Pressure advance doesn't affect the printed model

-

@skayred said in Pressure advance doesn't affect the printed model:

@NitroFreak will try on the weekend. I didn't try it before due to recommendation in the docs (~0.2 for long Bowden and ~0.1 for 400mm). And filament is PETG from DevilDesign if it matters.

Yes that documentation needs to be changed ASAP, i dont know how many people already did that mistake.

dc42 did the documentation based on his findings of needing 0.1 for a titan aero; however that one does have an extremely short filament path, and the length of the filament path is directly, loosely linearly related to the amount of pressure advance needed.Your safest bet is to do a Pressure Advance calibration based on this thread,

https://forum.duet3d.com/topic/6698/pressure-advance-calibration

But do it from 0.0 to 1.0.

That way you will get the best result. -

@NitroFreak okay, will try to do. And by the way, I tried to run the gcode generated by the provided script but Duet returns tons of errors and eventually hangs, that's why I insert the commands manually.

-

@skayred said in Pressure advance doesn't affect the printed model:

@NitroFreak okay, will try to do. And by the way, I tried to run the gcode generated by the provided script but Duet returns tons of errors and eventually hangs, that's why I insert the commands manually.

It´s all explained in the thread, you have to use the start and end gcode from another program to set the temperatures etc. otherwise you will get errors. Also you have to make sure that the script doesnt return gcode that sends the print head out of bounds. Best use a slicer to visualize the gcode that the script produced.

-

@NitroFreak well I did use start and end. Interpretation fails on the actual printing code, I suspect, due to Win line endings, but it doesn't really matter as I have own testing model

-

@skayred said in Pressure advance doesn't affect the printed model:

could it be the problem, that I have the wrong version that just doesn't support PA?

No, it should be supported regardless.

Setting pressure advance in config.g and then sending a new command later is fine. The most recent command will take over. When changing PA on the fly there may be a brief pause at the next segment. You can send M572 D0 in the console to get a read back of the currently set value if you want to verify that it's set.

M350 X64 Y64 Z64 E64 I1

Interpolation to x256 microstepping only works when using x16 microsteps on the Duet Wifi. You'll likely notice quieter operation if you switch back to x16 with interpolation. The other benefit is lower overhead on the CPU which could lead to missed steps on high speed moves. You can check if this is effecting you by sending M122 in the console and looking for the hiccup count.

I suggest pushing further with your speed testing and increasing the PA value.

-

So, I made a g-code with PA from 0 to 1, and it finally shows some difference. But my PA should be set to:

M572 D0:1 S0.64So, do I have to worry about such a high value or it is normal?

-

@skayred said in Pressure advance doesn't affect the printed model:

So, do I have to worry about such a high value or it is normal?

Based on your testing it's normal for you. Only way to be sure it to do some more testing of actual models and watch for anomalies.

-

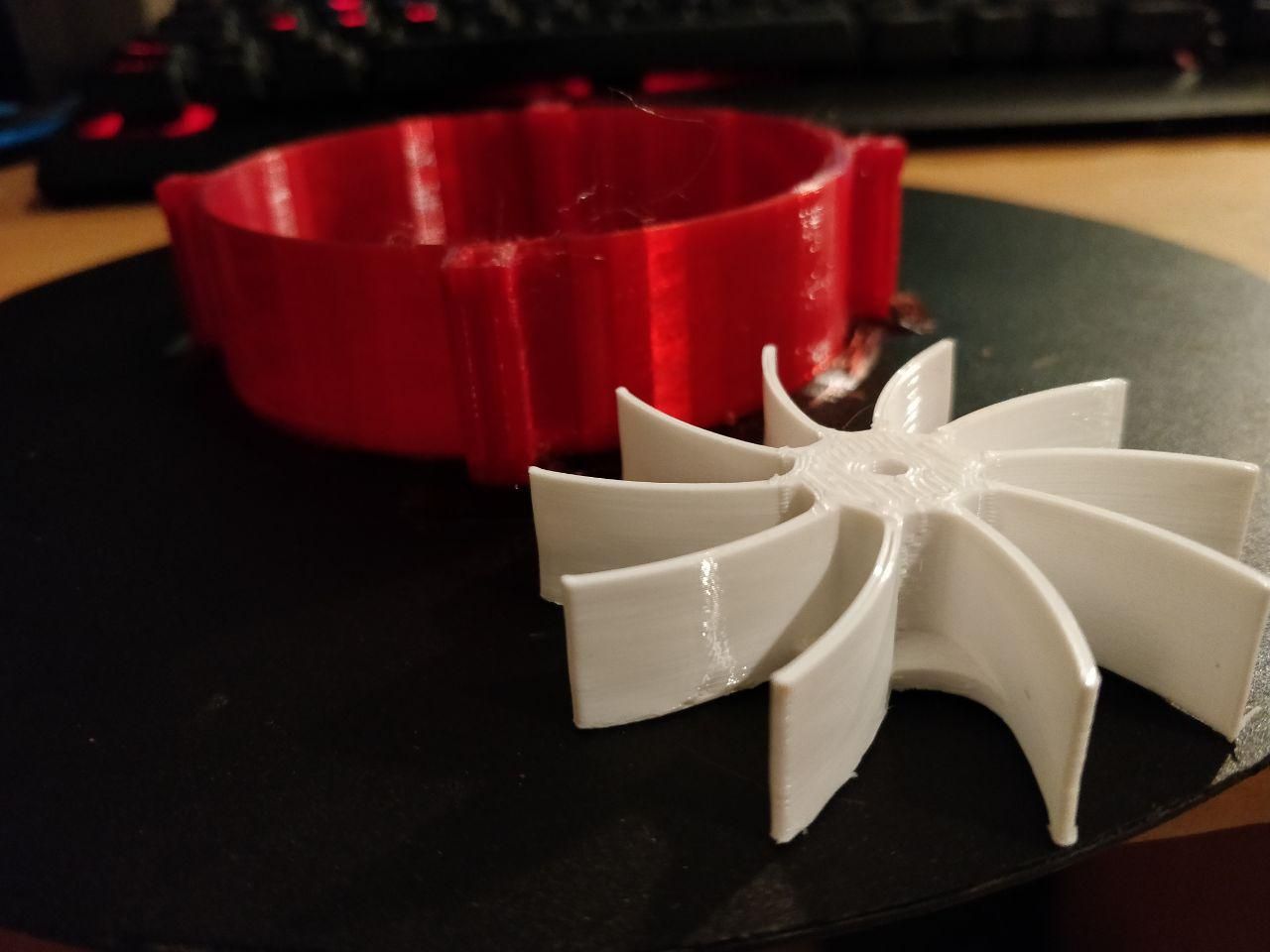

@Phaedrux will try to print the propeller because why not

-

Thank you, guys!

The propeller was printed perfectly, with no stringing and blobs so I can fit it to the shaft, finally! -

@skayred said in Pressure advance doesn't affect the printed model:

Thank you, guys!

The propeller was printed perfectly, with no stringing and blobs so I can fit it to the shaft, finally!Great! Photo?

-

@dc42 Can you edit the documentation to say that values of higher than 0.2 is very normal and maybe necessary for bowden setups? I even have some PC filaments that needed 0.68 for a 100mm direct drive setup.

What I have found is that the PA necessary is linearly related to the length of filament between the drive gears and the heat break. I needed pretty much exactly 1/5th the PA when i switched from a 100mm bowden to a 20mm direct drive.

This will reduce confusion with future users. -

@dc42 hello,

now it looks like this:

This is the propeller side with most retractions between wings. Not really invisible but good enough for me. I think I will need to experiment with retractions but the generally proper value of PA makes everything better.

But, as was said there, documentation is really confusing, I was not even trying to make PA much higher than recommended. -

@NitroFreak said in Pressure advance doesn't affect the printed model:

@dc42 Can you edit the documentation to say that values of higher than 0.2 is very normal and maybe necessary for bowden setups? I even have some PC filaments that needed 0.68 for a 100mm direct drive setup.

What I have found is that the PA necessary is linearly related to the length of filament between the drive gears and the heat break. I needed pretty much exactly 1/5th the PA when i switched from a 100mm bowden to a 20mm direct drive.

This will reduce confusion with future users.Yes I can update the documentation.

-

@NitroFreak I've made some changes to flesh out the documentation a bit. https://duet3d.dozuki.com/Wiki/Pressure_advance any feedback welcome.

-

The PA test procedure with the large cylinder is very interesting. I will give it a try. Possibly it can even be automated with slicer gcode conditions similar the to ones used for heat towers.

{if layer_z==1.6} ; T tower floor 1 M104 S225 {elsif layer_z==11.6} ; T tower floor 2 M104 S220 ... {endif} -

@zapta said in Pressure advance doesn't affect the printed model:

Possibly it can even be automated with slicer gcode conditions similar the to ones used for heat towers.

Yes exactly.

-

@Phaedrux said in Pressure advance doesn't affect the printed model:

Yes exactly.

I run this PA calibration and it was easy to set up and interpret the results. Best value is 0.15 for my BMG/Titan direct extruder. I expected it to be lower.

I use script in the Prusa Slicer's Before Layer gcode section (this one is after I narrowed down the search range)

{if layer_num== 1}M572 D0 S0.125

{elsif layer_num== 25}M572 D0 S0.130

{elsif layer_num== 50}M572 D0 S0.145

{elsif layer_num== 75}M572 D0 S0.150

{elsif layer_num== 100}M572 D0 S0.156

{elsif layer_num== 125}M572 D0 S0.160

{elsif layer_num== 150}M572 D0 S0.165

{endif} -

@zapta Well done. Would you be able to post a photo of the resulting print showing the difference along the seam? I could add the photo and the layer gcode to the documentation as example.

-

@Phaedrux, sure, I am not sure I kept it but can print another once. I did it in two phases, first first large steps and then smaller steps around the target area.

-

@Phaedrux

Yes that already looks very good, it will help new people a lot since i have already seen a lot of people thinking PA needs to stop at 0.2.

However for the basic PA test i would change the cylinder to a rectangle and set the start/endpoint in the middle of one of the faces. That way you can see how the seam looks as well as how the corners look (corner bulging).

I think the test from @DigitalVision is definitely the best, such a smart person, i would love to have him on my engineering team.