Adding a 24V safety relay for the heaters, any thoughts?

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

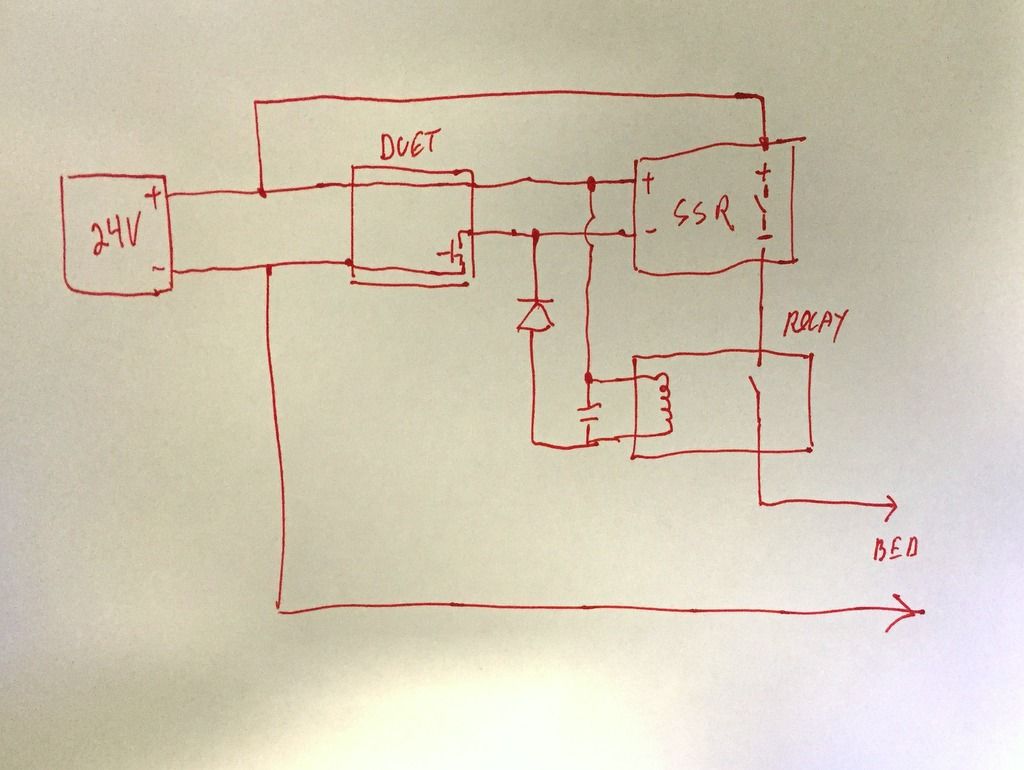

On a second thought, maybe the mechanical relay can be added without using the PS_ON signal. Something along the lines of the diagram below. The mechanical relay closes the circuit as long as the duet sends PWM to the heated bed. Once the duet stops sending PWM, the circuit will break even if the SSR's mosfet get shorted (the duet's mosfet drives a small load so much less likely to get damaged).

Will this work?

Looks to me like you basically duplicated the SSR function in the relay so that if either SSR or Relay fails, there is no power to the heat bed.

If you ae going to the trouble of a safety circuit then you might as well make it completely redundant by running the relay coil through a thermal fuse to the 24V power supply. As long as there is 24V and the fuse is ok, the bed has power that can be controlled by the SSR. In the event of an overheat situation, the fuse blows and the relay drops out.

Not sure why you have the diode in there and not a flyback diode. -

I don't understand the reluctance of using a thermal fuse for the bed. They are cheap and easy to use. If you are concerned with the reliability of a single fuse, put two in series.

Since thermal fuses generally are limited to 10A, using a relay helps to get the power rating up.None of this helps to guard against a printhead melt down but as mentioned before, you could mount a thermal fuse to the heatsink for some protection. Not sure how reliable that would be (you would need to figure out the maximum temperature that you would reach at the mounting location under normal use) but it would most certainly be better than no fuse.

-

relay contacts can still weld and effectively short like fet/ssr, but less common, and if you can avoid switching under load you greatly reduce the risk.

-

In the case of running the relay contacts off the 24V supply through a thermal fuse, you would never switch the contacts under load. The relay would activate when you power up the printer and stay active until you shut the printer off (unless the thermal fuse blows).

-

@jens55 "running the relay coil through a thermal fuse to the 24V power supply."

Yes, you are right, the thermal fuses fits well in this diagram since they don't have to handle the full bed current.

I plan to play a little with the PS_ON signal trying to understand it better. Will first use it to trigger a small 24 bulb so I can see when it's on and when it's off.

-

@zapta said in Adding a 24V safety relay for the heaters, any thoughts?:

@jens55 "running the relay coil through a thermal fuse to the 24V power supply."

Yes, you are right, the thermal fuses fits well in this diagram since they don't have to handle the full bed current.

I plan to play a little with the PS_ON signal trying to understand it better. Will first use it to trigger a small 24 bulb so I can see when it's on and when it's off.

Interesting that you mention a bulb .... I have a 100W 120V bulb permanently paralleled to my heat bed to let me know when it's powered up. It started as a 'temporary' thing but I really appreciate knowing what is happening.

-

Putting interlocks and checks on the coil side of the relay is the approach I used on a test system I built for a previous employer. It can reduce "diagnostic coverage" which is how much the system can be checked for correct opperation, but some of that can be covered with procedure. We're not needing a high performance level of the interlock compared to industrial systems such as robot cells where the probability of injury is far higher.

Risk of contact welding is significantly dropped by the use of suitably rated fuses to limit the current to well within the specification of the relay. Picking the relay to match the load is an obvious step amd thankfully inductive poad is minimal. Yes relays can fail shut but it isn't their common failure mode and relays are far more tollerant to transient spikes than MOSFETS.

Guided contact relays are expensive, but if the contacts on one pole weld shut the whole relay stays in the active position. You can use spare normally closed contacts to create a latch with a push button which effectively checks the relay each time you start the system.

-

Meltable heater fuses are common in all commercial products, why not use one for the bed? Normally they don't allow too much current to pass as they are intended to be used on mains so the heaters that run on mains can have the main heater wire just wired trough fuse, and if you are running a DC heater then it's required to either pass the main mains powering the printer trough this fuse or find thermal fuse with higher current capacity. You can easily find 10 and 15 Amp ones, that should be enough even for most DC powered beds.

e.g. Thermal Fuse 10A 250V 120˚C

or something like this https://www.digikey.com/product-detail/en/cantherm/SDF-DF144S/317-1135-ND/1014764

-

@Danal said in Adding a 24V safety relay for the heaters, any thoughts?:

(1) Trusting firmware for safety, if not designed from the very beginning around total shutdown driven by a hardware watchdog (charge pump, etc), is not safe.

..

To be clear: Relays are useless, and possibly worse than useless, by given a false sense that they accomplish something.In case of my 3D printer there is such a thing as 'good and unintrusive enough'. Quick incomplete analysis:

-

Bed heater stuck on full heat probably won't cause disaster; it is made out of aluminium, ceramic mat as insulation, silicone heater, supported on PTFE bushings and stainless steel screws. No real danger until the autoignition temperature of the plastic on top is reached and it is quite unlikely that the temperature rises that far given the limited power density of the heater.

-

Nozzle heaters stuck on full heat are worse, but only if they are buried in plastic. If they are free in the air, they bubble and boil plastic out, the last bits of plastic exit the nozzle in a fierce gaseous jet, and the silicone sock might turn dark brown and fall apart. But as long as the cooling loop keeps running no life threatening situation develops.

-

Motors are unlikely to burn, electronics are flame retardant enough and far away enough of flammable materials. Unlikely to cause a fire there.

Considering the above, being able to cope with a single point of failure and doing so preferrably before permanent damage is done is sufficient for me. This is something well within the capabilities of a mechanical relay and regular firmware. The remaining issue is that the Duet CPU currently is a single point of failure; if the processor decides to hang after the heaters and PS are turned ON there is no second mechanism left to act on that.

Regarding the AFO fireballs and similar solutions: I was about to buy a couple of them. But I asked two independant persons with a lot of knowledge and experience with firefighting before I did so. One had actually tested these fireballs, the other had no personal experience with them but knew what I was talking about. Both said independantly of each other 'Do not bother with them unless you really have to. It is better than nothing, but their their effectiveness is too low. If you want actual protection instead of a good feeling, use a sprinkler instead. Way cheaper also'.

-

-

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

use a sprinkler instead. Way cheaper also

Could you expand on that? It would seem a sprinkler requires a water supply, and it is hard to see how that is cheaper.

-

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

..................... It is better than nothing, but their their effectiveness is too low. If you want actual protection instead of a good feeling, use a sprinkler instead. '.

Better still, use a clean agent fire extinguisher as I mentioned above - much kinder to the electronics than water (or foam).

-

But nasty to people I guess? add ventilation or oxygen alam or no big deal?

-

@bearer Not sure about that TBH. I don't think they are desperately harmful - at lease there are no warning stickers to that effect. It is necessary to use a size which is appropriate to the volume of space in which it is enclosed but I think that's more to do with ability to put out a fire if the extinguisher was too small. The only thing I can add is to quote from the site that I linked too above which states "Typical applications include Boats, Computer Rooms, Clean rooms, switch rooms and telecomms, Data Storage Areas and art storage rooms."

-

.........bit more information here - https://blog.koorsen.com/a-comparison-of-the-three-most-common-fire-suppression-clean-agents-inert-novec-1230-and-fm-200 which indicates that clean agent systems are not a health risk in themselves - at least that's my take on it.

@zapta - apologies for going off at a tangent in your thread.

-

@deckingman i did have a read and couldn't say for sure which gas it is and if it was lighter or heavier than the oxygen its meant to displace, in any case displaced oxygen isn't a good thing for people. how dangerous it is depends a little on how it behaves in the event of a leak. it listed nitrogen but not sure if thats just a part of it or the whole thing.

-

@bearer Yes, not sure either. But I guess faced with a room full of smoke, the best advice would be to "leg it", regardless of what the atmosphere contained in addition to the smoke and other noxious combustion products.

In my own situation, the extinguisher is fitted to a fairly well sealed, enclosed "booth" which itself is inside my garage. So in the worse case scenario, I'd open the garage roller door to give plenty of ventilation before opening up the "booth" (after the fire has been extinguished of course). My main reason for fitting it was that the booth itself is made from MDF and painted, so nice and flamable

In my own situation, the extinguisher is fitted to a fairly well sealed, enclosed "booth" which itself is inside my garage. So in the worse case scenario, I'd open the garage roller door to give plenty of ventilation before opening up the "booth" (after the fire has been extinguished of course). My main reason for fitting it was that the booth itself is made from MDF and painted, so nice and flamable

-

@deckingman no, the worst case scenario is a leak or otherwise unintended discharge without a delay to allow evacuation of personnel; maybe a garage is less of an issue but given nitrogen actually kills people in industrial settings where the danger should be known I'd hesitate to recommend something like that for use in residential settings without much clearer warnings or monitoring.

-

@bearer That's true - hadn't thought about errant leakages.

Edit. But try as I might, I can't find any evidence that clean agent fire extinguishers are hazardous to health (unless you act really stupidly). My searches keep coming with sites such as this https://resources.impactfireservices.com/are-fire-suppression-systems-harmful-to-humans

TL:DR quote "These systems are generally people-safe and approved for normally-occupied rooms when designed within appropriate criteria."

-

@deckingman Maybe its better if you ask the manufacturer what the appropriate design criteria is; the US is or is looking into using nitrogen for their capital punishment - which I doubt they'd do if it didn't have some adverse health effects.

Maybe they have added a scent or colour to the gas, idk. But inert gasses are dangerous, even a common CO2 extinguisher can take care of both you and the fire if you use it in a small basement without some thought to your own safety.

-

@DaBit said in Adding a 24V safety relay for the heaters, any thoughts?:

given the limited power density of the heater

I have 750W, 1000W and 2500W silicone heaters here on some aluminium beds ... never tested how far they can go but they get up to 100C in seconds, I would never allow them to run without meltable fuse for security. Running low power beds that would settle at max power around 100-150C is safe but I don't run those and more and more printers are made/upgraded with high power beds.