Two stepper motors in parallel

-

Hi!

I want to try using Duet 3 Toolboard 1LC in my new printer.

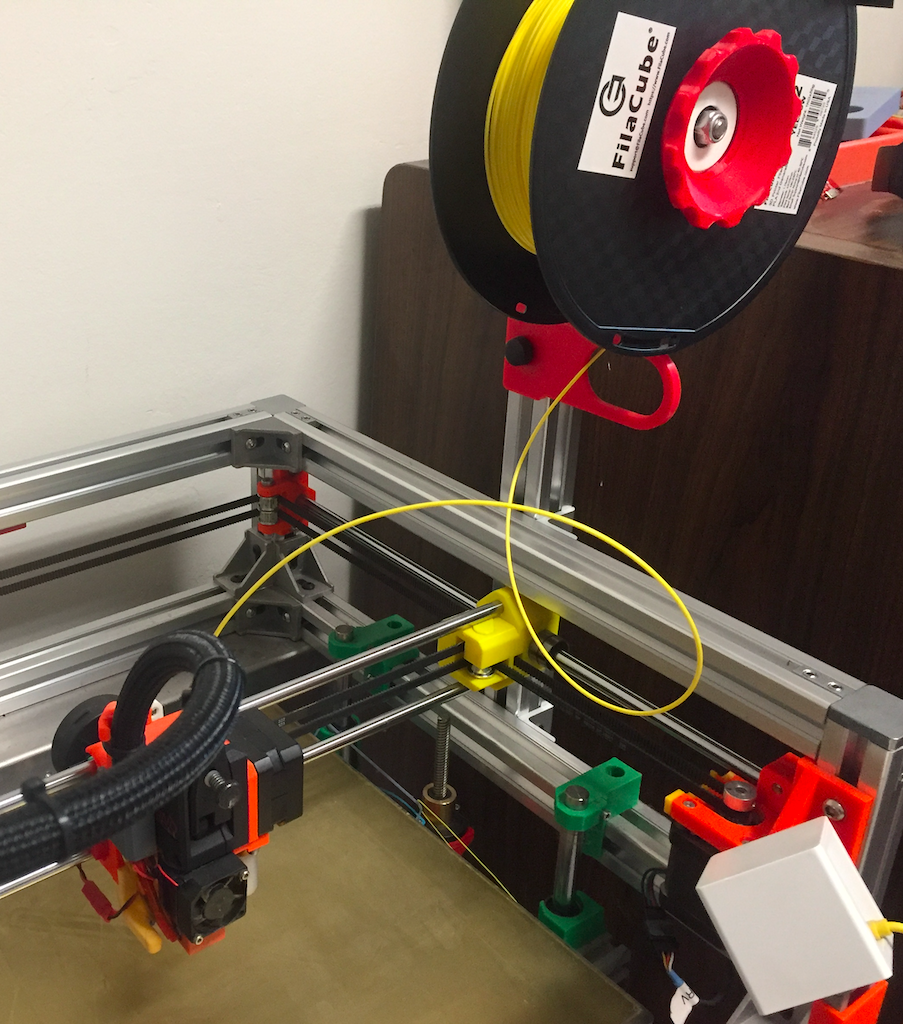

The problem is that I need 2 stepper motors to feed the filament - one on the extruder head and one near the plastic spool. Because the filament is very long and the spool is heavy (10 kg).

How can I connect a second motor in this case so that it rotates simultaneously with the motor on the extruder?

Is it possible?

-

@Dep said in Two stepper motors in parallel:

pper motors to feed the filament - one on the extruder head and one near the plastic spool. Because the filament is very long and the spool is heavy (10 kg).

Just run them in parallel or run them on separate drivers by mapping it in your config.g drive section. Idk that might be an issue in the long run, if there is any difference in the feed rate your gonna grind filament.

-

@Dep I would not do this in your use case, because you will have a nonsynchronized filament transport at some time, the spool motor disturbing the extruder.

10 kg is not so much, I would install an axis with 2 ball bearings (I am sure there are things for this). They will rotate so smooth that you will need a light brake additionally.

-

There have been some examples of a motorized spool feed that can be found online, but they do have issues of going out of sync. Having an bearing axis at the center of mass should make it relatively easy to feed though. Doesn't take much to make a wheel roll, regardless of weight.

This thing can get you a customized bearing hub to fit your spool.

-

Some users have configured a tool with 2 extruders to do this (see the M563 command). My suggestion to one of them was to use a low motor current for the one near the spool, so that it can skip steps if it gets out of sync with the main extruder drive.

-

You can also make a loop, with small switches, which will start/stop a small DC motor on the spool...

-

@dc42 said in Two stepper motors in parallel:

Some users have configured a tool with 2 extruders to do this (see the M563 command). My suggestion to one of them was to use a low motor current for the one near the spool, so that it can skip steps if it gets out of sync with the main extruder drive.

Great idea.

I have a question - I am planning to install Duet 3 Main Board and 2 pieces of Duet 3 Tool Distribution Board + 8 pieces of Duet 3 Toolboard 1LC.

Connection:

Duet 3 Main Board - 4 motors Z, X, Y.

I connect 4 extruders to the Tool Distribution BoardThe second Tool Distribution Board is installed near the spools of plastic and set parallel to the first board with M563 command.

Will this work?

-

@Dep said in Two stepper motors in parallel:

I have a question - I am planning to install Duet 3 Main Board and 2 pieces of Duet 3 Tool Distribution Board + 8 pieces of Duet 3 Toolboard 1LC.

Connection:

Duet 3 Main Board - 4 motors Z, X, Y.

I connect 4 extruders to the Tool Distribution Board

The second Tool Distribution Board is installed near the spools of plastic and set parallel to the first board with M563 command.

Will this work?Yes, I don't see any problems with that setup.

-

@dc42 Can you tell me if I can connect a magnetic filament monitor to one Toolboard 1LC board but control the motor on another board?

The configuration is as I wrote above: for each extruder there are two Toolboard 1LC boards (a motor at the plastic inlet and a motor at the extruder) and one filament monitor. But I would like to put the filament monitor on the plastic input and connect there. But I would like to control the flow of plastic on the extruder motor.

Will this work?

-

A filament monitor does not control a motor, it monitors filament motion and compares it with the commanded motor movement. If you configure a tool to use two extruders, each one can have its own filament monitor if you wish, or you can use a filament monitor on just one of them.

-

@dc42 Thank you very much for your reply!

-

@Phaedrux said in Two stepper motors in parallel:

Having an bearing axis at the center of mass should make it relatively easy to feed though. Doesn't take much to make a wheel roll, regardless of weight.

That's the approach I took for my 1Kg spools after considering motorized options and it works very well. It rotates so easily that the filament 'springiness' keeps one or two loops in the air and the spool even rotates backwards when the printing head moves toward it.

It's important to have the bearings at the center. Other configurations where the spool 'sits' on bearing don't rotate as easily for some reasons which I didn't expect.

For motorized solution you probably want to have a tension sensor of some kind because it's difficult to get perfect sync between the two motors and relying on slip will actually increase the required pulling force by the main extruder.

My 2c. I am not a mechanical engineer.

-

@zapta this configuration does not suit for me, since tube length over 2,5 meters. And there is a need to pull the filament completely out of it.

-

There is one more question: after assigning two motors to 1 extruder, I found that only one motor is rotating. The second works only if i send the command:

M567 P0 E1:1; mixingIt seems to me somehow wrong. I see that the M563 command has the L parameter:

Lnnn Drive to use for filament mapping parameter. By default RRF will use the first and only extruder drive if this parameter is not specified (supported by RRF> = 2.02)Perhaps this is what I need, but I cannot find information on how to use it.

Can you clarify this question?

-

@dc42 can you tell me about the last question? I cannot find information on this parameter.

-

In the description of the command "M563: Define or remove a tool" I see the parameter:

- Lnnn Drive to use for filament mapping. By default RRF will use the first and only extruder drive if this parameter is not specified (supported by RRF> = 2.02)

I thought this is just for the case when two motors are installed on 1 extruder. I have not found information on this parameter anywhere.

-

@dc42 Yes, but the question was:

can i connect a magnetic filament monitor to one Toolboard 1LC board but control the motor on another board?

And now I tried to connect the monitor to another board. I receive the following message:

M591 P3 C "31.io1.in" D0 S0 Error: M591: Filament monitor port must be on same board as extruder driverI need to control the motor "31" since motor "21" it is used only for loading and unloading the filament, the current on it is minimal and it skips a little steps because it is impossible to precisely syncronize. But the monitor is connected to the "21" board (because the other board is far away, it is inconvenient to pull the wires there).

Still, is it possible to connect a monitor to one board and control the motor on another board?

-

@Dep said in Two stepper motors in parallel:

Still, is it possible to connect a monitor to one board and control the motor on another board?

No, that isn't supported. The reason is that when data is received from the filament monitor, the firmware needs to fetch the step position of the extruder motor immediately, in order to compare commanded vs. measured movement.

-

@dc42 Ok thanks David!

-

@dc42 I want to use 2 Nema 23 high torque motors for the y-axis with Duet 3MB 6HC and 32v power supply. Will the series connection of such motors work with the default drivers of Duet 3? If not, how can I fix 2 motors for y-axis? Do I need any additional board for another motor of y-axis?