Dead Driver or Stepper Motor?

-

-

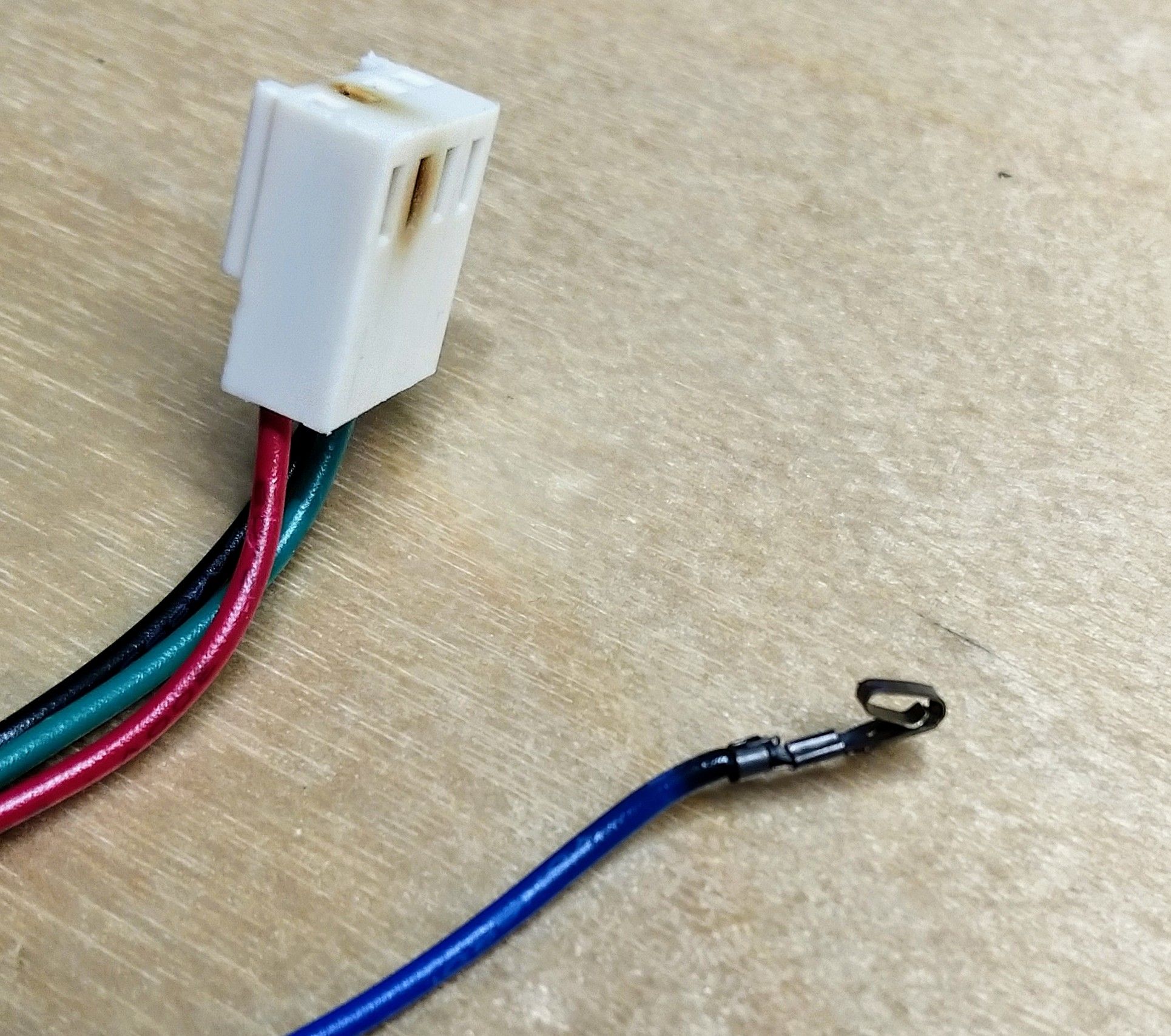

Could have been poor contact between the crimp and the pin, or the wire could be poorly crimped itself. Either way, I'd definitely recrimp them.

-

@Phaedrux

I will recrimp and possibly just not use this cable right now and replace the cable I took from spare inventory I just put into production... -

@BlueDust That was a very good find. I would say that you should just re-crimp that wire with a new pin and you will be all set. I would also replace that connector if possible. I would also highly suggest that you clean/gently scrap the connector that had connected to that failed pin. I only say this because you will most likely find some sort of a carbon buildup on it.

I have seen this kind of situation before many times while I was in the Air Force working on the Electrical System of many different Aircraft.

If you have any questions about this, please reply or send me a private message.

Take Care

Shawn B. aka Karma

-

Hey @Karma

I did "try" to scrap some of the carbon off the pin, but I don't think I was able to do a good job before I put it back together to test (and confirm it was just the wire/crimp). I will be taking it apart again to do a better job at cleaning the pin off.

I will replace the connector , as if I have more problems I don't want this burn mark to confuse me and hinder my troubleshooting in the future.

I am just happy it doesn't look like anything "real" was damaged. I really think this was a reminder that I planned to replace all of the motor wires with custom lengths and neatly hide them in the frame of the printer... Its a custom build, and I really haven't 100% finished it... After a lot of troubleshooting upfront I just wanted to print and prove it worked.... I think it has been almost 2 years now.

-

@BlueDust Bro, I get what you mean about just wanting to get it together just enough to see if it will print. My control box that has all my components in is falling apart. Stupid acrylic design. Cracked it on the first day, and also on the second and third. Very cheap design. I am going to customize where the control board will be with everything else. I seen how to do it and how it looks from a facebook group dedicated to the Tevo Black Widow. There is this one member that has completely redesigned the Black Widow and it looks mean as heck. He has also got the mmu from Prusa to work on it. Crazy, I know, but he did it. He had to figure out how to interfave with the mmu in order to get it to work. He didn't have enough Tx and Rx pins left on the main board. But somehow he figured it out and it runs great.

-

If the pins are plated then scraping anything off them will likely scrape off the plating resulting in a short term solution.

Best bet it replace both, should be possible to pull out a single pin and put in a new if de-soldering the whole header is a problem.

-

@bearer said in Dead Driver or Stepper Motor?:

Best bet it replace both, should be possible to pull out a single pin and put in a new if de-soldering the whole header is a problem.

It's possible to pull the plastic part off. It's easier of you use hot air at about 150-180C to heat the connector first. After that you should be able to remove and replace the connector pin.

-

@dc42

Does the printer automatically stop or pause when this error occurs?Warning: motor phase B may be disconnected reported by driver(s) 8I saw this error when I was trying to rehome the printer, and it didn't appear to stop. I hit the STOP button.

I am curious to know as if this happens again while printing, I would want it to stop or at least run the pause script (but the printer isn't working so that sounds dumb).Thanks!

-

@BlueDust said in Dead Driver or Stepper Motor?:

Does the printer automatically stop or pause when this error occurs?

No, because the warning isn't a 100% guarantee that the stepper motor phase has become disconnected.

-

@dc42

Is there a way to make it user configurable, so I can make the printer stop if this or similar error occurs? But then turn the it off if there are false errors?In my case it was happening, and it would have been bad for the printer to continue trying to print.

-

@BlueDust you could probably use daemon.g to monitor the driver for errors and act accordingly.

You’d have to see what values are available in the object model. -

@OwenD

Thanks for letting me know about daemon.g.

Is deamon.g for both the RR2.x and RR3.x?

I started to look into it but 1 quick search didn't find anything in the wiki. Do you have a link to any documentation I can read before I start asking questions?

I have yet to do any custom programming for the Duet2, and I guess spending a few minutes at least reading this may motivate me to get started.Thanks!

-

The daemon.g is only applicable to RRF3

-

@jay_s_uk

Thanks!

I have yet to upgrade to RR3....

Rebuilt printer with rails/new carriage, resolved extrusion problems, started to print large project.... will have to put large project on hold and upgrade to RR3...Thanks!