Mosquito vs water cooling

-

@tech-raton I am having a bit of a problem visualizing what you have done there. I see the heater and you say you use the E3D heat break so I am assuming that the heat break screws into your cooling block ? I am not sure what the red thing is in the square aluminum tube. How does the filament get guided to the heat break during a filament change ? What is the path of the coolant in that block - is it simply a blind hole at the entrance and exit with a cross drilled path connecting the two blind holes that is then plugged with the bolt shown in the middle of the block side ?

-

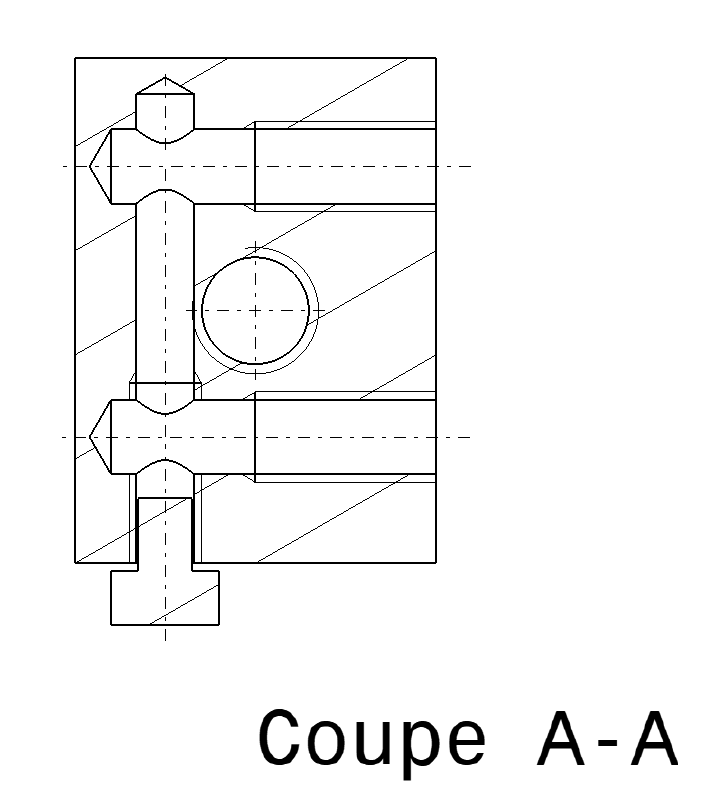

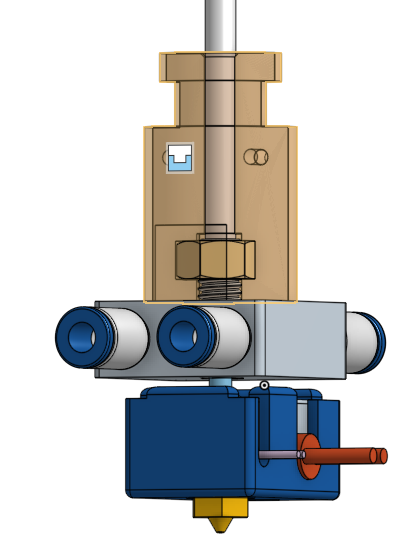

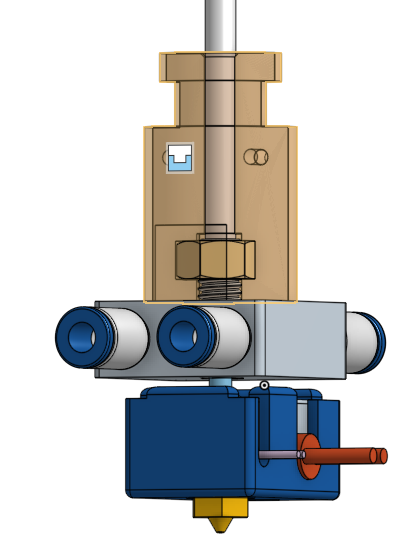

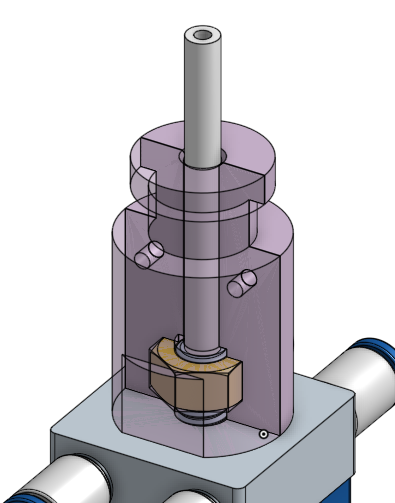

Here is what I planned to do for a friend:

The heatbreak is not the standard one, it is a full M6 thread, instead of the standard M6/M7 one.

-

@jens55 said in Mosquito vs water cooling:

@tech-raton I am not sure what the red thing is in the square aluminum tube.

A remote extruder, I think.

@tech-raton, what is the hotend, on the delta? I like round the heat block... Is it a piezo, above the water cooling block?

-

@fma said in Mosquito vs water cooling:

Herre is what I planned to do for a friend:

The heatbreak is not the standard one, it is a full M6 thread, instead of the standard M6/M7 one.

OK so the water cooling block is a straight through drill and then a loop on the far side back into the cooler ? The ptfe tube goes straight to the heat break ? I assume the top thing is the ptfe coupling ?

Is the nut captive somehow in the assembly ? How ?

Sorry about all the questions ....

-

Yup the red thing is a remote extruder.

The watercooling on the corexy is just a 8mm aluminium part with 7 holes drilled

A m7 for the heatbreak

2 m5 for the pushfits

A m4 to connect the 2 m5 holes

3 m3 holes to attach on the carriageOn the delta, the hotend is a maxiwatt with a homemade silicon sock

And yes with a piezo as z probeWhy you heat

-

Thanks for the clarification!

-

Why have 4 pushfits?

You could make a u shape inside your watercooling.

It will reduce the flow but will increase the heat exchange. -

@jens55 said in Mosquito vs water cooling:

OK so the water cooling block is a straight through drill and then a loop on the far side back into the cooler ?

Exactly.

The ptfe tube goes straight to the heat break ?

Yes.

I assume the top thing is the ptfe coupling ?

No, this is the standard groove for hotends. It is designed for direct extruding. But you can modify this part (3D-printed) for Bowden, using a coupler thread.

Is the nut captive somehow in the assembly ? How ?

The 3D-printed part is made in 2 parts (split along the vertical axis), and glued together (there are 2 holes to help aligning it. Here is a closer view:

Sorry about all the questions ....

You welcome! This design hasn't beed tested, and I would love to have feedback if you go that way.

-

@tech-raton said in Mosquito vs water cooling:

Why have 4 pushfits?

Easier to do.

You could make a u shape inside your watercooling.

How? I only have a drill...

It will reduce the flow but will increase the heat exchange.

It is the same, as I use a small external tube to make the half turn.

-

@tech-raton said in Mosquito vs water cooling:

On the delta, the hotend is a maxiwatt with a homemade silicon sock

Thanks! I'll have a look at this block...

-

Ahh, clever! If the ptfe tube is captured by clamping pressure that seems to make clearing a clog kinda tough ???

-

@jens55 said in Mosquito vs water cooling:

Ahh, clever! If the ptfe tube is captured by clamping pressure that seems to make clearing a clog kinda tough ???

As said, I didn't test it, and it may not work as expected. A longer heat break should be better, but I'm not sure if we can find one... But yes, the PTFE tube has to be clampled down, with the above part (extruder or bowden push fit).

-

Well I think that it shows great promise!

-

The goal of this design was to be able to use it in a standard setup (groove), but if you can customize the extruder side, it might be improved...

Another thing to check is if the 3D-printed part can handle the temperature. It should if the water flow is good, but better use PET-G or ABS. -

@tech-raton said in Mosquito vs water cooling:

And yes with a piezo as z probe

Do you have a CAD design of your setup, with Piezo? It is a nice and compact solution...

-

-

-

Ok, I see for the U. I will do that the next time!

STEP is ok for the CAD files. Thanks!

-

Do any of you guys have any links to the tube, fittings, and pump that you use. I'd like to use the smallest possible tubing and the quietest possible pump.

-

I'm about to test a car windshield water pump, for which I made a custom tank. I don't know if it will last long if on all the time, but it was on my old 350000km car, and still working fine! I think it is unbreakable

It has very small outputs, good for 2mm ID silicone tubes. The nice thing is it has 2 outputs (front and rear windshields), depending on the rotation direction of the pump, it sends water on one or the other.

See :

https://www.oscaro.com/pompe-de-lave-glace-peugeot-806-2-0-i-turbo-149cv-794-22222-0-gt#