Temp issues after upgrading to RRF v3

-

@pro3d Need to see the settings you're using for the heaters, really. Can you post your config.g and config_override.g (if used)? Or at least the heater setup. Make sure config_override.g isn't, well, overriding with the wrong M307 settings.

Ian

-

Thank you for the respons.

Config.g:

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit

M308 S1 P"e0temp" Y"pt1000" ; heater 1 uses a PT1000 connected to temp1

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limitOveride:

; config-override.g file generated in response to M500

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 A164.1 C247.3 D1.2 S1.00 V24.4 B0

M307 H1 A240.0 C121.0 D4.0 S1.00 V24.1 B0 -

@pro3d I looked up a couple of other posts where they're using an E3D v6:

M307 H1 A503.9 C237.3 D4.9 V24.2 B0 - https://forum.duet3d.com/post/140184

M307 H1 A462.8 C245.1 D4.5 V24.2 B0 - https://forum.duet3d.com/post/138913The A (gAin) and C (dominant time Constant) seem rather different from yours, and if theirs are right, it would make a significant difference to the hot end heating; see M307. Are you using a silicone sock on the v6 (recommended)? Is the fan angled too much towards the nozzle? The effect of the fan on the hot end can be very different depending on how high off the bed the nozzle and fan are, too. Do you have the M307 setting from your RRF2 setup? How does that compare to your current setting?

As far as I'm aware, there's been no change in the heater model in RRF3, and I don't particularly remember any bugs in RRF3. What version are you on? Send M115 and post response. Though I'd recommend using the latest, 3.01-RC4 currently https://github.com/dc42/RepRapFirmware/releases/tag/3.01-RC4

I'd run

M303 H1 S230a number of times (perhaps 3 times), making sure the hot end cools to room temperature between each one, and see if the numbers converge. It could be that, if you only ran it once, there were a specific set of circumstances that are not the same as when it's printing.Ian

-

Thank you very much Ian!

I do not have the sock on and never did.

I do not have my RRF2 settings.

The fan should be fine - Same setup as before

I have tested different heights for the fan shroud without luck

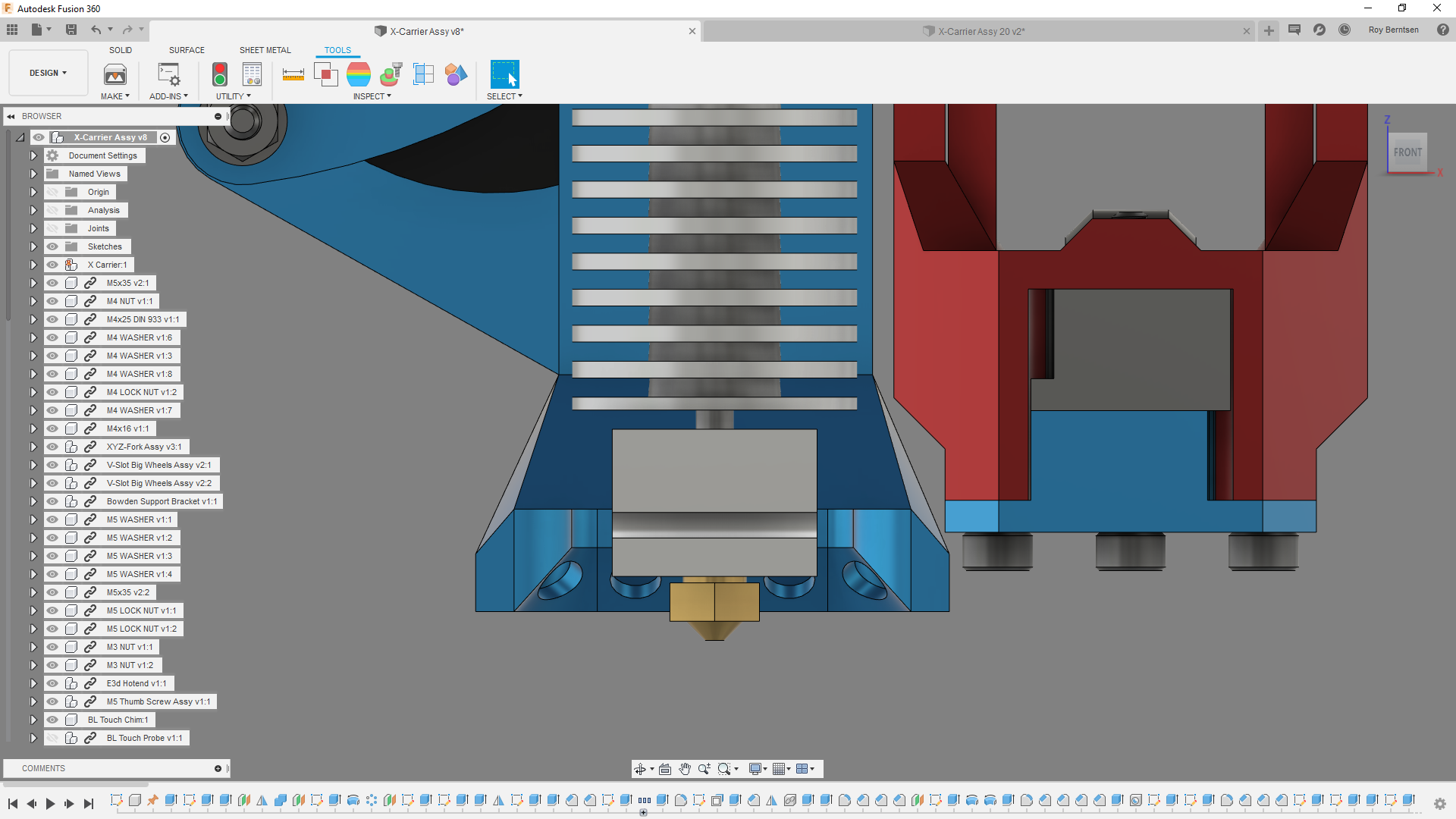

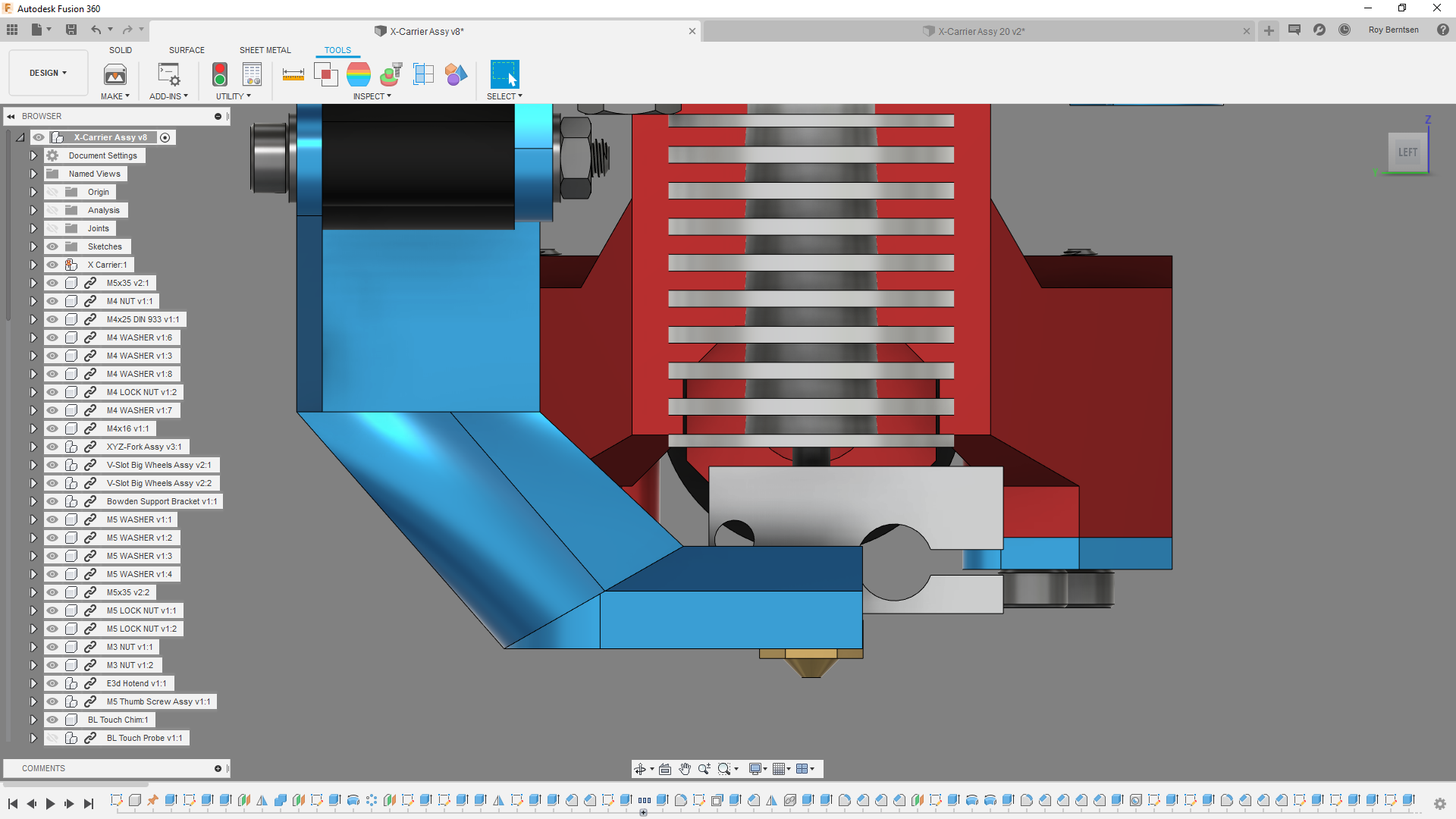

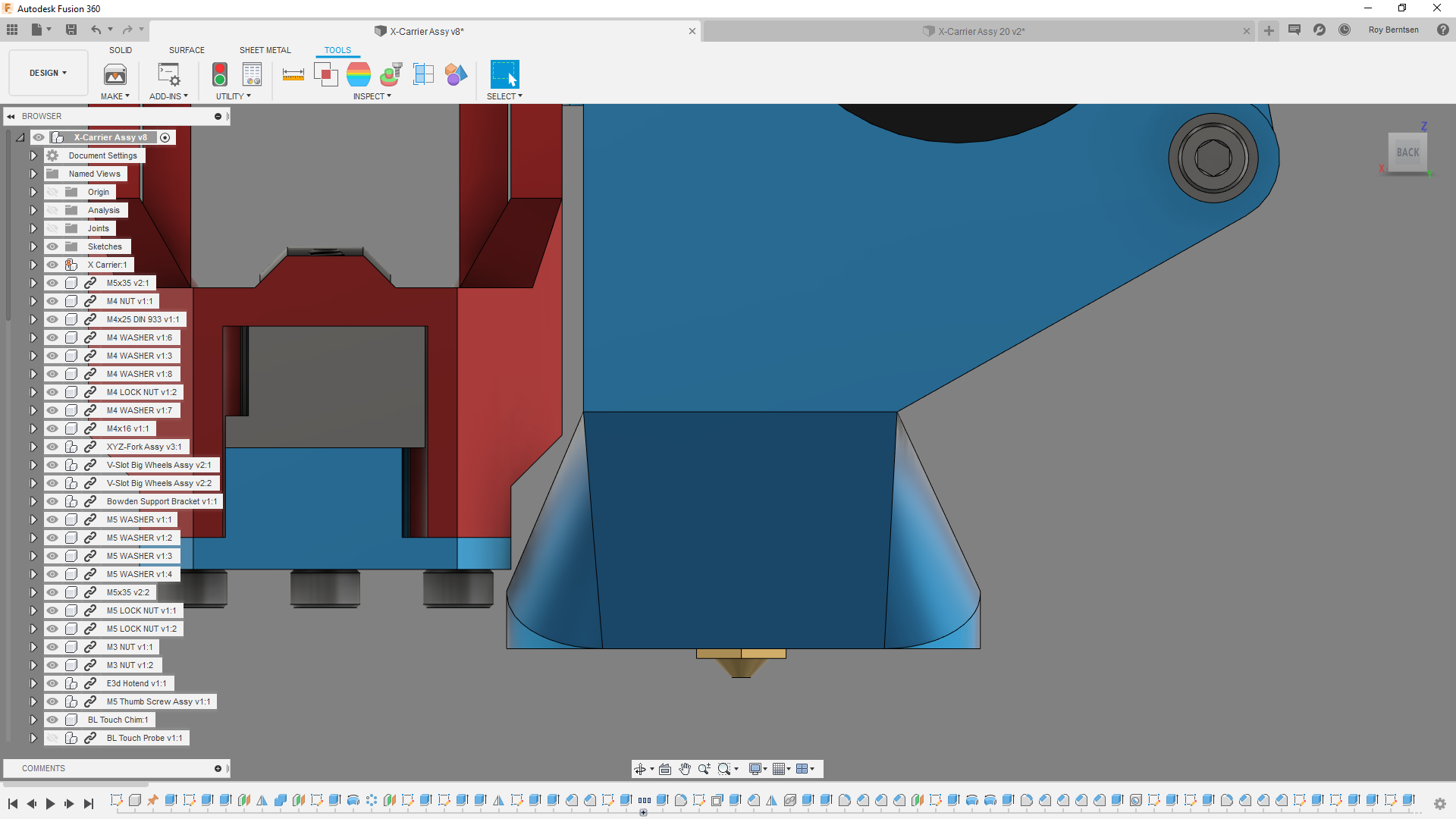

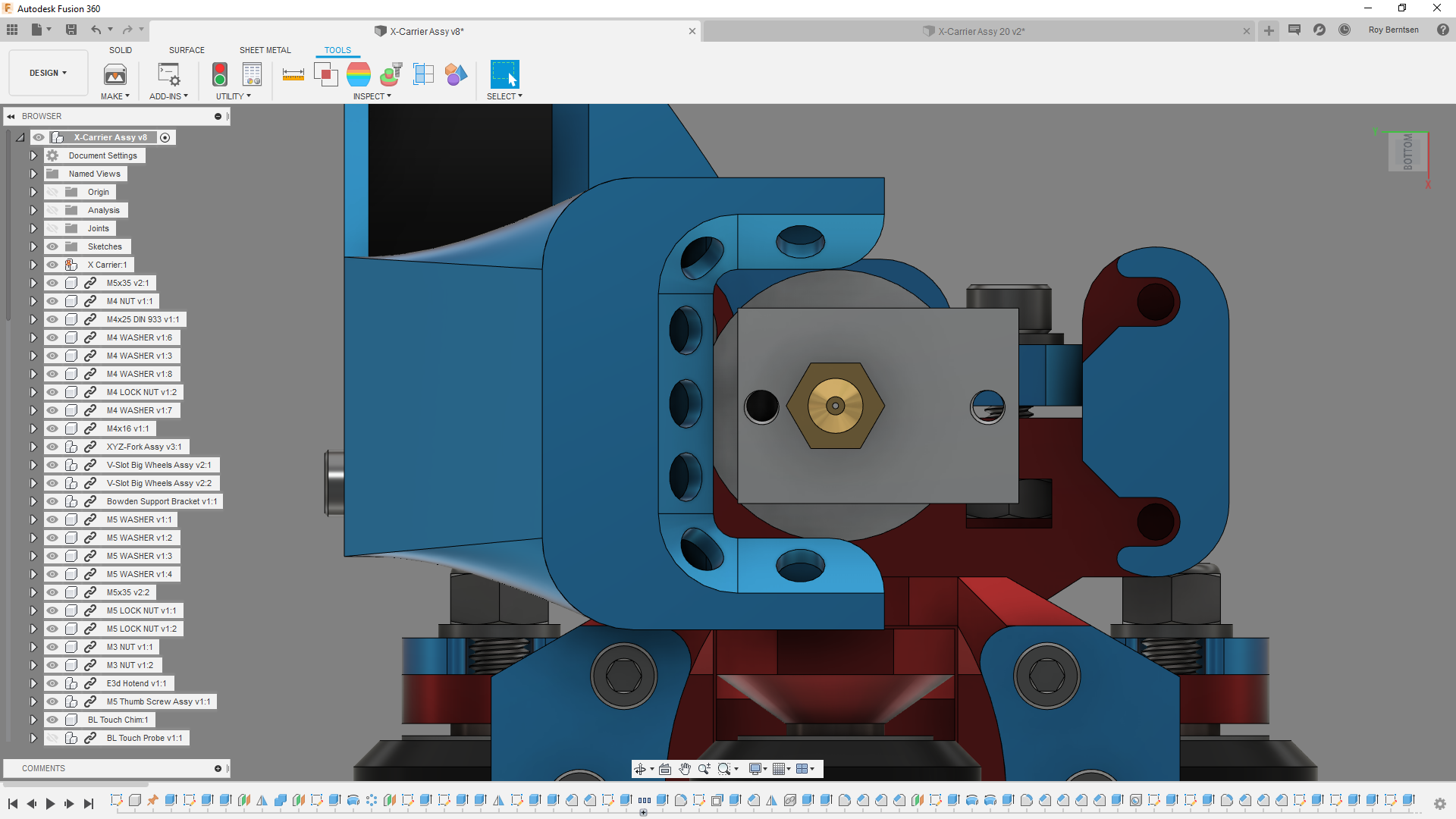

I did run m303 several times but I sis not compare the resultsHere you can see my fan setup:

-

@pro3d I'm not an expert in fluid dynamics, so I have no idea if the nozzle would have the effect. But if you didn't have any problems in RRF2, you shouldn't have them in RRF3. I'd suggest setting the M307 back to the default (comment out the M307 H1 command in config_override.g and reset the Duet), then run a few rounds of M303 tuning, and report back what M307 settings it settles on.

Ian

-

@pro3d This is a long shot and please don't take it the wrong way, but have you changed the board or just the firmware? If you changed the board have you set appropriate jumpers for the fan voltage? Some 12V fans will run at very high speed when fed with 24V (and others will go pop - I know from experience)

-

Nothing have been touched - 24V all the time with expensive low rev 24V 5015 Fan

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.0 (2020-01-03b3)

-

@pro3d Ah, OK - it was just a thought.

-

Here are my results:

-

m307 h1

Heater 1 model: gain 221.5, time constant 112.2, dead time 1.4, max PWM 1.00, calibration voltage 24.0, mode PID

Computed PID parameters for setpoint change: P62.6, I4.916, D63.3

Computed PID parameters for load change: P62.6, I12.801, D63.3 -

Auto tune cancelled because temperature peak was not identified

-

m307 h1

Heater 1 model: gain 222.4, time constant 112.4, dead time 5.5, max PWM 1.00, calibration voltage 24.0, mode PID

Computed PID parameters for setpoint change: P16.3, I0.653, D63.1

Computed PID parameters for load change: P16.3, I1.216, D63.1 -

m307 h1

Heater 1 model: gain 221.5, time constant 112.3, dead time 4.1, max PWM 1.00, calibration voltage 24.0, mode PID

Computed PID parameters for setpoint change: P21.9, I1.018, D63.4

Computed PID parameters for load change: P21.9, I2.040, D63.4

-

-

@pro3d you're on an older version of RRF3.

Could I suggest upgrading to RRF3.01-RC4? -

@pro3d it would be best to tune with a target temperature, using the S parameter eg M303 H1 S220. Base the target on the temperature of the material you most print. See if that makes a difference.

Ian