Issues with print quality, wall surface rough.

-

@Corexy Ah ok yeah ill print with the new settings now EDIT yes 16x interpolate on

-

Mate I've got to go to work now, so please consider this in the meantime.

As well as that, please don't let me be the only one giving you tips. I could be wrong and others should weigh in with their experience too.

There's a major setting issue here it seems, so it's time to really go back to basics. Here's where I would go from here (assuming the machine is assembled correctly and the esteps are correct, and all at 0.2mm layer height/0.5mm layer width):

-

Extrude filament while dropping the temp 2 degC at a time (no fan). When the extruder starts to click and the filament is "pigtailing" as it comes out of the nozzle, add 10 degC to that temperature, and use it as your print temp. Ignore what the reading is and whether it sounds strange, just do it to that temp.

-

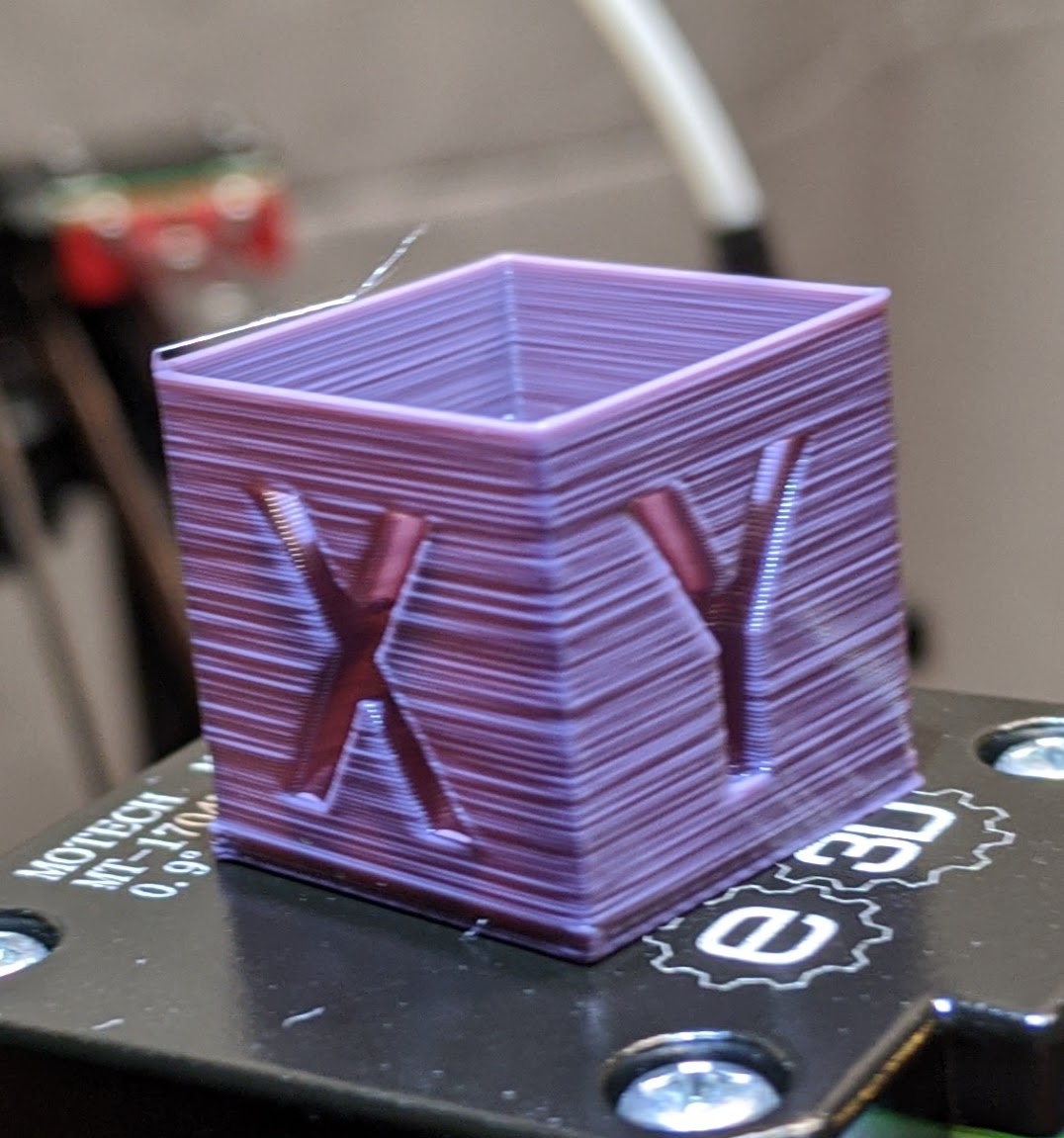

Print a 50mm cube with 2 wall thicknesses and 50 bottom layers (no fan). Using the Duet DWC and starting at 100% extrusion multiplier in the slicer, lower the extrusion (in the DWC or Paneldue) by 5% at a time until you see gaps in the extrusions. When gaps appear, then raise the EM by 2% at a time until they just close, possibly dropping 1% after that. ALLOW A FULL 3 LAYERS BETWEEN ADJUSTMENTS, and click the setting just as the print starts a new layer. Again, don't worry if the setting that works seems unorthodox, just find what works. The extrusion % you get in the DWC will become the EM value you enter in your slicer for that material profile. That's a start point, and as you print more technical prints like benchy's, you may alter it slightly. If the middle of the extrusions are neat and just touching, but the ends/direction changes are gluggy, that would suggest coasting will help but leave it for the moment.

-

After that, do one of those "retraction tester" prints, the one with 2 vertical posts on a base. It's on thingiverse. Start at 0 retraction and increase by 0.2mm every 5mm of height by setting multiple processes in your slicer. Use 30mm/sec retraction speed and 120mm/sec free movement speed/40mm/sec print speed throughout. No wipe/coast/vertical lift...nothing at all but the retraction height. No fan, and don't worry if there's some stringing. Just go for the best result, and then you can do it again using that retraction setting but adding 10% fan every 5mm of print height.

Please take pics of all these tests and post them here.

It has been my experience that settings that vary wildly from S3Ds generic profile settings indicate an underlying issue, but don't dwell on that for now.

Also please remember I'm just one of a million opinions/methods on the internet and take my advice as you will.

Good luck!

-

-

@Corexy said in Issues with print quality, wall surface rough.:

Also, did you say 16x micro stepping?

@Phaedrux You're the expert on that mate....what do you think of that?

x16 with interpolation is the way to go.

-

Can you try a vase mode print?

-

@Phaedrux Yep! give me 15 min.

-

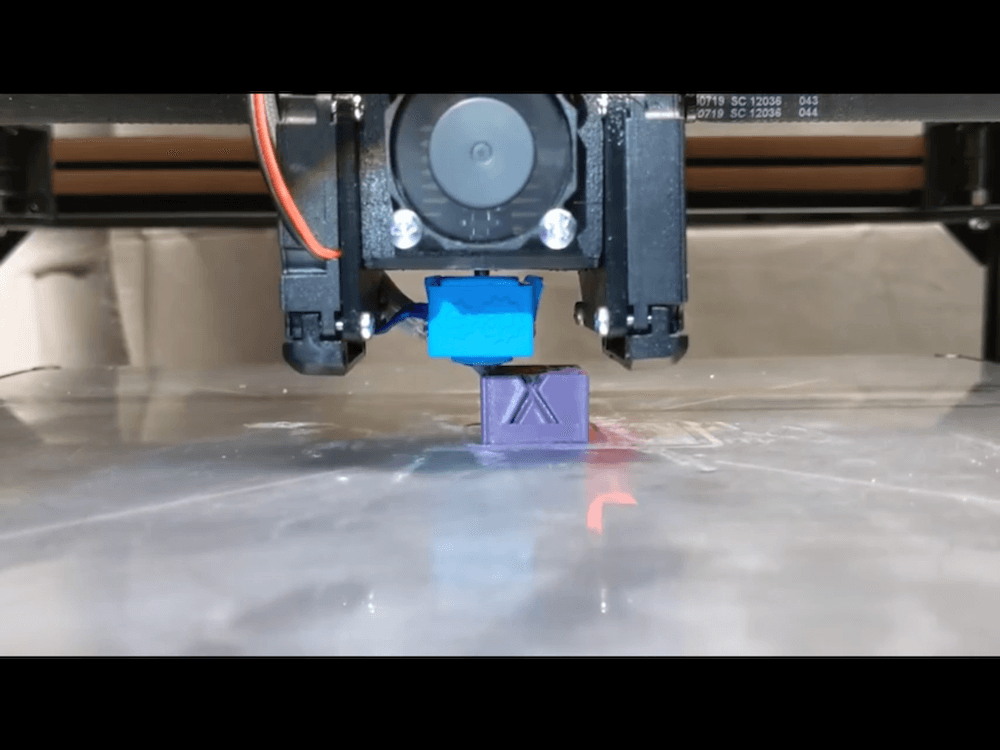

Here's what leads me to believe the part cooling ducting can be improved. This is from his earlier video. Working on new ducts now.

-

@mwolter You are amazing thank you!!!!!!

-

@Phaedrux Not a good look. 75% fan, 200C 30mm/s 90%flow

-

Have you done any prints larger than tiny cubes? The heat from the bed and hot nozzle can have a big effect. Try a scaling that up to a 100x100 cube with 10% infill.

-

@Phaedrux how many walls? Can I still do 20mm high?

-

@Phaedrux Also slow still? or can I speed things back up a bit?

-

I have seen this before on my old and new printers. I believe what I did was calibrate the XY esteps to VERY high precision, like 0.02 mm precise. I did this with digital calipers, directly measuring the movement traveled and averaging it over 5 trials. You say you have a dial indicator, that would be very helpful. Also, improved part cooling helped as well.

I'm pretty sure that fixed the issue, but it was a while ago, and I could be remembering wrong.

-

@SAtech If the esteps are a little bit off, why cant that be compensated for with the extrusion multiplier?

-

@CorvoDewittV2

I'm talking about the X and Y esteps, as yes, extruder esteps can be compensated with exctrusion multiplier.My theory is that very slight deviations in the X and Y axes can stack up, creating slight and varying position offsets. That's just my thinking, so correct me if I'm wrong.

-

@SAtech I'm not sure, I have always heard that messing with xy esteps isn't a good idea, but I don't know for sure.

-

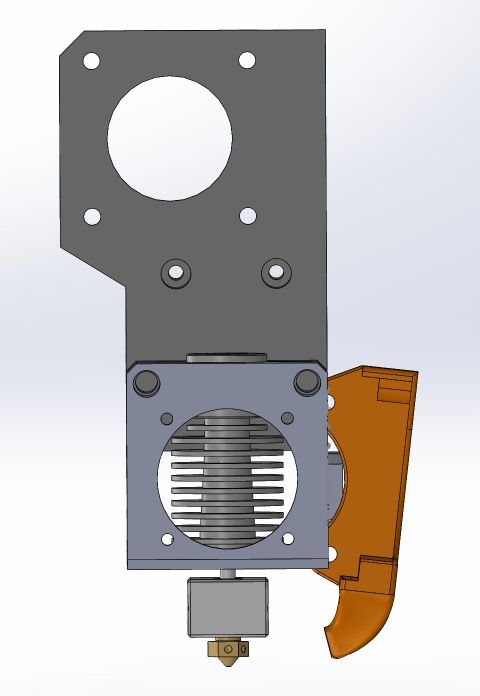

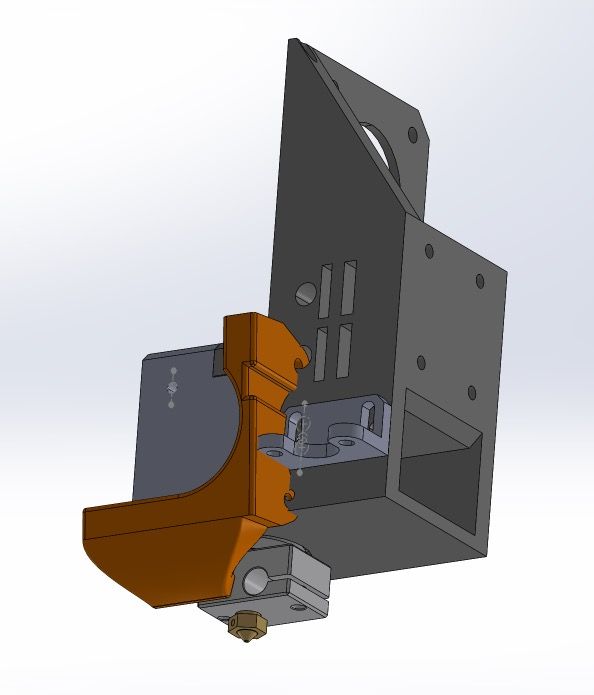

Here's a quick mockup using a duct from a previous project. Obviously the mount will need to be changed to work with your hotend but would something like this work? The fan tilts outward a little, wanted to make sure this won't interfere with the frame or anything else close by.

-

@mwolter yeah that should be perfect! You can mount it however, or just make it part of the front piece. Oh I'm so excited you are awesome!

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@SAtech I'm not sure, I have always heard that messing with xy esteps isn't a good idea, but I don't know for sure.

Yeah it's generally not a good idea, especially for corexy. Use the calculated steps and then see if there is some geometric inaccuracy after everything else is tuned. If the Corexy is properly designed and well built it shouldn't be an issue. I'd be surprised if that was a problem with the ratrig kit.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Phaedrux how many walls? Can I still do 20mm high?

I'd do full height. Something large that's more representative of an actual object you'd print. I'd also try a vase close to the max of your height to see if the extrusion pattern stays the same.

-

Vase mode is a good idea, I should have thought of that....I rarely print vases lol.

Did you try those 3 steps for getting it into the ballpark?

I agree that messing with the XY steps shouldn't be necessary, and really should be avoided IMHO.

My extra parts for my v-core were sitting on the table when I got home. I really need to make a start now, out of excuses.

Yes those fans are too high when you look at them from that angle.

That's a nice looking duct! May I enlist some of your skills when I've got my BMG/Mosquito in place on my v-core?