Replacement bed

-

I am interested in replacing my 3mm stock Creality metal bed. I find their thin beds to be very warpy, I can get them flat with the BL touch, but its a constant adjustment every day.

My Creality CR10s has a moving Y axis bed. Changing to a 4mm+ bed would mean more mass to move. Now, I have already upgraded the motor operating the motion of that bed to a 2A, 59Ncm stepper, which I assume as more torque and can handle the additional and additional 1 or 2mm of mass to move.

Are their finished aftermarket beds available on the market with a heater already attached to it? If so, please help me out with a link.

If not, then it is about sourcing a heater and pad, along with a machined plate. The heater and pad are straight forward. But where is the easiest place to get the plate machined accurately?

Thanks

Ryan -

There’s this on AliExpress which may or may not be flat enough to meet your needs:

https://a.aliexpress.com/_mtlWH1ZIf not, you might find a local machine shop who could surface it for you, although I’m not sure how much meat there is left above the magnets.

Otherwise, you can also order tooling plate aluminum cut to size form Midwest Metals if you’re in the US. https://www.midweststeelsupply.com/store/castaluminumplateatp5 Then it’s just a matter of putting some holes in the right spot and slapping a heater on there. Most recommend Keenovo for that, you can order in 24V or mains AC.

Good luck!

-

Additional vote for Silicone encapsulated heater pads, with pressure sensitive adhesive.

Plus MIC6 aluminium plate (should come already more than flat enough).From McMaster, 12x12x1/4" is $53.20 with a flatness tolerance of 0.015".

You could then get it ground or milled as flat as you are willing to pay for, but I've never had an issue with the tolerance off-the-shelf.Its the same thing as the ATP5 from Midwest, who are quite a bit cheaper.

If you look around locally for ATP5 or MIC6, you should be able to find it anywhere, its ground that flat by the aluminium mill so it available globally.

-

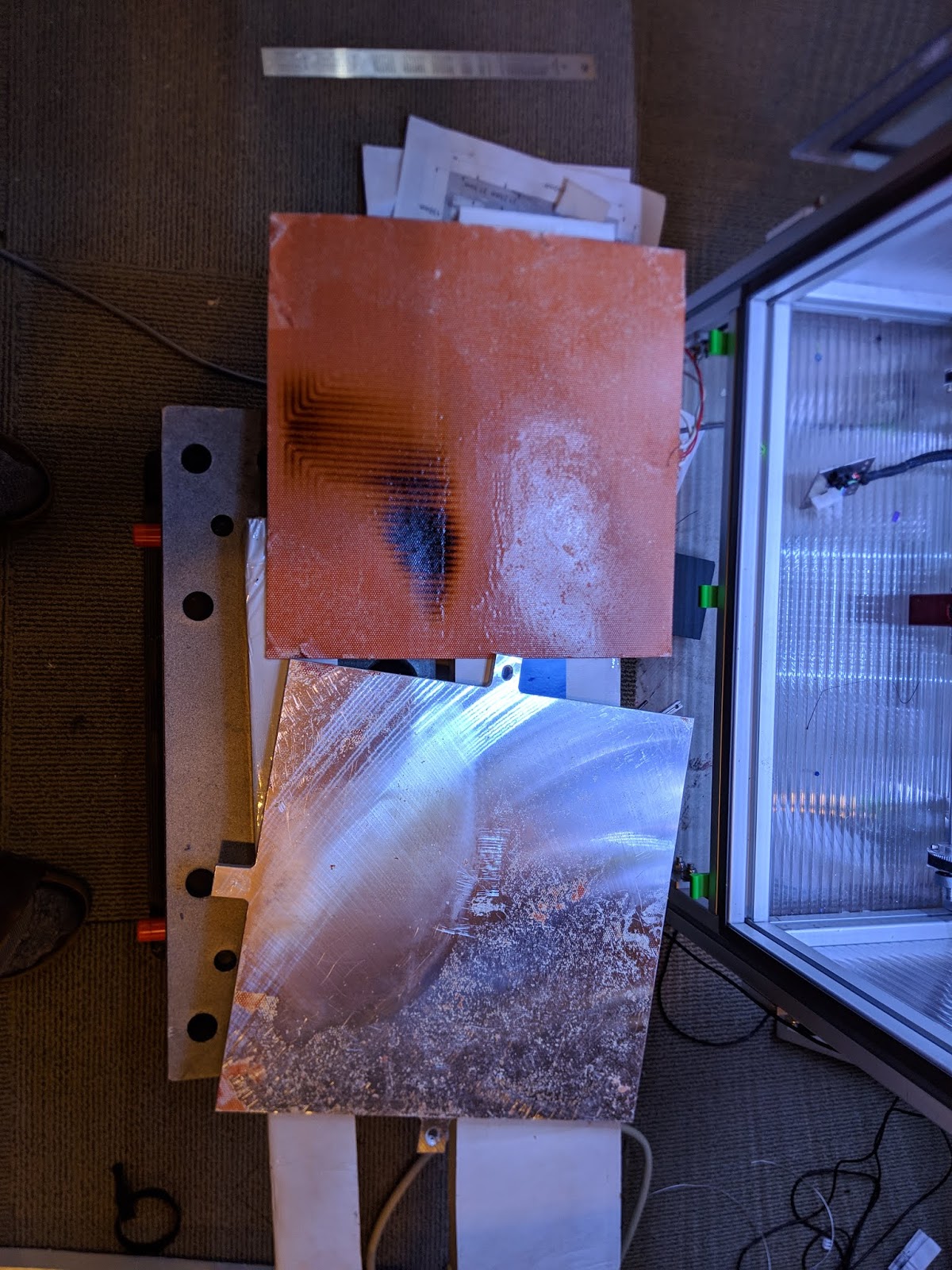

Buy the heater without adhesive, and glue it to the plate using high temperature silicone. The pressure sensitive adhesive will let go after about 2 years of use, and scorch the heater wherever it starts letting go of the plate.

-

That looks a lot more serious than the adhesive failing...

Plus silicone doesn't stick very well to alumimum.

No matter what, people should always have a mechanical attachment given the normal orientation.

High temp foam under the heater to keep it pressed up and in contact.Hundreds of machines, at least, with silicone heaters with PSA, never had a heater or its adhesive fail. But they were all mounted on top of a high temp foam. Which also greatly decreases heat loss.

-

if you tell us where you are located maybe people that live in the same country can give you some advice.

you could also give https://de.aliexpress.com/item/33041249544.html a try. if its not flat you get to keep the pei sheet for the other bed.

if you live in europe there is a shop that sells a fine milled aluminium plate with pei applied

https://clever3d.de/epages/7a4290fc-7c7f-46cc-9b99-eadef22228e2.sf/en_US/?ObjectPath=/Shops/7a4290fc-7c7f-46cc-9b99-eadef22228e2/Products/c3d-DDP-PEI-natur -

@Veti Sorry guys. Ive solved my bed issue. It had to do with fan induction as my BL Touch is sitting in front of it and screwing with its readings.

-

@RyanP Interesting. I wonder how prevalent that is with the BLtouch issues people have. Something to look out for.

-

Well, I certainly have a love hate relationship with my BL Touches. Basically, as much as I HATE it, the dive speed for probing has to be SLOOOOOW. If I use any more than than F60 in my M558 command, I get weird results. So I have it set to F60, but my even agonize going down to F30 to see what the bed compensation results will be.

That all being said, a warped bed is a warped bed. The less you have to compensate the better.

-

@RyanP You can do a double probing to speed up the first probe and then slow down for accuracy.

M558 F600 A1 ; probe onec fast

G30

M558 F60 A10 ; probe for accuracy

G30 -

You always teach me something.