Which crimper to get for JST-VH connectors

-

@wesc said in Which crimper to get for JST-VH connectors:

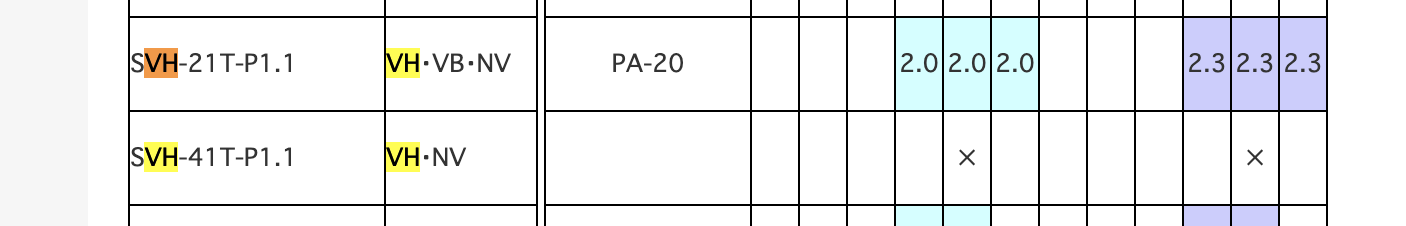

The SVH-21T-P1.1are crimpable by my PA20s, but the SVH-41T-P1.1 are not.

?

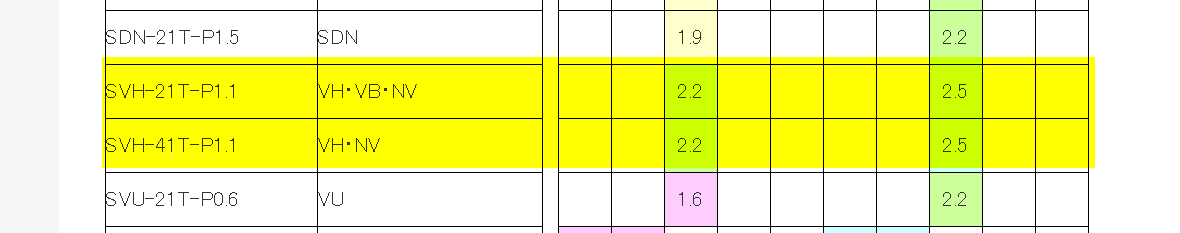

Doesn't the table say you need the 2.2. and 2.5 dies for both?

-

From. the PA-20 sheet:

I just tried it with my PA-20s. Crimped beautifully. Like 10x easier than the smaller KK terminals. 18 ga wire.

-

@wesc said in Which crimper to get for JST-VH connectors:

I just tried it with my PA-20s. Crimped beautifully.

Ah, looked at the wrong datasheet; but interesting one says to use the same dies and the other says it cannot do it.

Waiting for the VH terminals here, will test the IWS-2820 which only goes up to 2.2 when the world start working again.

-

Using an Engineer PA 21 on both the "small" and "large" connectors that are supplied with Duet, I find it worthwhile to:

- Start in the narrowest slot that will accommodate the "wings" that stick up from the bare-wire spot on the connector. Do a soft crimp, the purpose being to correctly "roll over" the "wings"

- Do the same, separately, for the wings that will crimp over the insulated portion. Again, a relatively soft crimp. Note that this may or may not be the same slot that crimped the bare wire portion; use the one that fits the wings for the insulated portion.

- Now, move to the next narrower slot (from the original bare wire slot) and do a second bare-wire crimp. Crimp this as hard as you can squeeze

- Last, the next narrower slot (from the insulated original slot), recrimp the insulated part. This is a medium crimp only, you don't want to crush it out flat.

Takes a long time to write up, very quick to do all four operations when you get used to it. The end result will work fine, no loose connections, and it will slide into the shell just fine. The second, narrower, crimp is the key to getting it to slide into the shell.

I've found the PA21 can be used on a VERY broad variety of sizes of pins by using the above four step process.

-

The iwiss SN-28B can also be used, is cheaper, and ratchets.

https://www.amazon.com/IWISS-Terminal-0-1-1-0mm-AWG28-18-connector/dp/B017JU20Z6/ref=sr_1_1I like it because you can place the pin in the die and squeeze it just enough to hold it then flip it over and insert the wire and just keep squeezing. And if you're as absent minded as me and forget to strip the wire first, you can put down the tool with the pin still held securely, strip the wire, pick up the tool, insert, and squeeze.

-

Everybody his own preferences. My vote goes to the Iwiss brand crimpers.

I have an Iwiss 3220M or something like that at home and Engineer at work. I very much prefer the Iwiss over the Engineer. Contacts tend to stick inside the Engineer PA, you need to crimp the wire and insulation separately, when slightly misplaced the Engineer misforms the contact, and they are twice as expensive.

-

Everybody does have their own preferences...

At the same time, I will say that I personally do not like ratchets, nor do I like crimpers that have each station with the dual width "stepped" slot for performing the bare and insulated crimp in one operation. This does mean I have to do four, instead of one or two, operations... I will trade that overhead for what seems like a lot more control, and variety of pin types and sizes.

Having said that, a stepped-slot, ratcheting, crimper that truly fits the pins can be a lot more productive. So it really is personal preference.

P.S. I used to get pins stuck in the PA21. Since I went to the four step process, it is very rare, if ever, to get one stuck.

-

@Danal said in Which crimper to get for JST-VH connectors:

Using an Engineer PA 21 on both the "small" and "large" connectors that are supplied with Duet, I find it worthwhile to:

- Start in the narrowest slot that will accommodate the "wings" that stick up from the bare-wire spot on the connector. Do a soft crimp, the purpose being to correctly "roll over" the "wings"

- Do the same, separately, for the wings that will crimp over the insulated portion. Again, a relatively soft crimp. Note that this may or may not be the same slot that crimped the bare wire portion; use the one that fits the wings for the insulated portion.

- Now, move to the next narrower slot (from the original bare wire slot) and do a second bare-wire crimp. Crimp this as hard as you can squeeze

- Last, the next narrower slot (from the insulated original slot), recrimp the insulated part. This is a medium crimp only, you don't want to crush it out flat.

Takes a long time to write up, very quick to do all four operations when you get used to it. The end result will work fine, no loose connections, and it will slide into the shell just fine. The second, narrower, crimp is the key to getting it to slide into the shell.

I've found the PA21 can be used on a VERY broad variety of sizes of pins by using the above four step process.

Can you make a detailed video of your procedure? It would clarify the process.

-

@luckyflyer said in Which crimper to get for JST-VH connectors:

@Danal said in Which crimper to get for JST-VH connectors:

Using an Engineer PA 21 on both the "small" and "large" connectors that are supplied with Duet, I find it worthwhile to:

- Start in the narrowest slot that will accommodate the "wings" that stick up from the bare-wire spot on the connector. Do a soft crimp, the purpose being to correctly "roll over" the "wings"

- Do the same, separately, for the wings that will crimp over the insulated portion. Again, a relatively soft crimp. Note that this may or may not be the same slot that crimped the bare wire portion; use the one that fits the wings for the insulated portion.

- Now, move to the next narrower slot (from the original bare wire slot) and do a second bare-wire crimp. Crimp this as hard as you can squeeze

- Last, the next narrower slot (from the insulated original slot), recrimp the insulated part. This is a medium crimp only, you don't want to crush it out flat.

Takes a long time to write up, very quick to do all four operations when you get used to it. The end result will work fine, no loose connections, and it will slide into the shell just fine. The second, narrower, crimp is the key to getting it to slide into the shell.

I've found the PA21 can be used on a VERY broad variety of sizes of pins by using the above four step process.

Can you make a detailed video of your procedure? It would clarify the process.

Sure, probably over the weekend.

-

I'll do one as well with the iwiss and we can have a race.

-

@Danal That would be great.

-

@gtj0 said in Which crimper to get for JST-VH connectors:

I'll do one as well with the iwiss and we can have a race.

Oh, the Iwiss will be faster; I can concede the race without even seeing it.

I just believe the four step can deal a little better with things like a wire that is too small for the connector, or too large, and/or a broader range of connectors, or etc., because the human controls the tension, and width of each section independently. The price for that is slow speed, and a little more burden on the human to get a given connector 'right'.

And, having said all of that... for JUST the connector sizes in a Duet connector pack, everything I'm saying is probably not relevant and an iWiss style is probably fine. A really good choice.

I do a ton of other electronics, with all kinds of connectors. I will say with some confidence that the PA21 covers a lot more ground than a 4 slot with stepped slots (I have several of those as well).

-

I ordered this crimper for my build https://www.amazon.com/gp/product/B07R1H3Z8X/ref=ppx_yo_dt_b_asin_title_o08_s00?ie=UTF8&psc=1 only to discover that it will not crimp the VH terminals. I don't mind saving a buck when I can but when it comes to tools I'll usually pay for the better/more versatile etc tool. Video's of the two tools will go a long way to helping a person decide.

Thanks -

Bigclivedotcom did a YouTube video recently, covers lots of tools. But I was surprised to see what he said about the PA09, I would guess poor tolerance on the terminals or excessive wear on the tool. I've only experienced that problem with cheap terminals or if using a die too small. (DaBit said basically the same as bigclive, maybe there is more to it?)

The VH connectors was in the mail today so will test after dinner:)

(or a quicke before dinner .. I'd say you'd need larger dies than 2.2 to make good crimps on the insulation, but its miles better than no tool. Iwiss does make a larger version of the IWS-2820 that would likely be perfect)

-

I will trade that overhead for what seems like a lot more control, and variety of pin types and sizes.

Absolutely; unless in a production setting where you'd just buy the manufacturers ridiculously expensive tool because time and quality certifications I'd go with the manual Engineer or Iwiss tools hands down.

-

I think PA-09 is what I use at work also, and the one I don't really like. Maybe PA-21 is a different animal altogether?

I am mostly using 2mm and 2.54mm terminals (JST, Wurth), and not all that many. Maybe 100 crimps a year or so. -

@DaBit said in Which crimper to get for JST-VH connectors:

I think PA-09 is what I use at work also, and the one I don't really like. Maybe PA-21 is a different animal altogether?

I am mostly using 2mm and 2.54mm terminals (JST, Wurth), and not all that many. Maybe 100 crimps a year or so.The JST VH terminals as shipped need the PA21 because the wings of the crimp pins that go over the insulation are long, which needs the different shape and larger die of the PA21. But I've heard of users cutting the wings shorter and using a different crimp tool.

The PA21 is also OK for the Molex KK connectors, but not for smaller ones such as JST PH (the PA09 does those).

-

think PA-09 is what I use at work also, and the one I don't really like. Maybe PA-21 is a different animal altogether?

I am mostly using 2mm and 2.54mm terminals (JST, Wurth), and not all that many. Maybe 100 crimps a year or so.I've used the PA-09 for pretty much everything except some circular amp connectors (where I had the $$$ amp tool) and only time I've had terminals stick is with the cheapest of cheap chinesium terminals where I with the naked eye can see the variance from terminal to terminal. Mine has been through a lot of chinesium terminals, most are just fine.

I only got the Iwiss to test as a cheaper alternative to reccomend; and for the value its pretty good, but still prefer the Engineer.

But I've heard of users cutting the wings shorter and using a different crimp tool.

I find it faster to just reduce the width of the terminal; if that doesn't work then the wire is too thick for the tool anyway. The VH in the picture above is on a thin insulation 0.75mm2 wire; woudn't have worked with regular 0.75mm as it would have been too wide for the 2.2 die.

-

Most of my contacts come either directly from Wurth, or from Farnell/Digikey/Mouser.

But oh well, every crimp tool needs a bit of feeling and a bit of exercise, I am probably just not doing it enough and the Iwiss is simply more idiotproof. I suspect most people here crimped an RJ45 to CAT5 at least once. Remember how long it took before you got the first one correct?

-

I think I have more than 200 different crimping tools/pliers in my drawers, boxes, floor, shelves ... PA09 and PA20 are the only ones "non stop on the table" (recently got PA21 too but not using them that often). When you need to crimp a single pin, especially if that's new - unknown pin, and especially to "not the default size" wire PA09/20/21 are indispensable. Now if I need to do a 100 terminals, all same, all same size wire, the "dual" tools like iwiss are faster. I have some moderate experience (I crimp in average 2-3 pins a day past 35 years let's say) with dual, rachet type tools, in "ideal conditions" (good pins, proper wire size) around 1% of the pins will not be ok (bad crimp - wire falling out or pin bent/destroyed/broken or everything looks secure but bad contact, usually if insulated part goes under wrong part of the pin). On the other hand, I'm yet to have bad crimp with engineer PA## crimpers

They are slower but super precise, and I don't do the 4 step, find no need for it, 2 step is more than adequate if you are using proper wire and proper die the first time. It is only important to select proper width of the die for every crimp.

They are slower but super precise, and I don't do the 4 step, find no need for it, 2 step is more than adequate if you are using proper wire and proper die the first time. It is only important to select proper width of the die for every crimp.