Delta stepper upgrade - advice welcome

-

Single Shaft Steppers

I am in the middle of planning and acquiring parts for a major revision to my Deltex build, a large-ish delta printer. Part of this upgrade is possibly a new set of stepper motors for the main towers. My machine (many more details in the bio link) is running a Duet 2 Wifi powered on 24V and currently uses these steppers from aliexpress. The most requirement for the steppers is a 0.9° step angle and must be suited with a large delta in mind.

My idea is that I should be looking at as high as possible holding torque, while staying below ~3A (to drive them at 2,4A). As well as staying below ~4mH and preferably keeping rotor inertia as low as possible. Advice and recommendations are welcome

Dual Shaft Steppers

In addition to this, me and some other people are discussing in an other thread how to best deal with the load of tightly tensioned belts. The tl;dr is that I want to have (going from the stepper face axially outwards) a bearing, the pulley and then a second bearing. It would be these bearings that deal with the radial loads. However, Finding steppers with a shaft long enough seems to impossible. At one point is the thread this was suggested:

@Dougal1957 said in Flexible coupling or direct mount for delta?:

there is another possible option and that is to use a dual shaft stepper and put a bearing on the rear shaft to take care of that side load.

Which might be an easy the implement solution, given that I can find suitable steppers with dual shafts. Again, advice and recommendations are welcome

EDIT:

To keep a good overview of all the models that have been suggested, I am creating a google sheet with most characteristics in there. If you want to see a column added or spot an error be sure to give me a nudge.

You can find it here: Stepper Motor Chart

-

To kick off the stead I went looking at some popular suppliers:

LDO Motors

OMC-Stepper Online

- Nema 17:

- Rated current: 1.68 A

- Holding torque: 44 Ncm (62.48 oz.in)

- Inductance: 4.10 mH

- Rotor inertia: 68 gcm²

- Nema 23: No 0.9°, dual shaft models available

Moon Industries

- Nema 17: No steppers that are in the upper regions of holding torque and stay near the 4mH inductance limit.

- Nema 23_2:

- Rated current: 3.50 A

- Holding torque: 0.59 Nm (83.56 oz.in)

- Inductance: 4.30 mH

- Rotor inertia: 121.5 gcm²

- Nema 23_2:

- Rated current: 3.60 A

- Holding torque: 1.50 Nm (212.43 oz.in)

- Inductance: 1.62 mH

- Rotor inertia: 221.5 gcm²

- Nema 23_3:

- Rated current: 3.00 A

- Holding torque: 2.40 Nm (339.89 oz.in)

- Inductance: 3.90 mH

- Rotor inertia: 391.0 gcm²

I think that especially that last one from Moon is a very nice model. Although I cannot estimate how the massive rotor inertia expresses itself. And it is wildly expensive.

- Nema 17:

-

@Nxt-1 I know zero about Deltas so could be way off the mark, but I did upgrade my UV gantry to Nema 23s when the mass started to excede 3 Kgs. One thing I noticed was that the shaft was a bigger diameter and I had to buy pulleys with a bigger ID to suit. Now given that you are looking for something with beefier bearings, to take highly tensioned belts, then a bigger diameter shaft would indicate the bearings would be bigger too. Also, Nema 23s can have much higher torque than Nema17s which is another indication that the bearings might be beefier. A very quick gander at Stepper Online threw up this example of a 0.9 degree Nema 23 rated at 2.8Amps https://www.omc-stepperonline.com/nema-23-stepper-motor/nema-23-bipolar-0-9deg-1-26nm-178-4oz-in-2-8a-2-5v-57x57x56mm-4-wires.html

The shaft diameter is 6.35 mm so I guess it's 1/4 inch. But the inductance is a little high at 4.5mH. No idea about rotor inertia - maybe that is a reason why Nema 23s aren't a good choice for deltas?

EDIT. Was typing while you were posting so I missed your latest - looks like you are ahead of me.

EDIT 2 - Stepper online do have 0.9 degree Nema 23 versions as per my link

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

Rated current: 3.00 A

Holding torque: 2.40 Nm (339.89 oz.in)

Inductance: 3.90 mH

Rotor inertia: 391.0 gcm²I have, 3x noname, from ALI, in my mini milling machine, with similar spec, 3A, 3Nm, 4.5mH (measured, was not in spec at all, no spec for inertia, no idea how to measure) and while they work awesome on my mill I tried them on the old darwin and they were skipping steps left and right on higher speeds (100+mm/sec on 22T 2.08 mm pitch belt ML or MML IIRC) driven from 12V and alegro drivers. I didn't have duet then to try with it but looks like this 4.5mH might be too much. Your is 3.9mH and you will be running duet at probably 24V but I'd check the calculation online to see what max speed you can expect with that inductance. As for the rotor inertia I don't think on 2.4Nm that's going to be an issue, but then again... online calculator

-

I use the 17HM19-1684S stepper motor from OMC in my Duet WiFi-powered delta printer; however if I was starting again I would use the 17HM19-2004S.

-

@deckingman said in Delta stepper upgrade - advice welcome:

@Nxt-1 I know zero about Deltas so could be way off the mark, but I did upgrade my UV gantry to Nema 23s when the mass started to excede 3 Kgs. One thing I noticed was that the shaft was a bigger diameter and I had to buy pulleys with a bigger ID to suit. Now given that you are looking for something with beefier bearings, to take highly tensioned belts, then a bigger diameter shaft would indicate the bearings would be bigger too.

I am not per se looking for larger bearing inside the motor. I am looking to place bearings outside the motor, on its axle. That way, the motor would take 0 radial load and would only need to be constrained against rotation really. And probably axial travel. Now the reason I want outside bearings is so that I can make them larger then the tiny bearing in my nema 17's currently, so you are kind of right .

.Also I feel that I should nuance my wishes for belt tensioning. I am not looking gitar strings, yet I noticed that when applying more than what I consider moderate pressure, I can hear my current steppers really bog down due to the load. That's a large part of what started this whole upgrade process.

Also, Nema 23s can have much higher torque than Nema17s which is another indication that the bearings might be beefier. A very quick gander at Stepper Online threw up this example of a 0.9 degree Nema 23 rated at 2.8Amps https://www.omc-stepperonline.com/nema-23-stepper-motor/nema-23-bipolar-0-9deg-1-26nm-178-4oz-in-2-8a-2-5v-57x57x56mm-4-wires.html

The shaft diameter is 6.35 mm so I guess it's 1/4 inch. But the inductance is a little high at 4.5mH. No idea about rotor inertia - maybe that is a reason why Nema 23s aren't a good choice for deltas?

Yeah, the increased torque is what I drawing me towards the nema 23's. As I will post later I have just enough room to fit them, so why not. The only reason I can imagine is increased rotor inertia causing issues with high accelerations. However looking at what your CoreXYalphabet is doing, this seems to not be an issue. @arhi seems to confirm this as well.

The thing is, rotor inertia is only specified on brand name motors/stores and nobody that I could find has done any actual testing on that topic. So we are all kind of just going with it and not paying to much attention to it sadly.

-

@arhi said in Delta stepper upgrade - advice welcome:

@Nxt-1 said in Delta stepper upgrade - advice welcome:

Rated current: 3.00 A

Holding torque: 2.40 Nm (339.89 oz.in)

Inductance: 3.90 mH

Rotor inertia: 391.0 gcm²I have, 3x noname, from ALI, in my mini milling machine, with similar spec, 3A, 3Nm, 4.5mH (measured, was not in spec at all, no spec for inertia, no idea how to measure) and while they work awesome on my mill I tried them on the old darwin and they were skipping steps left and right on higher speeds (100+mm/sec on 22T 2.08 mm pitch belt ML or MML IIRC) driven from 12V and alegro drivers. I didn't have duet then to try with it but looks like this 4.5mH might be too much. Your is 3.9mH and you will be running duet at probably 24V but I'd check the calculation online to see what max speed you can expect with that inductance. As for the rotor inertia I don't think on 2.4Nm that's going to be an issue, but then again... online calculator

Any calculators you prefer using or can recommend?

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

@arhi seems to confirm this as well.

I have nema23 running darwin printer's not sure how that relates to delta (never did anything wrt delta) and I print PP and HDPE on my darwins - think 8-10mm/sec printing, I'm not sure your delta can even move that slow

My nema23 also run my mill and that's also nowhere close to what you want to go at so what I'm saying is please use the calculator

https://www.reprapfirmware.org/

- go to EMF calculator

- punch in your data

- see if motor will run at speed you want it to

I feel those motors will work ok on delta with 24V but that online calculator is worth 100000000000x more then my feelings

-

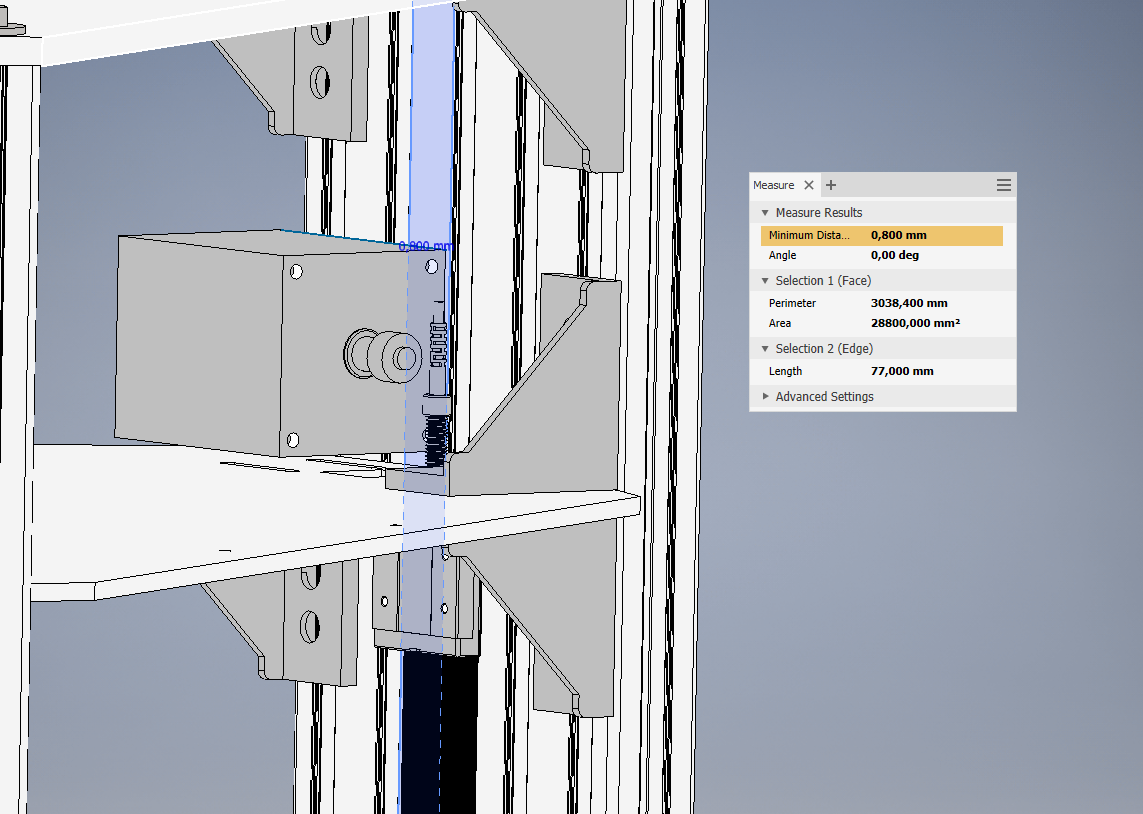

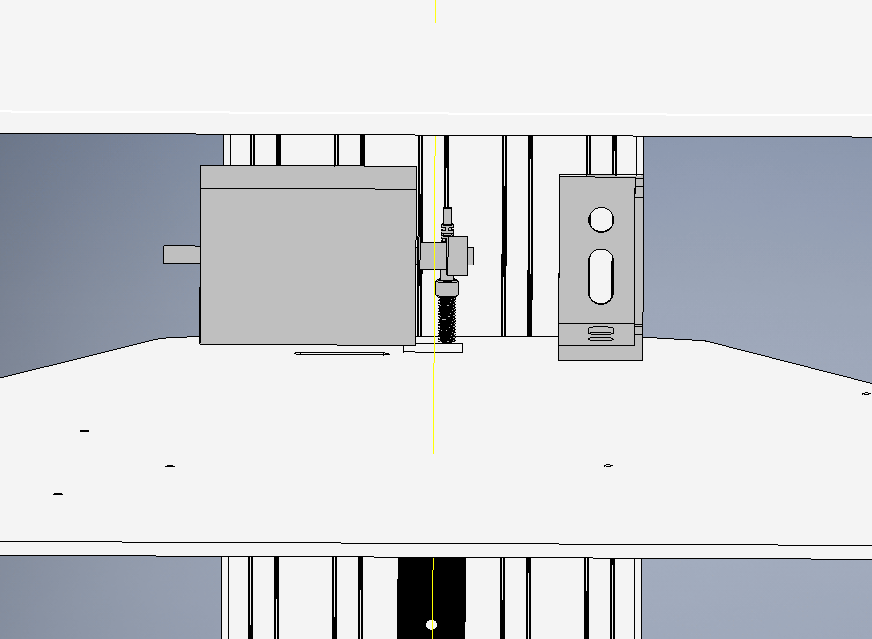

Since nema 23's have seemingly come a major contender, I quickly sketched one up and placed it in my current CAD design. Low and behold there is 0.8 mm clearance between the side of the tower extrusions and the side of the stepper. This all assuming noting changes to where the belts sit compared to their current place, which I would prefer if at all possible.

On the back side their seems to be just enough meat to the lower plate to attach some bracket locating the back bearing. What has me worried though is the length of the front shaft, it is 20.6 mm long according the specs (for the 3rd moon industries). A quick glance on some local webstores shows me that pulleys for 9 mm wide belt are 16 mm heigh, leaving just 4 mm for a bearing on that side.

-

@arhi said in Delta stepper upgrade - advice welcome:

@Nxt-1 said in Delta stepper upgrade - advice welcome:

@arhi seems to confirm this as well.

I have nema23 running darwin printer's not sure how that relates to delta (never did anything wrt delta) and I print PP and HDPE on my darwins - think 8-10mm/sec printing, I'm not sure your delta can even move that slow

My nema23 also run my mill and that's also nowhere close to what you want to go at so what I'm saying is please use the calculator

https://www.reprapfirmware.org/

- go to EMF calculator

- punch in your data

- see if motor will run at speed you want it to

I feel those motors will work ok on delta with 24V but that online calculator is worth 100000000000x more then my feelings

Sadly the calculator is not kind on me. I punched in the numbers for the nema 23 on the left and the numbers for the motor I am using (from aliexpress so how accurate are they?) on the right. The first image is 200 mm/s moves (travels) and the 2nd with something more realistic for actual printing.

One thing to note though, the calculator outputs the speeds at which the torque starts to drop but gives no info on how much is drops in function of speed. In the end it might be fine actually.

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

One thing to note though, the calculator outputs the speeds at which the torque starts to drop but gives no info on how much is drops in function of speed. In the end it might be fine actually.

From my experience with high inductance motor on 40:1 geared extruder where high speeds are required and error I was getting @dc42 explained that drivers will complain if they can not push asked current into the motor by applying maximum voltage. So if you are running Vin at 24V, and you need let's say 4V for the 2A you configured your stepper at, if back EMF is over 20V there's not enough voltage driver can apply to push 2A in. How much loss in torque due to lower current is impossible to say without actual graphs from the motor manufacturer but how much less current is supplied you can get from that calculator by using the less current in the motor current field. So you setup calculator with 2A and see the data, then setup 1.9A and see the data etc etc ..

-

@arhi said in Delta stepper upgrade - advice welcome:

@Nxt-1 said in Delta stepper upgrade - advice welcome:

One thing to note though, the calculator outputs the speeds at which the torque starts to drop but gives no info on how much is drops in function of speed. In the end it might be fine actually.

From my experience with high inductance motor on 40:1 geared extruder where high speeds are required and error I was getting @dc42 explained that drivers will complain if they can not push asked current into the motor by applying maximum voltage. So if you are running Vin at 24V, and you need let's say 4V for the 2A you configured your stepper at, if back EMF is over 20V there's not enough voltage driver can apply to push 2A in. How much loss in torque due to lower current is impossible to say without actual graphs from the motor manufacturer but how much less current is supplied you can get from that calculator by using the less current in the motor current field. So you setup calculator with 2A and see the data, then setup 1.9A and see the data etc etc ..

I understand how back emf works and why the there is a loss of torque, that is not the issue. Calculating how much torque is lost is the interesting part. But as you pointed out correctly, that is purely dependent on motor design and thus can never be calculated by a simple calculator. I was just complaining that the calc can't do it, even there is no way it could

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

I was just complaining that the calc can't do it, even there is no way it could

yes, but like I said, you can see at that speed how much current will be supplied to the motor by using different current settings in the calculator

... and asuming some linear drop in torque with current is safe bet imo at those speeds

... and asuming some linear drop in torque with current is safe bet imo at those speeds -

@arhi said in Delta stepper upgrade - advice welcome:

@Nxt-1 said in Delta stepper upgrade - advice welcome:

I was just complaining that the calc can't do it, even there is no way it could

yes, but like I said, you can see at that speed how much current will be supplied to the motor by using different current settings in the calculator

... and assuming some linear drop in torque with current is safe bet imo at those speeds

... and assuming some linear drop in torque with current is safe bet imo at those speedsAh, I understand now. Thanks for the insight.

For the nema 23 the current at which emf due to inductance becomes 24 V is just 920 mA (@200 mm/s). Assuming the linear relation between current and holding torque, that would leave me with 73.6 Ncm. That is still more then just about any nema 17 motor I have seen though. Leading me to believe that this is a non issue.

-

So the moonsindustries.com webpage for the nema 23 that is the highest contender at the moment, specs the stepper at 3.9 mH inductance. While the moonsindustries.eu catalogue (page 40) specifies winding inductance at 6.9 mH.

My guess this has to do with taking the inductance of one coil or both combined. It does confuse me to say the least. Any have any insight in this?

-

-

2.8A/phase

-

.6Nm

-

2.1mH/phase

-

120gm*cm^2

-

single shaft, 6.35mm

- double shaft of above model

-

2.8A/phase

-

.6Nm

-

2.1mH/phase

-

150gm*cm^2

-

single shaft, 8mm

- double shaft of above model

Other options available

-

-

@sebkritikel Thank you for the suggestions. Do you have any experience with either of the motors you suggested?

I have also found these from the same supplier:

- Rated current: 2.80 A

- Holding torque: 1.32 Nm

- Inductance: 3.90 mH

- Rotor inertia: 290.0 gcm²

(6.35 mm shaft)

- Rated current: 2.80 A

- Holding torque: 1.40 Nm

- Inductance: 3.00 mH

- Rotor inertia: 310.5 gcm²

(8 mm shaft)

These see to be the longer versions of the ones you linked (54 mm vs 39 mm)

-

@Nxt-1 said in Delta stepper upgrade - advice welcome:

@sebkritikel Thank you for the suggestions. Do you have any experience with either of the motors you suggested?

I have also found these from the same supplier:

- Rated current: 2.80 A

- Holding torque: 1.32 Nm

- Inductance: 3.90 mH

- Rotor inertia: 290.0 gcm²

(6.35 mm shaft)

- Rated current: 2.80 A

- Holding torque: 1.40 Nm

- Inductance: 3.00 mH

- Rotor inertia: 310.5 gcm²

(8 mm shaft)

These see to be the longer versions of the ones you linked (54 mm vs 39 mm)

I don't have any experience with those models, however I do use two PKP264D28AA2 NEMA23s (2.8A/phase, 1.8°, 39mm, 74Ncm, 1.5mH inductance) on my printer, and they are fantastic.

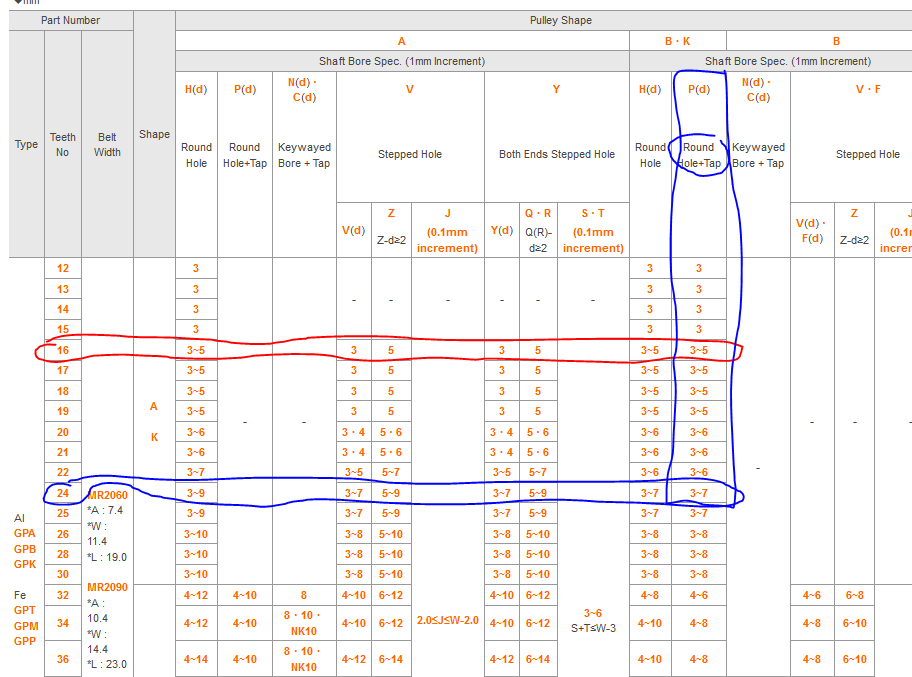

I see you're trying to hit 200steps/mm with a 2mm pitch belt @ 16teeth on a pulley... I don't know how realistic it will be to find a pulley with 16 2mm teeth, and 6.35mm or greater shaft bore

Excerpt from Misumi's 2mm PowerGrip

GT

GT 3 catalog listing

3 catalog listing

-

@sebkritikel Good point, a quick look at a local 3D printer parts supplier supports what you say. No 16T pulley with >5 mm ID bore. However jumping up to 20T pulleys (available in both 6,35 mm and 8 mm) is not per se a deal breaker for me. It will lower the steps/mm by 20% but I guess I can take that hit.

-

To keep a good overview of all the models that have been suggested, I am creating a google sheet with most characteristics in there. If you want to see a column added or spot an error be sure to give me a nudge.

You can find it here: Stepper Motor Chart