Hey all,

Yesterday I decided to take, oh I don't know 5 hours, and tune my Ender 5. This printer has a Duet Maestro, Bondtech BMG bowden setup, microswiss hot end and 0.4mm nozzle. All primary inital calibrations have been completed.

My bowden tube for this setup is 510mm, so slightly on the long side. I had been using a PA of S0.14 for the past while with decent results, but not perfect. Certain aspects of prints were beautiful while others were not.

I started using a script I found here:

PA script

And I ran this with from S0.0 to S1.0. Thought the results were inconsistent, and the only thing I took away was the S0.0 to S0.2 were meh, S0.5 and S1.0 seem to give the best results. So as you can see, inconsistent.

Then I moved over to another test I really like prior:

Bowden Only

As I was browsing the many, many threads on PA, I stumbled along a two year old post from @Phaedrux stating a possible connections between PA and Jerk. But I think acceleration is tied into a trio with PA and Jerk. Here are my findings.

So what I did was started printing https://www.thingiverse.com/thing:4175047

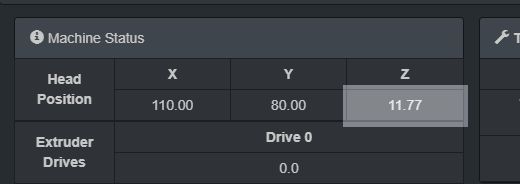

PA set to S0.5, print accel M204 P1000, and jerk set to M566 X1200 Y1200. Also E Jerk and accel are set high enough as to not affect movement.

Results were ok. But I wanted to see what would happen when I adjusted each of the above setting individually to see how they would react to the print. I started by leaving PA alone, set at S0.5 and focusing on accel and jerk.

Tuning jerk lower to something like 10 M566 X600 Y600 I found caused problems with the connection of infill lines to wall lines. Then I set it to 40 M566 X2400 Y2400 and this was two violent for small movements. So I set it back to 10.

Then I decreased my print accel to M204 P500 and infill extrusion improved but caused problems at the start of new lines. Basically under extrustions.

So then I started treating Accel and Jerk like knobs I could turn up and down. And my best results were with a lower acceleration and high jerk.

Now your acceleration cant be too low or your prints will take forever because your print head takes too long to get up to speed. But it does need to be lower to allow small aspects of your print to slow down. I now have jerk set to 30. With jerk set to 40, the printing movements of long lines were fine, but short infill lines were way too violent. Turning it down below my initial setting of 20 caused it to slow at line endings too much. So I set it 30 M566 X1800 Y1800 and there were no issues with directional changes and blobs, as well as not being too violent.

So my final settings are

M572 D0 S0.5

M204 P500

M566 X1800 Y1800

With accel tuned lower, it slows down short portions of your print so that they don't get herky jerky by your higher jerk. And PA keeps things in check by doing a decent job of keeping a consistent pressure in the nozzle.

Truth be told, I don't know how correct any of my methodology is, so I would love to hear from everyone what their thoughts are. I will be trying this same tuning method on my CR10 today, and later my Ender 5 Plus.