Printing different than GCode

-

For some reason the resulting print is different than the GCode.

Printer:

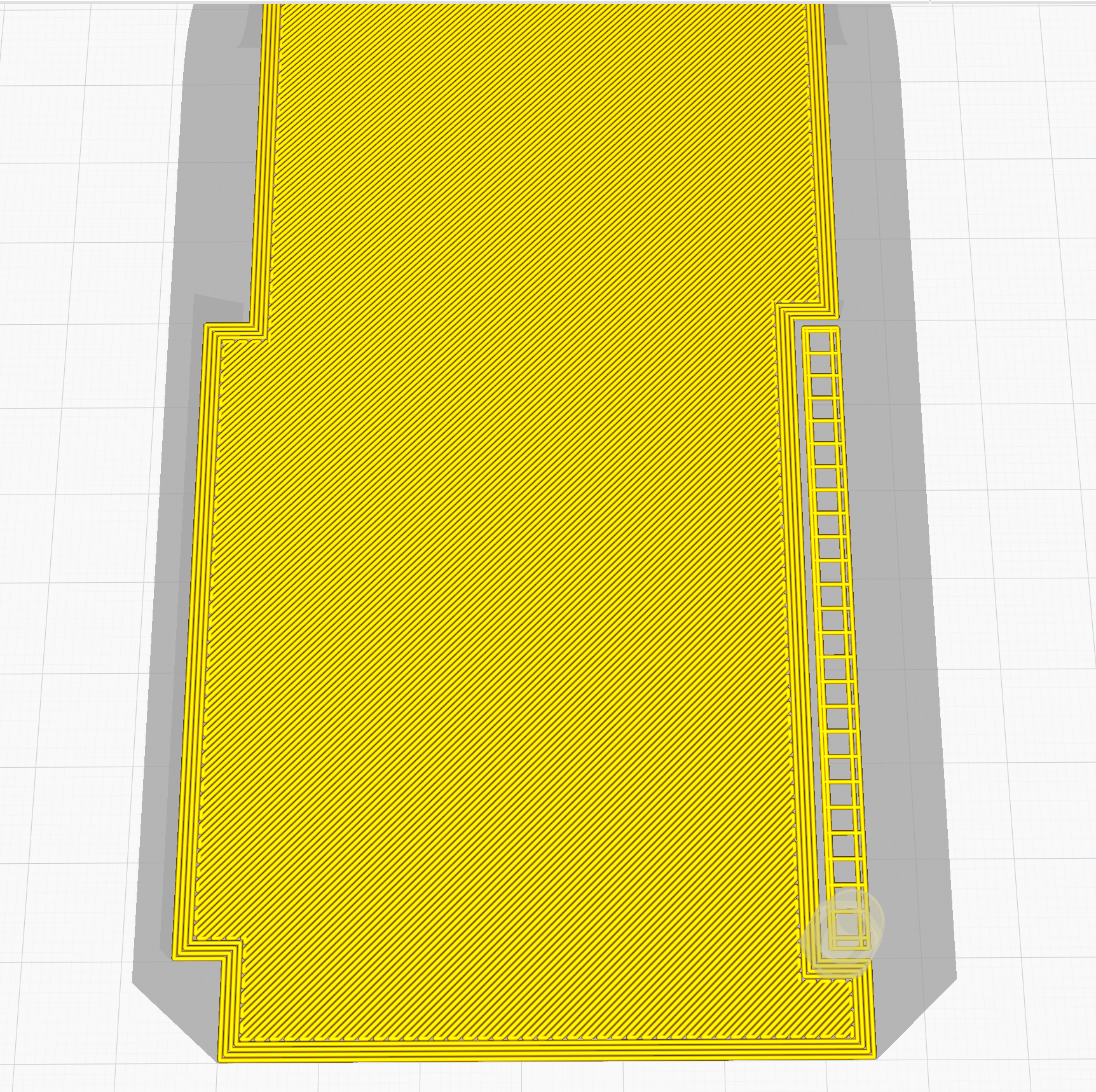

BLV Cube with Duet2 Wifi and firmware 3.1.1I designed the file in Fusion360, exported the stl and sliced it in Cura 4.7.1 . One of the attached pictures is the path from Cura. The path for the bottom layers looks very linear.

I analyzed the GCode with an online viewer and it also shows that the path for the bottom layers are very linear. This is the second attached picture.

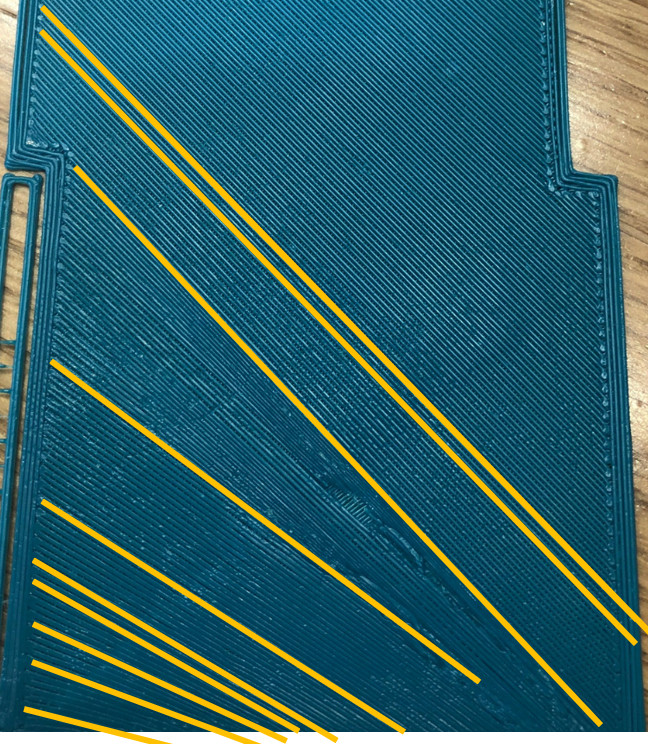

And finally the reality: most of the bottom layers are linear, however once it reaches the very bottom it starts to fan out and fill in the rest. This means that it repeatedly goes over the same start point creating a lump. I paused the print, shaved down the lump and allowed it to do the second layer. Once it reached the end it did the same thing. I re-sliced, tried it again and it continues to happen.

I'm not sure where the problem lies, but since Cura is showing the same thing as the online analyzer, I'm thinking it may be with Duet? I thought these devices just follow GCode and don't do any "thinking" of their own?

-

@Saentis said in Printing different than GCode:

I thought these devices just follow GCode and don't do any "thinking" of their own?

they do, but its an open loop system, i.e. there is no feedback to adjust for unforseen things like added friction or collision with lumps - it relies on the machine being rigid and powerful enough to reach the commanded position under all circumstances.

so if your nozzle is hitting something then adjust your extrusion multiplier or e-steps to avoid that.

however the slanted lines has be thinking one of your belts or pulleys might be slipping?

-

@Saentis Is the bottom (bottom of the picture specifically) close to the edge of the print area? Or, better said, an extreme edge (max X, Y, etc)?

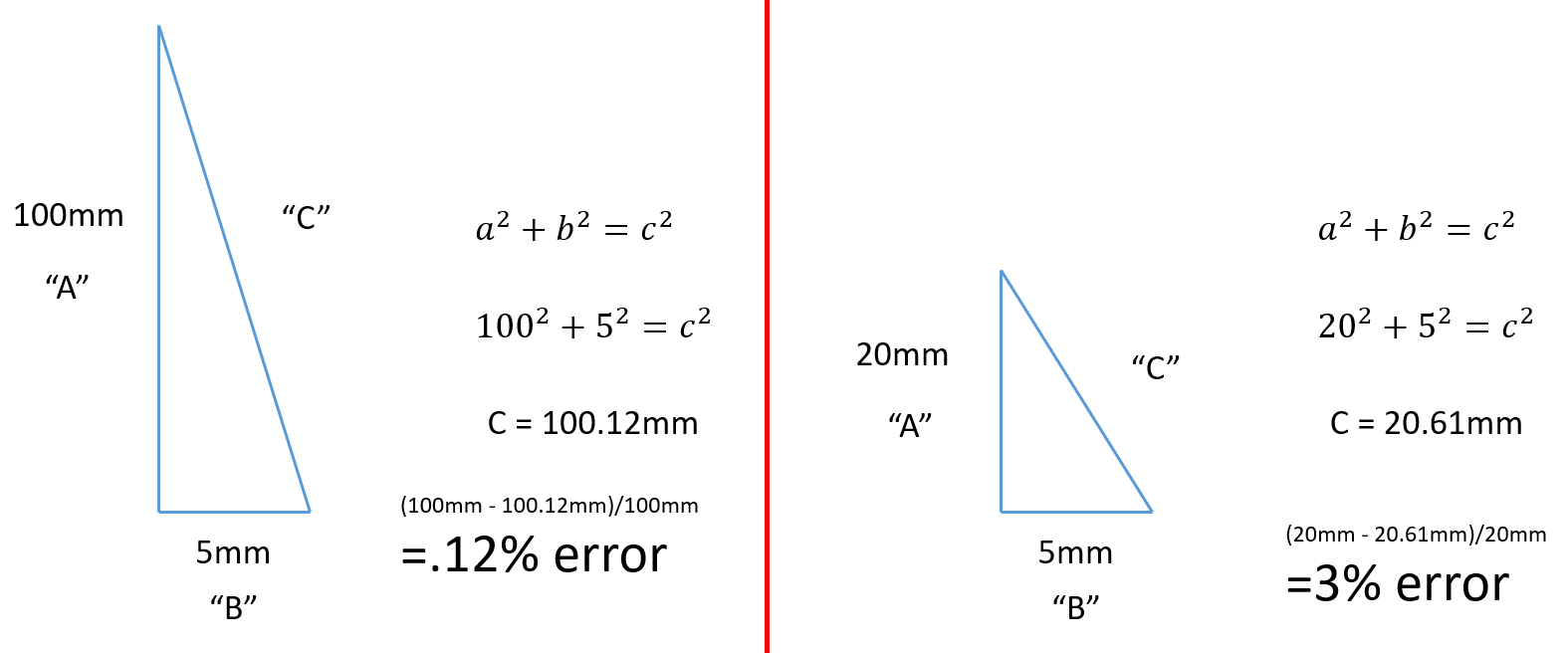

I could guess bed leveling could be an issue, but if the problem area gets worse as it approaches the min/max of the X or Y axis... could it be your belt path - in that the certain belt lengths are not parallel to the associated axis?

Disclosure: I am no CoreXY expert - so thinking out loud here.

The angles between the fill lines remain consistent in the top 2/3rds or so of the print image, and then slowly start to drift. I could totally see that happening IF the bottom of the image approaches the print surface limits, as the error associated with non-parallel belt-axis paths gets worse closer to the idler/pulley. If you think about a right triangle, where the belt is the hypotenuse, and the axis of travel is the vertical leg, the further you get away from the idler/pulley (thus a longer vertical leg), the length of the hypotenuse (the belt) approaches the length of the leg. The closer you get to the idler/pulleys (thus the shorter the vertical leg of the triangle), the belt length diverges from the vertical leg of the triangle - more error.

-

I think you both might be on to something. The error area is at one of the extreme ends. I'll try turning the print by 90º (or maybe 45º) to see if that fixes it.

A little embarrassed actually - comparing what was printed to Cura, it appears that around 1cm is cut off from the bottom. Time get the bounds of the print surface dialled in.

-

@Saentis said in Printing different than GCode:

I think you both might be on to something. The error area is at one of the extreme ends. I'll try turning the print by 90º (or maybe 45º) to see if that fixes it.

Another thing to check is if that area commanded by the GCODE is actually reachable... I've done that by mistake where the GCODE said, say, "go to X500" but the firmware was maxed at , say, X475. I think it discounted those commanded moves, but I cannot recall what specifically happens.

-

@sebkritikel said in Printing different than GCode:

but I cannot recall what specifically happens.

You'll get what you see in the print photo where it just prints over itself at the boundary edge.

-

@Phaedrux said in Printing different than GCode:

@sebkritikel said in Printing different than GCode:

but I cannot recall what specifically happens.

You'll get what you see in the print photo where it just prints over itself at the boundary edge.

Gotcha, thanks. Figured that was what would happen. Not so sure it specifically causes this number:

-

Can you post your config.g, homing files, the results of M122, and M98 P"config.g"? That will give us a lot more useful information to go by. You could also export your cura project as a .3mf and post it as well.