@sebkritikel quello che ho corretto io funziona bene

ho provato e l'estrusore funziona bene

Best posts made by Leblond

-

RE: Release 3.01-RC10posted in General Discussion

-

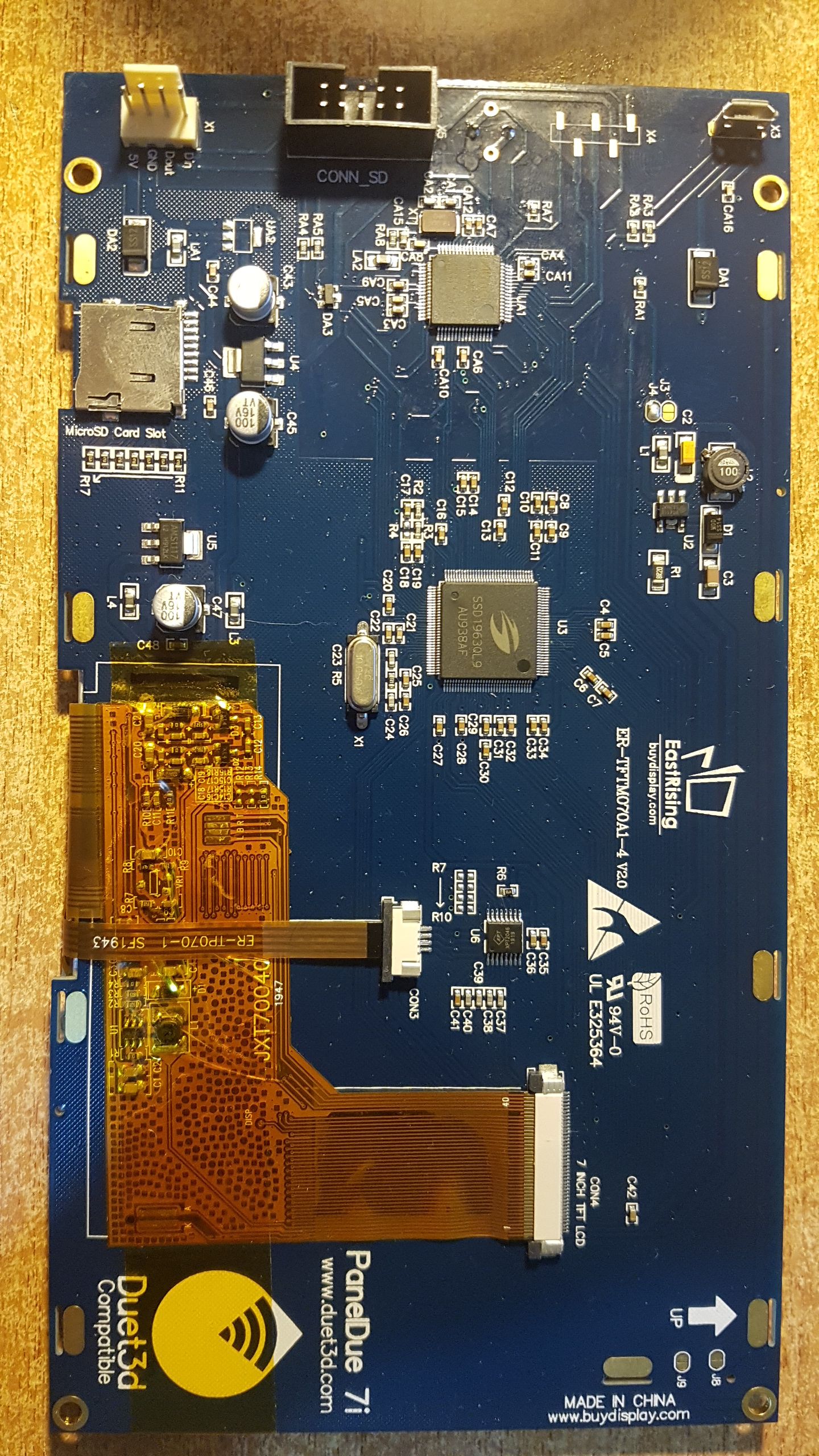

RE: Cambio elettronicaposted in Duet Hardware and wiring

ecco la configurazione funzionante per la tronxy x5sa pro con duet, in caso qualcun'altro ne avesse bisogno

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 02 2020 20:16:54 GMT+0200 (Ora legale dell’Europa centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"X5SA PRO" ; set printer nameM669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z100.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-5 Y0 Z0 S1 ; set axis minima

M208 X352 Y330 Z400 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"!ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P5 C"! zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X60:300 Y50:300 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

RE: Release 3.01-RC10posted in General Discussion

no problem, I don't wear it and I'm happy like this

-

RE: Helpposted in General Discussion

@Phaedrux

Thanks guy, the problem was that I didn't know that when you do a G32 that then it goes to call the BED.G

the probe does not activate in the moment of fast descent towards the floor, but it activates in the moment in which it proceeds with the probing coordinates, I thought that the probe activated in the moment in which the G32 command is given, while if the command is given G30 followed by the coordinates the probe is active -

RE: Triangular wave and print areaposted in Duet Hardware and wiring

ok, I'll call you hawkeye, correct and take the test again

-

RE: Triangular wave and print areaposted in Duet Hardware and wiring

@Phaedrux ok I will try in the meantime I disassembled the x axis turned the bearings

"just to give it a try while I was waiting for some advice from you" and now I've reassembled it and put it back to making a cold mesh to see if anything has changed, then I'll try to print to see if the mesh works or not, tomorrow I will post the results with and without mesh, for the moment thanks @Phaedrux.

Latest posts made by Leblond

-

RE: 3.5.0-rc2 G32/G30 on linear delta crashes into bedposted in Beta Firmware

allora,ho rifatto la sd della stampante ed ora funziona

-

RE: 3.5.0-rc2 G32/G30 on linear delta crashes into bedposted in Beta Firmware

@DavidG_68kg_PLA confermo che anche la rc3 ha lo stesso problema, la sonda si schianta sul piano, ho notato che il sensore a video legge anche in object model viene letto il sensore, ma quando si lancia la calibrazione della delta si schianta e si trascina il sensore

-

RE: Helpposted in General Discussion

@Phaedrux

Thanks guy, the problem was that I didn't know that when you do a G32 that then it goes to call the BED.G

the probe does not activate in the moment of fast descent towards the floor, but it activates in the moment in which it proceeds with the probing coordinates, I thought that the probe activated in the moment in which the G32 command is given, while if the command is given G30 followed by the coordinates the probe is active -

RE: Helpposted in General Discussion

@Phaedrux

hi so the settings i used are:M558 P8 C"!zprobe.in" H10 F120 T6000 reset to initial dwc 0, if I put my hand underneath and press it it goes to 1000.

M558 P8 C"^zprobe.in" H10 F120 T6000 result in initial dwc 1000, if I put my hand below it goes to 0

I made a G30 and it works but I don't understand why when I go to make a G32 it doesn't work

-

RE: Helpposted in General Discussion

@Phaedrux

Inglese

si l'ho provato e funziona, da 0 a riposo a mille quando lo premo, e ho provato anche al rovescio da 1000 a 0 sempre manualmente e funziona, nel momento in cui vado a sondare il letto se non metto la mano sotto il probe non si ferma e si schianta sul letto, non ne riesco ad uscire, ho provato anche a cambiare l'input di ingresso ed e uguale al precendente, domaninmattina ti posto il bed.g

yes I tried it and it works, from 0 at rest to a thousand when I press it, and I also tried it backwards from 1000 to 0 always manually and it works, when I go to probe the bed if I don't put my hand under the probe it does not stop and crashes on the bed, I can't get out of it, I also tried to change the input input and it is the same as the previous one, tomorrow morning I'll post the bed.g -

RE: Helpposted in General Discussion

@Phaedrux I took +5v on the expansion connector, GND+Zprobe on the ZPROBE connector

-

RE: Helpposted in General Discussion

@Phaedrux X2 Y2 Z2 works, but I have a serious problem that I can't solve, pressing the switch manually on the screen it shows me that it works but once I start probing the work surface the nozzle crashes on the surface