Issues with print quality, wall surface rough.

-

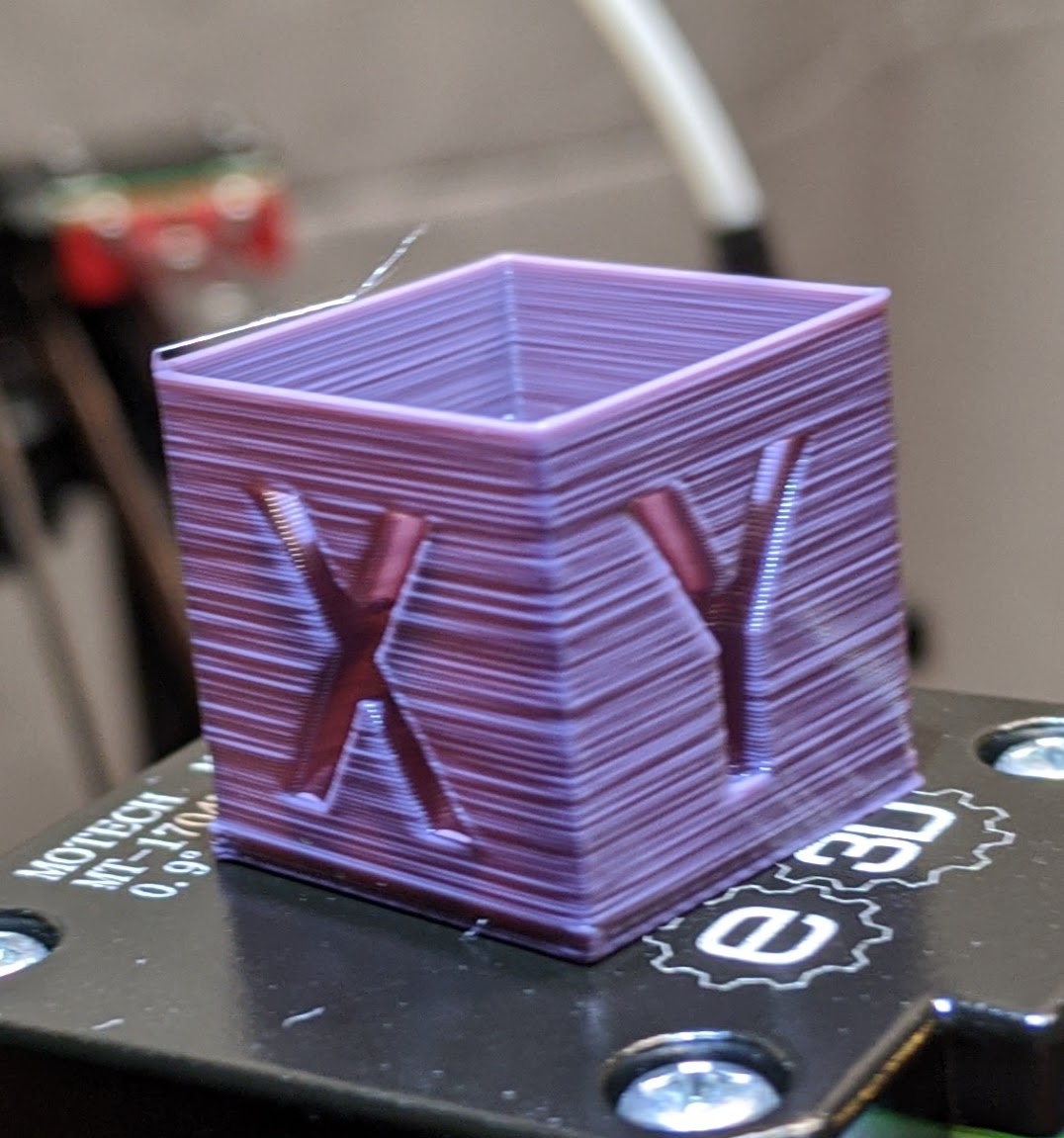

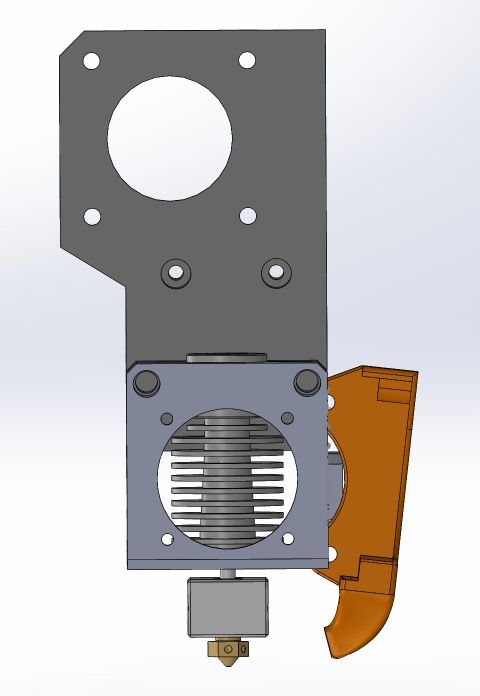

Here's what leads me to believe the part cooling ducting can be improved. This is from his earlier video. Working on new ducts now.

-

@mwolter You are amazing thank you!!!!!!

-

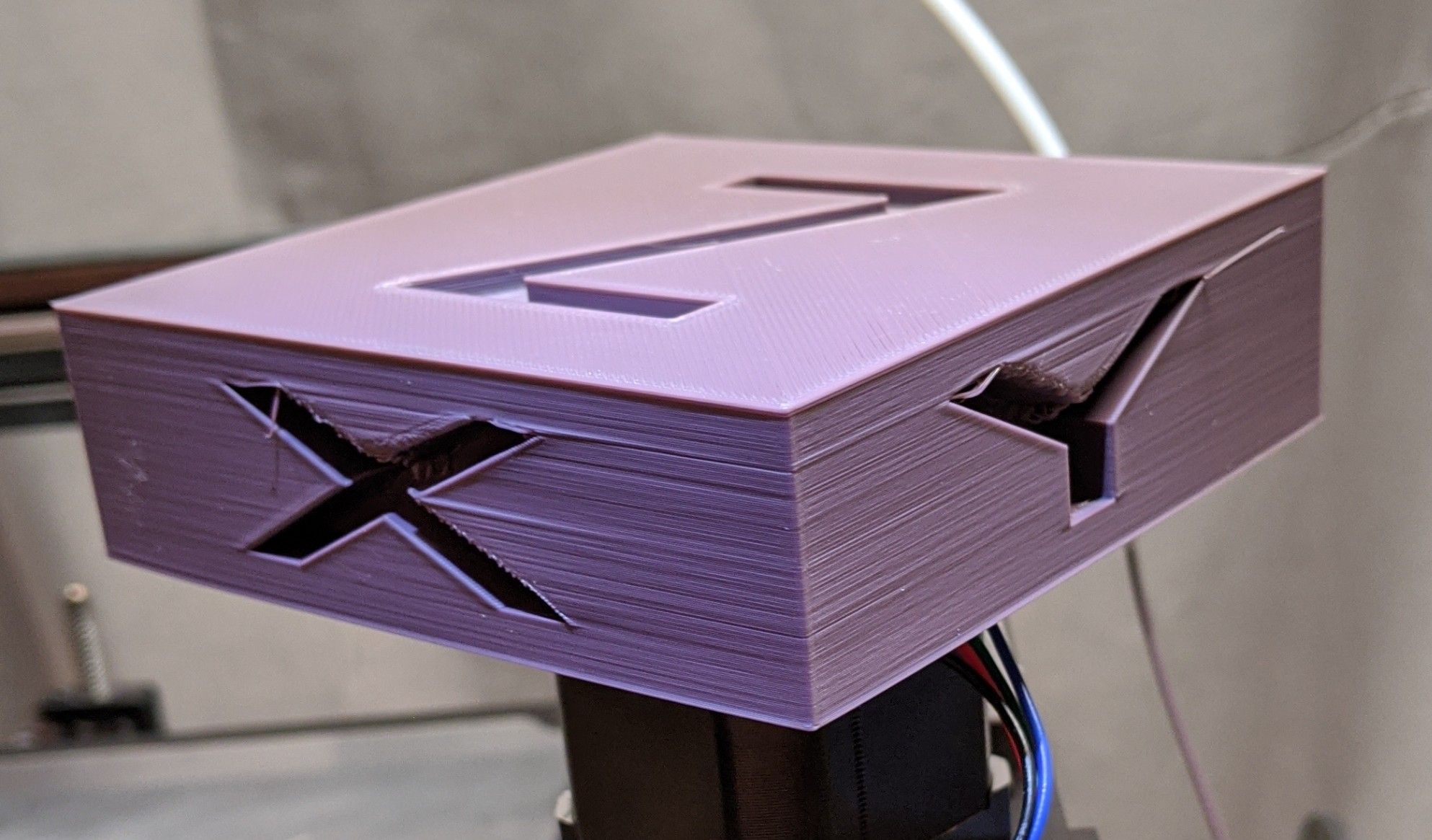

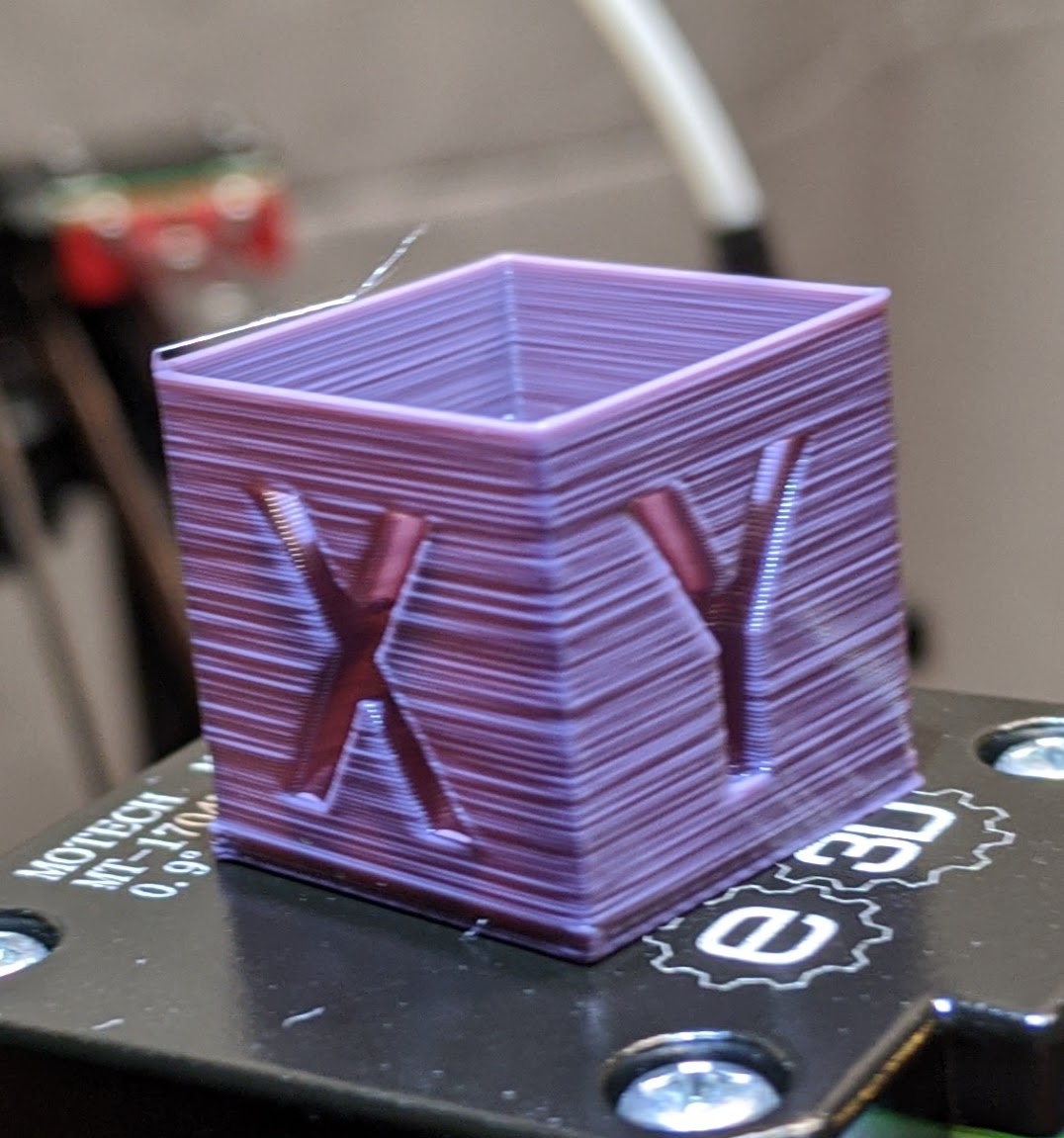

@Phaedrux Not a good look. 75% fan, 200C 30mm/s 90%flow

-

Have you done any prints larger than tiny cubes? The heat from the bed and hot nozzle can have a big effect. Try a scaling that up to a 100x100 cube with 10% infill.

-

@Phaedrux how many walls? Can I still do 20mm high?

-

@Phaedrux Also slow still? or can I speed things back up a bit?

-

I have seen this before on my old and new printers. I believe what I did was calibrate the XY esteps to VERY high precision, like 0.02 mm precise. I did this with digital calipers, directly measuring the movement traveled and averaging it over 5 trials. You say you have a dial indicator, that would be very helpful. Also, improved part cooling helped as well.

I'm pretty sure that fixed the issue, but it was a while ago, and I could be remembering wrong.

-

@SAtech If the esteps are a little bit off, why cant that be compensated for with the extrusion multiplier?

-

@CorvoDewittV2

I'm talking about the X and Y esteps, as yes, extruder esteps can be compensated with exctrusion multiplier.My theory is that very slight deviations in the X and Y axes can stack up, creating slight and varying position offsets. That's just my thinking, so correct me if I'm wrong.

-

@SAtech I'm not sure, I have always heard that messing with xy esteps isn't a good idea, but I don't know for sure.

-

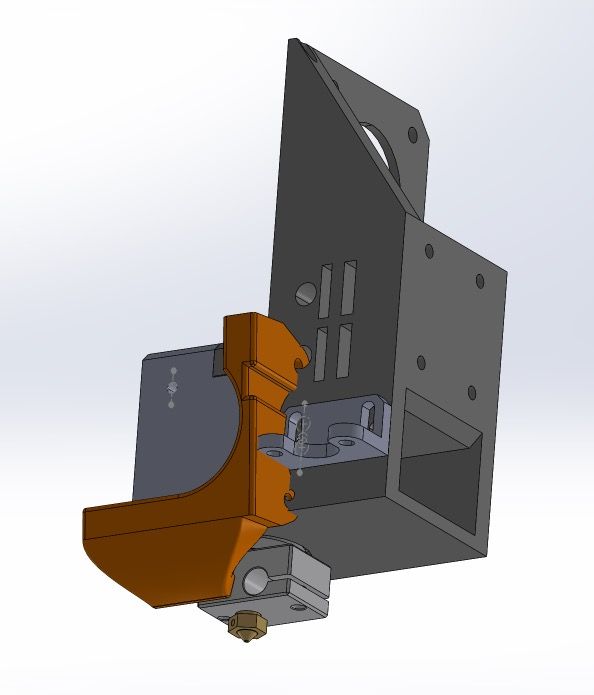

Here's a quick mockup using a duct from a previous project. Obviously the mount will need to be changed to work with your hotend but would something like this work? The fan tilts outward a little, wanted to make sure this won't interfere with the frame or anything else close by.

-

@mwolter yeah that should be perfect! You can mount it however, or just make it part of the front piece. Oh I'm so excited you are awesome!

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@SAtech I'm not sure, I have always heard that messing with xy esteps isn't a good idea, but I don't know for sure.

Yeah it's generally not a good idea, especially for corexy. Use the calculated steps and then see if there is some geometric inaccuracy after everything else is tuned. If the Corexy is properly designed and well built it shouldn't be an issue. I'd be surprised if that was a problem with the ratrig kit.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Phaedrux how many walls? Can I still do 20mm high?

I'd do full height. Something large that's more representative of an actual object you'd print. I'd also try a vase close to the max of your height to see if the extrusion pattern stays the same.

-

Vase mode is a good idea, I should have thought of that....I rarely print vases lol.

Did you try those 3 steps for getting it into the ballpark?

I agree that messing with the XY steps shouldn't be necessary, and really should be avoided IMHO.

My extra parts for my v-core were sitting on the table when I got home. I really need to make a start now, out of excuses.

Yes those fans are too high when you look at them from that angle.

That's a nice looking duct! May I enlist some of your skills when I've got my BMG/Mosquito in place on my v-core?

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Phaedrux Not a good look. 75% fan, 200C 30mm/s 90%flow

Geez that's awful.

It still looks like over extrusion, but combined with a Z binding issue...you can see the regular intervals up the walls that suggest a Z screw wobble.

But it's not just that, there's a slicer/config setting issue of some sort going on there.

Once you've done those 3 steps, you could try just a large tall cylinder in vase mode with zero infill and single wall thickness, something like 100 diameter by the full 300 tall.

That would be worth a look.

-

@CorvoDewittV2

Can you please provide information for the thermistors you are using?

Your config is set up for the generic ones, which is uncommon. -

@DIY-O-Sphere said in Issues with print quality, wall surface rough.:

@CorvoDewittV2

Can you please provide information for the termistors you are using?

Your config is set up for the generic ones, which is uncommon.There we go...

That could very well explain why it looks like it's been printed at way too hot a temperature.

-

@Corexy I have not gotten to those steps, I was still messing with flow just by different cubes.

@DIY-O-Sphere I am using a genuine e3d cartridge style thermistor and the one that comes with the keenovo heater pad.... What do they need to be set to?

-

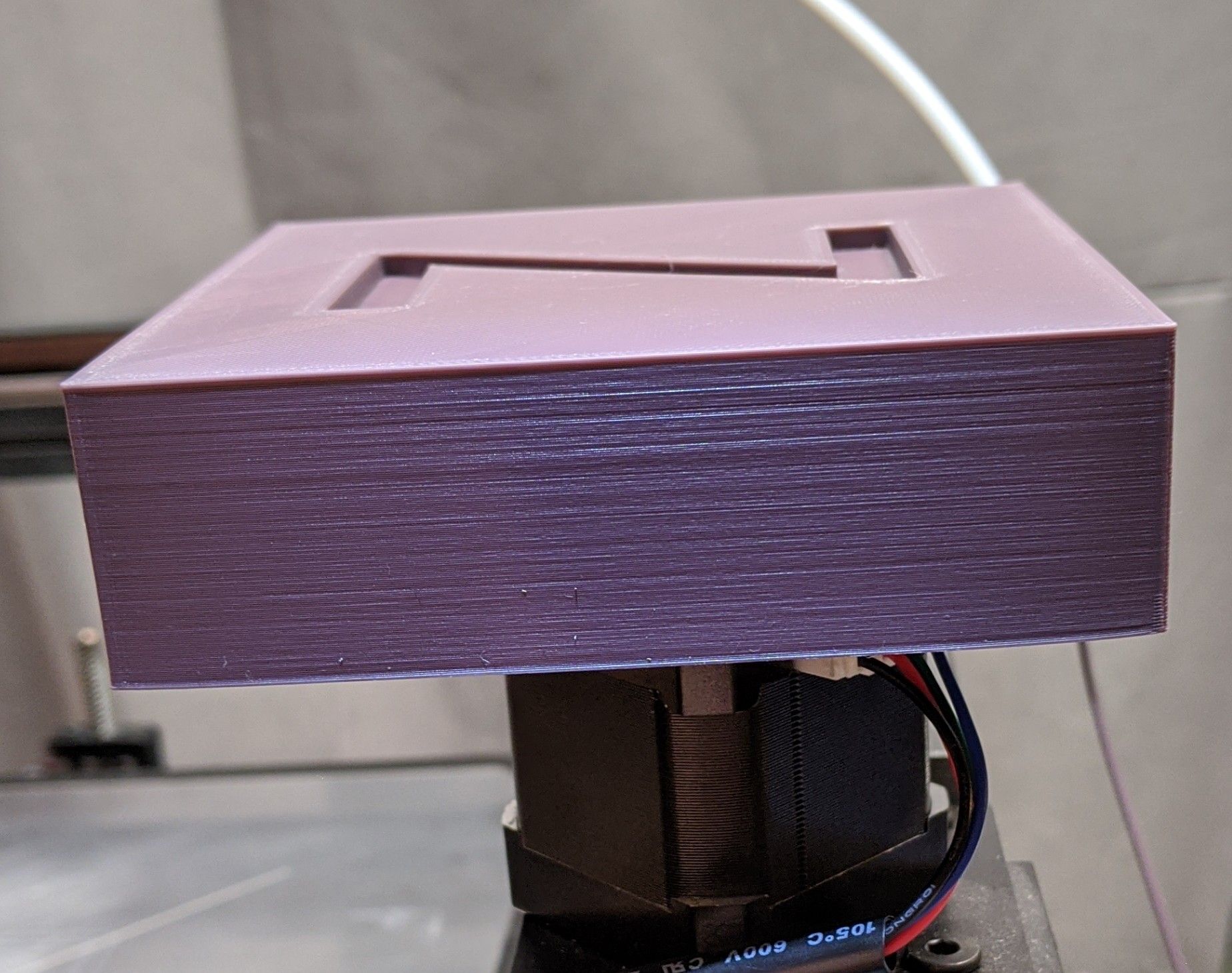

@Phaedrux I had already started the wide cube when you messaged me, I'm going to do a tall vase now:

Please note! The image is not stretched, the cube is 100x100x30