How to setup the Bigtreetech smart filament sensor?

-

-

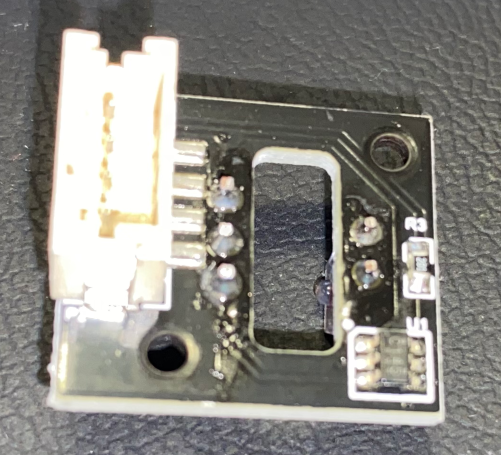

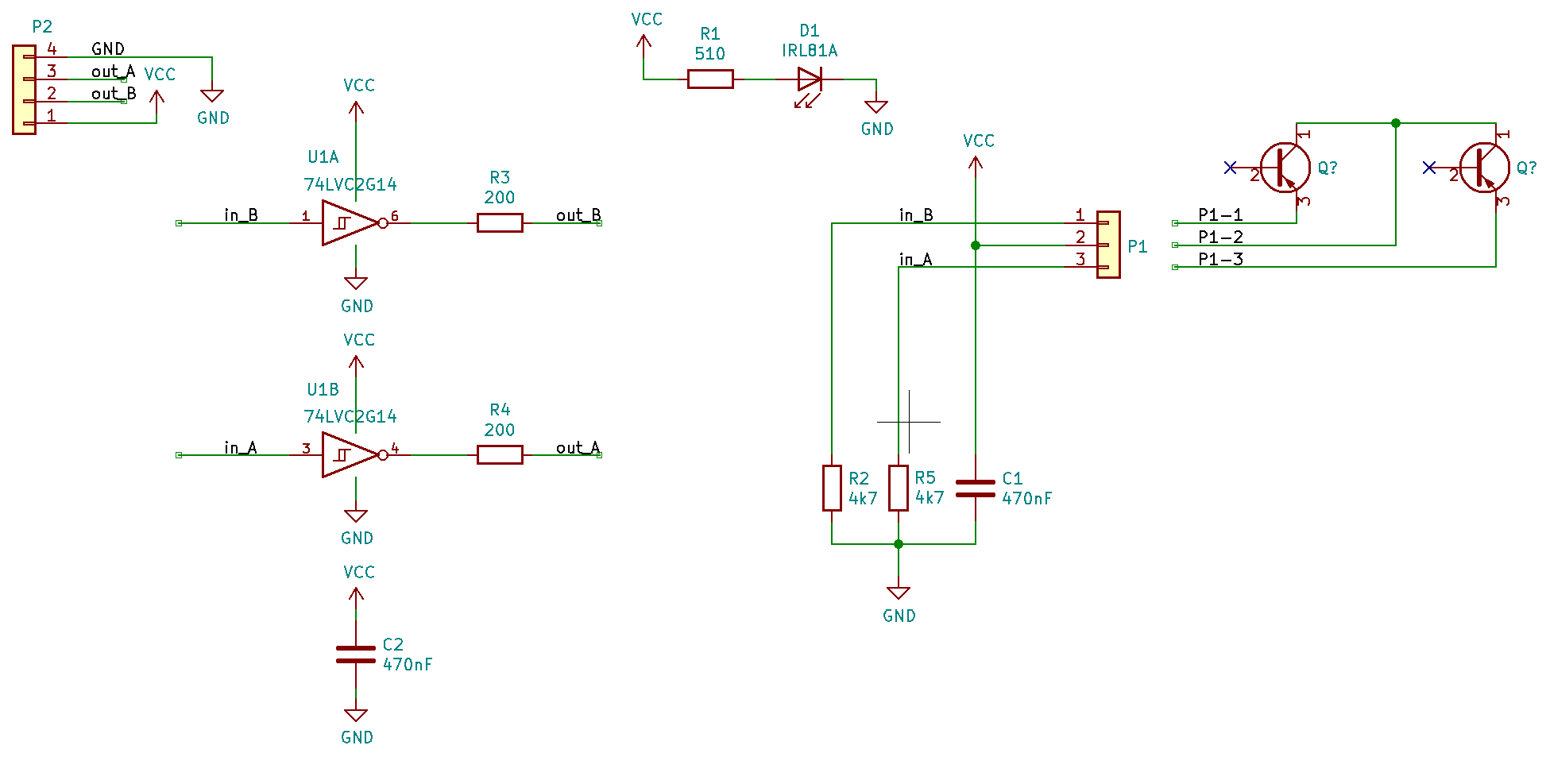

The only thing I'm unsure about is the foto sensor as I never seen PNP foto-transistor, nor I seen them in this dual packages before. Normally they are NPN and single package but the way it is connected I have to assume this is PNP.

Now, Vcc - GND, I tested 5V and 3.3V and both work perfect.

The out_X is already push-pull so you do not need any pull-up/push-down on the IO pin on duet. And no need for resistor dividers, only power the sensor from 3.3V and you should be golden.Have not yet connected to my duet but scope shows impulses going ok.

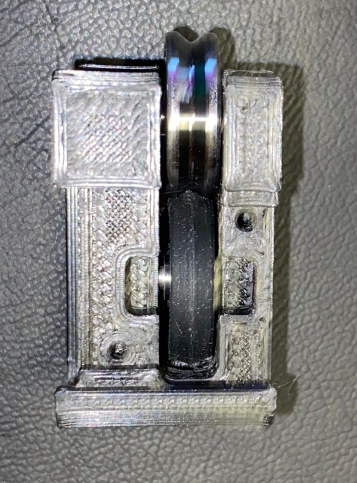

I have to say I don't get the construction?!?!

- the spring (at least in the one that @omni brought here today for me to test) is so damn strong the sensor deforms the filament and makes it very hard to pull. Not a big deal if you are running BMG but cmon, there's no need for this, the original spring must go away and to be replaced with a softer one

- there is a fixed idler bearing with V grove ?!?!

normally you make this idler moveable so it presses on the drive gear, but they decided to make this bearing static and to move the whole block with electronics, connector... to press the filament ?!!? WEEEEEEIRD

- then, instead of encoder wheel (with rubber outside ring, soft and sticky to grab the filament easily) having contact with the filament, they add another bearing between encoder wheel and the filament, another V groved metal bearing that have zero grip on the filament (probbly why the spring is so strong so filament don't slip on the smoth side of the bearing)

So, to "fix"

- replace the spring with something softer

- need to add grip on the bearing in the slide-block, I assume a small wide rubber band will do the trick (those used for money wide ones are great)

To connect:

Pin closes to the bowden coupling is Ground, than there are 2 output pins and the pin farthest from the bowden connector is Vcc. Connect Vcc to 3v3, Ground to Ground, one of the output pins to the E_stop and that's it

-

and, def. works

need to be now properly configured (this is configured for my encoder) but to get you started

M591 D0 P7 C"e0stop" L0.5 R90:110 E3 S0now you need to setup your own L value and your own span .. for start it's disabled but will collect data, when you are happy with the way you calibrated it you enable it and enjoy

@omni 's U1 was not dead, I'm not sure how was he connecting it when it was not working but he did not burn the U1 so I just retraced the whole schematic (I desoldered the photo transistor pack to test it separately and make sure it's not ghosting my schematic, and then put it back after I was done, tested transistors separately with IR transmitter from a remote controller

)

)All in all, it works directly from 3v3 so all pins you need are on the E0STOP and E1STOP connectors on duet2ethernet (I assume the other duet's have similar/same connector)

-

Thank you for your extensive testing!

Looking at your schematic do you think I could have blown up U1 when it was wired up wrong? I still have the desoldered chip and assuming I did not damage it during desoldering I could place it back.Does it anywhere say what your board version is? I notice the housing for the one you have is 3D printed while mine is injection molded. Maybe they changed the spring too, mine is certainly stiff but does not deform the filament, there is some noticeable resistance to get it going but it rolls smooth after that. I do wonder if the stiff spring will be a problem with flexible filaments.

-

@Infinitysnek said in How to setup the Bigtreetech smart filament sensor?:

Thank you for your extensive testing!

I ordered this filament monitor myself (stuck in the post somewhere for months

) and I'm helping out @omni to migrate to duet and upgrade his printer and he's using this monitor too so it's for selfish reasons

) and I'm helping out @omni to migrate to duet and upgrade his printer and he's using this monitor too so it's for selfish reasons

Looking at your schematic do you think I could have blown up U1 when it was wired up wrong?

Looling at the documents from btr they put there GSV and not GSSV so if you really pay attention you see on the images that there is a wire missing between S and V on their image but it's visible only if you really know what to look for, normally it looks like GSVx and in that way you power the output of the circuit. There's 200R on the output but it could maybe kill that PRC clone of the dual schmitt trigger.

omni also connected the device wrong but it is working ok, the U1 did not die. What did you power it with? 5V? 12V?

I still have the desoldered chip and assuming I did not damage it during desoldering I could place it back.

I doubt you can kill it by desoldering those can survive a lot of heat, but you measured something other than Vss/Vcc on the 2-3 pins and output of schmitt trigger cannot float, it's either 0 or 1 hence me assume that U1 is dead.

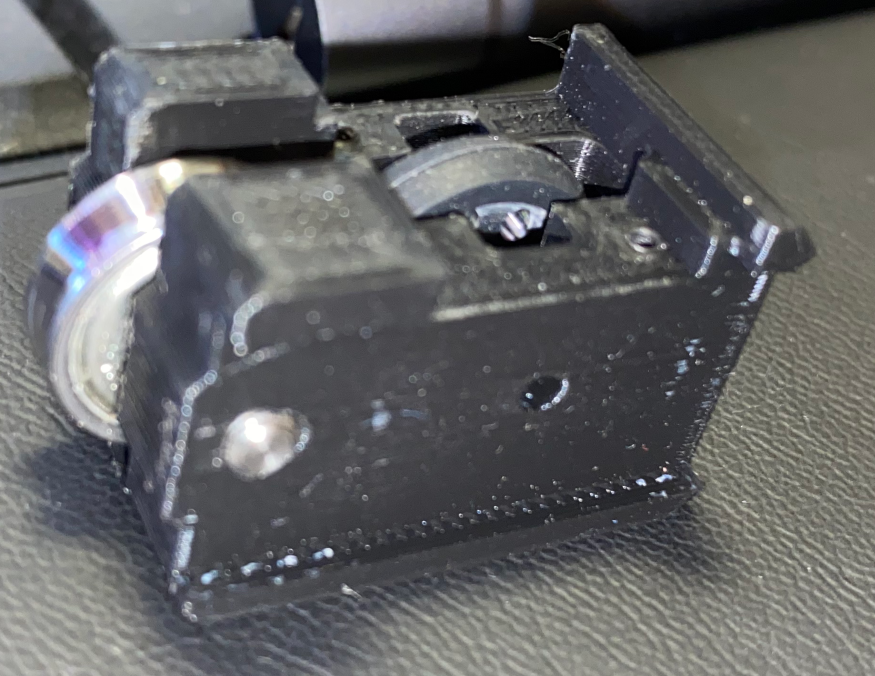

Does it anywhere say what your board version is? I notice the housing for the one you have is 3D printed while mine is injection molded.

Yes, @omni's sensor is 3d printed case. PCB is v1.2

sorry images are total %$#%^@ I was not looking if they are in focus I assumed stupid iphone will focus properly

Maybe they changed the spring too, mine is certainly stiff but does not deform the filament

I pressed this one few times fully and now it does not deform filament any more but it still offer way more resistance than I'd like

there is some noticeable resistance to get it going but it rolls smooth after that. I do wonder if the stiff spring will be a problem with flexible filaments.

this one will be but it's super easy to replace so I'm sure omni will do it... it's more that whole design is imo wrong, the connector slides instead of bearing, the additional bearing between wheel with holes and idler, no rubber on the drive wheel.. dunno, makes no sense to me really, I expected much more refined design

-

@arhi said in How to setup the Bigtreetech smart filament sensor?:

What did you power it with? 5V? 12V?

Only 3V3 and 5V never any higher.

Since I have to wait anyway for a replacement chip could I measure on the pins for resistance to check? Otherwise I'll just going to solder it back and hope it magically fixed itself.

-

@Infinitysnek said in How to setup the Bigtreetech smart filament sensor?:

@arhi said in How to setup the Bigtreetech smart filament sensor?:

What did you power it with? 5V? 12V?

Only 3V3 and 5V never any higher.

omni did the same and did not kill it

Since I have to wait anyway for a replacement chip could I measure on the pins for resistance to check?

Nope, you need to power it on to test it.

Otherwise I'll just going to solder it back and hope it magically fixed itself.

it is easiest way to test it, you can easily remove it if it does not work.

When you power it (3.3V enough) irrelevant to what input is, output (pins 4 and 6) must be either ground or vcc, can't be nothing in between, if you measure something in between it is dead. BUT make sure you keep the sensor in dark when you are measuring as if the sensor is picking up some noise it could be turning the input on/off quickly that will then translate to output going quickly between Vcc and Vss and since you are measuring with DMM and not a scope you will get some RMS value that will be between Vcc and Vss. So put some metal cap over the transistor when measuring outputs

-

@arhi said in How to setup the Bigtreetech smart filament sensor?:

@Infinitysnek your schematic was very close to the real thing

...

...here's my take

The two phototransistors will be NPN, but otherwise that looks highly plausible. In which case, it has quadrature outputs, so by using two inputs on the Duet and appropriate firmware it would be possible to sense direction of filament travel as well as amount.

-

@dc42 said in How to setup the Bigtreetech smart filament sensor?:

The two phototransistors will be NPN

I never seen PNP photo transistor, but with NPN one would normally do E to Vss, out from C and pull up resistor from C to Vcc, but here the C is on Vcc and output is on the bottom which is why I assumed PNP and not NPN .. in any case works the same as base does not exist

it has quadrature outputs

I assumed that transistors are one next to another so that light opens one first than another, but tbh didn't manage to get that on the scope, they both open/close at the same time

so by using two inputs on the Duet and appropriate firmware it would be possible to sense direction of filament travel as well as amount.

is that needed at all? firmware knows the direction it is turning the motor at ?

I'm using on my printer (not yet enabled still using in disabled state) a 600 steps optical encoder but only the A output.

-

@arhi said in How to setup the Bigtreetech smart filament sensor?:

they both open/close at the same time

would be okay in one direction, did you try both?

-

@bearer said in How to setup the Bigtreetech smart filament sensor?:

@arhi said in How to setup the Bigtreetech smart filament sensor?:

they both open/close at the same time

would be okay in one direction, did you try both?

I did not waste too much time on it as RRF uses only one impulse train anyhow so as soon as I got it working I wrapped it up and moved to a next task

and whatever's in that IR receiver is not very useful as I can't purchase another one like that so investigation was not going anywhere

and whatever's in that IR receiver is not very useful as I can't purchase another one like that so investigation was not going anywhere

But in both direction one need to come first they should never turn on in the same time

-

@arhi said in How to setup the Bigtreetech smart filament sensor?:

But in both direction one need to come first they should never turn on in the same time

not a problem as long as its different in the other direction. (ofc. if they turn on and off at the same time in one direction it'll make it tricky to distinguish the other direction)

-

@arhi said in How to setup the Bigtreetech smart filament sensor?:

and, def. works

need to be now properly configured (this is configured for my encoder) but to get you started

M591 D0 P7 C"e0stop" L0.5 R90:110 E3 S0now you need to setup your own L value and your own span .. for start it's disabled but will collect data, when you are happy with the way you calibrated it you enable it and enjoy

@omni 's U1 was not dead, I'm not sure how was he connecting it when it was not working but he did not burn the U1 so I just retraced the whole schematic (I desoldered the photo transistor pack to test it separately and make sure it's not ghosting my schematic, and then put it back after I was done, tested transistors separately with IR transmitter from a remote controller

)

)All in all, it works directly from 3v3 so all pins you need are on the E0STOP and E1STOP connectors on duet2ethernet (I assume the other duet's have similar/same connector)

So after a month I have a working sensor. Measured the signal pin and it now gives a 3.3v pulse like it should and wired it all up like you mentioned earlier.

Yet I keep getting no data received. I've switched to the other extruder port to check and changed all the settings multiple times yet nothing seems to be doing anything.... -

@Infinitysnek try a simple test

- remove your "real filament" going trough the sensor and feed it to your extruder directly

- push a 20cm piece of filament into the sensor

- connect the sensor to duet and configure (disabled state)

- start any print from sd

- when the printer start printing check the status of the sensor (should be no data)

M591 D0 - now move, using your hand, those 20 cm of filament all the way trough the sensor one way, then return it all the way to the other end, repeat this few times

- check the status again

M591 D0

you should now see some data

-

@arhi Well at least something changed. I tried that as well as doing a full print. Now it says

no calibration dataso I assume my config isnt right yet? -

Just a short update from my side about the Bigtree filament sensor.... It works as intended now!

My settings are M591 D0 P7 C"e0stop" L7 R75:125 E22 S1

The readings are usually from 93 to 108%, but I keep it on the safe side with the 75/125 % min/max settings.

It already saved one print....

Hope it helps.

-

its SN74LVC1G14 Single Schmitt-Trigger Inverter

you can refere to Page 11 ( https://www.ti.com/lit/ds/symlink/sn74lvc1g14.pdf?ts=1601472384457&ref_url=https%253A%252F%252Fwww.google.com%252F)

i hope this useful

-

I don't know if this will help anyone but I have been been running the BTT filament sensor for a few months ago with the below settings. Besides for a few false faults while printing with some clearish filament it's been working great!

M591 D0 P7 C"e0_stop" S1 R80:120 L6.2 E18.6M591 D0 Pulse-type filament monitor on pin e0stop, enabled, sensitivity 6.200mm/pulse, allowed movement 80% to 120%, check every 18.6mm, measured sensitivity 6.252mm/pulse, measured minimum 96%, maximum 102% over 33984.9mm -

@phiednate how do you connect to duet/duex board? Is the extra circuitry discussed above necessary to get it working?

-

@Popstar

No additional electronics is needed. It works as is - without any problems - just make sure you get the pinout right and put this line to configure the sensor :M591 D0 P7 C"^e0stop" L7 R50:250 E22 S1 ;pulse, disabled, 7 mm/pulse, measure every 22 sec, minimum 50 maximum 250

Also it would be wise to disassemble the sensor and "squeeze" the spring a little bit, to make the filament go through more easily, since by default the spring is too strong and puts a lot of resistance to the filament flow....