Ender 5 Pro Hemera Bltouch upgrade to Duet Wifi Firmware 3

-

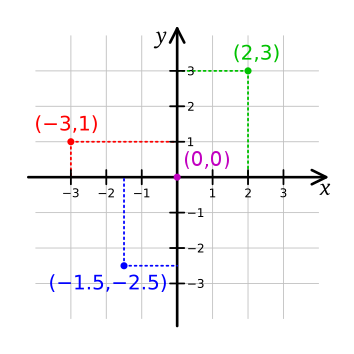

Doing high end for both would give you the 180 degree rotation we discussed earlier.

This is normally how the coordinate system would appear when looking at your printer from the front. The homing location is irrelevant. Instead of homing to 0 it would home to 280 or whatever.

-

@Phaedrux

Ok, I tried changing the configuration without success on the RRF to try to get those S2 values to show. I finally changed it on the config and we are like this; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Sat Apr 18 2020 22:46:43 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Daniel Ender 5" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z779.00 E409.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z900.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z50.00 E5000.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X220 Y220 Z300 S0 ; set axis maxima; Endstops

M574 X2 S2 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S2 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y3 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:160 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"E3D V6 Nozzle X" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

-

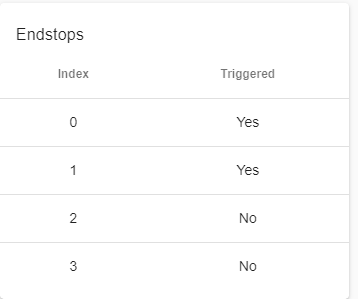

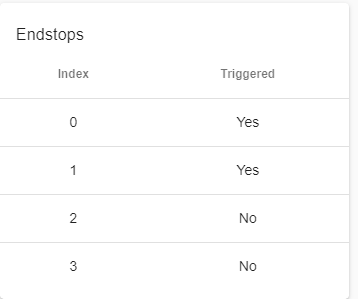

However in our machine specific configuration, the end stops continue to show like this when the head is in the middle of the bed....

Is this right?

-

@Daniel said in Ender 5 Pro Hemera Bltouch upgrade to Duet Wifi Firmware 3:

M574 X2 S2 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S2 P"ystop" ; configure active-high endstop for high end on Y via pin ystopDid you get a full new config set from the configurator? At this point it may be easier (for me anyway) if you stick with one config and we manually alter it. If you keep changing things in the configurator it makes it a lot harder to notice everything that's changed.

For instance the config now has Y2 X2, which would be the high end of travel. That's fine, it would be the more traditional way of doing it.

@Daniel said in Ender 5 Pro Hemera Bltouch upgrade to Duet Wifi Firmware 3:

However in our machine specific configuration, the end stops continue to show like this when the head is in the middle of the bed....

Is this right?

Can you post a photo of the endstops and how you have them wired?

-

@Phaedrux

Sorry Phaedrux,

I was trying to get this to show more like your logic, so the alignment on the Bltouch later comes easier to you.

Let me take the pictures and return to you. -

-

I have oriented the colors to match the letters for Signal Ground and Voltage in the printer run end sensor and in the motherboard. Double Checked.

The original wire on the Ender 5 is a 2 wire cable. Just connected in both ends of the run end sensor = S and V

The instructions on the Duet 2 page mention the 2 wires from the ender connector should be connected on the outer two of the three connectors on the motherboard (leave the center empty). That would mean that S and V from the ender should be connected to S and G in the motherboard.

That did not seem right to me, so I preferred to keep the convention matched on both circuits and made my own cable.Phaedrux, Whatever they pay you to do this job (if any) is too little.... please let me know how can I compensate all this help and assistance. Best regards. Daniel

-

Ok, those 3 wire endstops might need to be wired a little differently, I'm not sure because I'm having a hard time orienting your photo against the wiring diagram.

But hopefully based on this info and the wiring diagram you can verify it.

https://duet3d.dozuki.com/Wiki/Connecting_endstop_switches#Section_Microswitch

-

Nope, sorry, disregard that. You only need the 2 wires for that endstop connected to the outer two pins on the endstop port. Doesn't matter which way.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+1:+Wiring/37#s119

-

I found this in the endstop documentation not sure if it applies.

If using RepRapFirmware 3, invert the polarity by putting a ! character in front of the pin name.

-

@Daniel don’t wish to muddy the water as I don’t have a great deal of knowledge, however I also have an ender 5 but running a duet 3, both my end-stops configured using 2 wires only as the they are only normally closed micro switches, I’d hazard a guess your issue is the center wire that’s been added for 3.3v it maybe holding the switch closed, I’ve added my config hopefully it will help

config.gRegards Jim

-

@Phaedrux, @bricor, @jumpedwithbothfeet ... Gentlemen. What a feast of knowledge in this trail. Wow...Thank you all. Sometimes the forest does not let you see the tree....

Each one of you hold a piece of the puzzle...

@Phaedrux, thanks for Ockham’s razor application: The simplest solution is the right one. I re-wired using the 2 wire cable connected to the ends of the motherboard endstop connector.@Bricor, inverting the polarity of the connection by software was brilliant. The RRF equivalent selection was x-stop inverse.

@jumpedwithbothfeet, Ender 5 end stops are normally closed!!!. You see the little metal lever open...but when you test it....the circuit is closed... Thanks for the config file. I don’t know how did you assign I04 and I05 to the end stops, so I am still far away form your level of illumination

Now, after all this, standing in front of the printer 0,0 is on the nearest left corner. The end stops are on the far right corner.

From the center of the bed:

Negative values of x move the head left

Negative values of Y move the head towards me

Positive values of Z move the bed downwardsI still have questions on the z-stop and BLTouch proper nomenclature.

Basics of Gcoding with the differences between S1 or S2.... But the printer works....so I will try to give you a free Sunday.Thank you guys!

-

Glad it's working out now. Come back with any questions any time.

-

Would you welcome a summary page doccument for ender 5 users?

-

Absolutely.

-

@Daniel the pins were assigned during the config build but I obviously had to re-pin the end stop plugs, you can also manually change the config file in DWC however I’m using the duet 3 board I’m not sure if you can configure/assign pins on the duet 2, I’m sure @Phaedrux would be able to confirm that.

Glad to hear you want to create a guide for the ender 5 if I can help let me know

Regards Jim

-

@jumpedwithbothfeet said in Ender 5 Pro Hemera Bltouch upgrade to Duet Wifi Firmware 3:

I’m using the duet 3 board I’m not sure if you can configure/assign pins on the duet 2, I’m sure @Phaedrux would be able to confirm that.

In RepRapFirmware 3 pins can be re-defined in software. That applies to Duet 3 and Duet 2 boards.

-

@Phaedrux

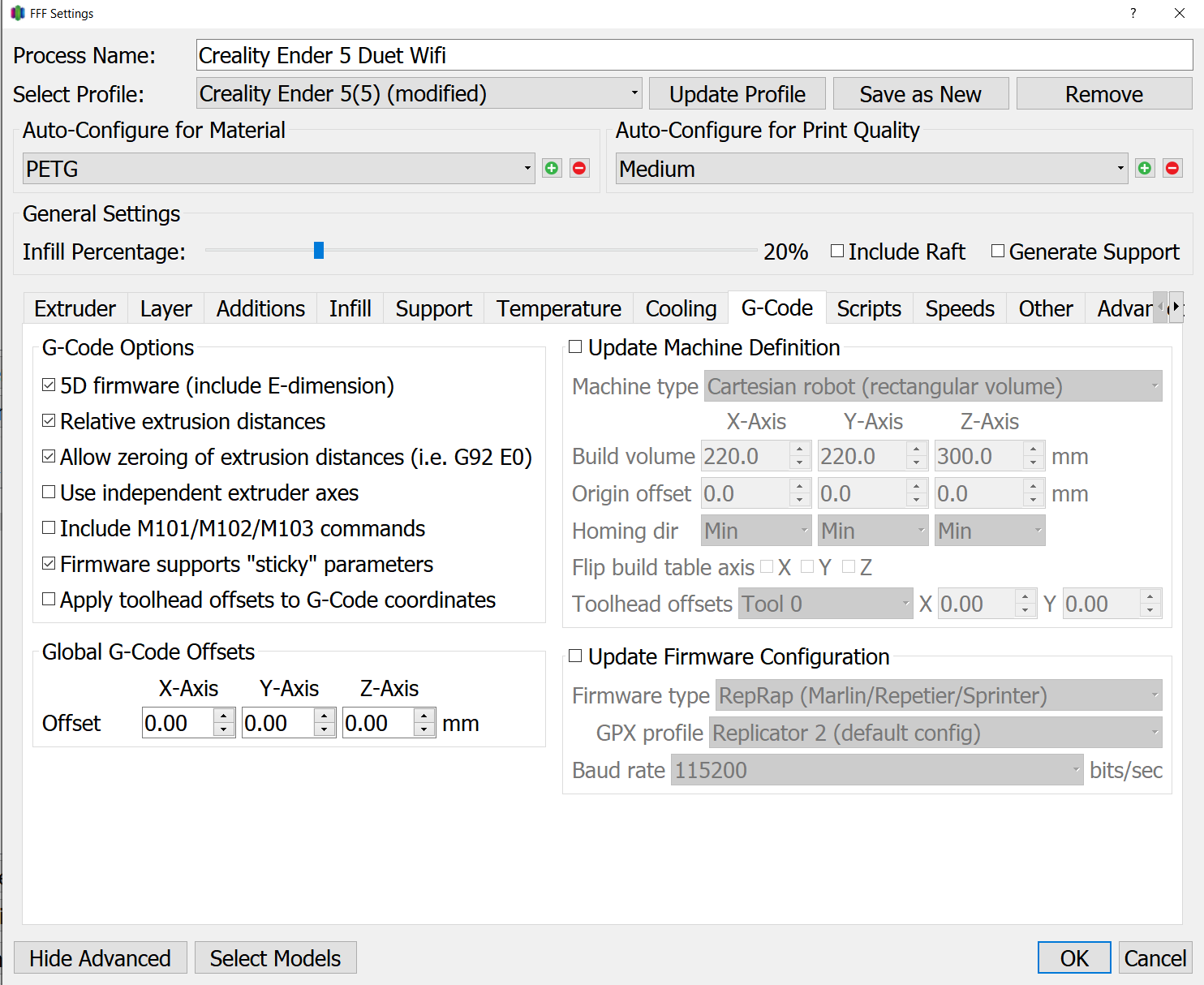

I have not posted in a while and I wanted to thank for all the help received, by posting the latest config for the machine.

Best configuration (so far) working with Simplify 3D. Please uncheck the boxes as per this picture to let the firmware control the printing.

The config is below

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Apr 19 2020 17:01:43 GMT-0400 (Eastern Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Daniel Ender 5 Duet 2 Wifi" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z811.00 E409.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E4000.00 ; set maximum instantaneous speed changes (mm/min)

M201 X6000.00 Y6000.00 Z60.00 E4000.00 ; set accelerations (mm/s^2)

M203 X15000.00 Y15000.00 Z600.00 E8000.00 ; set maximum speeds (mm/min)

M204 P800 T2000 ; set accel for XY print (P) and travel moves (T).

M207 S0.85 R-0.000 F3200 T2600 Z0.0 ; set firmware retraction

M572 D0 S0.050 ; set pressure advance

M906 X850 Y850 Z850 E850 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X220 Y220 Z300 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"zprobe.in" H5 F120 T12000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y3 Z1.95 ; set Z probe trigger value, offset and trigger height

M557 X15:160 Y15:200 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A88.4 C265.5 D2.0 S1.00 V23.9 B0 ; disable bang-bang mode for the bed heater and set PWM limit (Values copied from auto tune D corrected from 0.9 to 2 by Phaedrux)

M140 H0 ; map heated bed to heater 0

M308 S1 P"e0temp" Y"thermistor" T98801 B4185 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M307 H1 A390.6 C153.8 D3.5 S1.00 V23.9 B0 ; disable bang-bang mode for heater and set PWM limit (Values copied from auto tune); Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"E3D V6 Nozzle X" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossEnjoy printing!!!