Not Homing correctly At all. and nozzle issues

-

You just need to choose a point close to the lead screw but still on the bed and both need to be in line on the Y axis.

-

@Phaedrux said in Not Homing correctly At all. and nozzle issues:

G28 ; home M401 ; deploy Z probe (omit if using bltouch) G30 P0 X20 Y100 Z-99999 ; probe near a leadscrew, half way along Y axis G30 P1 X180 Y100 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors M402 ; retract probe (omit if using bltouch)

THANK YOU. it worked and I found my correct bed coordinate points. do I have to change any config for my BLtouch current settings are

Z-Probe

M558 P9 H2 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X0 Y0 Z2 ; set Z probe trigger value, offset and trigger height

M557 X5:350 Y5:350 S50 ; define mesh grid

I have version 3 -

The dive height is a little low. It should be at least a mm more than the trigger height. Try M558 H3

Also change G31 P500 to G31 P25

Have you calibrated our probe and measured the offsets yet?

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

-

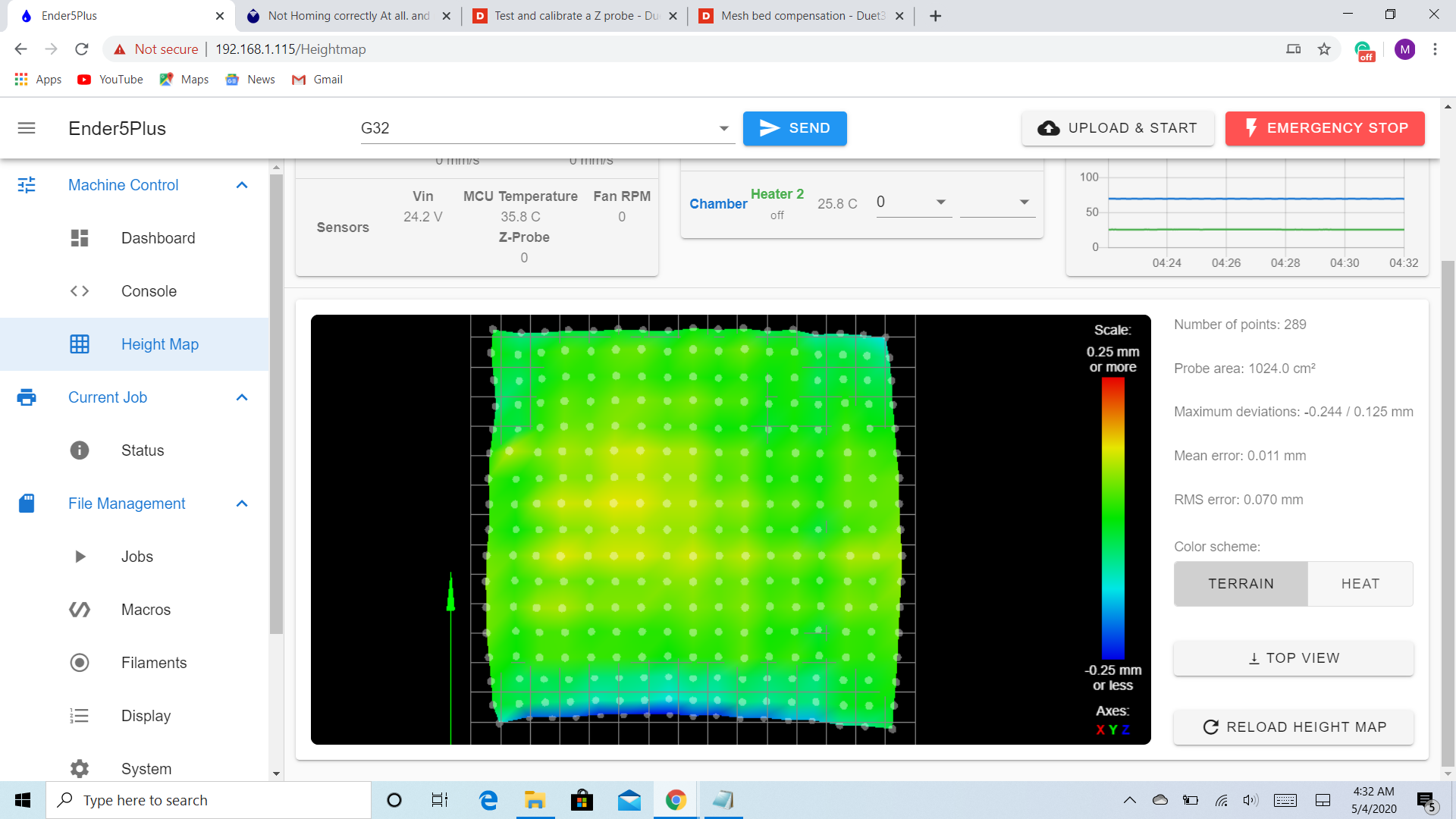

so I have adjusted all the settings accordingly here's a photo of the hight map

so I don't if that's ok or it should be 0 all the way I tried to print a file 340 x 340 and it looks like it's not adjusting probably. here's my updated file config.g

so I don't if that's ok or it should be 0 all the way I tried to print a file 340 x 340 and it looks like it's not adjusting probably. here's my updated file config.g; Configuration file for Duet Maestro (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Apr 30 2020 23:57:45 GMT-0500 (Central Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Ender5Plus" ; set printer name; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M569 P4 S0 ; physical drive 4 goes backwards (Z2 axis)

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M671 X0:285 Y0:180 S0.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axis

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z800.00 E96.00 ; set steps per mm

M566 X480.00 Y480.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

M203 X30000.00 Y30000.00 Z600.00 E3000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z100.00 E5000.00 ; set accelerations (mm/s^2)

M906 X960 Y980 Z960 E960 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X365 Y365 Z415 S0 ; set axis maxima; Endstops

M574 X1 Y1 S1 ; set active low and disabled endstops

M574 Z1 S2 ; set endstops controlled by probe; Z-Probe

M558 P9 H3 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X0 Y0 Z1.758 ; set Z probe trigger value, offset and trigger height

M557 X5:335 Y5:335 S20 ; define mesh grid; Heaters

M141 H2 ;Assign chamber heater to heater 2

M307 H2 A11 C99000 D2000 B1 ; chamber heater operates in bang-bang mode

M305 P2 T10000 B3988 C0 R2200 ; Set thermistor + ADC parameters for bed

M143 H2 S80 ; set temperature limit for heater 2 to 80C

M305 P0 T98801 B4138 R2200 ; set thermistor + ADC parameters for heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M305 P1 T98801 B4138 R2200 ; set thermistor + ADC parameters for heater 1

M143 H1 S300 ; set temperature limit for heater 1 to 300C; Fans

M106 P0 S0.5 I0 F500 H1 T45 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S0.5 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 S"Nozzle" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tooland file bed.g

; bed.gG28 ; home

M401 ; deploy Z probe (omit if using bltouch)

G30 P0 X0 Y180 Z-99999 ; probe near a leadscrew, half way along Y axis

G30 P1 X285 Y180 Z-99999 S2 ; probe near a leadscrew and calibrate 2 motors

M402 ; retract probe (omit if using bltouch)G29 S0

G29 S1I don't know if i have to enable some settings to run hight map while it prints maybe from slicer or from DWC. thank you for all your help

-

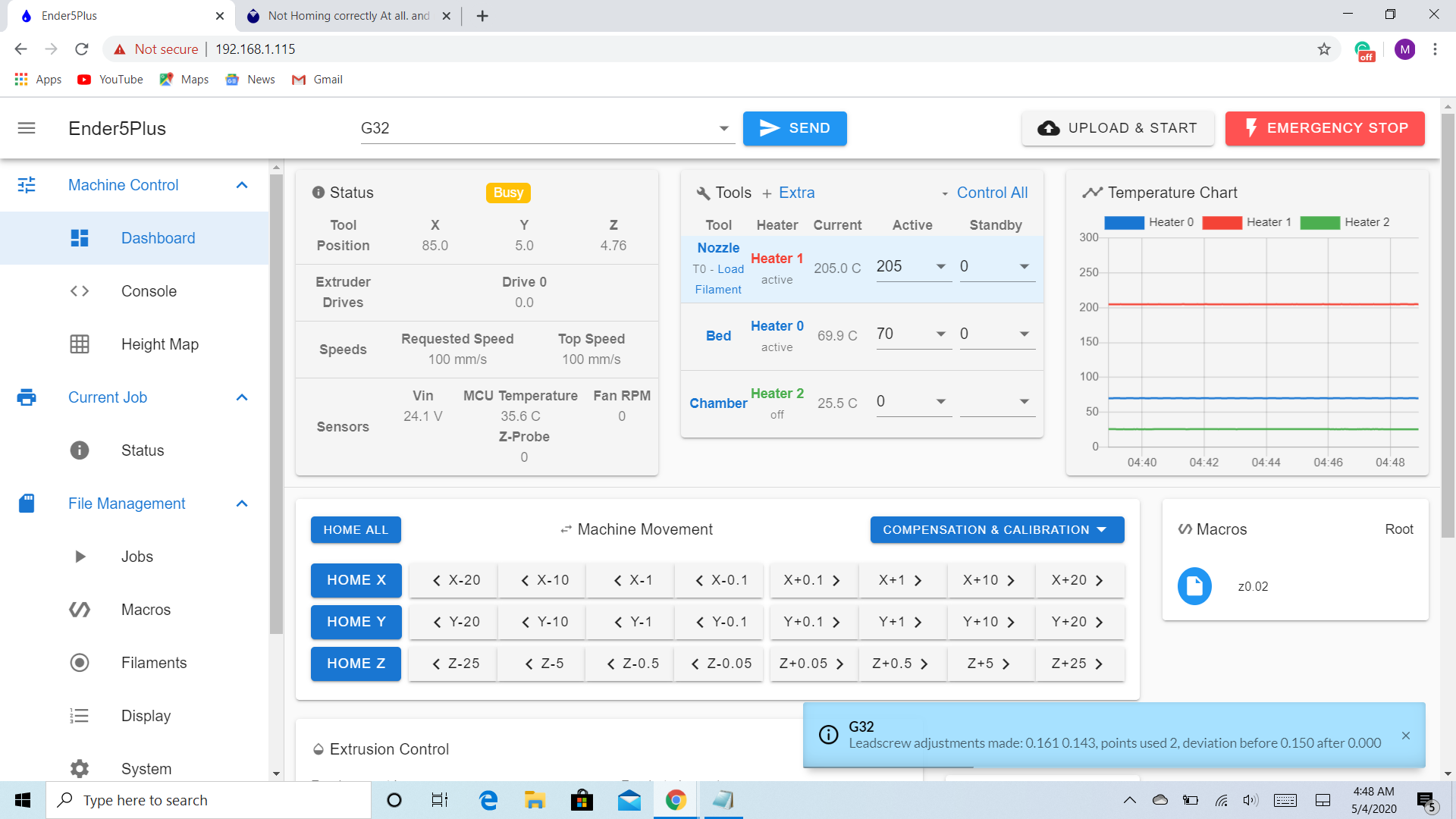

when I run G32 here's the message I get

does that meat its successfully calibrated. -

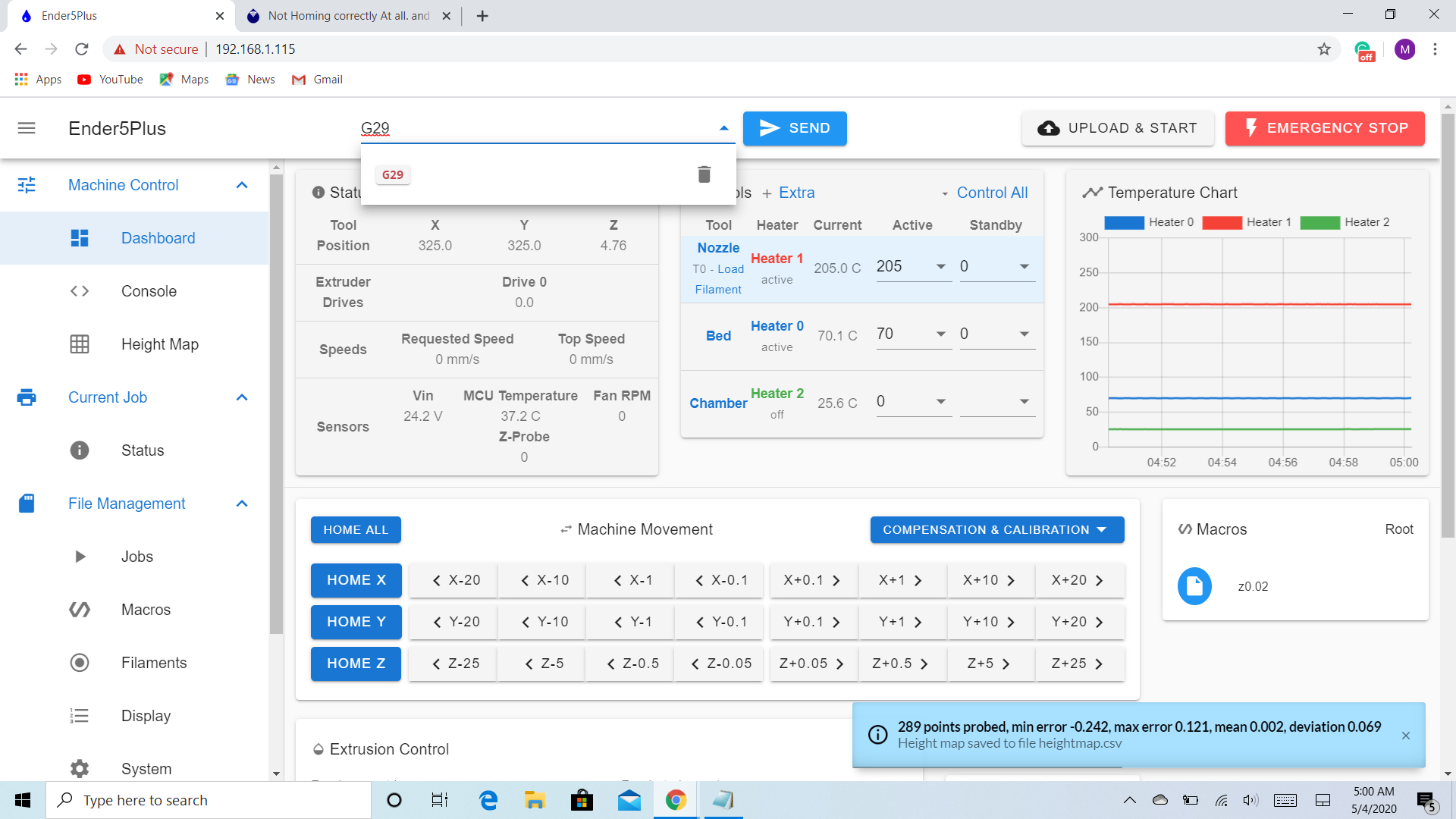

also here's the message when I run G29.

please let me know if that looks good sorry I know I have been asking you a lot. Thanks again -

Print a test file like this one with mesh enabled and again disabled. You should be able to tell if it's being applied correctly.

-

Yes I did what you told me and it looks like its not working properly. Any other suggestions would be helpful. Thanks

-

@moe-adams9093 What slicer are you using? Please post your start GCode from your slicer.

Regards,

Paul -

@moe-adams9093 said in Not Homing correctly At all. and nozzle issues:

G31 P25 X0 Y0 Z1.758

You need to measure your X and Y probe offset otherwise the corrections will be off in X Y position.

The heightmap itself looks ok. After measuring the offset redo the G29 and reprint the test file to see if it's behaving better.

-

Thank you for the additional information so my x offset is 44mm and the y offset is -5mm but when I try to run mesh compensation its starting from 44 to 285 and my actual build volume is 350 x 350 so please correct me on that one am I loosing that left over space since it only probing from 44 to 285. Also when I checked my old configuration from the original bord it says offest x0 y0 z1.78 so I don't if that does matter or not. Please let me know thank you