RRF 2.03 pressure advance causes 20% overextrusion

-

Duet Web Control 2.0.4

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5

WiFi firmware version 1.23 -

Got it. Had to find iap4e.bin from a really old firmware release. Had to find out about this by googling a forum post. I'm sorry, but what the heck? Why not document this in the release notes, or just put the file in the release bundle? Jeez, that's really bad.

-

@jschall said in RRF 2.03 pressure advance causes 20% overextrusion:

Got it. Had to find iap4e.bin from a really old firmware release. Had to find out about this by googling a forum post. I'm sorry, but what the heck? Why not document this in the release notes, or just put the file in the release bundle? Jeez, that's really bad.

It is in the release bundle. iap4e.bin is included in the .zip file updates for RRF 2.05.1, 2.05, 2.04, and some earlier releases.

-

@dc42 said in RRF 2.03 pressure advance causes 20% overextrusion:

It is in the release bundle. iap4e.bin is included in the .zip file updates for RRF 2.05.1, 2.05, 2.04, and some earlier releases.

It is not in Duet2and3Firmware-3.0.zip

-

@Phaedrux said in RRF 2.03 pressure advance causes 20% overextrusion:

Update to 2.05.1 to get on recent code.

Post your config.g.

I did suggest you update to 2.05.1 first.

The issue of missing IAP files does come up and should be better addressed in the documentation. I'll see what I can do about that.

-

Currently running the test on RRF3.1.1. It is with x16 microstepping+interpolation, but I'll do a new control test with no PA as well.

-

Where the heck in the code are the reverse pins written?

Also my logic analyzer keeps failing.

-

Found it.

-

Got the logic analyzer to work... It is very picky about USB ports.

fwd_count 10734771

rev_count 8650049

net_count 2084722

mm 2638.8886083 changes on this one:

- RRF 3.1.1, prior tests were at 2.03

- x16 microstepping, prior tests were at x8

- 100% speed, prior tests were at 200% speed

- Unplugged the extruder stepper and plugged in an identical stepper so I wouldn't have to listen to the gears make noise.

File is supposed to be 2545.00 mm + 15mm of priming, so this print was within 3% - pretty decent, but there's still a bug.

I am reverting the speed change and testing, and then I'll revert the microstepping change if it doesn't go back up to nasty overextrusion.

-

Just a thought, for a next generation path following algorithm, what I would do is:

- Segment the toolpath into linestrings in which the angles between the lines are less than some threshold (such as 30 degrees)

- Smooth those segments, using maybe a series of cubic splines (long lines may need to be split up into shorter lines first).

- Compute the speed curve along the segment such that tangential and radial acceleration is limited and such that the extruder can keep up with pressure advance. Each segment starts at zero speed and pressure and ends at zero speed and pressure.

"Jerk" (bad choice of term) becomes unnecessary. Corners below the angle threshold are rounded smoothly, without ringing or asymmetry. The printer will come to a brief stop at sharp corners above the angle threshold, thus making them as sharp as possible.

A lot of this could be done (and may have to be done) in a preprocessing step.

-

RRF 3.1.1, 200% speed, x16 microstepping, 1.0 PA:

fwd_count 12180087

rev_count 10084959

net_count 2095128

mm 2652.060759 -

Starting test: RRF 3.1.1, 200% speed, x8 microstepping, 1.0 PA

This one should be apples-to-apples to the tests on RRF 2.03.

-

RRF 3.1.1, 200% speed, x8 microstepping, 1.0 PA

fwd_count 6073637

rev_count 5024835

net_count 1048802

mm 2655.194937So this is not terribly huge overextrusion, I could try printing with this. There's still a bug.

-

@jschall said in RRF 2.03 pressure advance causes 20% overextrusion:

Just a thought, for a next generation path following algorithm, what I would do is:

- Segment the toolpath into linestrings in which the angles between the lines are less than some threshold (such as 30 degrees)

- Smooth those segments, using maybe a series of cubic splines (long lines may need to be split up into shorter lines first).

- Compute the speed curve along the segment such that tangential and radial acceleration is limited and such that the extruder can keep up with pressure advance. Each segment starts at zero speed and pressure and ends at zero speed and pressure.

"Jerk" (bad choice of term) becomes unnecessary. Corners below the angle threshold are rounded smoothly, without ringing or asymmetry. The printer will come to a brief stop at sharp corners above the angle threshold, thus making them as sharp as possible.

That's similar to what I have planned. A disadvantage is that the existing effect whereby the perimeters of holes are always under-sized would be made a little worse.

-

@jschall said in RRF 2.03 pressure advance causes 20% overextrusion:

The printer will come to a brief stop at sharp corners above the angle threshold, thus making them as sharp as possible

it will be interesting to see if PA can compensate for the large blob seen when stopping briefly at corners. Currently sharp corners are slightly rounded because the printer does not come to a complete stop - but they are smooth, where as when the print hed has to be raised (e.g. to the next z level, there is a visible Z "seam".

Maybe this is better off combined with jerk for angles > than the smoothing process works on.

-

@dc42 said in RRF 2.03 pressure advance causes 20% overextrusion:

That's similar to what I have planned. A disadvantage is that the existing effect whereby the perimeters of holes are always under-sized would be made a little worse.

Holes are undersized because of the low resolution meshes. I generally export my STLs with higher resolution.

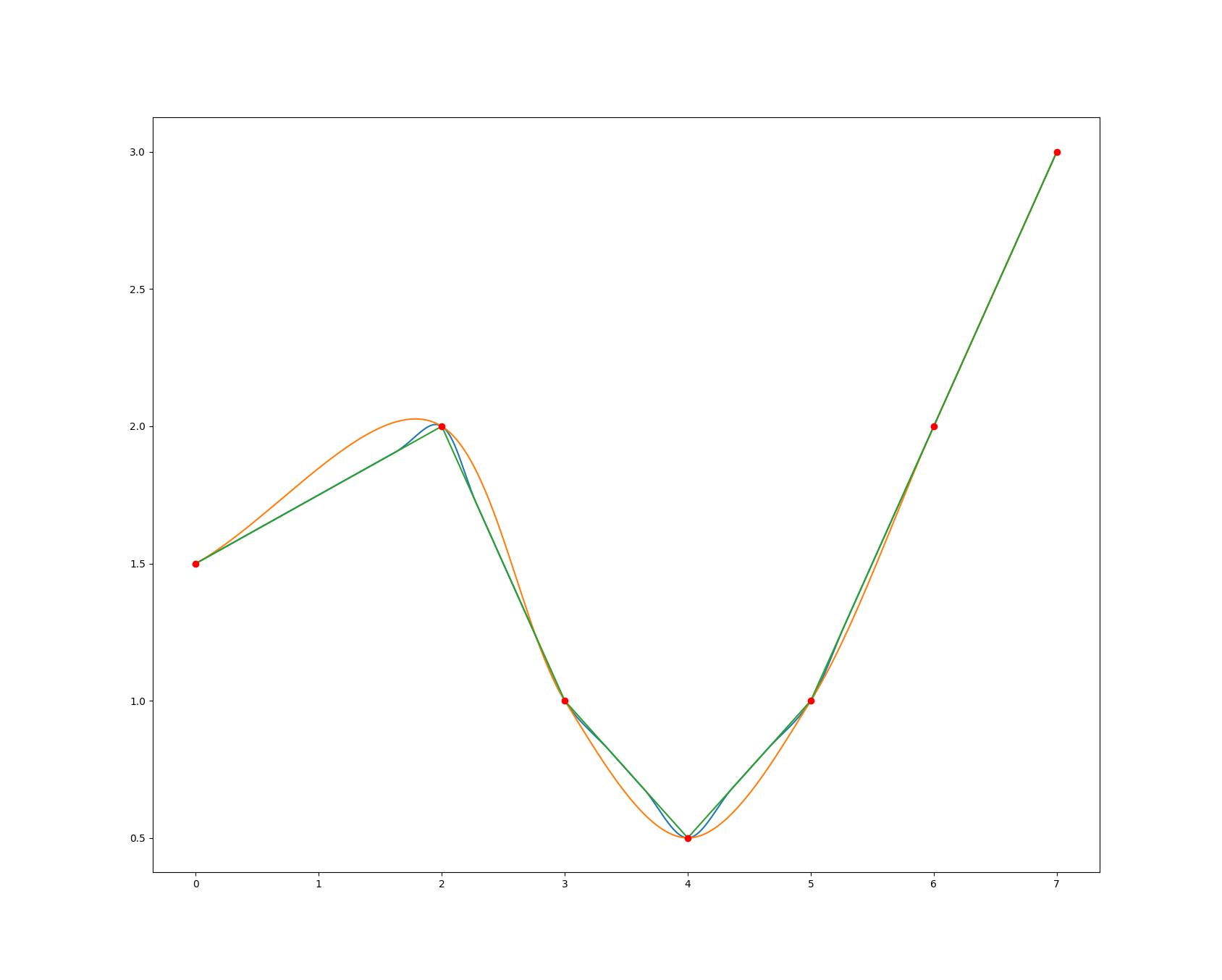

I did this real quick, based on wikipedia's python example of catmull-rom splines. The yellow line is the spline drawn through only the provided points, and the blue line is the spline when additional control points are added to limit the length of curved sections. It shouldn't cause holes to undersize - if anything it will make them better.

-

@T3P3Tony said in RRF 2.03 pressure advance causes 20% overextrusion:

Maybe this is better off combined with jerk for angles > than the smoothing process works on.

Here's the thing though - just increase acceleration. That's effectively what jerk is doing anyway.

-

Hard enough to get PrusaSlicer to generate gcode without 20% more extrusion than the volume of the STL in the first place

-

@jschall You have to be careful with just increasing the acceleration. Because of decreasing torque with increasing speed, high acceleration combined with high speed can cause lost steps. You can tolerate much more acceleration at low speed (where jerk comes into play) than at high speed.

I have a low-accel setting for my printer (1200 mm/s^2) that allows travel up to 150 mm/s. I had to make my high-accel (1800 mm/s^2) macro drop the travel speed to 120 mm/s to not lose steps.

I actually would like, someday, in RRF a variable-acceleration mode which drops the acceleration as the speed approaches a specified target, to keep the system inside the torque-speed envelope. It isn't a difficult calculation, and might allow somewhat faster overall printing.

-

@mendenmh yes, could just model that and limit acceleration to stay within torque limits.