Cambio elettronica

-

Use this method to identify the phases: https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Identifying_the_stepper_motor_phases

-

@Phaedrux ok fatto grazie 1000

-

@Leblond if the phases are wrong, The motors won’t move and you will quickly get a message that there is a problem. As your motors are moving, I think your motors are correctly wired.

Ian

-

@Phaedrux ok allora le fasi sono corrette, un problema in meno

ho misurato gli assi e ho 352mm su x, e 352mm su y, si parla anche di valori negativi se la testina di stampa esce dal piatto

quindi nel comando M208 invece di X0 dovrei mettere M208 X-5 mm, perche' la testina e' fuori dal piatto di 5mm a sx come X min, e come X max dovrei mettere M208 X352 mm, perche' si parla di layout fisico giusto? -

That sounds correct.

-

-

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 02 2020 20:16:54 GMT+0200 (Ora legale dell’Europa centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"X5SA PRO" ; set printer nameM669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-5 Y0 Z0 S1 ; set axis minima

M208 X352 Y330 Z400 S0 ; set axis maxima; Endstops

M574 X2 S1 P"! xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"! ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"! zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X60:300 Y50:300 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

-

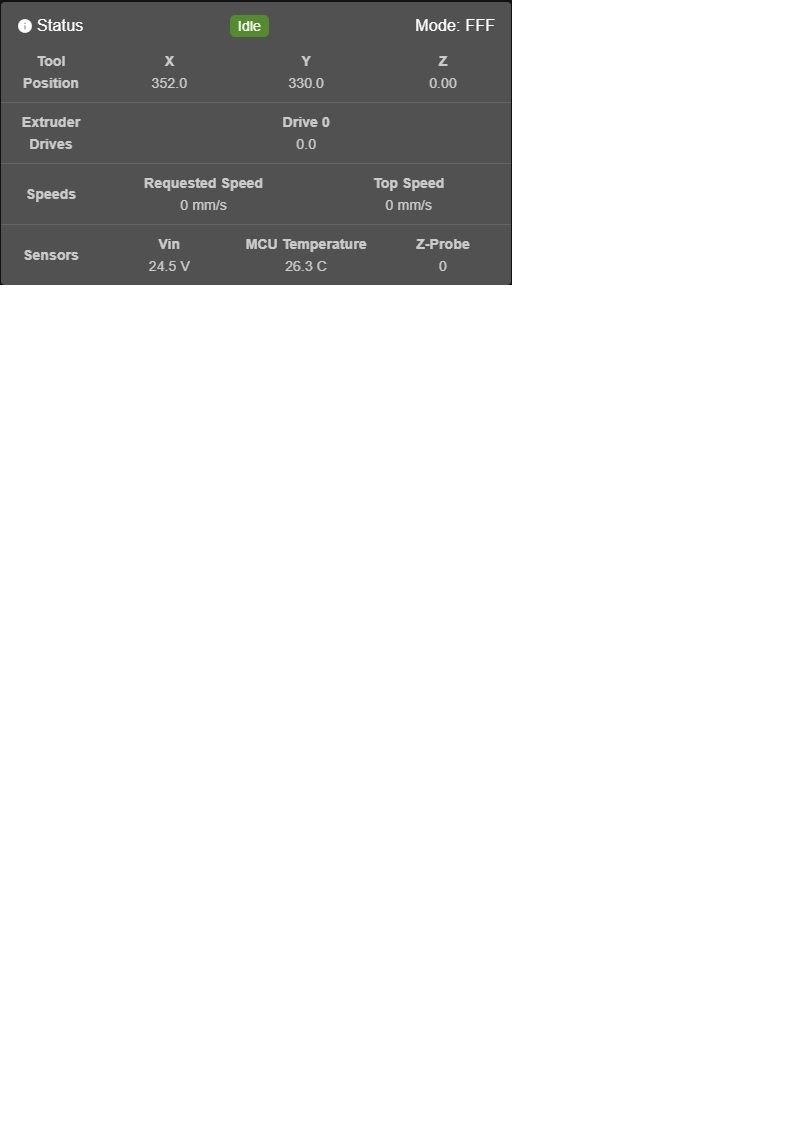

asse X e Y tornano verso il finecorsa, fin qui tutto ok, ma il risultato non e' quello che mi aspettavo. "Foto in alto della dashboard"

-

@Leblond said in Cambio elettronica:

M574 X2 S1 P "! Xstop"; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P "! ystop"; configure active-high endstop for low end on Y via pin ystopX2 and Y2 mean the endstops are at the high end of travel. So when homed the axis position would be the max value.

Is the X endstop on the right side? Is the Y endstop at the back?

-

no la stampante vista da "davanti", X si ferma a sx dove posizionato il finecorsa, Y si ferma davanti dove posizionato il finecorsa

-

ti mando schizzo

-

-

@Leblond said in Cambio elettronica:

no the printer seen from "front", X stops on the left where the limit switch is positioned, Y stops in front where the limit switch is positioned

Ok, go back to my post above: https://forum.duet3d.com/post/142912

You've managed to change the configuration to force it to work, but it's not working properly.

If the endstops are on the low end it must be M574 X1 Y1.

This also means the homing moves must be negative.

If the motors do not move the right direction at this point you must do these tests to correct the motor rotation:

https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareCoreXYPrinter#Section_Testing_motor_movement

-

ok guardo

-

quindi quando si parla di parte bassa si intende il davanti della stampante e parte alta il dietro, giusto?

ho riportato i valori su S1 ma si spostano di pochi cm. e mi da errore, quindi presumo che bisogna far girare i motori al contrario? -

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 02 2020 20:16:54 GMT+0200 (Ora legale dell’Europa centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"X5SA PRO" ; set printer nameM669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-5 Y0 Z0 S1 ; set axis minima

M208 X352 Y330 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"! xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"! ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"! zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X60:300 Y50:300 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

non funziona

-

siamo ritornati al punto di partenza quando non andava

-

@Leblond said in Cambio elettronica:

Correct.

@Leblond said in Cambio elettronica:

when we talk about the lower part we mean the front of the printer and the upper part the back, right?

Correct.

@Leblond said in Cambio elettronica:

; Axis Limits

M208 X-5 Y0 Z0 S1; minimum axis set

M208 X352 Y330 Z400 S0; set axis maxima

; Endstops

M574 X1 S1 P "! Xstop"; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P "! ystop"; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2; configure Z-probe endstop for low end on ZCorrect.

@Leblond said in Cambio elettronica:

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 02 2020 16:46:31 GMT + 0200 (Central European

Summer Time) G91; relative positioning

G1 H2 Z5 F6000; lift Z relative to current position

G1 H1 X-335 Y-335 F1800; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X-335; home X axis

G1 H1 Y-335; home Y axis

G1 X5 Y5 F6000; go back a few mm

G1 H1 X-335 F360; move slowly to X axis endstop once more (second pass)

G1 H1 Y-335; then move slowly to Y axis endstop

G90; absolute positioning

G1 X60 Y50 F6000; go to first bed probe point and home Z

G30; home Z by probing the bedCorrect.

Now you must do these tests to find the correct motor settings.

@Leblond said in Cambio elettronica:

M569 P0 S1; physical drive 0 goes backwards

M569 P1 S1; physical drive 1 goes backwardsChange these to S0.

Then move print head to the center and send G92 X100 Y100.

Then send G91 G1 S2 X10 F3000

If the head moves diagonally in the +X and +Y directions, all is well. If it moves in the -X and -Y directions, change the S parameter to S1 in the M569 P0 command. If it moves towards +X and -Y, or towards -X and +Y, then either turn the power off and swap the X and Y motor connections, or use M584 in config.g to swap the X and Y motor drivers over.

When you have the X motor moving correctly, test the Y motor by sending from the console: G91 G1 S2 Y10 F3000

If the head moves diagonally in the +X and -Y directions, all is well. If it moves in the -X and +Y directions, change the S parameter in the M569 P1 command to S1.