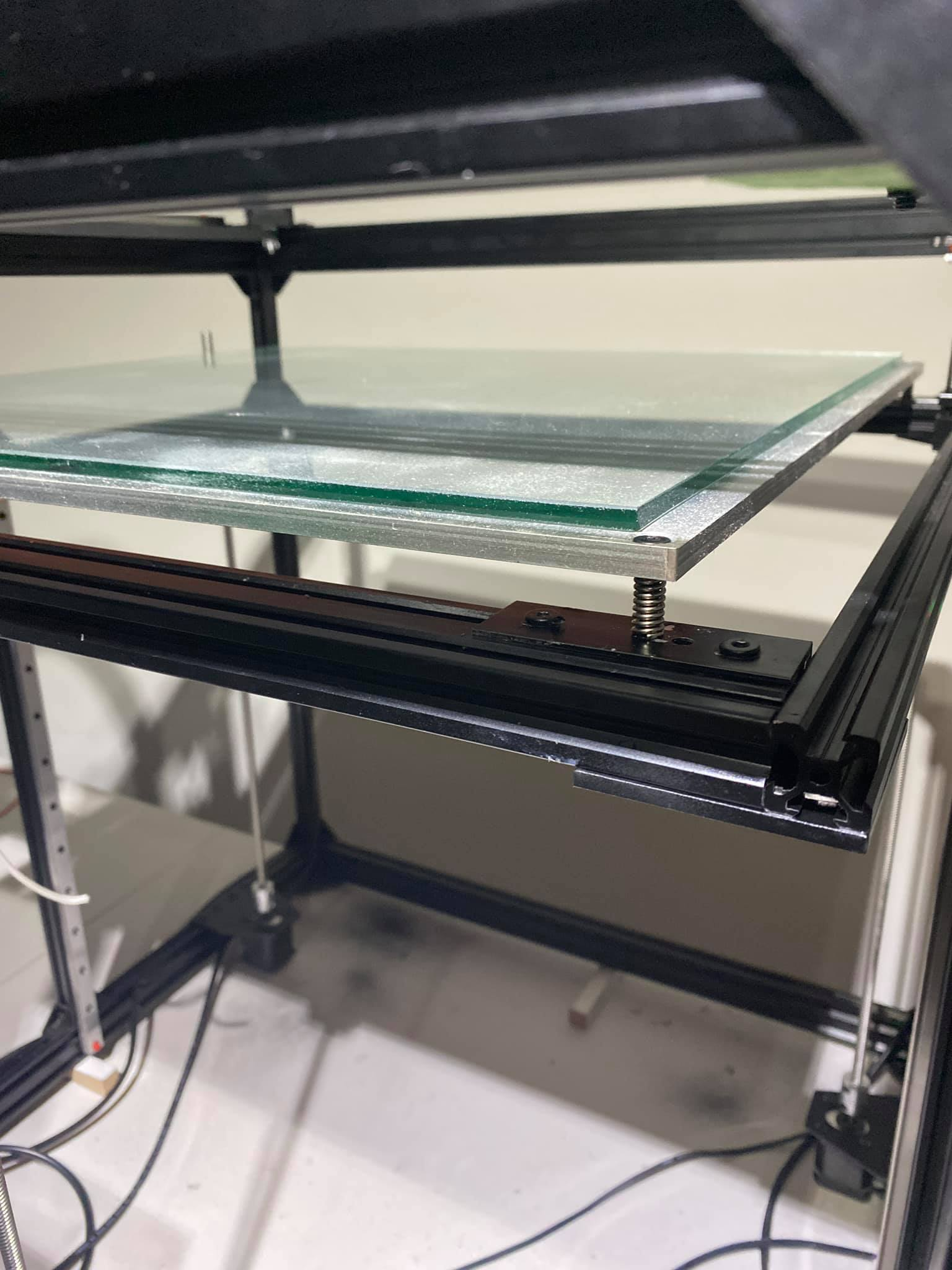

I found an engineering company here in Perth that could start with a 10mm plate, and machine it. Their advice was it would have to be machined on both sides, because of surface tension. Turns out, to get the plate "flat" it had to be machined 5 times. The resulting thickness was 7.7mm, which thanks to the advice above I know would mean there is minimum sag, due to own weight.

So I got the plate installed, and added my 6mm glass plate and finally got by bed mesh done.

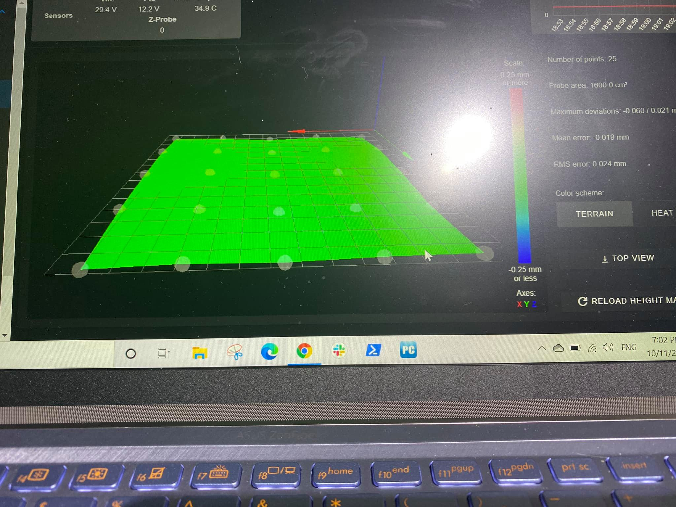

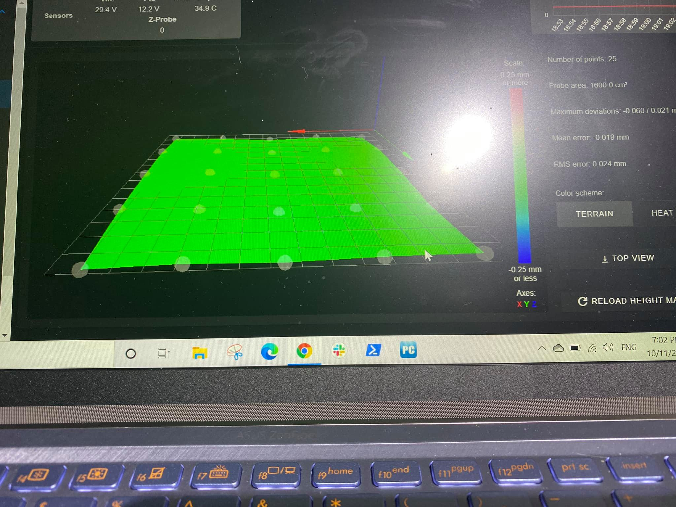

I think it's safe to say the result is amazing.

I have a few more things todo before I can actually print, but I have my "shutdown" and "startup sequence", which puts me in a great place with consistent bed mesh results.

- I have mechanical endstops for X and Y, so my homing here is pretty accurate

- I use stalling on my Z axis, and send the plate to max-z until it touches the couplings. And I call this my "parked" position"

- I now have a macros that raises the bed 480mm from the parked position, then I home all. So X then Y then Z all home.

- When I execute G29 now, I get an amazing height map.

Now I have to say the bed has been an investment, but clearly a worthwhile one. The plate cost me $280 AUD. The glass was about $25.

I've been cautioned about my bolt mountings, where the plate rests on the springs/bolts. The concern being, will the aluminium expand when heated (of course it will, by about 0.7mm), so the question comes will the plate be able to expand with these bolts in place without being completely constrained, therefore warping. Some thoughts on this would be useful.

Largely though, my issues seem to all be resolved.