Pressure advance doesn't affect the printed model

-

@skayred said in Pressure advance doesn't affect the printed model:

Thank you, guys!

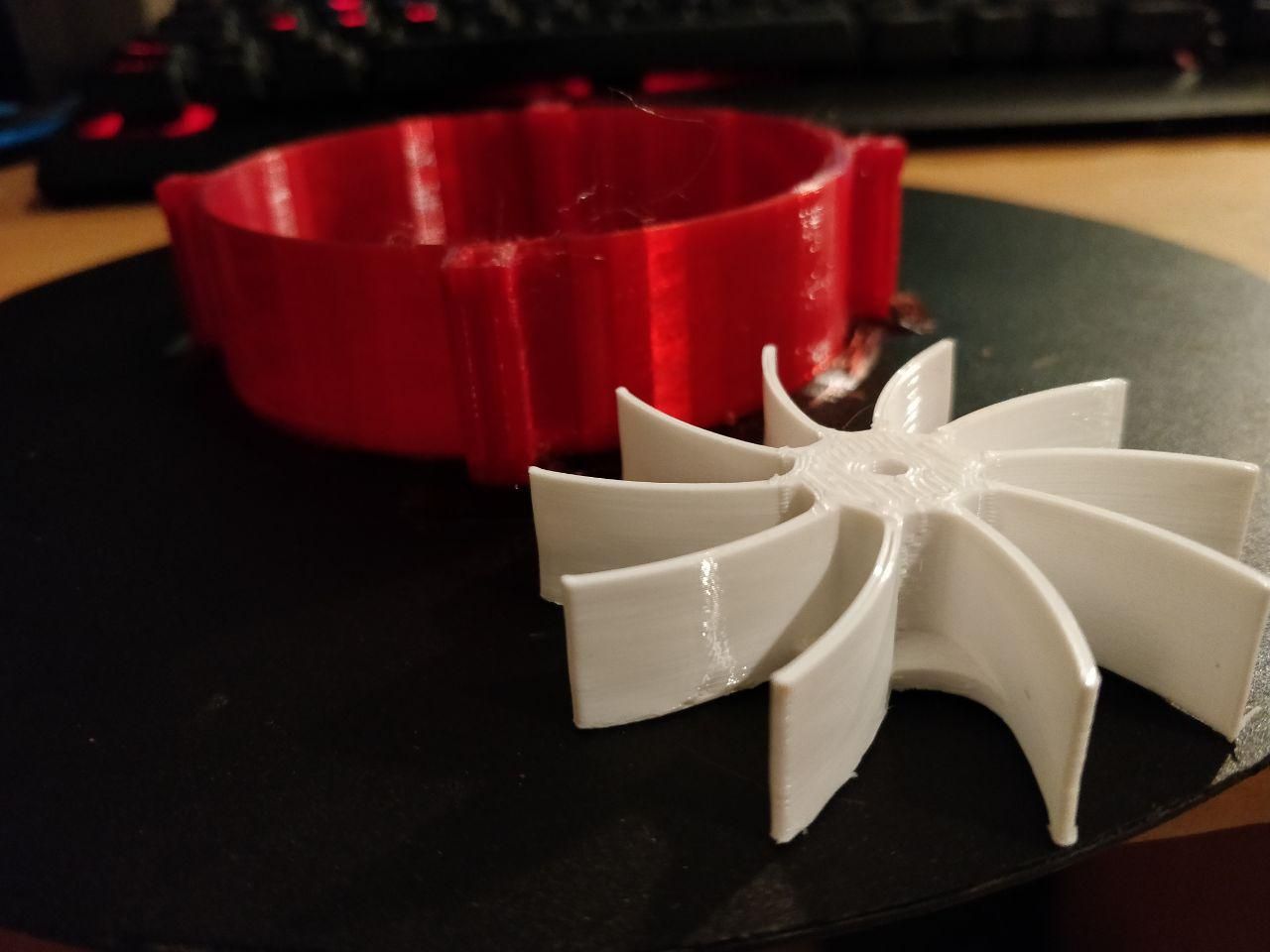

The propeller was printed perfectly, with no stringing and blobs so I can fit it to the shaft, finally!Great! Photo?

-

@dc42 Can you edit the documentation to say that values of higher than 0.2 is very normal and maybe necessary for bowden setups? I even have some PC filaments that needed 0.68 for a 100mm direct drive setup.

What I have found is that the PA necessary is linearly related to the length of filament between the drive gears and the heat break. I needed pretty much exactly 1/5th the PA when i switched from a 100mm bowden to a 20mm direct drive.

This will reduce confusion with future users. -

@dc42 hello,

now it looks like this:

This is the propeller side with most retractions between wings. Not really invisible but good enough for me. I think I will need to experiment with retractions but the generally proper value of PA makes everything better.

But, as was said there, documentation is really confusing, I was not even trying to make PA much higher than recommended. -

@NitroFreak said in Pressure advance doesn't affect the printed model:

@dc42 Can you edit the documentation to say that values of higher than 0.2 is very normal and maybe necessary for bowden setups? I even have some PC filaments that needed 0.68 for a 100mm direct drive setup.

What I have found is that the PA necessary is linearly related to the length of filament between the drive gears and the heat break. I needed pretty much exactly 1/5th the PA when i switched from a 100mm bowden to a 20mm direct drive.

This will reduce confusion with future users.Yes I can update the documentation.

-

@NitroFreak I've made some changes to flesh out the documentation a bit. https://duet3d.dozuki.com/Wiki/Pressure_advance any feedback welcome.

-

The PA test procedure with the large cylinder is very interesting. I will give it a try. Possibly it can even be automated with slicer gcode conditions similar the to ones used for heat towers.

{if layer_z==1.6} ; T tower floor 1 M104 S225 {elsif layer_z==11.6} ; T tower floor 2 M104 S220 ... {endif} -

@zapta said in Pressure advance doesn't affect the printed model:

Possibly it can even be automated with slicer gcode conditions similar the to ones used for heat towers.

Yes exactly.

-

@Phaedrux said in Pressure advance doesn't affect the printed model:

Yes exactly.

I run this PA calibration and it was easy to set up and interpret the results. Best value is 0.15 for my BMG/Titan direct extruder. I expected it to be lower.

I use script in the Prusa Slicer's Before Layer gcode section (this one is after I narrowed down the search range)

{if layer_num== 1}M572 D0 S0.125

{elsif layer_num== 25}M572 D0 S0.130

{elsif layer_num== 50}M572 D0 S0.145

{elsif layer_num== 75}M572 D0 S0.150

{elsif layer_num== 100}M572 D0 S0.156

{elsif layer_num== 125}M572 D0 S0.160

{elsif layer_num== 150}M572 D0 S0.165

{endif} -

@zapta Well done. Would you be able to post a photo of the resulting print showing the difference along the seam? I could add the photo and the layer gcode to the documentation as example.

-

@Phaedrux, sure, I am not sure I kept it but can print another once. I did it in two phases, first first large steps and then smaller steps around the target area.

-

@Phaedrux

Yes that already looks very good, it will help new people a lot since i have already seen a lot of people thinking PA needs to stop at 0.2.

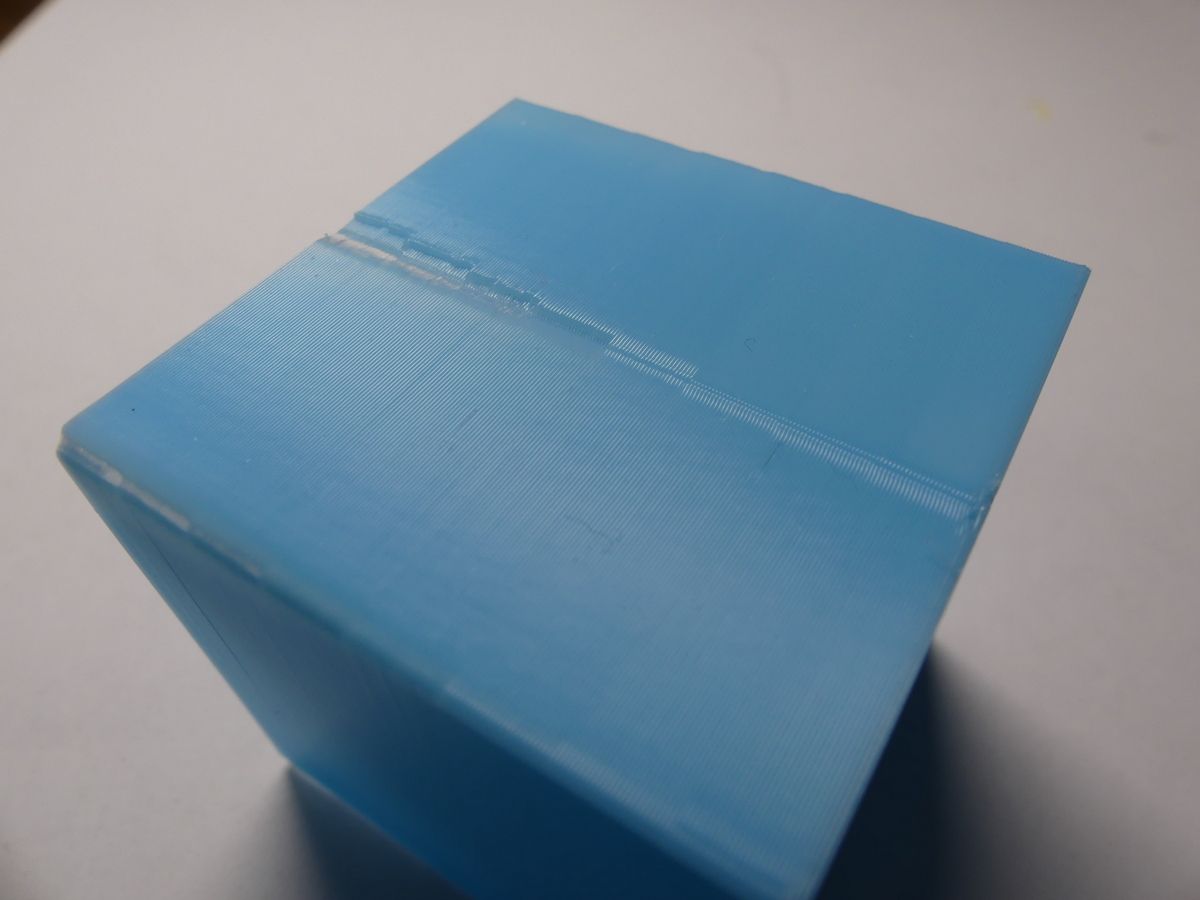

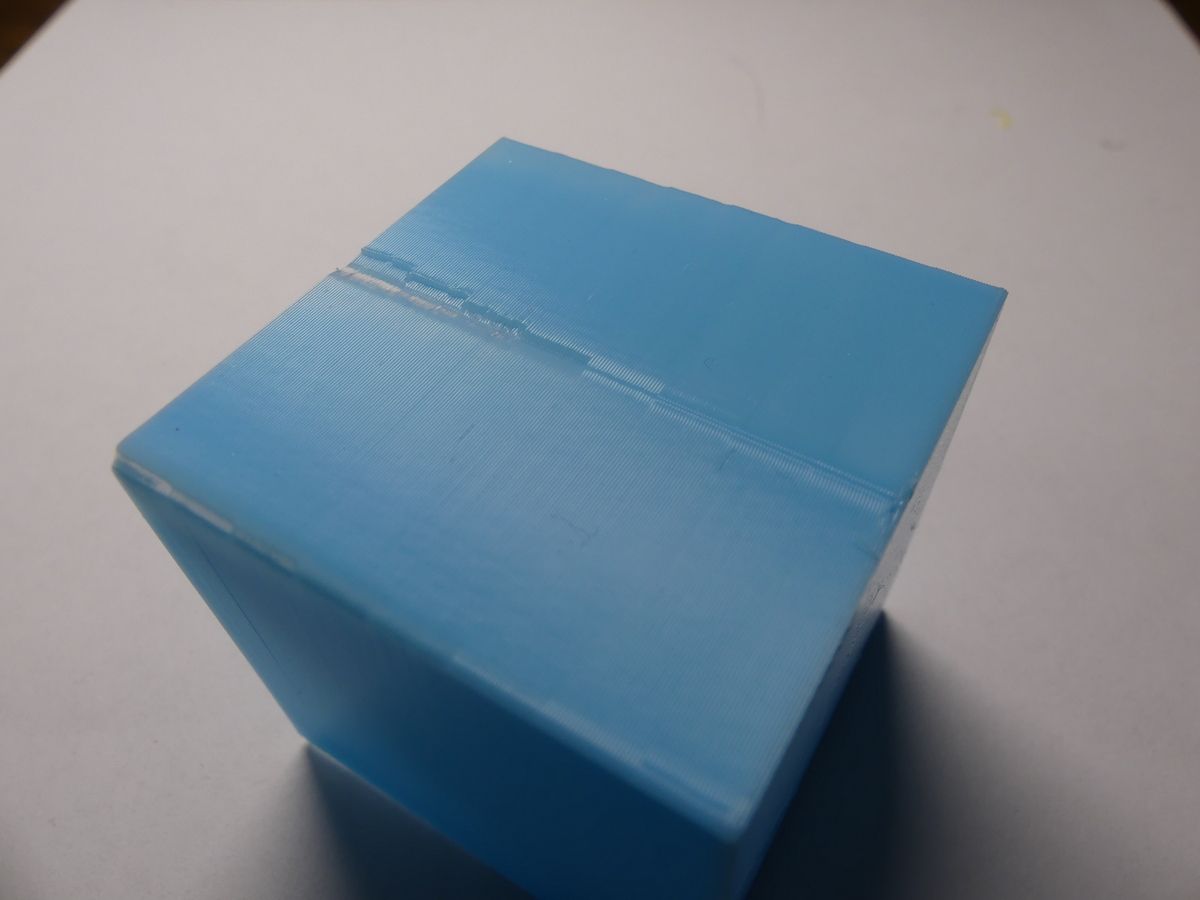

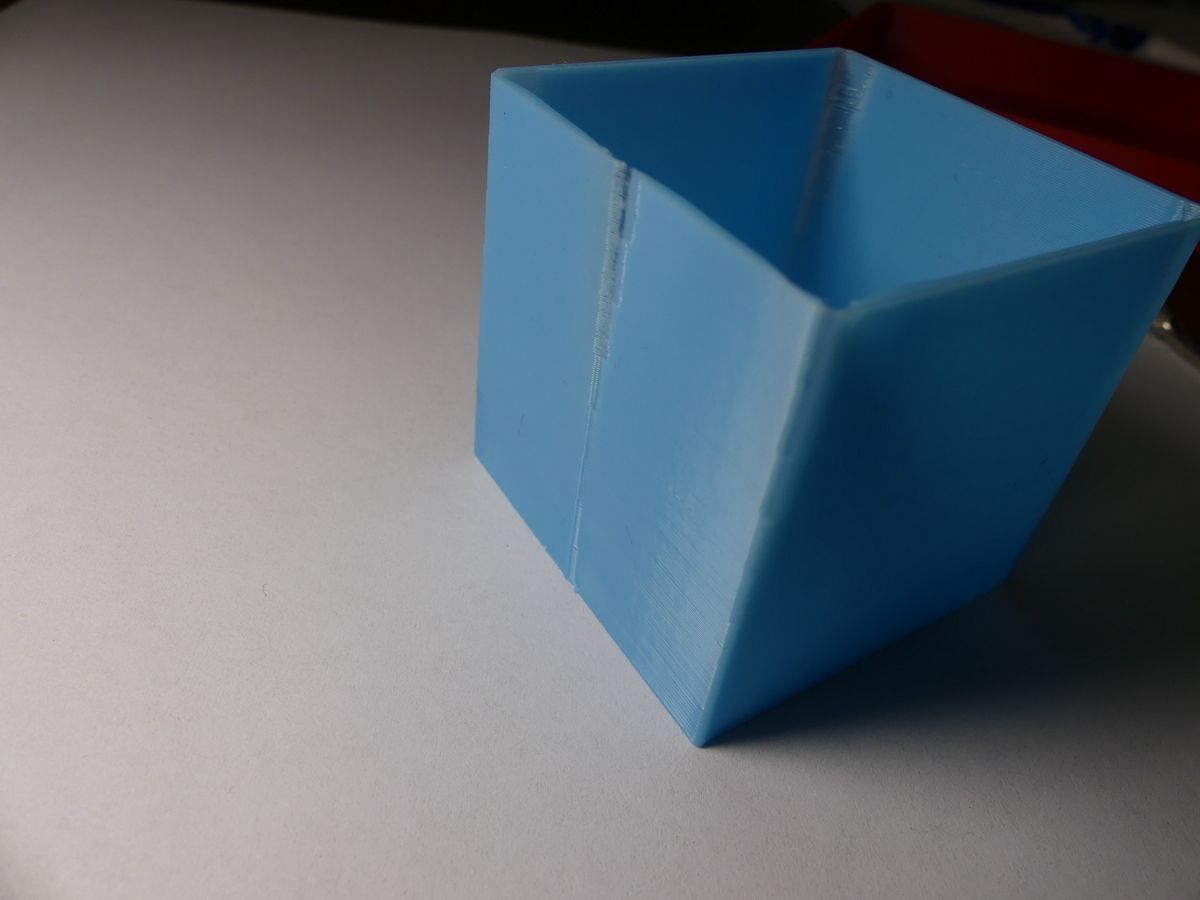

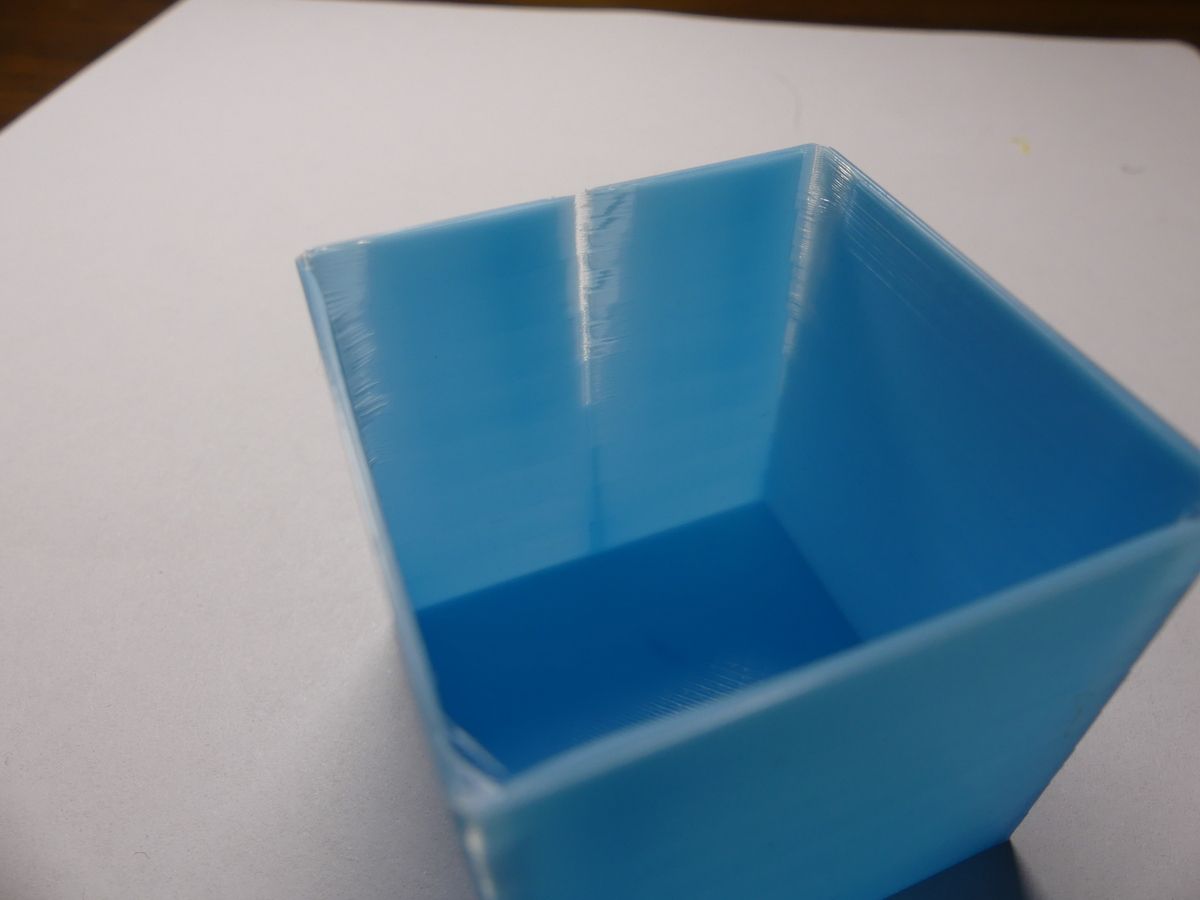

However for the basic PA test i would change the cylinder to a rectangle and set the start/endpoint in the middle of one of the faces. That way you can see how the seam looks as well as how the corners look (corner bulging).

I think the test from @DigitalVision is definitely the best, such a smart person, i would love to have him on my engineering team. -

I have an ongoing long print that will end if 20h

so will print the test and take pictures then. I tried in the past one of the python based PA tests that posted here but I think that requiring installation and running a python script is a high bar in general so slicer only solution or an online tool that generates the test are more accessible IMO.

so will print the test and take pictures then. I tried in the past one of the python based PA tests that posted here but I think that requiring installation and running a python script is a high bar in general so slicer only solution or an online tool that generates the test are more accessible IMO. -

@Phaedrux said in Pressure advance doesn't affect the printed model:

Would you be able to post a photo of the resulting print showing the difference along the seam?

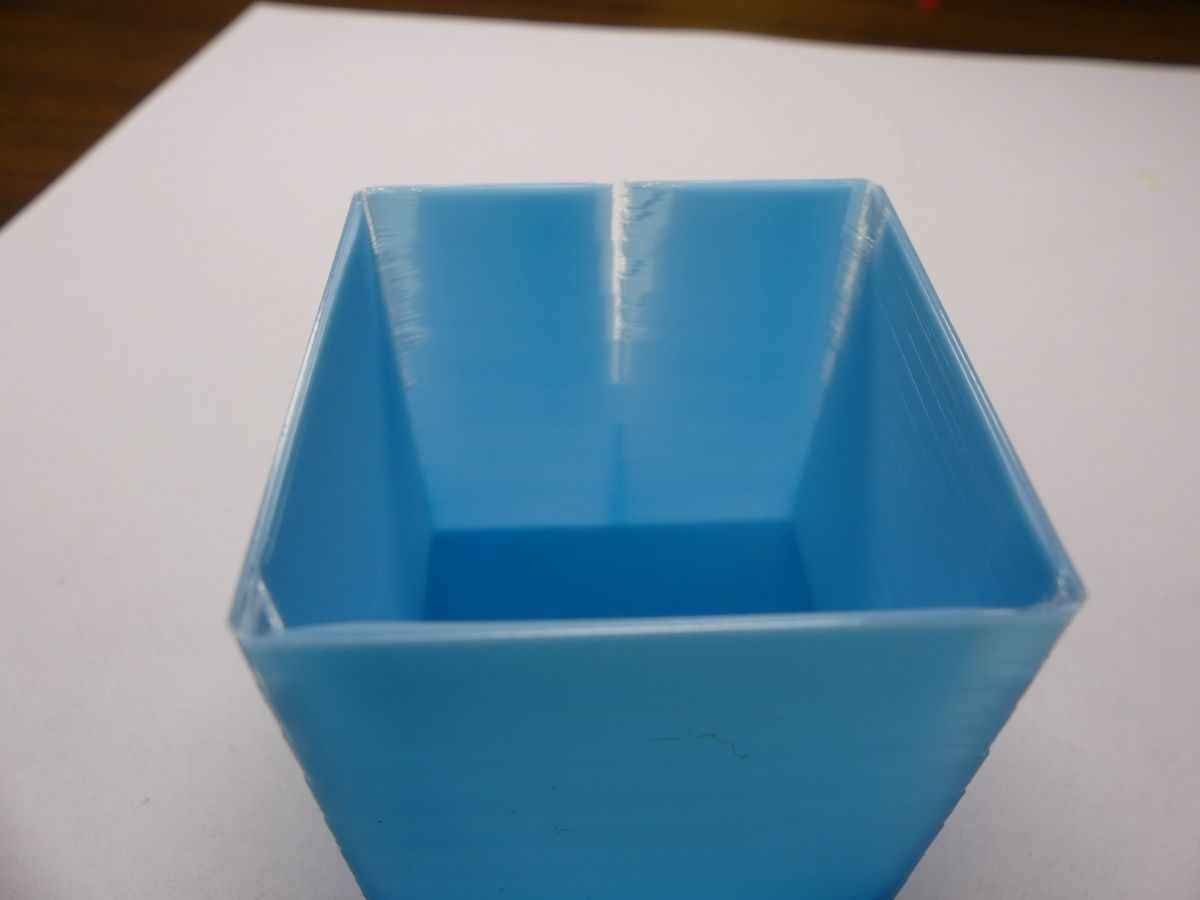

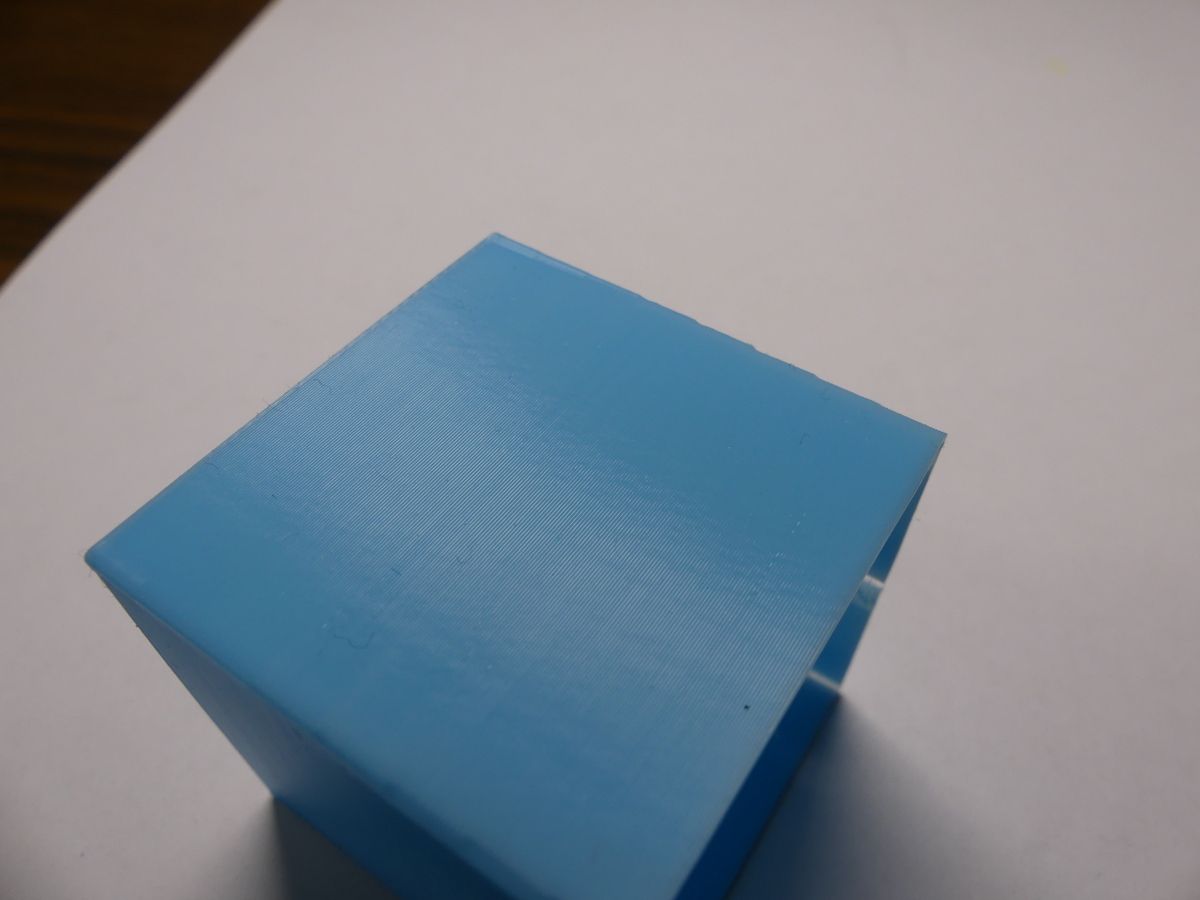

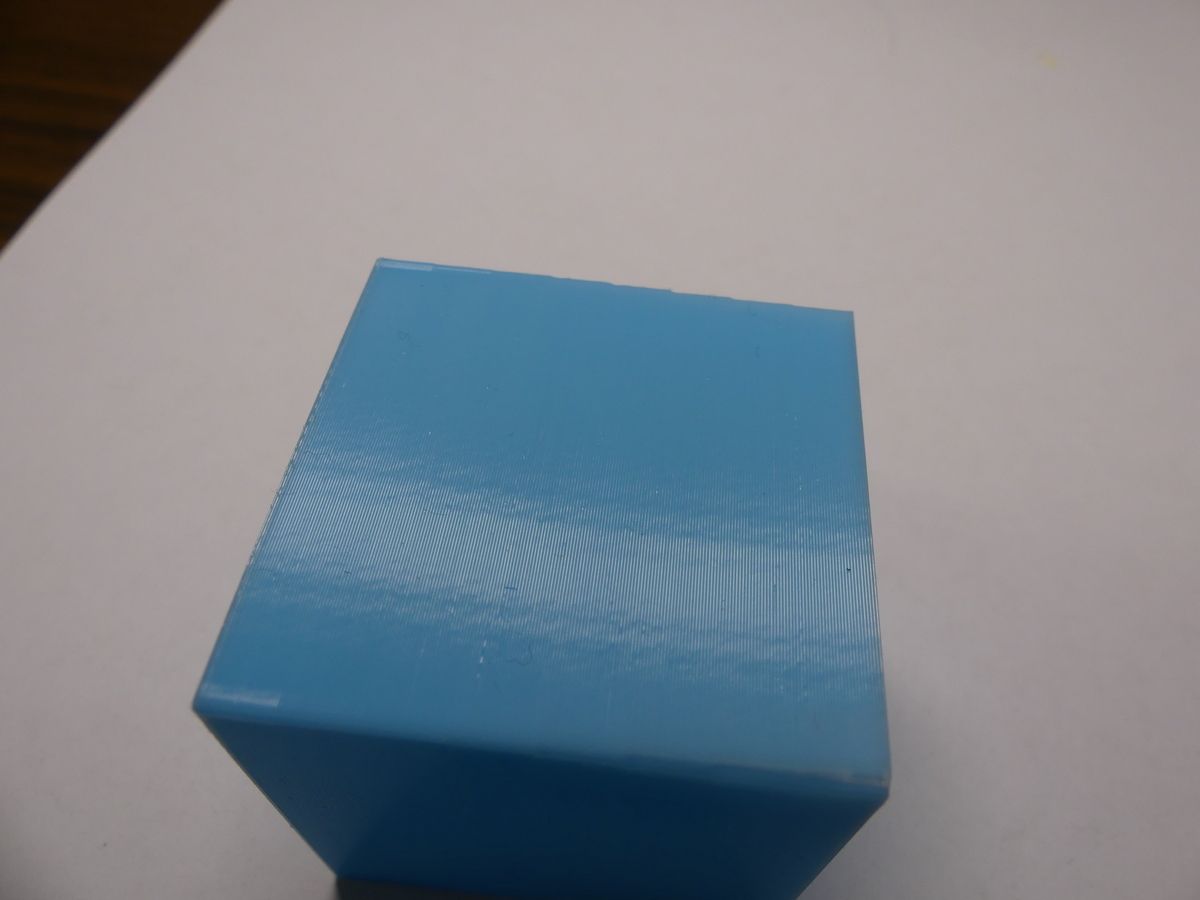

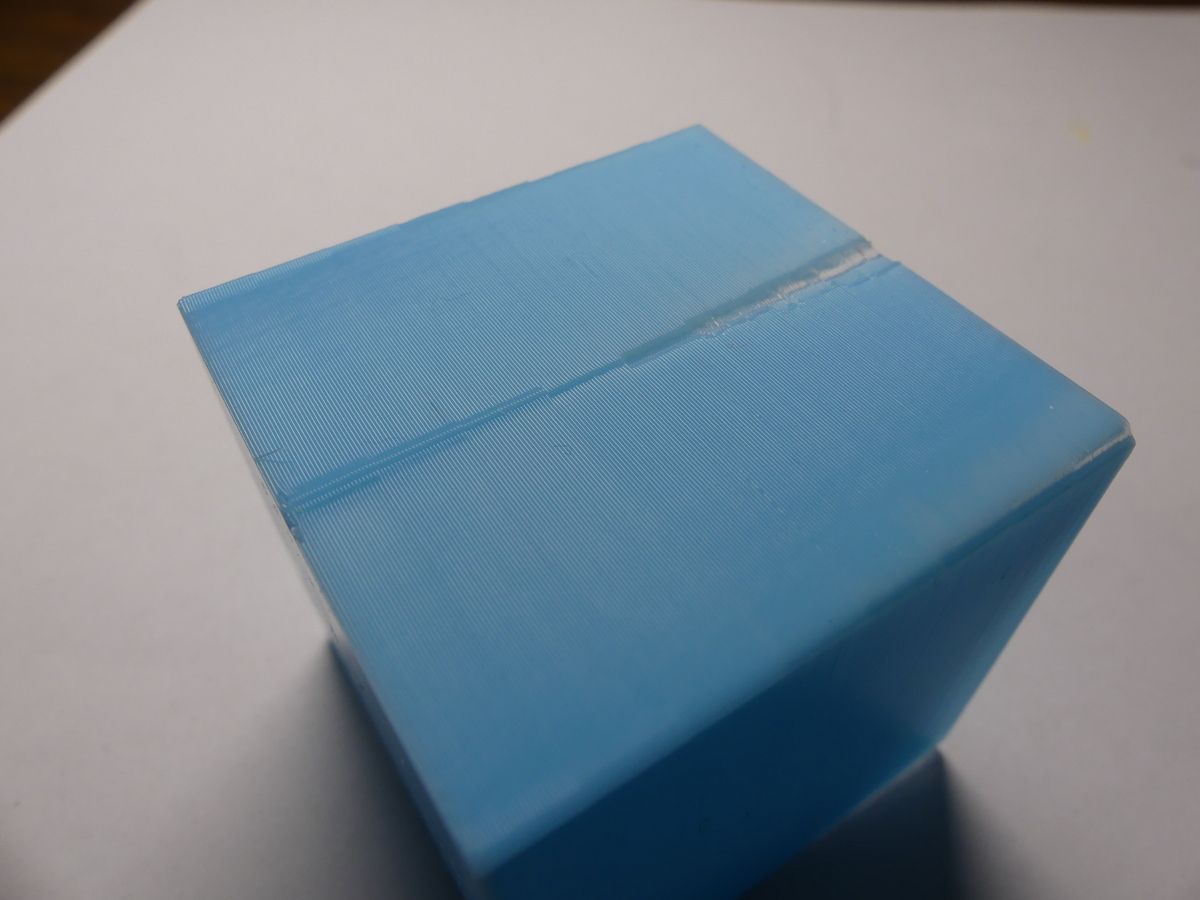

Below are some pictures. This is a 40x40x40mm cube, 2 layers bottom, 2 perimeters, 0 layers top, 0 infill, Prusa Slicer with this before-layers conditional gcode:

; 0.2mm layer, 8 bands 5mm each, total height 40mm {if layer_num== 1}M572 D0 S0.0 {elsif layer_num== 25}M572 D0 S0.05 {elsif layer_num== 50}M572 D0 S0.10 {elsif layer_num== 75}M572 D0 S0.15 {elsif layer_num== 100}M572 D0 S0.20 {elsif layer_num== 125}M572 D0 S0.25 {elsif layer_num== 150}M572 D0 S0.30 {elsif layer_num== 175}M572 D0 S0.35 {endif}The optimal band is the 4th from the bottom at PA=0.15. This is with a BMG+Titan direct extruder.

-

@zapta That's perfect. Thank you. I'll update the PA doc.

-

@Phaedrux said in Pressure advance doesn't affect the printed model:

I'll update the PA doc.

Thanks Phaedrux.