Very Strange Mesh map

-

@droftarts As requested

m115 FIRMWARE_NAME: RepRapFirmware for Duet 2 Maestro FIRMWARE_VERSION: 3.0 ELECTRONICS: Duet Maestro 1.0 FIRMWARE_DATE: 2020-01-03b3and

; Configuration file for RailCore II 300 ZLT ; Communication and general M111 S0 ; Debug off ;Network M550 P"RailCore II" ; Set machine name M552 P192.168.0.7 S1 ; Enable network and set IP address M553 P255.255.255.0 ; Set netmask M554 P192.168.0.1 ; Set gateway M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S1 ; Enable Telnet M575 P1 B57600 S1 ; Comms parameters for PanelDue G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration M669 K1 ; CoreXY mode ; Drives M584 X0 Y1 Z5:6:7 E3:4:8:9 ; Map Z to drivers 5, 6, 7. Define unused drivers 3,4,8 and 9 as extruders M569 P0 S1 ; Drive 0 goes forwards (change to S0 to reverse it) X stepper (Rear) M569 P1 S0 ; Drive 1 goes backwards Y Stepper (Front) M569 P2 S1 ; Drive 2 goes forwards Unused M569 P3 S1 ; Drive 3 goes forwards Extruder M569 P4 S1 ; Drive 4 goes forwards Extruder (unused) M569 P5 S1 ; Drive 5 goes backwards Front Left Z M569 P6 S1 ; Drive 6 goes backwards Rear Left Z M569 P7 S1 ; Drive 7 goes backwards Right Z M84 S30 ; Set idle timeout ;Leadscrew locations M671 X-10:-10:333 Y22.5:277.5:150 S7.5 ;Front left, Rear Left, Right S7.5 is the max correction - measure your own offsets, to the bolt for the yoke of each leadscrew ; Axis and motor configuration M350 X16 Y16 Z16 E16 I1 ; set 16x microstepping for axes& extruder, with interpolation ;Endstop Configuration M574 X1 S1 P"xstop" ; _RRF3 M574 Y1 S1 P"ystop" ; _RRF3 ;Speeds M906 X1400 Y1400 Z2400 E700 I60 ; Set motor currents (mA) M201 X3000 Y3000 Z100 E1500 ; Accelerations (mm/s^2) M203 X24000 Y24000 Z900 E3600 ; Maximum speeds (mm/min) M566 X1000 Y1000 Z100 E10 ; Maximum jerk speeds mm/minute M92 X200 Y200 M92 Z1600 M92 E407 ; steps/mm ; M204 P1500 T1500 ; M208 X-10:310 Y-8:293 Z-0:550 ; set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed) ; Thermistors ;Bed Configuration M308 S0 P"bedtemp" Y"thermistor" A"Bed-Top" T100000 B3950 R4700 H0 L0 M950 H0 C"bedheat" T0 M143 H0 S120 M307 H0 A481.6 C758.5 D11.3 V24.2 B0 ;HotEnd Configuration M308 S1 P"e0temp" Y"thermistor" A"E3Dv6" T100000 B4725 R4700 C7.06e-8 H0 L0 ; M950 H1 C"e0heat" T1 ; M143 H1 S280 M307 H1 A503.9 C237.3 D4.9 V24.2 B0 ; ; Other Tempreture Inputs M308 S6 P"exp.thermistor6" Y"thermistor" A"Keenovo" T100000 B3950 R4700 M308 S7 P"exp.thermistor7" Y"thermistor" A"RoomTemp" T100000 B3950 R4700 ; Fans M950 F0 C"fan0" ;Part Cooling Fan M106 P0 H-1 ; M950 F1 C"fan1" Q500 ;Hotend Fan M106 P1 S1 H1 T40 ; M950 F2 C"fan2" ;_RRF3_ define fan2 M106 P2 H-1 ; M106 P0 S0 ; turn off fans ; Tool definitions M563 P0 D0 H1 ; Define tool 0 G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ; Z probe and compensation definition M558 P9 C"^zprobe.in" H5 R1 F120 T6000 A5 S0.02 ;BLTouch connected to Z probe IN pin M950 S0 C"duex.pwm1" ;BLTouch Servo (S0) on duet pwm1 G31 X2 Y42 Z1.422 P25 ; Customize your offsets appropriately - do a paper test, and put the probed value in the Z value here M557 X30:280 Y30:280 S20 T0 ; select first hot endThanks for looking.

P.

-

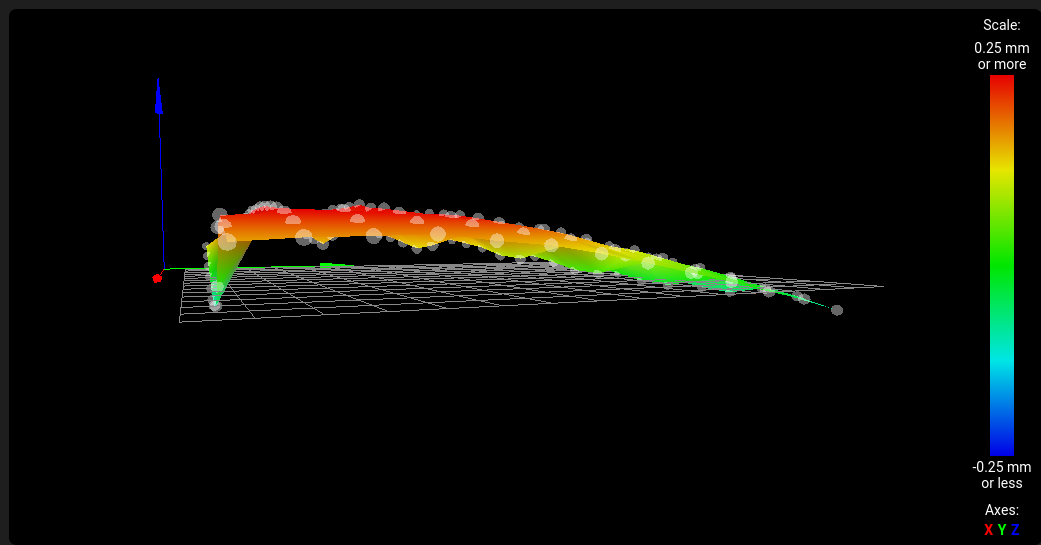

@PaulHew yes, 40mm X offset on probe. All points on the mesh in one direction are high, and low in the other direction, so the carriage is rotating in the XZ plane. What’s the X axis? Linear rail? HiWin or cheaper Chinese copy? I’d guess latter, and tolerances aren’t great, causing lateral movement. Alex Kenis has done some great YouTube videos on these, worth watching.

You may be able to reduce this by tightening the belts, but I’m not sure.

Ian

-

@droftarts All axis have original HiWin rails, 3 on Z, 2 on Y and 1 on X.

I will check the belt tension.

Could a slight wobble on one of the Z leadscrews cause this too?

Thanks again Ian

-

@PaulHew said in Very Strange Mesh map:

Could a slight wobble on one of the Z leadscrews cause this too?

I wouldn't think so. Seems like a case of backlash though. Are you able to wiggle the print carriage by hand? Are the belts equally tensioned?

-

@Phaedrux The print head is solid, I purchased all of the aluminium upgrade parts so there is no plastic.I will check the belt tension, again as I have just plucked the belts and one sounds higher than the other.

Belts were about 60-60hz. Have tweaked them down to 50hz and running a mesh now.

Thanks @Phaedrux and @droftarts

Paul

-

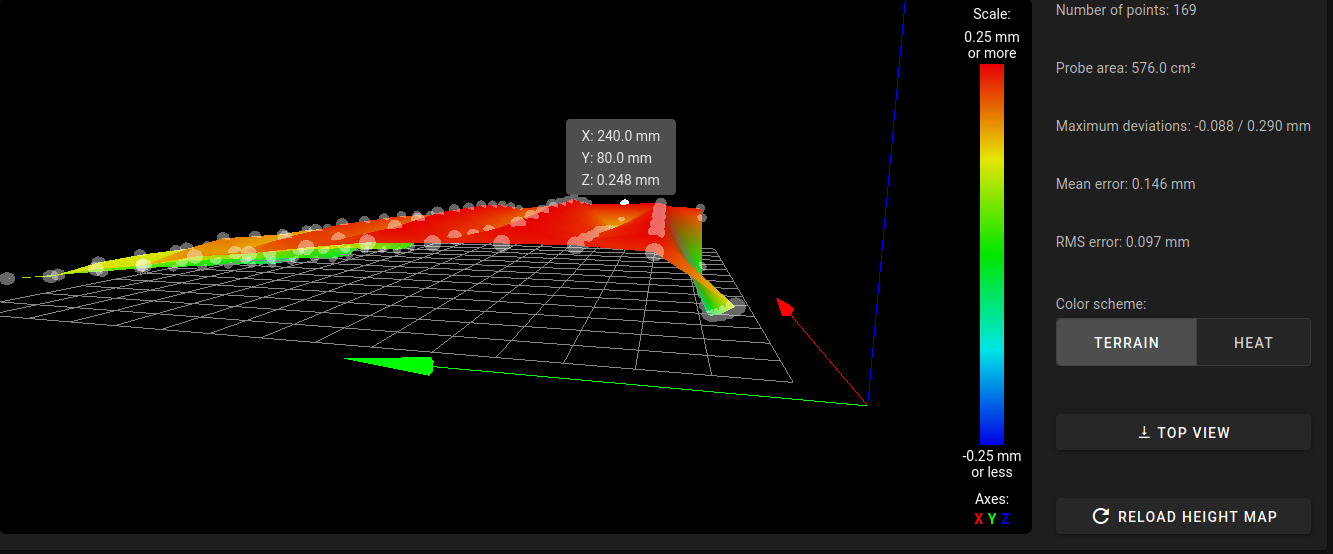

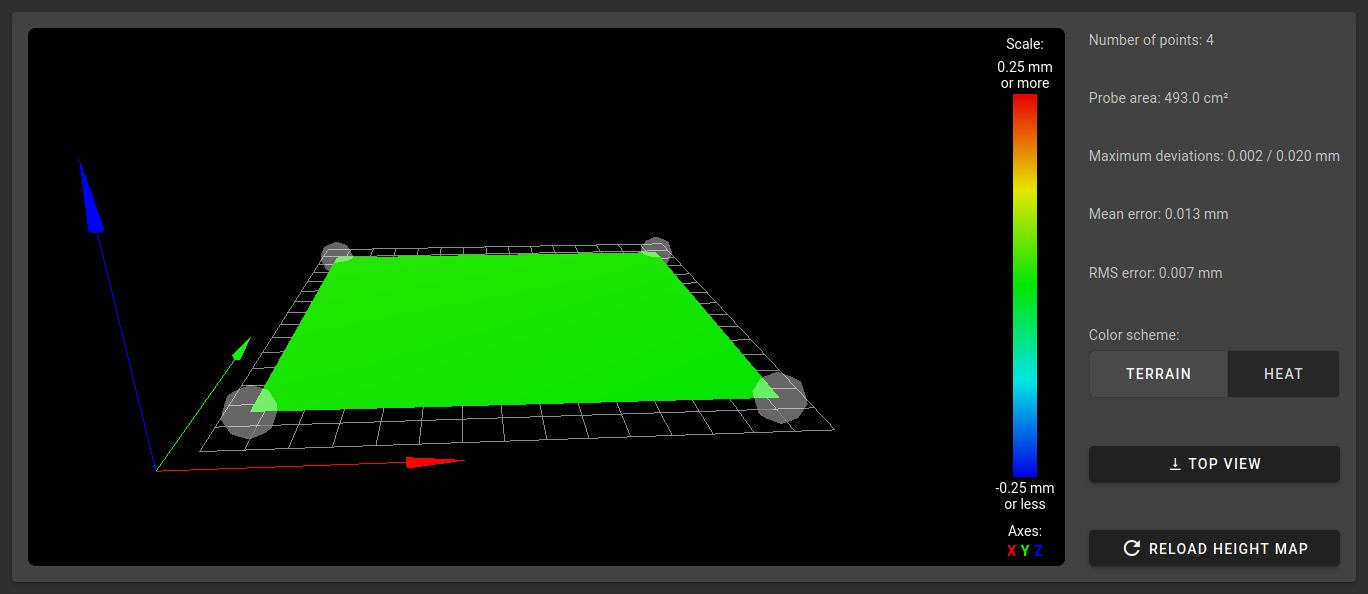

Latest mesh after re-tuning the belts

and another angle

-

So... better?

-

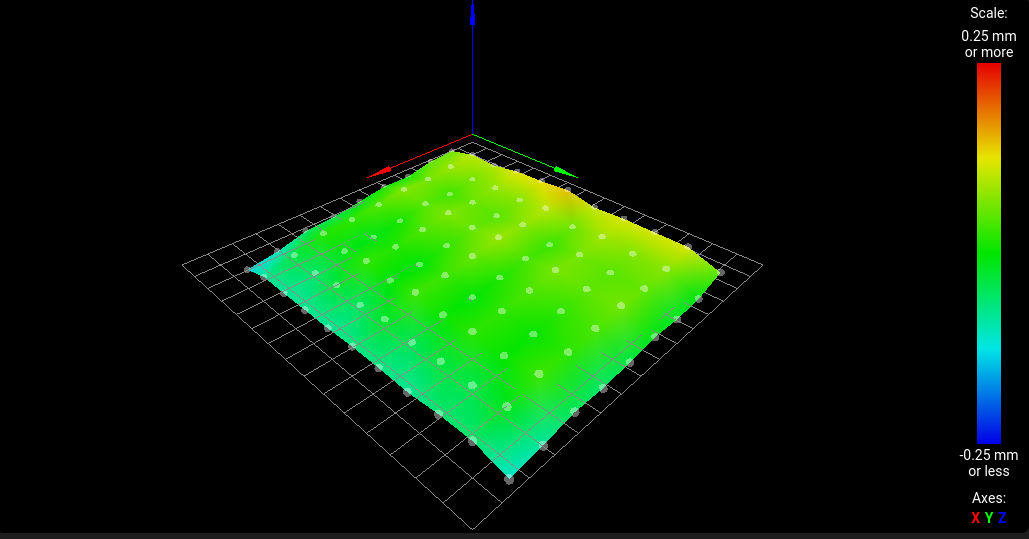

I was expecting something better than this, This is on my Ender3

Considering the cost and only putting premium parts in it, I was expecting or hoping to get it green all the way.

This is the latest from my Railcore with a 9 point grid.

I have a 4mm glass mirror tile on a 6mm machined bed.

Maybe I should take the glass off and probe the bed.

-

@PaulHew said in Very Strange Mesh map:

Maybe I should take the glass off and probe the bed.

Would be interesting to see the difference. Is it possible the bed was damaged in shipping or that it came with some waves?

-

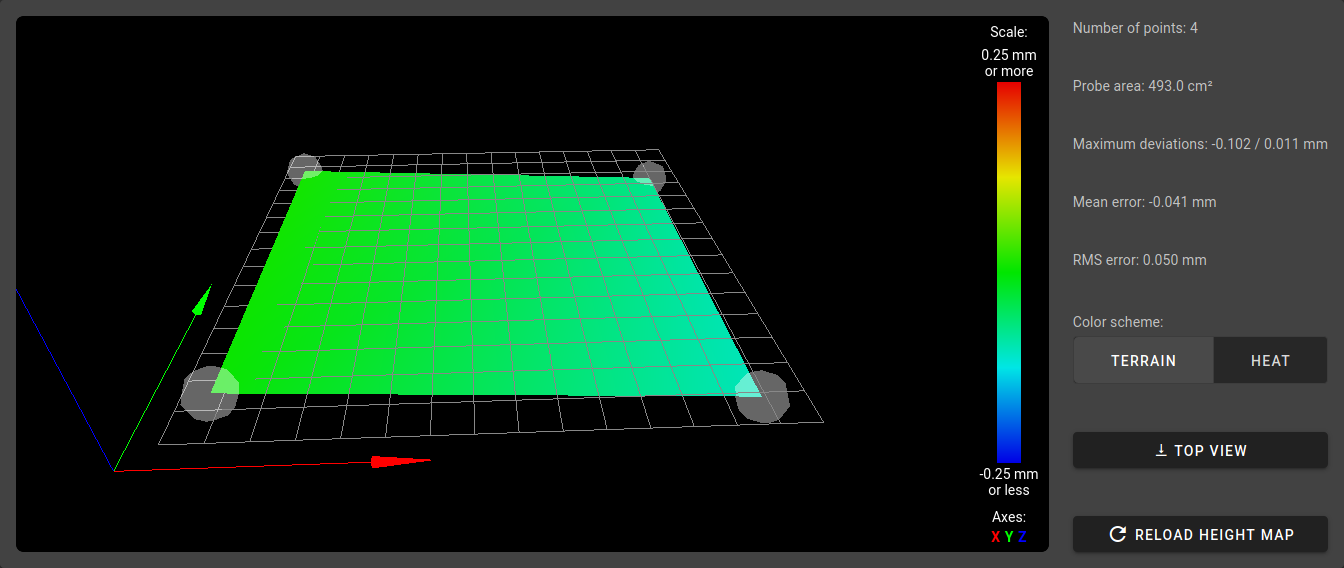

I have changed to a 4 point probe and adjusting the rails as I need.

Its looking better than the previous posts.

Long process, but getting there! -

Ah yes, the rails. Should have thought of that.

-

Your bed map looks very good with just a slight tilt. I'd be extremely happy to have something that smooth.

Going to 9 point is like trying to look at a picture with the vast majority of it's pixels removed and substituted with average values - useless. 4 point and 9 point meshes are good for the very initial steps of leveling the bed but nothing beyond that. -

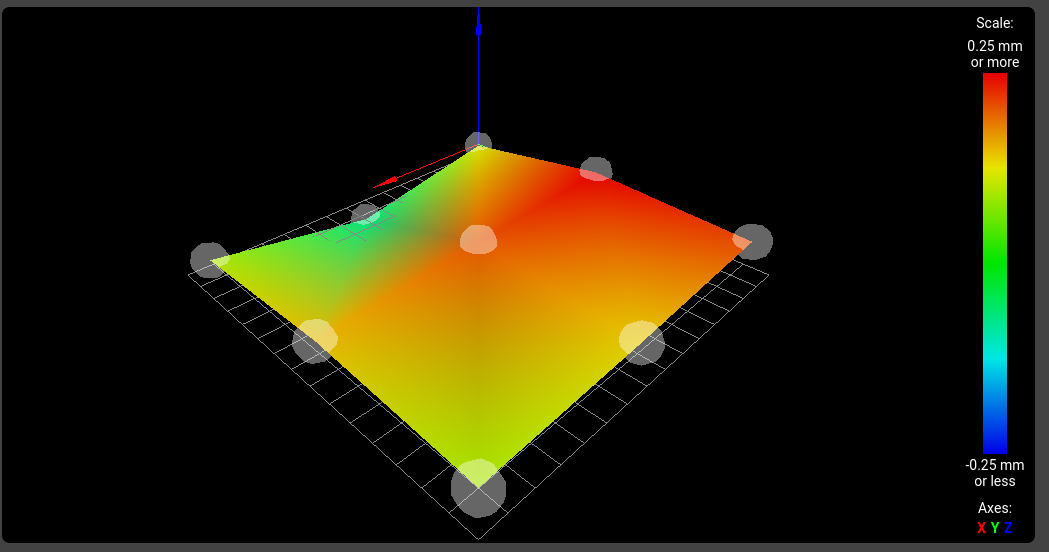

So after adjusting rails and tweaking things, I am now here.

I thought I would update so others could benefit.

I was close before, but one corner was not right, front right. Back right was OKish

Satre on the Railcore discord forum asked me to try something.

Originally I was running a 3 point levelling routine, near the leadscrews.

He suggested I use a 4 point, so changed my bed.g toM561 ; clear any existing bed transform G1 Z5 ; RRF3 remove S2 G30 P0 X15 Y45 Z-99999 G30 P1 X15 Y275 Z-99999 G30 P2 X275 Y275 Z-99999 G30 P3 X275 Y45 Z-99999 S3 G1 X0 Y0 F5000 ; move the head to the corner (optional)Power off then on, (I wait at least 15secs before powering back on)

I ran G32 5 times to get the bed as near as level then ran a 4 point mesh and ended up with a nigh on perfect mesh.So pleased and can get printing now that I have all of the niggles ironed out.

Issues were bad idlers, cheap belt, belt tension was also toooooo high - 65hz, at about 50hz now.Thanks to all who suggested brilliant ideas, everything on here and discord got me to this place.

Kind Regards,

Paul.

-

While you certainly have done a great job levelling the bed, you do NOT have a mesh map!

Your printer has exactly ZERO information about what is going on in the middle of the bed. All it knows is that the 4 corners are looking good.

If you are happy printing without mesh bed compensation then you are golden but you are wasting a great feature and doing yourself a dis-service by not going to the highest resolution mesh.