PTC Bed heater

-

@akstrfn said in PTC Bed heater:

It gets slower the closer it gets to rated temperature (as it should btw) but to solve this problem get a heater rated to 180 or 200 degrees and temperatures of around 120 would be reached quickly.

That's correct, the higher the 'passive' target temperature compared to the 'active' target temperature, the faster the active temperature will be reached, but in a sense, this trades safety for speed. We also make similar tradeoff with regular heaters when we select their power.

The beauty of thermal fuse is that 1) it allow to heat at full speed, 2) it provides the control loop full power around the working temperature to react to changes, and 3) once a problem occurred, it turns off the heater rather than keeping it on higher than normal working temperature.

That's my 2c, and I am not an expert by any mean. I appreciate the experiments that your are doing ('don't listen to the nay sayers') and I will welcome any innovation that will improve the safety of our 3D printers.

-

My 3D systems machine has a 400 watt PTC heater as it came from the factory, but used as a chamber Heater

-

@DallasH which 3d printer do you have?

-

@akstrfn Cube Pro converted to Duet and dual Mosquito hot end and bondtech extruders

-

@zapta I think that it should be possible to find a PTC heater which will have sharp increase in resistance hence keeping close to max heating power longer but I am still looking although I might give up looking since what I have tested so far works better than expected for my needs.

-

@akstrfn said in PTC Bed heater:

think that it should be possible to find a PTC heater which will have sharp increase in resistance

Yes, I agree. Sharper curve is better in this case.

-

@akstrfn said in PTC Bed heater:

If the community would not be like "thermal fuse does the job" or "thermal runaway does the job" I believe that by now good heaters made for safe use would be long available for 3d printers... As well as fuses for hotends or even ptc hotend heaters for that matter... (I believe that e3d is working on one though ;))

How does a thermal fuse not do the job?

And its not like you can't just go buy a thermal fuse off-the-shelf and add it to a hotend or a heated bed... We could have had one on every single 3D printer since well, 30 years ago.Besides, its actually easier (and just as good) to design a hotend that even if left on 100% with no cooling fan, can't damage itself... not that we get that all the time.

Now if you really want to get fussy, there are only limited options above 200C, and iirc nothing above 300C. And good luck finding a self-resetting fuse over about 100C. But if you want to be that fussy, PTC heaters are less safe than a thermal fuse, because the control can fail on and they stay hot. With a thermal fuse, if the control fails on, the fuse melts and the heater turns off.

Why are people not using PTC heaters? The real reason?

Because when you ask for one from a manufacturer they respond with "pay us a bunch of money and we will design one for your needs".

-

How does a thermal fuse not do the job?

And its not like you can't just go buy a thermal fuse off-the-shelf and add it to a hotend or a heated bed... We could have had one on every single 3D printer since well, 30 years ago.Thermal fuse does the job but physics does the job better i.e. in extraordinary situations fuses can fail to function whereas the material properties will always stay true. Fuse is also an external safety thing which 2 more added connectors and a way to secure it to the bed whereas PTC heater needs none of those.

You can also notice that a lot of devices that have something to do with heating are going the PTC way whenever they can.

Additionally the whole setup is so easy that all I needed to do in my tests is put electricity through the heaters and I was done and everything was perfectly safe (at least thermally).

Besides, its actually easier (and just as good) to design a hotend that even if left on 100% with no cooling fan, can't damage itself... not that we get that all the time.

I totally agree and by this logic I also prefer PTC bed heater over fuse if possible and why I use v6 30W hotend heater.

Now if you really want to get fussy, there are only limited options above 200C, and iirc nothing above 300C. And good luck finding a self-resetting fuse over about 100C. But if you want to be that fussy, PTC heaters are less safe than a thermal fuse, because the control can fail on and they stay hot. With a thermal fuse, if the control fails on, the fuse melts and the heater turns off.

PTC is always safer because it can not cross critical point and has less complexity than the fuse system. The fact that it does not power down is irrelevant when no damage can be done. In the experiment I've done I've left the heater on with no control and the temperature never crossed 80 degrees with just one heater and never crossed 100 degrees with 2 of them. In the worst case with 100% perfect insulation (aka no heat loss)the whole system would never cross 140 degrees. I believe here you should apply the same logic you used for hotend heater...

Why are people not using PTC heaters? The real reason?

Because when you ask for one from a manufacturer they respond with "pay us a bunch of money and we will design one for your needs".

If the demand would be there, there would be heaters hence my rant about "fuse does the job". I started investigating the price options and send message to some ali sellers to see if custom design is possible, let see how that goes. Price wise it seems that these heaters are cheaper and one could make a mesh out of them i.e. use bunch of these for example.

The only downside I can see is that PTC heaters that are not mains powered but powered from duet might be problematic because I've measured big initial spike in current.

-

A thermal fuse does indeed do the job, assuming it can be relied upon. OTOH a PTC heater with a temperature limit of e.g. 160C will also do the job very well if 160C is a safe temperature but the highest temperature you actually want to use is 120C; and it is a simpler solution.

-

@dc42 said in PTC Bed heater:

A thermal fuse does indeed do the job, assuming it can be relied upon. OTOH a PTC heater with a temperature limit of e.g. 160C will also do the job very well if 160C is a safe temperature but the highest temperature you actually want to use is 120C; and it is a simpler solution.

Agreed, the only problem is now it is possible to source PTC heaters which get very slow to hit their target temperature so sizing them to be just a bit above max temperature would speed them up significantly.

@dc42 would PID autotune work with PTC heater?

-

@akstrfn said in PTC Bed heater:

@dc42 would PID autotune work with PTC heater?

The results would be accurate at the temperature at which it was tuned, but less accurate at substantially different temperatures.

-

@dc42 ok makes sense. Can we have multiple pid parameters that are picked based on desired temperature?

I should have one more PTC heater (so total of 4) and 8mm alu bed in the next weeks to continue with this experiment. I'm just worried that the current draw will be a problem. One led lighbulb that shared the extension cord with heaters died during my testing (although the new one didn't seem to mind)... Probably due to current fluctuation.

-

What is the resistance of each PTC heater when it is cold? Knowing that, you can work out the surge current when you turn them on from cold.

-

When they stabilize they read ~650Ω. Interestingly they often get stuck around 2000Ω and when I put my hand on it for a few seconds they go to 600Ω. But the resistance fluctuates quite a bit until it reaches equilibrium. I've heated it a bit and then the resistance went to 450Ω.

-

I've finally managed to get everything going again and PTC heaters are tested. My first test on 300x300x8mm alu bed looked like this:

This was mainly to test if I want to do this since I also bought a Keenovo heater as well. After initial tests I thought its perfect because it managed to reach 100 degrees in around 15 minutes with temperature measured in the middle as can be seen on the picture.

Next, I've then added thermal pads, drilled and tapped the holes to firmly hold the heaters. I still need to earth the whole thing and to use plastic screws instead of metal ones but one step at the time. Picture is a bit blury but you get the idea.

Unfortunatelly now it seems that the plate is heating too fast (PID tuned) even though these are 150W heaters in theory so in sum 450W. It hits around 90 degrees in 5 minutes. Keep in mind that the temperature is measured in the middle and not on the heater. I was very optimistic how tightly I managed to get the heaters to the bed with Kapton tape in my first test so there was probably a lot of air in between.

As I observed initially the power of PTC heaters should not really be measured in watts, namely I've measured a power draw of around 1.1kW on cold start so these heaters are actually consuming way more power when cold and they hit 50-60 degrees very fast.

I also did tests with 24V PTC heater and observed that it has different max temperatures depending on the input voltage. Considering that PTC heaters can be observed as closed loop control system and the max temperature seems to be tied to PWM then the PID system for PTC is not necessary.

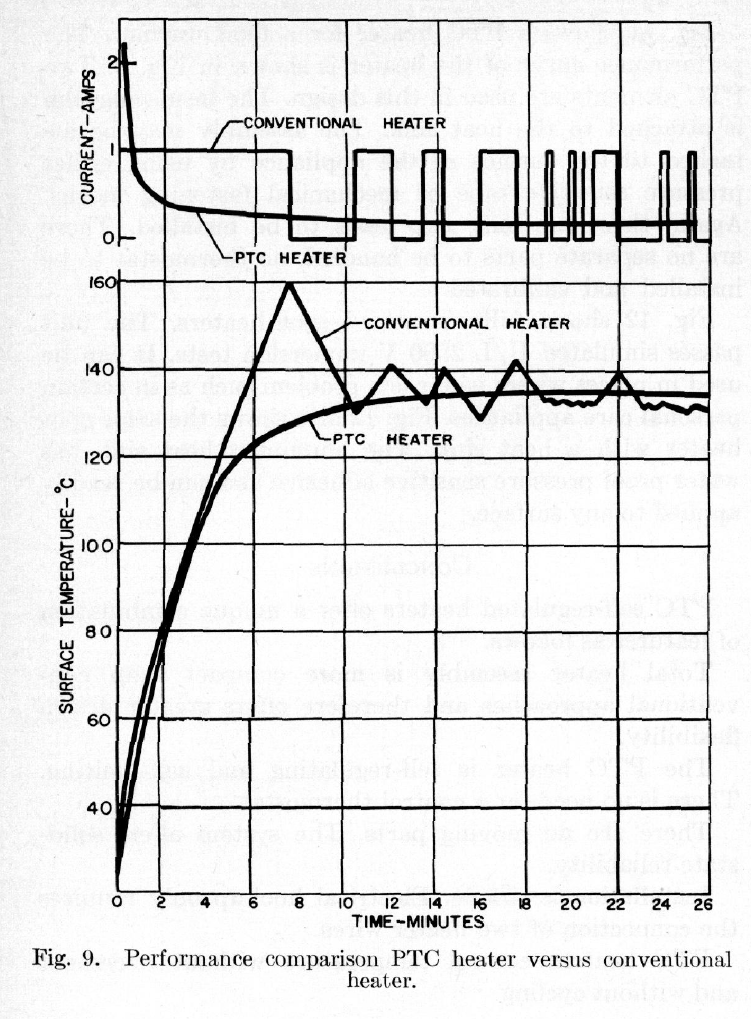

I looked around and found a graph in Self-Regulating PTC Heating Systems: A New Approach for Electric Heating Appliances (or sci-hub link) which actually explains most of the points I observed i.e. initial power draw, control and fast heating on lower temps:

@dc42 do you think its sensible to have a feature in firmware to select different PWM for different temperatures and leave the heater constantly on or dynamically adjust max PWM based on temp measurements?

Even with the present problems this solution seems far superior to other heaters, first its cheaper (although its mostly because its bare bones) and second it is safer. My setup can definitely be improved and I will probably work in it over time if I don't remove the bed heaters and just add chamber heating.

-

@akstrfn said in PTC Bed heater:

@dc42 do you think its sensible to have a feature in firmware to select different PWM for different temperatures and leave the heater constantly on or dynamically adjust max PWM based on temp measurements?

Is there any problem with leaving the PID loop running when using a PTC heater?

-

@dc42 said in PTC Bed heater:

@akstrfn said in PTC Bed heater:

@dc42 do you think its sensible to have a feature in firmware to select different PWM for different temperatures and leave the heater constantly on or dynamically adjust max PWM based on temp measurements?

Is there any problem with leaving the PID loop running when using a PTC heater?

It might be the issue that the temperature sensor is separated from the heaters but now it oscillates. I did PID tunning for 90 degrees and then used the bed at 80 degrees and the temperatures went from 79 to 82. Also the gain was estimated to 220 which is not correct for the heater I have since its max temp is 150 degrees.

-

I'd be tempted to try attaching the sensor directly to one of the heaters. Since the performance of all 4 should be well matched. Then you have more direct PID control feedback from the actual heater.

-

@Phaedrux I am still trying to tune it manually and if I fail then I'll try your suggestion. Today I did few test with different PWM duties and I was quite disapointed to see that PWM of 0.2 leads to max temps of around 102 meaning that my idea of fixing PWM is not very useful. Might be due to SSR and low PWM but at the end I'll probably need to read more of PTC theory in order to figure out whats exactly happening.

-

Is there any chance you can shoot a picture of the bed with a thermal camera?