Extrusion Calibration?

-

Thanks...

Let me repeat it: The roughness comes from over extrusion because the gab between the nozzle and the bed is to narrow.

I will re level the bed and will print tiny batches of first layers. Lets see how they look than.

Cheers, Chriss

-

bedlevel_nozzle_0.4_200x200-0.3-0.8.stl

Here's a good quick bed level test print to verify mesh compensation is working well. Print once with it disabled and once with it enabled.

-

Yes, I will. I will make sure that the mechanical part will do it's job too.

-

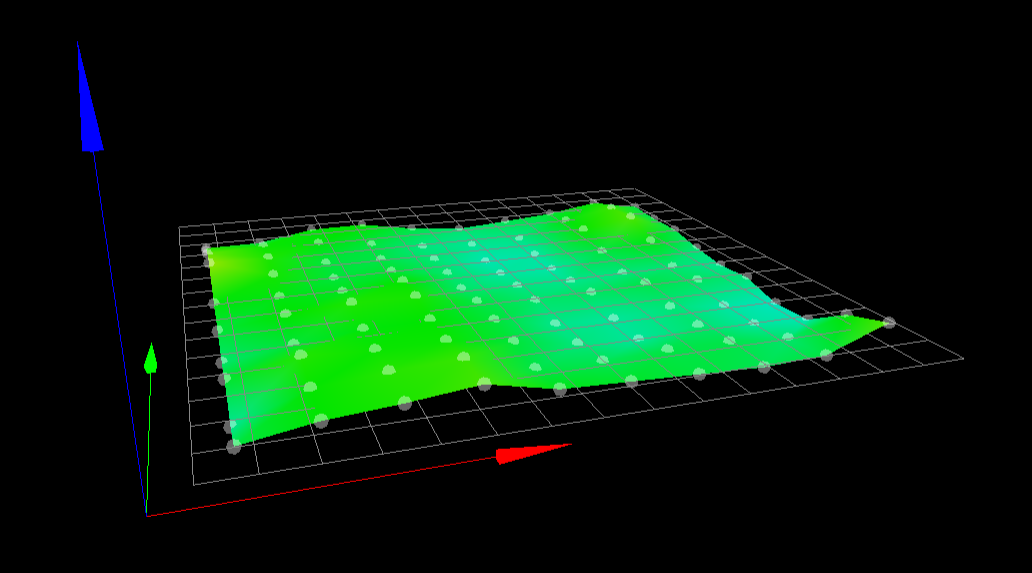

The HightMap looks like that now:

Very much the same warping which is not an surprise. The front right corner is a bit smoother now.

-

I have printed the "leveling_test" files. Once "normal" with the mesh compensation and once without it (G29 S2). I touched the lead screws from time to time so I was able to feel that the motors where rotating while the head was traveling when the mesh compensation was enabled. They did not rotate while the mesh compensation was off.

With:

Without:

I have some more pictures, but I do not want to spam here.

The squares on the bed to look very good stick on the bed. I will print the big one again, lets see how that ends up now.

Cheers, Chriss

-

What is your printer a know type like a cr10 ?.

Have you tried printing on glass or a mirror ? -

It is a cr10 pro v2.

No, I tried PEI, Pertinax, FR4 and I have a sheet of printbite on my RatRig CoreXY. But this one is still "under construction". I had no chance to tune it in toll now. The CR10 have still to much problems.I'm not sure whether I want to try glas or not. I heard about enough problems there, too. And I think that the trend goes away of it, too.

Cheers, Chriss

-

Yes , another cr10s pro owner !!!!

Mine is a cr10s pro v1 , but with the bltouch upgrade .Now I know your machine a little better , how is the gantry on Z is it level and is the uprights level.

Mine was a pig at first I had to take to gantry apart to get the z axis to run level.

Just a personal one !!!! did you fit the duet in the control box.I use one of these :-

-

The portal was not optimal square and it was slightly bent to the back. I fixed that with some slices metal out of a beer can.

But I would not bet that it is perfect now.

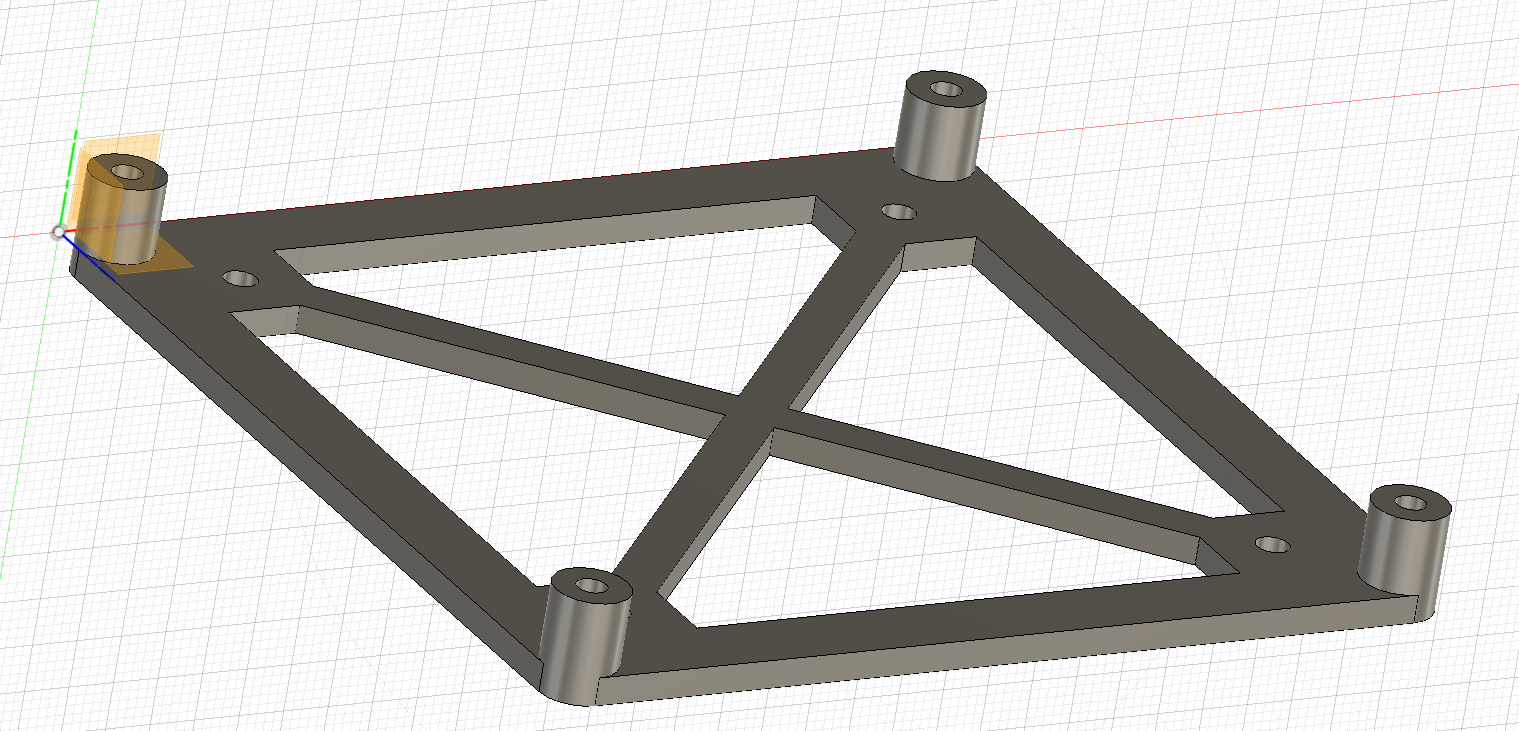

But I would not bet that it is perfect now.I printed a "holder", which are basically for "pins" on a rectangle:

I glued it right to the original mainboard and the expansion board to the place where the original mainboard was. That works very well.

I do not need access to the USB and micro SD card, so that is no problem for me, I'm happy with the network access. I swapped to many floppies, harddisks, SD-Cards in my live, I'm more than happy that I do not have to do that any more.

Hahaha... I ordered the same product a minute ago while you edited your post.

Cheers, Chriss

-

Didn't the cr10s pro v2 come with one of these ?.

https://technologyoutlet.co.uk/collections/printer-parts-spares/products/carborundum-glass-plate?variant=32606698438735Or was it like the v1 a metal plate with a buildtakie clone sheet ?

-

I'm not sure whether it is getting better or not:

I will cut it again later and measure it again. I need to spend some attention to the paperwork for my accountant.

Cheers, Chriss

-

@peter247 said in Extrusion Calibration?:

Or was it like the v1 a metal plate with a buildtakie clone sheet ?

It came with that plastic thingy glued on a alu plate, I guess to reach the same high as the carborundum plate. I tried to get that some month ago but I was not to get one of them. There where so hard soled out that even Creality in CN canceled my order after some month.

I ordered on from Amazon and I ordered a similar one from one of my preferred dealers here in Germany:

https://www.3djake.de/3djake/glasplatte-mit-chem-beschichtungIt seams to me that this is very much the same coating.

Btw: I replaced the original heater and the metal plate with a fine routed 4mm aluminum plate. The original one was to close to a banana for me. And I wanted to switch to a 240V heater anyway.

Cheers, Chriss

-

try the UK version :- https://www.3djake.uk/3djake/glass-plate-with-chemical-coating

-

Hahaha... well, as a German....

-

Hahahaha... they are from Austria!

-

I've ordered off them before , but thought they was Czech , but I think I was mixing that up with Fillamentum which is what I purchased.

( The niceshops group is an Austrian company )

-

i am currently trying

https://princore.de/collections/dauerdruckplatten-prinplate/products/prinplate-extreme-dauerdruckplatte-2mm-1and it sticks very well (only tested pla)

-

This post is deleted! -

This is my test of my cr10s pro.

My test file is 200mm x 200mm x 0.2mm , 30mm smaller and a second layer , 30mm smaller and another layer .

Had a little problem in one corner , but I think it was due to not cleaning the bed for the test and running over the remains of my last print. -

Looks good to me, well at least I can tell with this resolution of the picture.

I will get my glass surface in the next days, lets see what the results will show than. I have enough 3D printer for today.